High-strength pipeline steel, steel pipe and manufacture method thereof

A high-strength technology for pipeline steel, applied in the field of pipeline steel, can solve problems such as pipeline failure and large displacement strain of pipelines, and achieve the effects of high strain strengthening index, low yield ratio, and high uniform elongation

Active Publication Date: 2013-03-06

BAOSHAN IRON & STEEL CO LTD

View PDF7 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Traditional pipeline design is based on stress design. However, in areas prone to geological disasters such as earthquakes, pipelines will bear large displacement and strain, and pipeline failure is not only controlled by stress.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

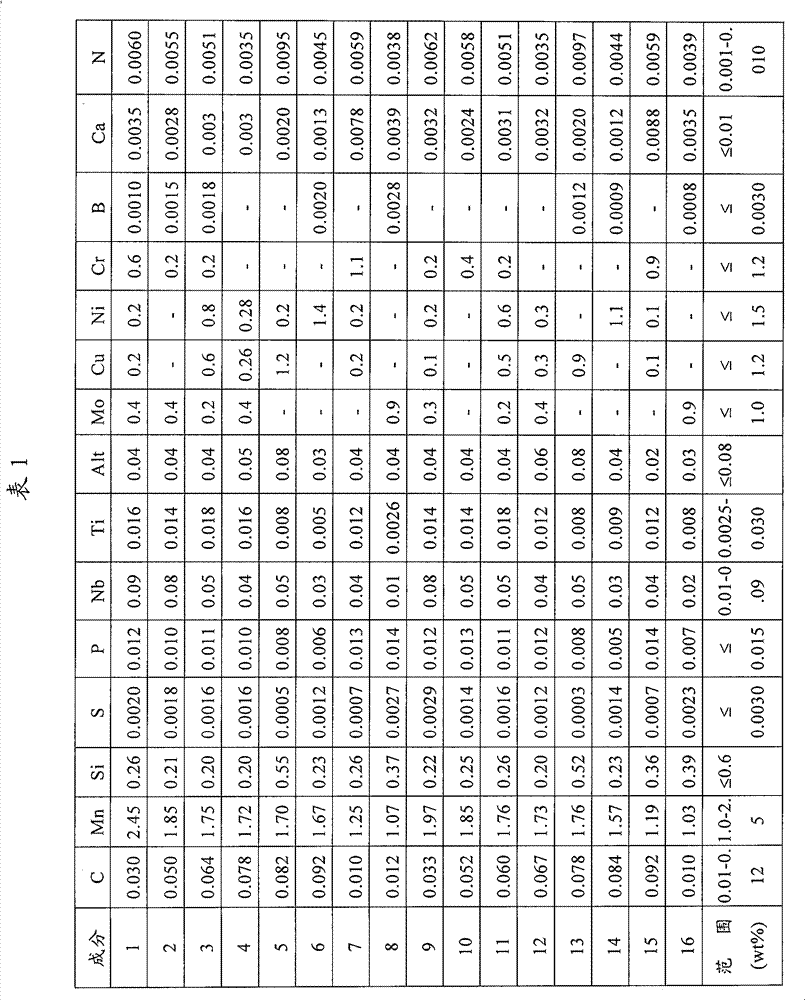

[0059] Table 1 shows the chemical composition of the examples of the present invention.

[0060] Table 2 and Table 3 show the process parameters and test performance results of the embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Login to View More

Abstract

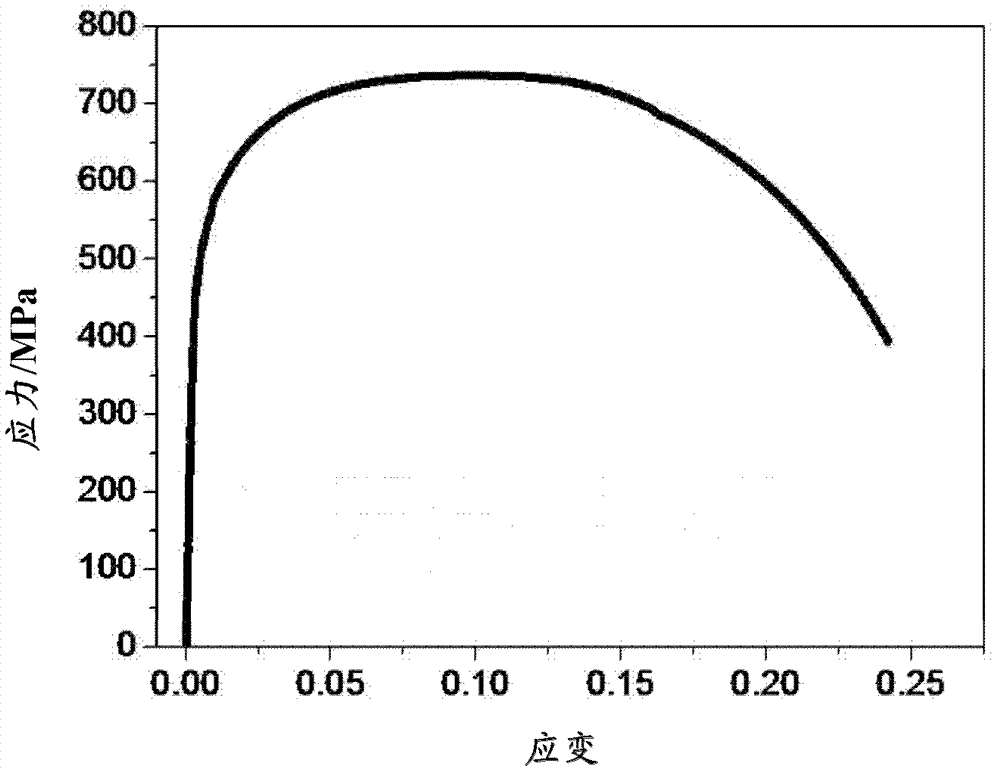

The invention relates to a high-strength pipeline steel which comprises the following chemical components by weight percent: 0.01-0.12 % of C, 1.0-2.5 % of Mn, less than or equal to 0.6 % of Si, less than or equal to 0.0030 % of S, less than or equal to 0.015 % of P, 0.01-0.09 % of Nb, 0.0025-0.030 % of Ti, less than or equal to 0.08 % of Alt, less than or equal to 1.0 % of Mo, less than or equal to 1.2 % of Cu, less than or equal to 1.5 % of Ni, less than or equal to 1.2 % of Cr, less than or equal to 0.0030 % of B, less than or equal to 0.01 % of Ca, 0.001-0.010 % of N, and the balance being iron and unavoidable impurities. The steel is polygonal ferrite and bainite duplex structure. A manufacture method of the high-strength steel pipe comprises heating slab with a temperature of 1100 to 1250 DEG C, rolling a non-recrystallization region with a starting temperature of 750 to 920 DEG C and a terminating temperature of 720 to 840 DEG C, two-stage cooling under control with an ACC terminating cooling temperature of 200 to 580 DEG C and a cooling rate of 5 to 30 DEG C per second, and manufacturing the pipe by using a UOE technology with a compression rate of 0.1 to 0.5 % and a diameter-expanding rate of 0.5 to 1.5 %. The obtained steel pipe can meet demands of low yield ratio and high uniform elongation.

Description

technical field [0001] The invention relates to pipeline steel, in particular to steel for pipeline steel pipe with low yield ratio, high uniform elongation and high strength, steel pipe and its manufacturing method. Background technique [0002] With the development of the pipeline industry, long-distance oil and gas transportation pipelines need to pass through special areas such as seismic zones and permafrost layers. In order to ensure the safety of pipeline transportation, people have begun to pay attention to the strain resistance of high-strength pipeline steel in recent years. Traditional pipeline design is based on stress design. However, in areas prone to geological disasters such as earthquakes, pipelines will bear large displacement strains, and pipeline failure is not only controlled by stress. For this kind of pipeline engineering, a new concept of "strain-based design" is proposed, and certain strain resistance is required for this kind of pipeline steel. In ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/58C22C38/54C22C38/50C22C38/38C22C38/32C22C38/28C22C38/16C22C38/14C21D8/10B21B37/74

Inventor 郑磊崔天成张备吴晓辉徐国栋黄卫锋

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com