Filter plate and pressing filter assembly for electroosmotic sludge high-dryness dewatering equipment

A technology of dehydration equipment and filter plates, which is applied in the field of sludge disposal equipment components, can solve the problems of inconsistent deformation of diaphragm filter plates and uneven sludge pressing, and achieve the effects of reducing moisture content, increasing pressing pressure, and uniform pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] In the present invention, the orientation words used such as "up, down, left, and right" usually refer to the up, down, left, and right shown in the accompanying drawings; inside and outside.

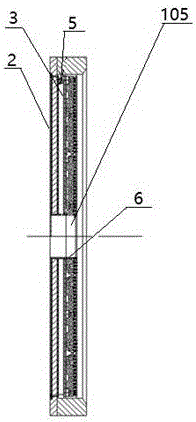

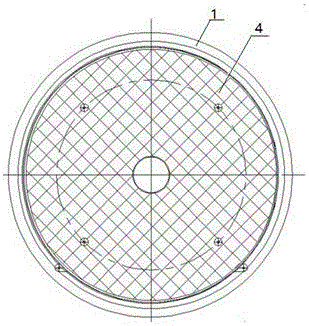

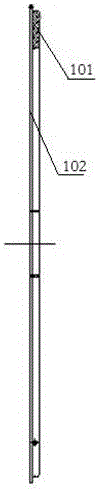

[0028] Such as figure 1 , figure 2 As shown, the press filter plate used in the electroosmotic sludge high-dry dehydration equipment of the present invention mainly includes a fixed plate frame 1, an anode plate 2, a movable platen 3, a cathode conductive net 106, a tympanic membrane 5 and a sludge guide cylinder 6. The cathode conductive net 104 is installed on the movable platen 3 , the anode plate 2 is installed on the fixed plate frame 1 , and the tympanic membrane 5 is installed between the fixed plate frame 1 pre-pressed and the movable platen 3 .

[0029] Such as figure 1 , figure 2 As shown, there are raised steps on the peripheral edge of the fixed plate f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com