Production method of dampproof copy paper

A production method and technology of copy paper, which are applied in the fields of pulp beating method, pulp beating/refining method, special paper, etc., can solve the problems of easy moisture absorption, lint and powder loss, and poor sizing effect of copy paper, and achieve Improve stiffness and moisture resistance, enhance sizing effect, and improve surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

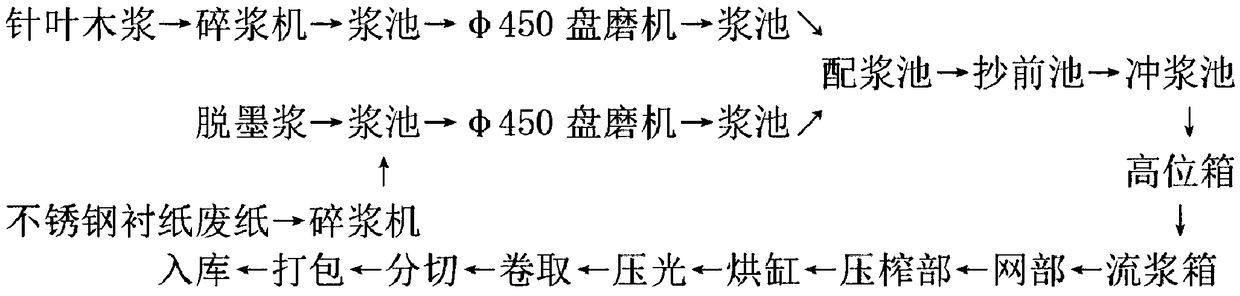

[0034] A method for producing moisture-proof copy paper includes the following processing steps: (1) Preparation of raw materials: stainless steel liner waste paper, softwood pulp, deinked pulp, starch modified talc, cationic rosin glue, AKD sizing agent, Coniferous wood pulp: stainless steel lined paper, waste paper: weight ratio of deinked pulp = 1:4:5; (2) Beating and refining: coniferous wood pulp fiber is longer, choose Dandong Refining Mill Cutting Fin series grinding discs, using " “Strike fast” method, control the beating degree 35°SR, the wet weight is 4.0g, the stainless steel liner waste paper and the deinked pulp fiber are shorter, and the fibers are deflated and mixed and refined according to the ratio. The soft fin series of Dandong Mill Refining sheet adopts the method of "light knife and slow beating" to reduce fiber cutting, control the beating degree to 30°SR, and the wet weight is 2.5g; (3) Paper machine papermaking: send the slurry after refining and beating ...

Embodiment 2

[0037] A method for producing moisture-proof copy paper includes the following processing steps: (1) Preparation of raw materials: stainless steel liner waste paper, softwood pulp, deinked pulp, starch modified talc, cationic rosin glue, AKD sizing agent, Coniferous wood pulp: stainless steel lined paper, waste paper: weight ratio of deinked pulp = 1:4:5; (2) Beating and refining: coniferous wood pulp fiber is longer, choose Dandong Refining Mill Cutting Fin series grinding discs, using " The method of "heavy knife quick hit", control the beating degree 40°SR, the wet weight is 5.0g, the stainless steel lining paper waste paper and the deinked pulp fiber are shorter, and the fibers are deflated and mixed and refined according to the ratio. The soft fin series of Dandong Refining Mill is selected. Refining sheet adopts the method of "light knife and slow beating" to reduce fiber cutting, control the beating degree of 35°SR, and the wet weight is 3.0g; (3) Paper machine papermakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com