Preparation method of J55-grade steel ERW (electric resistance welding) expansion pipe with high diameter expansion performance

A technology of expansion pipe and steel grade, which is applied in the direction of drill pipe, casing, earthwork drilling, etc., can solve the problems of microstructure coarsening, difference in microstructure of base metal and weld area, high cost, etc., and achieve good comprehensive benefits and wide application The effect of application prospect and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

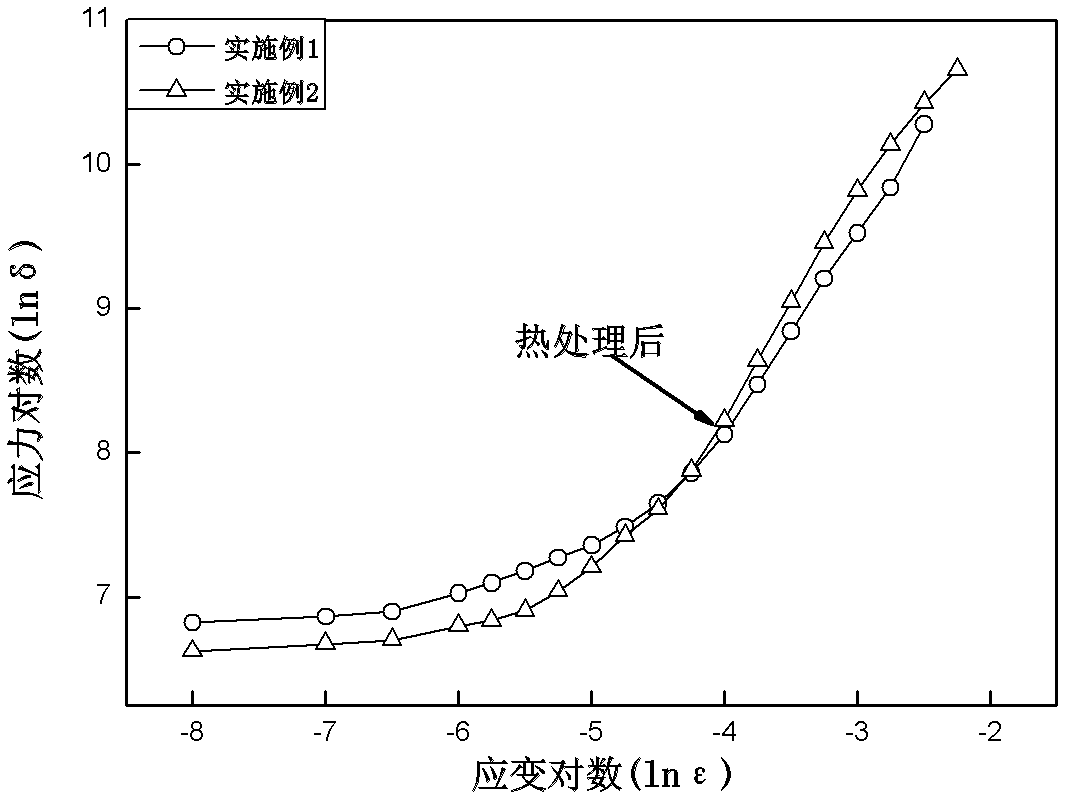

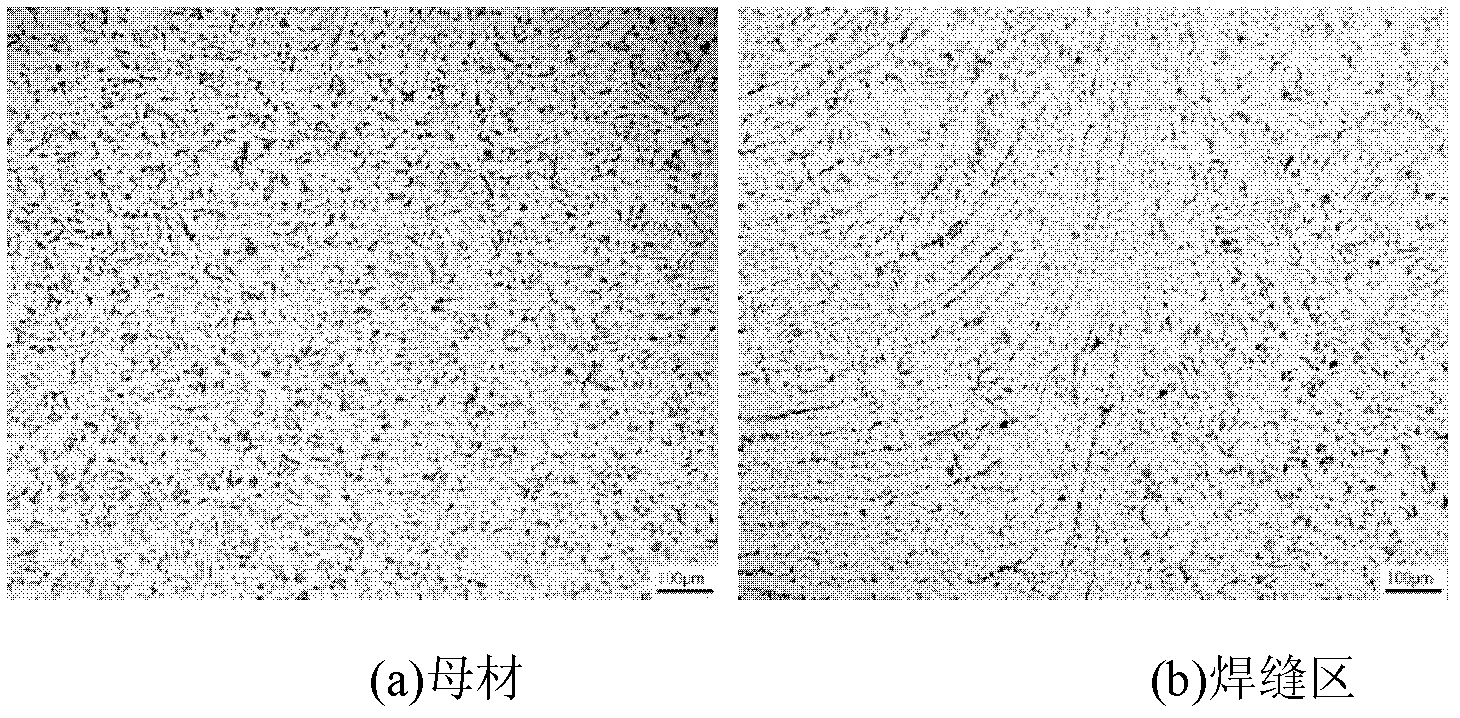

[0016] Heat the J55 steel grade ERW expansion tube whose alloy composition is shown in Table 1 to 1150°C and keep it warm for 30 minutes, then air cool to room temperature; then reheat to J55 steel grade expansion tube A C3 Point above 50°C (890°C) and keep it warm for 60 minutes, then air cool to room temperature; finally, keep the steel plate in the two-phase zone of 700°C for 60 minutes. From figure 1 It can be seen that the obtained J55 steel grade ERW expansion tube has a large n value after heat treatment; the r value calculated by formula (1) is 1.4 ([8] Wu Shi. Stamping Technology [M]. Xi'an: Northwestern Polytechnical University Press, 1987 , 5-6); from Table 2, it can be seen that the uniform elongation of the base metal and the weld zone are both above 16%, and the mechanical properties are relatively close, meeting the performance requirements of API Spec 5CT for J55 steel grade; at 13% After pre-straining, the tensile strength of the base metal is 571 MPa, the yi...

Embodiment 2

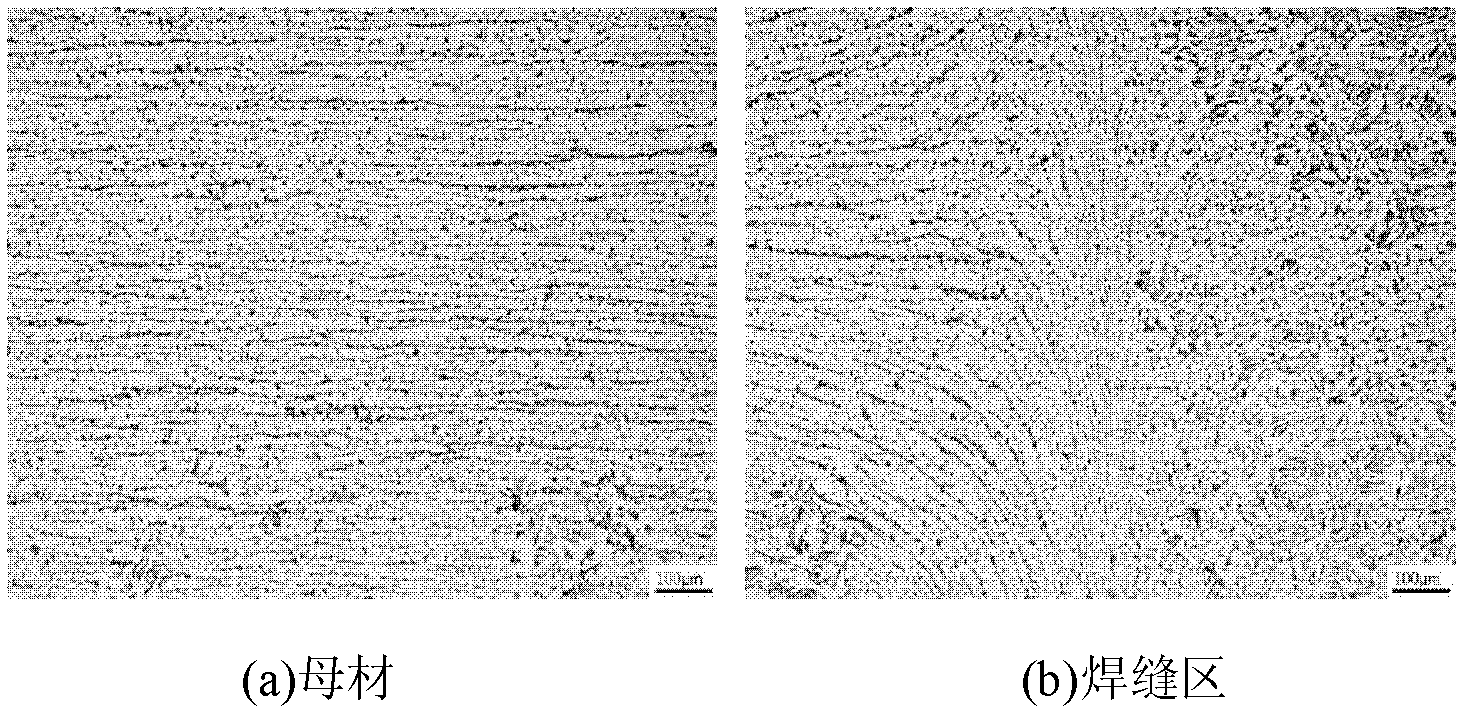

[0028] Heat the J55 steel grade ERW expansion tube whose alloy composition is shown in Table 3 to 1000°C and keep it warm for 60 minutes, then air cool to room temperature; then reheat to J55 steel grade expansion tube A C3 Point above 100°C (930°C) and keep it warm for 30 minutes, then air cool to room temperature; finally keep the steel plate in the two-phase zone of 750°C for 30 minutes. From figure 1It can be seen that the obtained J55 steel grade ERW expansion tube has a large n value after heat treatment; the r value calculated by the formula (1) is 1.2; it can be seen from Table 4 that the uniform elongation of the base metal and the weld zone reaches more than 13%, and The mechanical properties are relatively close and meet the performance requirements of the API Spec 5CT standard; after 13% pre-strain, the tensile strength of the base metal is 672MPa, the yield strength is 664MPa, the tensile strength of the weld zone is 679MPa, and the yield strength is 670 MPa; fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com