Food dough cutting method and cutting apparatus

a cutting method and cutting device technology, applied in the field of cutting methods and cutting devices, can solve the problems of unstable quality of food dough produced, low productivity, and uneven width on both sides of food dough strips, and achieve the effect of preventing oversupply, preventing the occurrence of large differences in weight, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

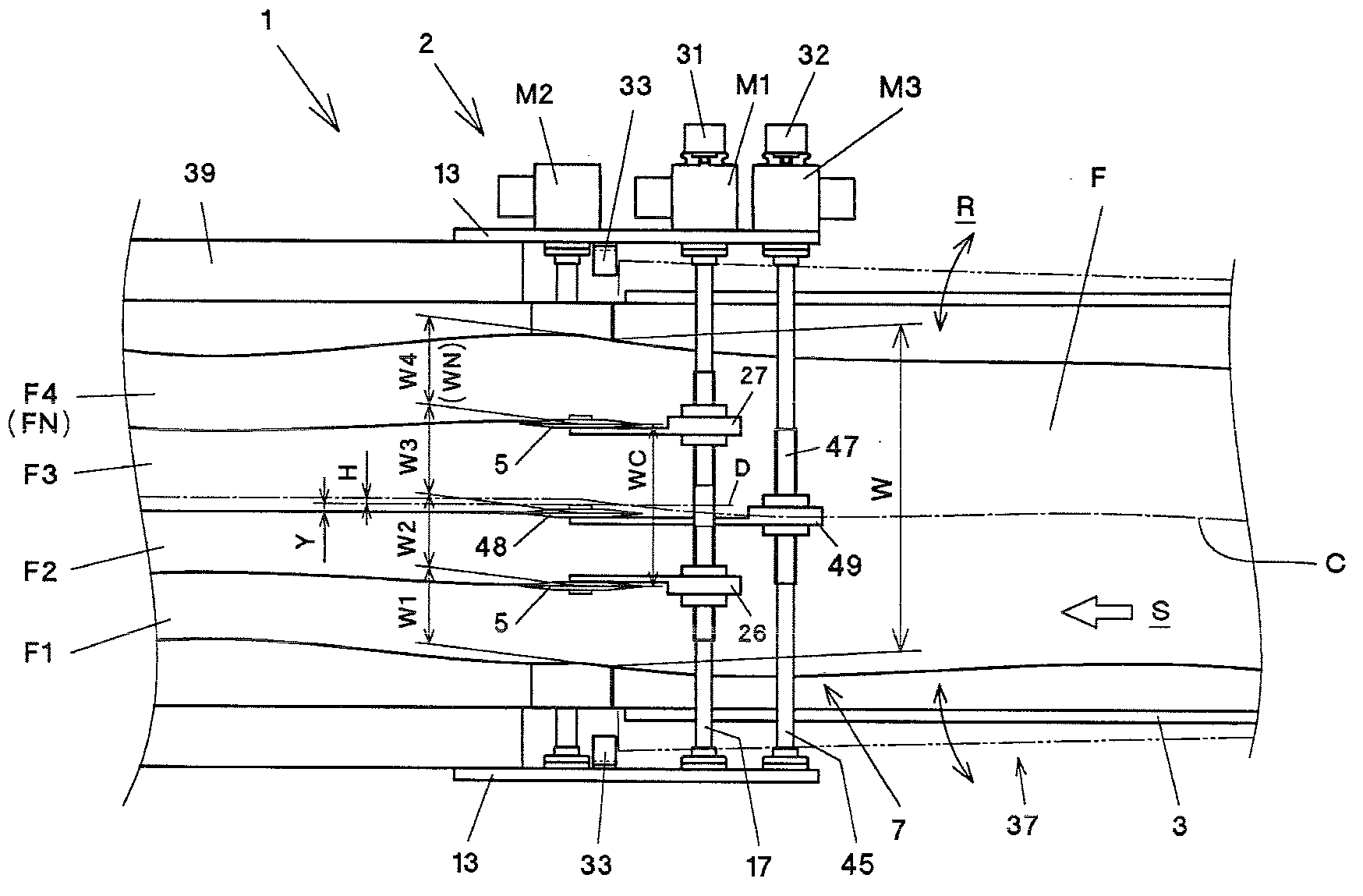

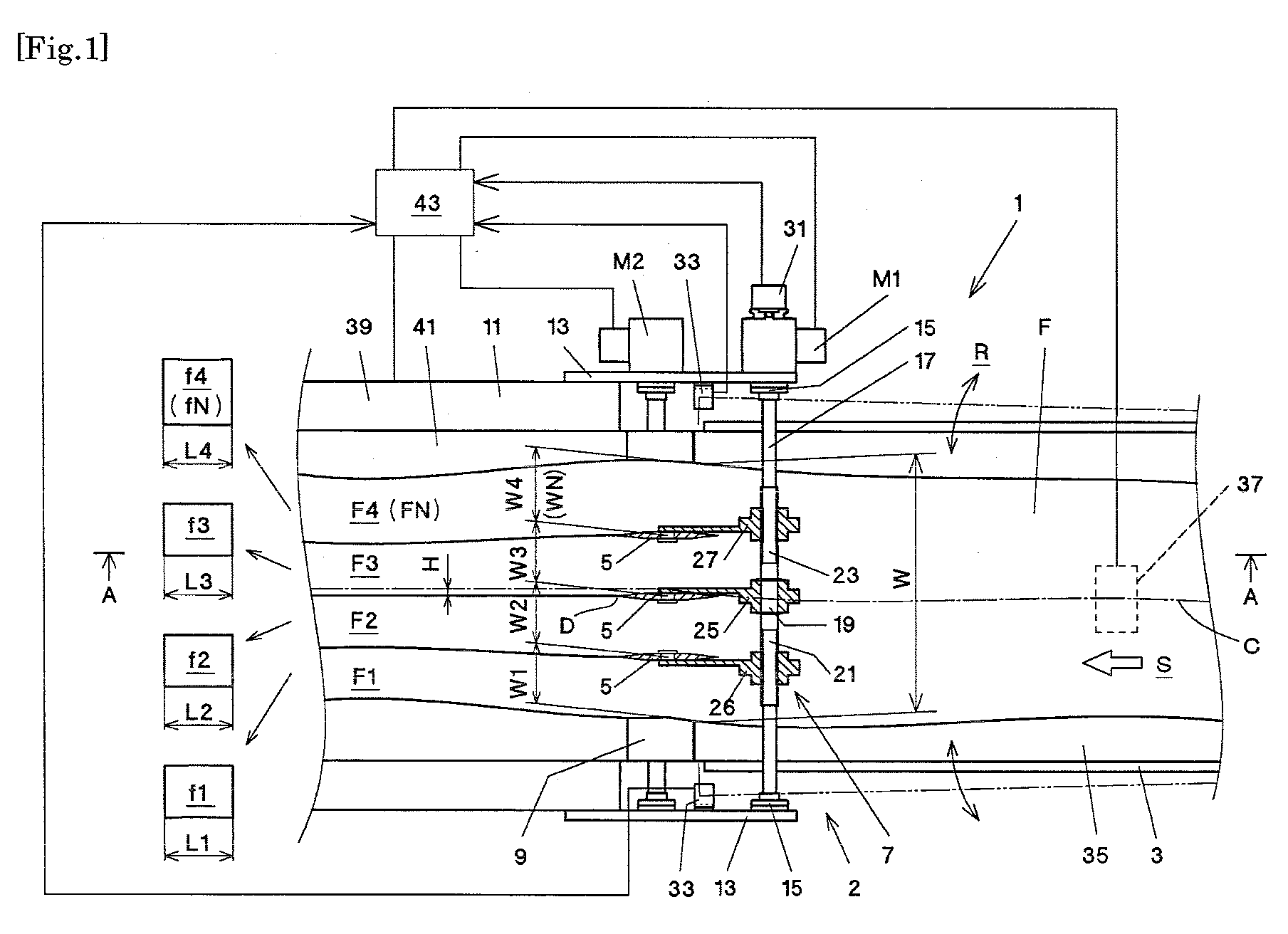

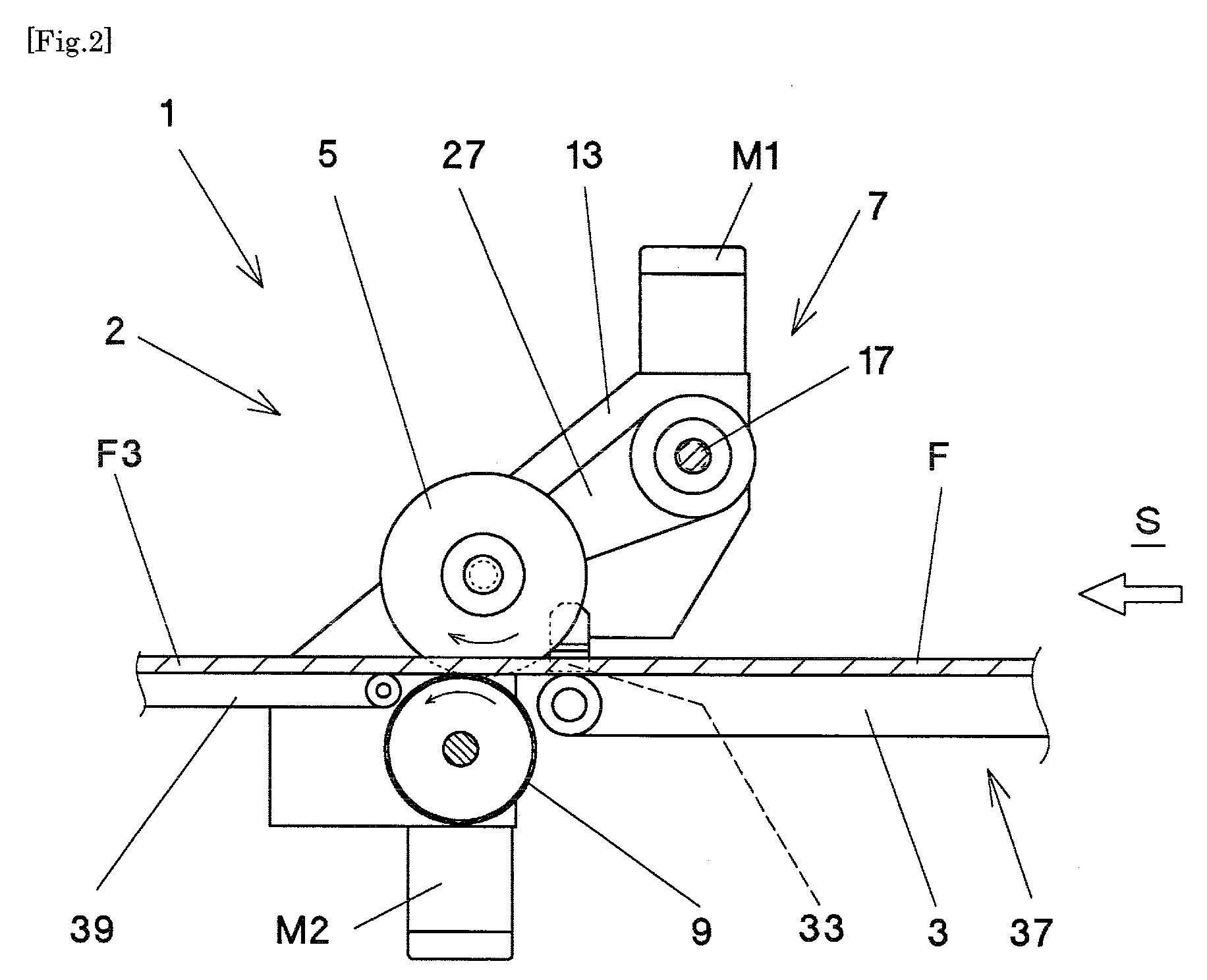

[0024]The cutting device 1 of the invention will be explained using the drawings. FIG. 1 is a top view of a cutting device 1. FIG. 2 is a front view as seen in the direction of section A-A of FIG. 1. FIG. 3 is a left side view of FIG. 2.

[0025]As shown in FIG. 1 to FIG. 3, the cutting device 1 comprises a multiple-strip cutting device 2 that cuts band shaped food dough F that is conveyed by a conveyor 3 along the conveyance direction S into four food dough strips F1, F2, F3, F4. The multiple-strip cutting device 2 comprises: three circular rotating blades 5 as the cutting members; a cutting member interval adjustment mechanism 7 that adjusts the installation interval between the rotating blades 5; and a conveyor roller 9 that conveys the food dough F against the rotating blades 5. Also, the multiple-strip cutting device 2 is installed on opposing side plates 13 that are fastened to the side surfaces of the conveyer frame of the conveyor 3.

[0026]The cutting member interval adjustment ...

second embodiment

[0058]In this second embodiment, the reference position D is located between the rotating blades 5 on both sides that are supported by the rotating shaft 17 by way of movable support members 26, 27. Also, the interval W2 between the rotating blade 5 and rotating blade 48 that cut the food dough strip F2, is taken to be equal to the interval W3 between the rotating blade 48 and rotating blade 5 that cut the food dough strip F3.

[0059]The interval WC between the rotating blades 5 on both sides is expressed as (W2+W3), and can be calculated from Equation 1 as two times the value of the interval WD between the rotating blades 5 that was explained in the first embodiment (WC=(W2+W3)=2×WD). Therefore, it is possible to control the rotation of the control motor M1 by a correction instruction from the control device 43 that is based on the interval WD, and to adjust the position (interval) of the rotating blades 5 on both sides by way of the rotating shaft 17 and movable support members 26, ...

third embodiment

[0067]In the case of the cutting device that is disclosed in Japanese patent application 2001-95468, when dividing food dough into two food strips, the center position C of the width of the food dough F is aligned without displacement with respect to the cutting position of the cutting member as a reference position, and is divided into equal parts so that the width dimensions of the food dough strips F1, F2 on both sides are symmetrical. However, when the characteristics of the food dough, such as the thickness or density of both side portions of the food dough that is divided as described above, become non uniform, the width dimensions W1, W2 of the food dough strips F1, F2 on both sides are obtained by dividing the width dimension W of the food dough F into two equal divisions, and when cutting the food dough strips F1, F2 on both sides into food dough pieces f1, f2 having a specified weight, the cut lengths L1, L2 may not be the same length. Therefore, in this third embodiment o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com