Simulated manual dough kneading robot

A robotic and manual technology, applied in dough extruders, dough mixers, dough cutting machines, etc., can solve the problems of low dough kneading efficiency, large floor space, complicated processes, etc. The cost of noodles and the effect of simplifying the process of noodle making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below with reference to the accompanying drawings.

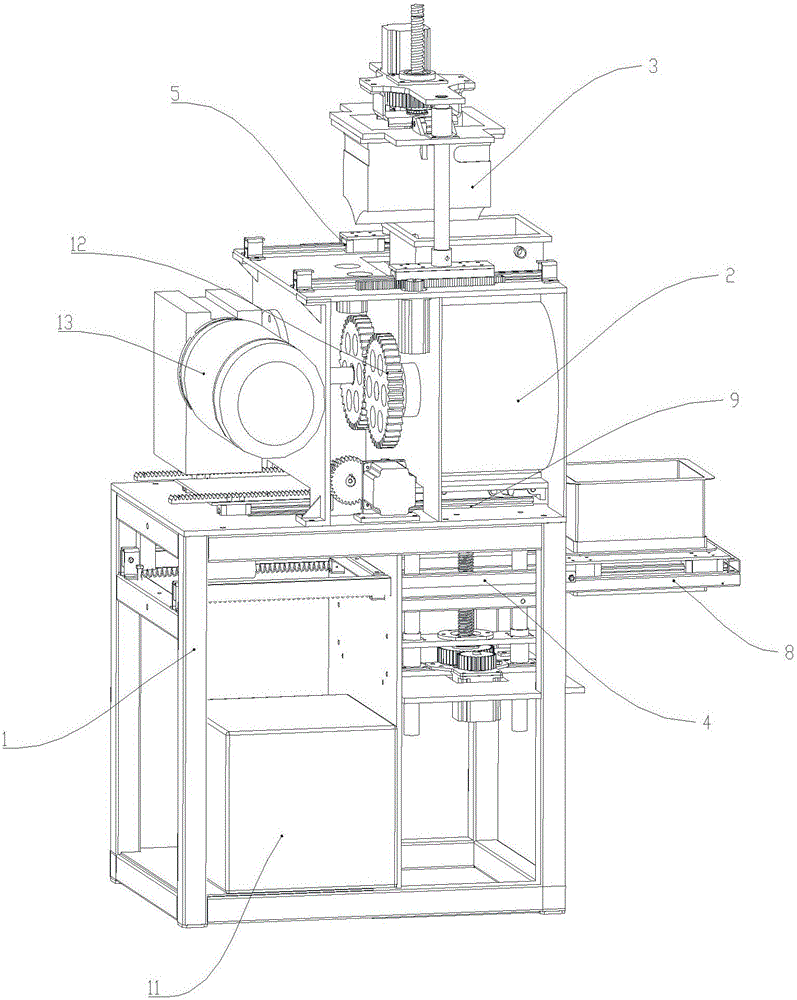

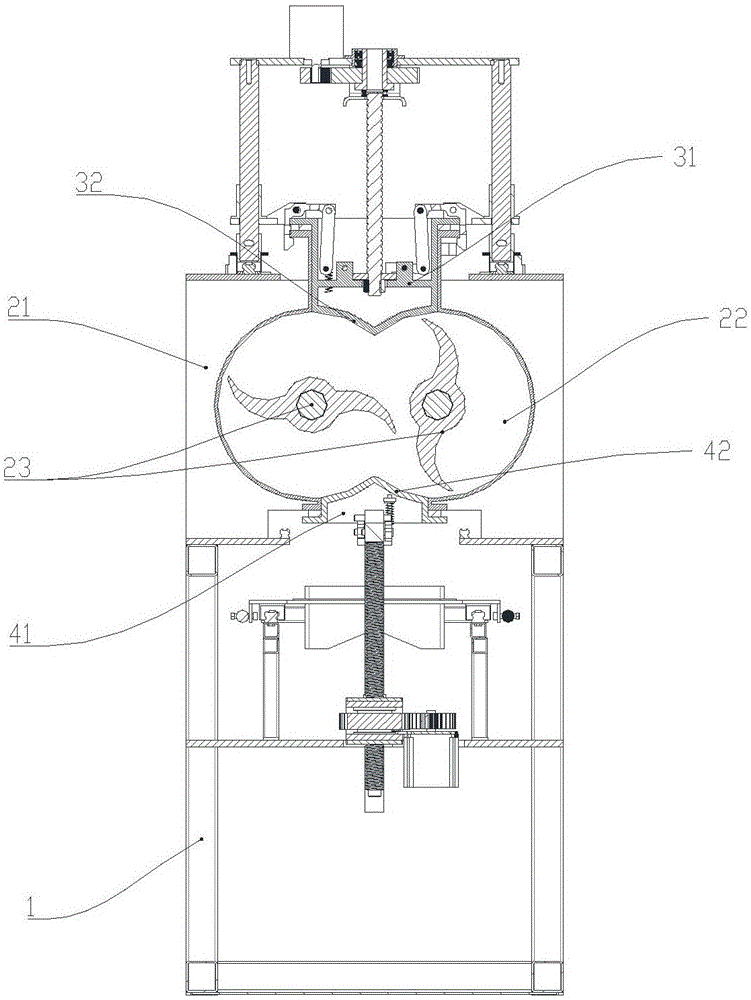

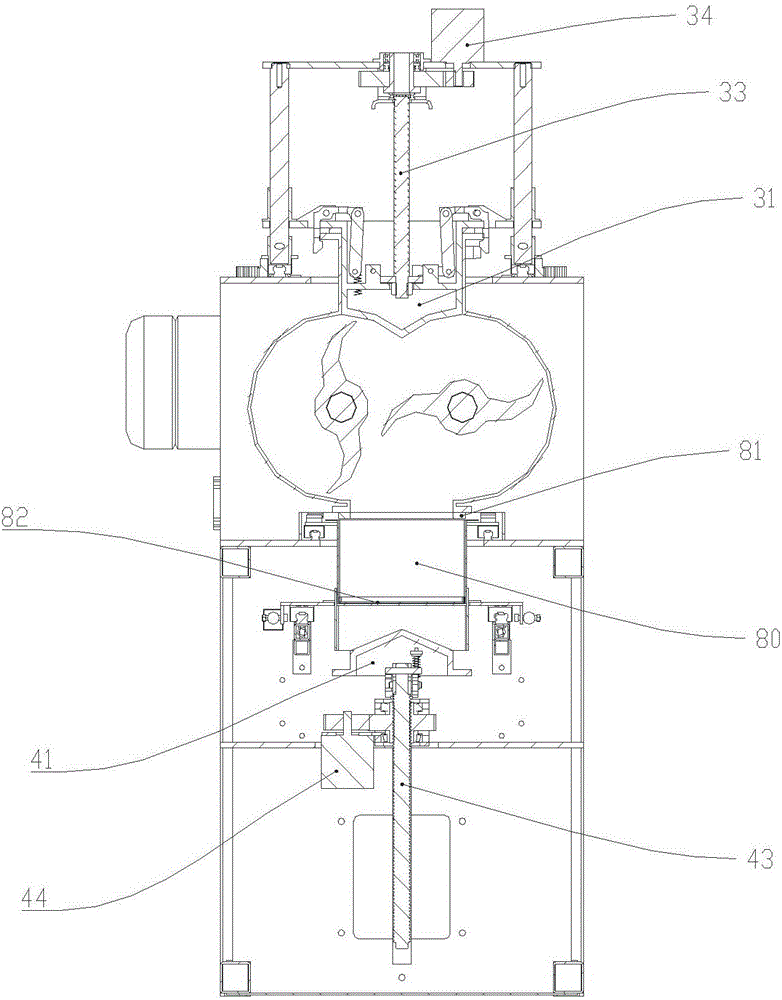

[0038] Please refer to the attached figure 1 to attach Figure 10 , in the present embodiment, this imitation artificial dough kneading robot comprises: frame 1, frame 1 is used for supporting and fixing other component devices, and the kneading box assembly 2 fixedly installed on the top of frame 1, this kneading box assembly 2 It includes an upper cover assembly 3 and a lower cover assembly 4 , wherein an upper cover translation assembly 5 is also provided between the upper cover assembly and the kneading chamber of the kneading box assembly 2 . Further, an upper cover self-locking device 6 is also provided between the upper cover assembly 3 and the kneading dough box assembly 2, and a lower cover self-locking assembly 7 is also provided between the lower cover assembly 4 and the kneading dough box assembly 2, and is located at the lower The cover assembly 4 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com