Intelligent dumpling wrapper moulding robot

A technology of dumpling wrappers and robots, applied in the field of robots, can solve the problems of waste of dough, low work efficiency, substandard quality, etc., and achieve the effects of saving resources, improving production efficiency and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

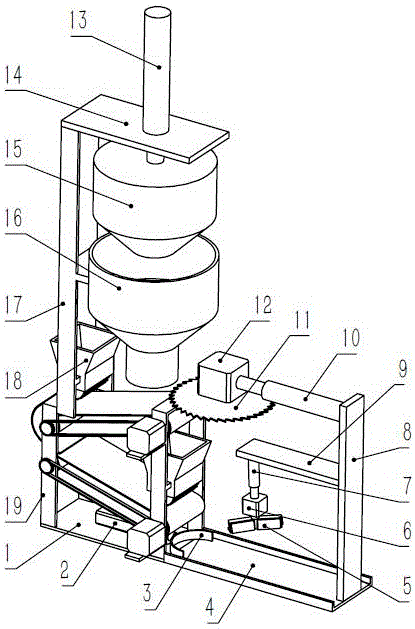

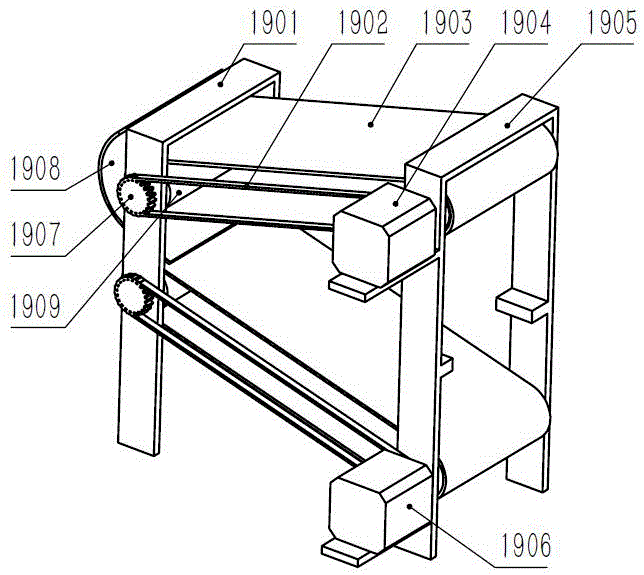

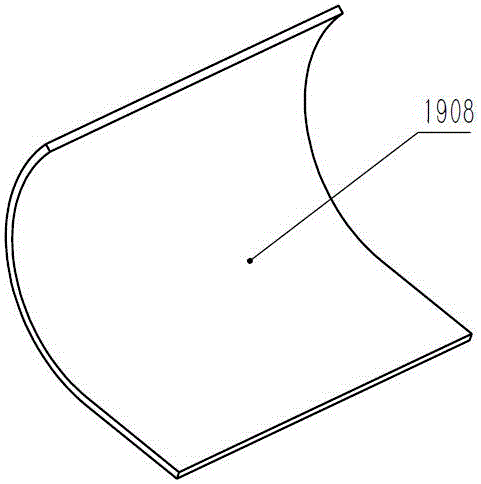

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A kind of dumpling wrapper intelligent forming robot shown, the left and right sides of feeding plate 4 are provided with baffle plate, and it is installed on the front end of base plate 1, and the first support 8 is vertically fixedly installed on the front portion of feeding plate 1, and the second support 9 is horizontal Fixedly installed behind the middle part of the first support 8, the second electric cylinder 7 is fixedly installed vertically downward under the rear part of the second support 9, and the first stepping motor 6 is fixedly installed vertically downward on the second electric cylinder 7 On the telescopic rod, the noodle as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com