Patents

Literature

160results about "Combs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

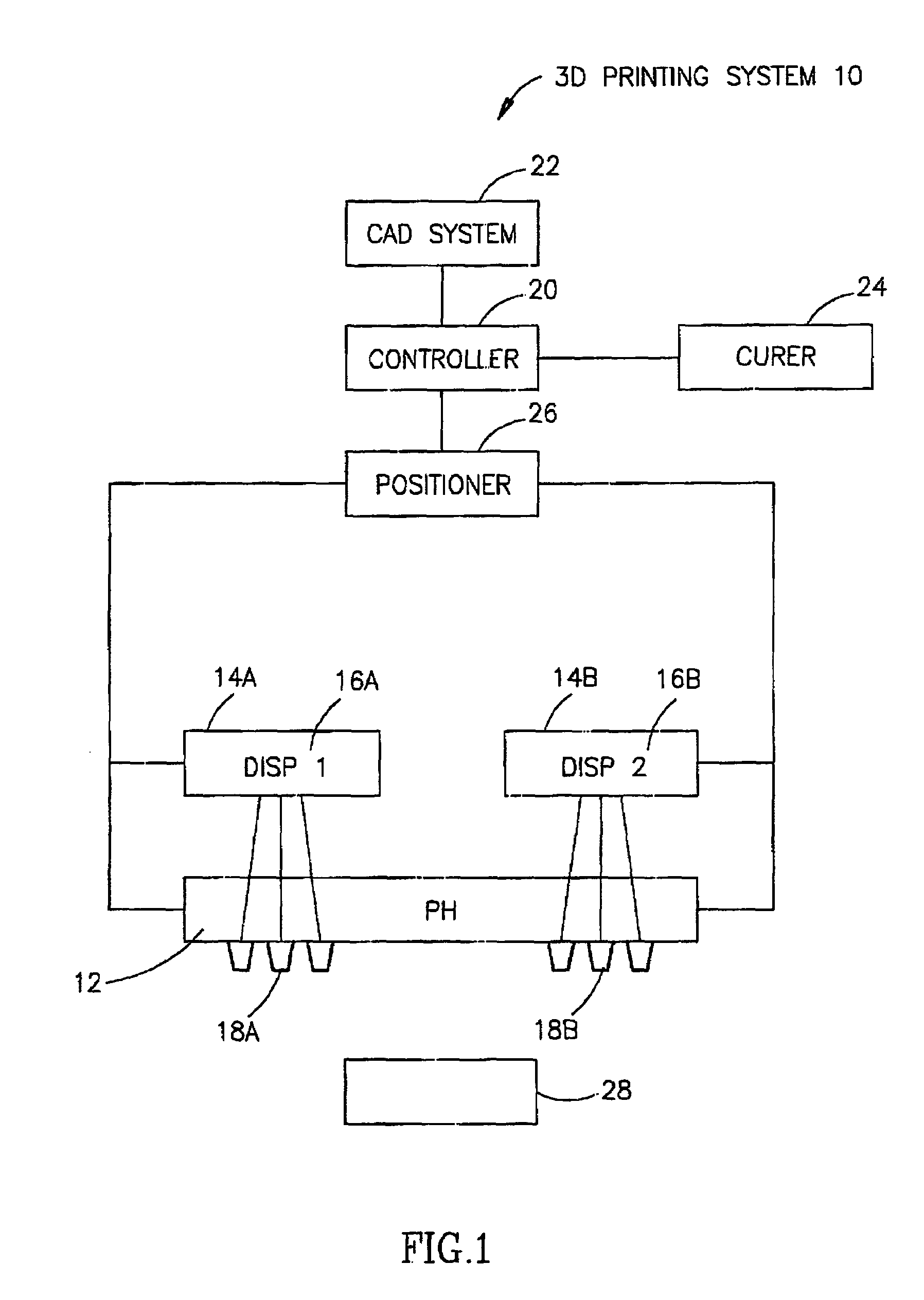

Compositions and methods for use in three dimensional model printing

InactiveUS7300619B2Similar elasticitySimilar strengthButtonsLiquid surface applicatorsOrganic compoundPolymer chemistry

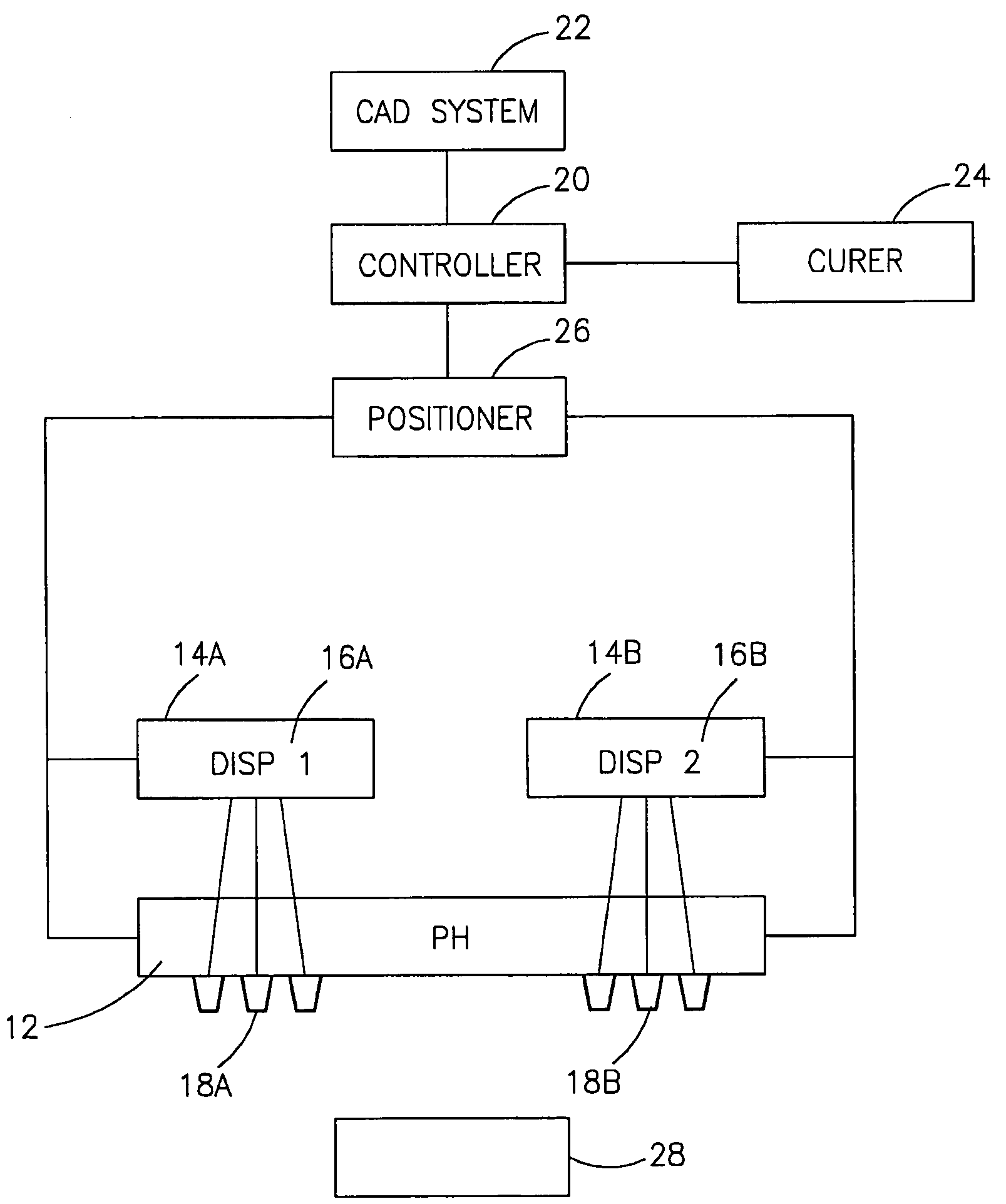

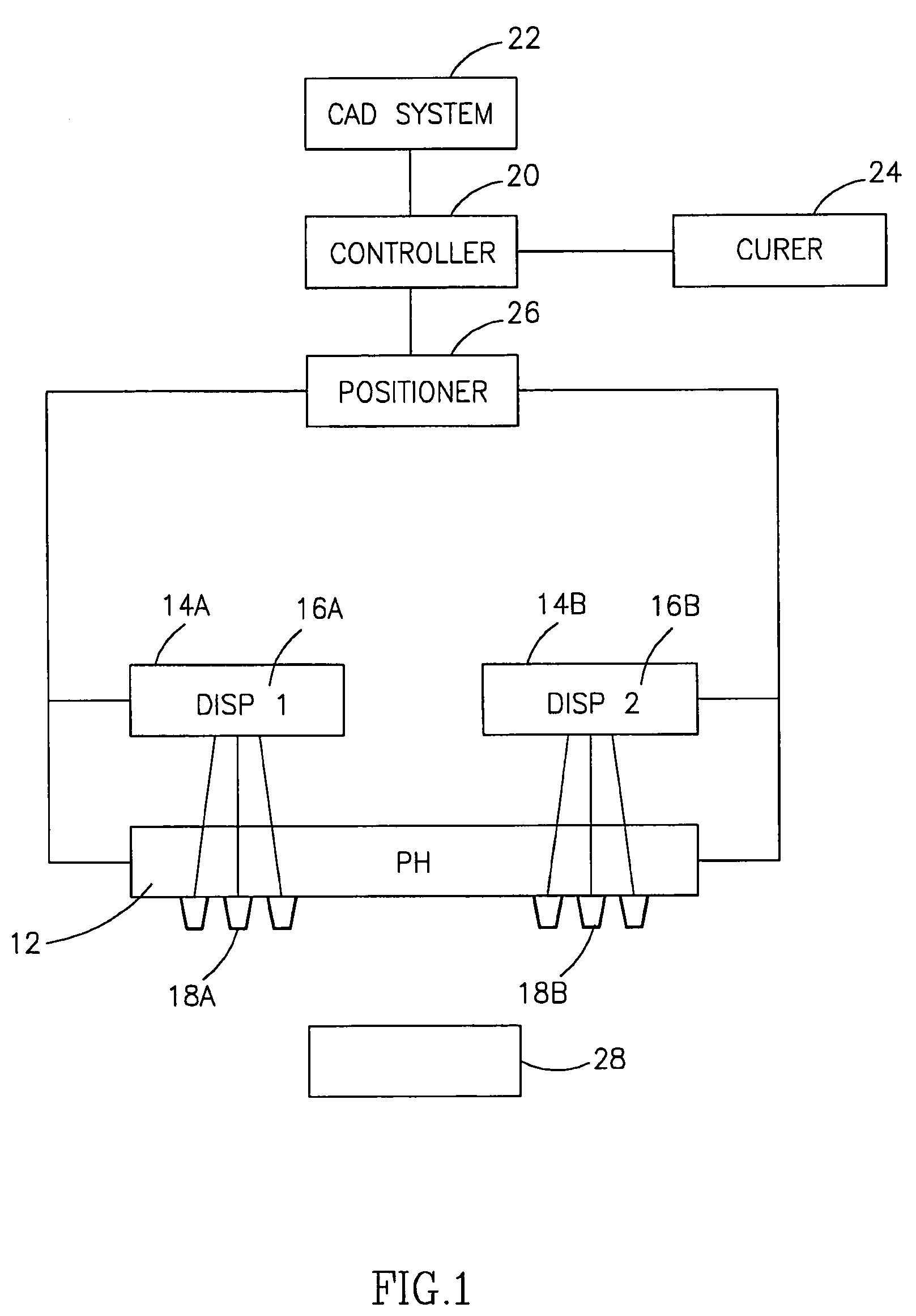

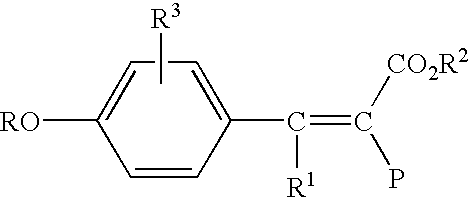

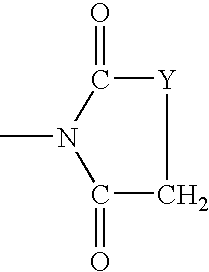

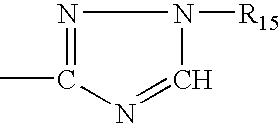

A pseudo composite material, may include, inter alia, a first phase and a second phase, wherein each phase may include, inter alia, an organic compound, wherein each phase comprising a multiplicity of construction layers, wherein the layers were deposited by ink-jet printing, wherein the pseudo composite material exhibits non-homogeneous three-dimensional structure. A method is disclosed for the preparation of a pseudo composite material. An apparatus is disclosed for printing a pseudo composite material. Furthermore, there is disclosed a method for printing a three-dimensional object using various suitable materials.

Owner:STRATASYS LTD

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

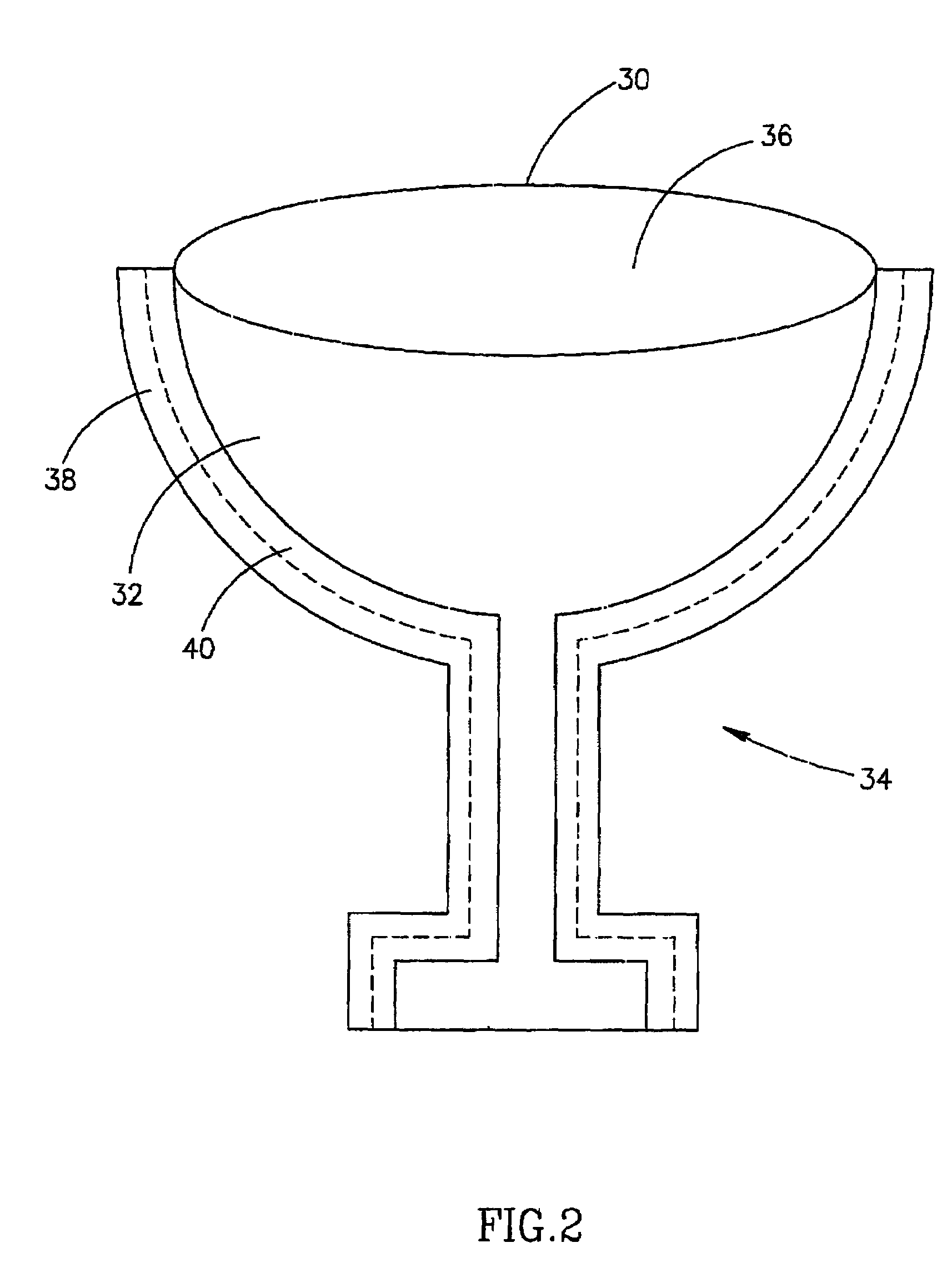

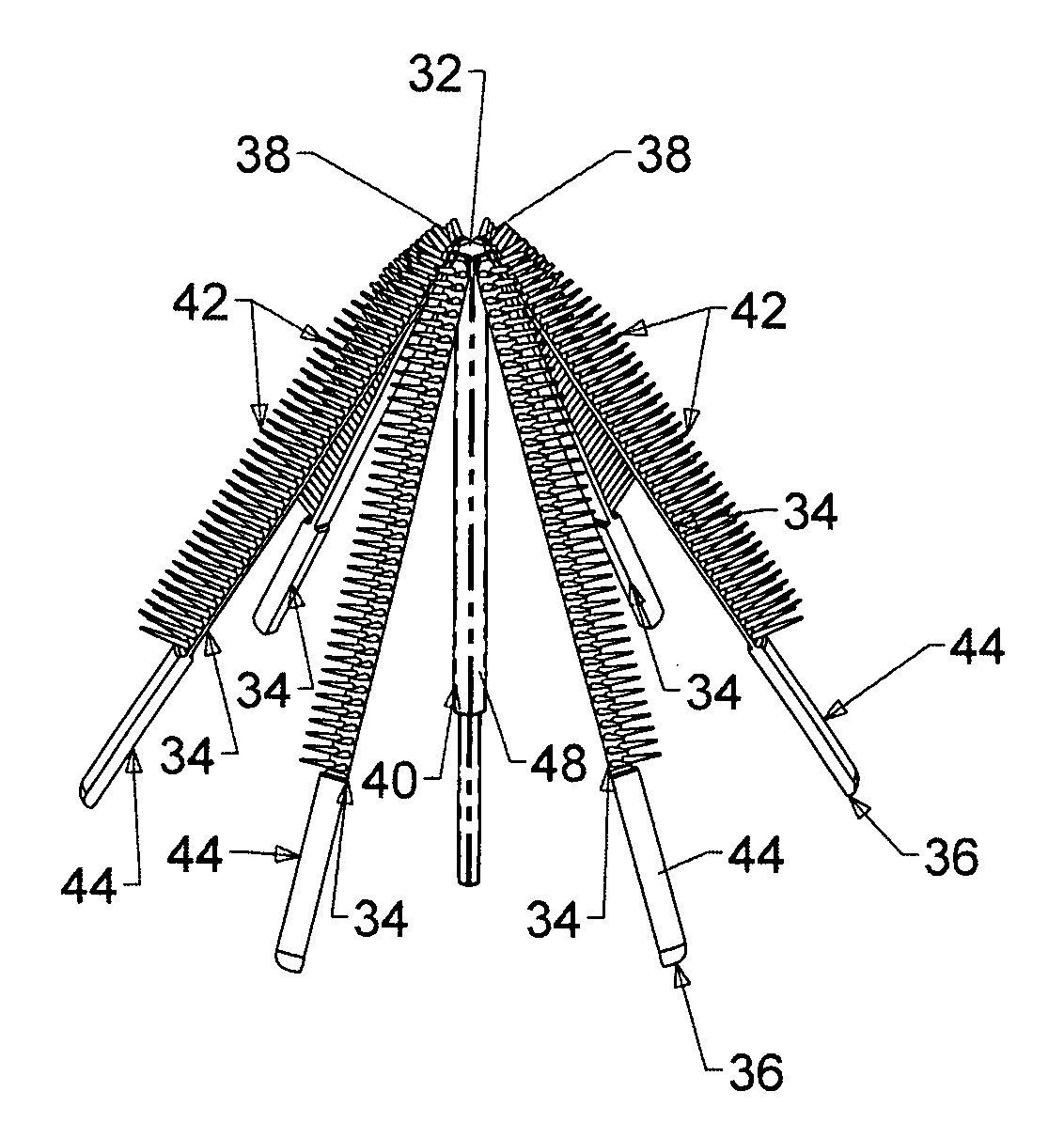

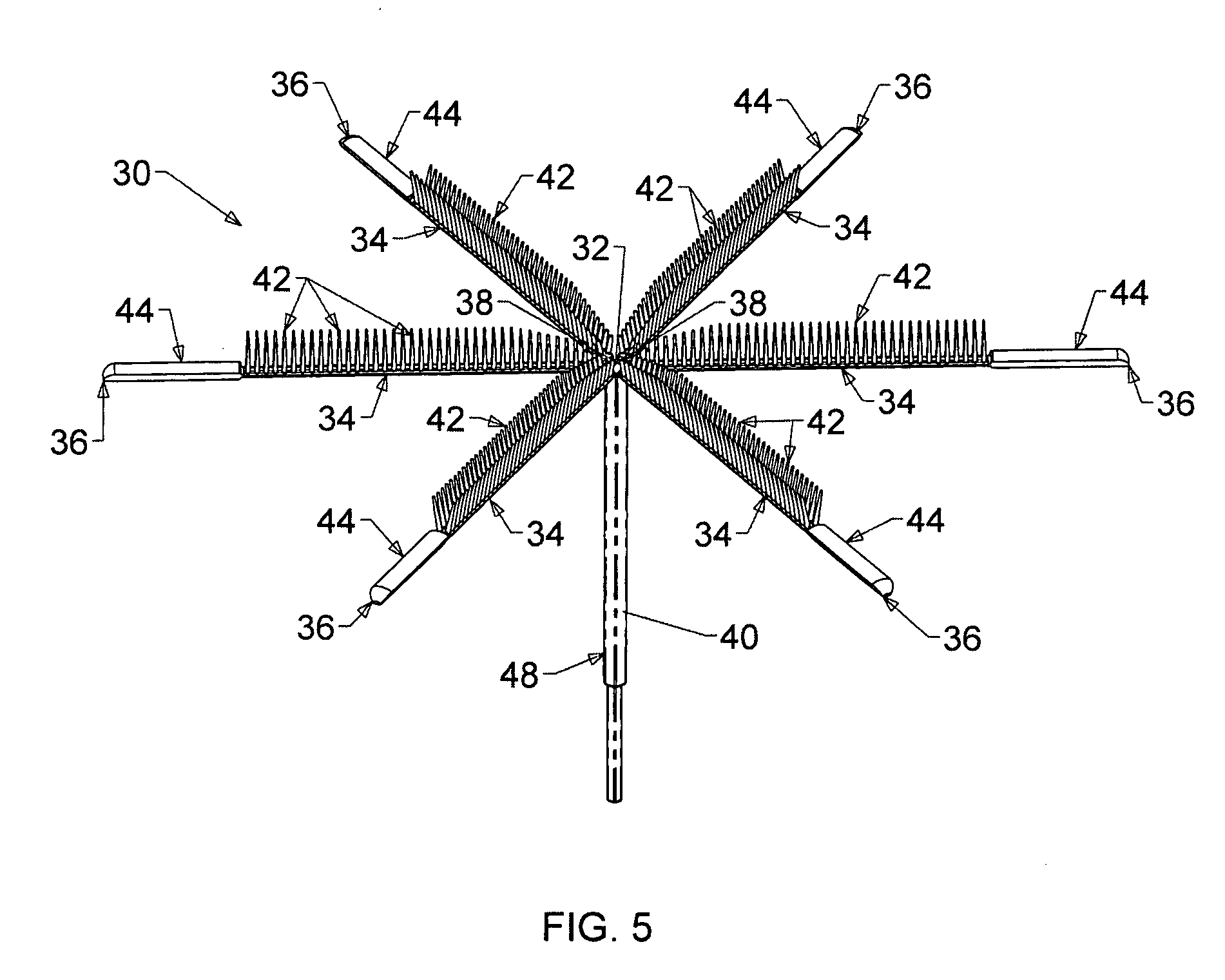

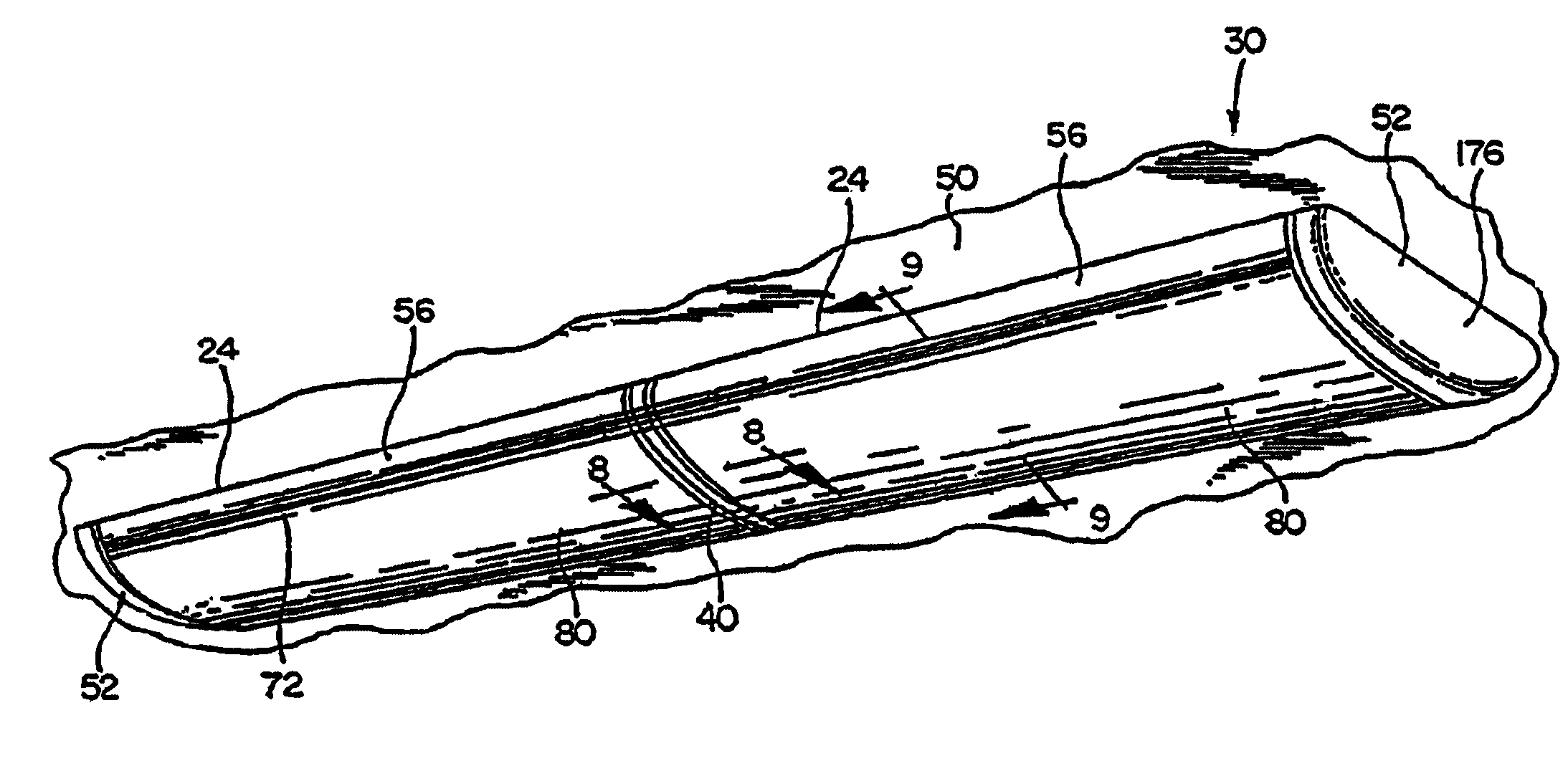

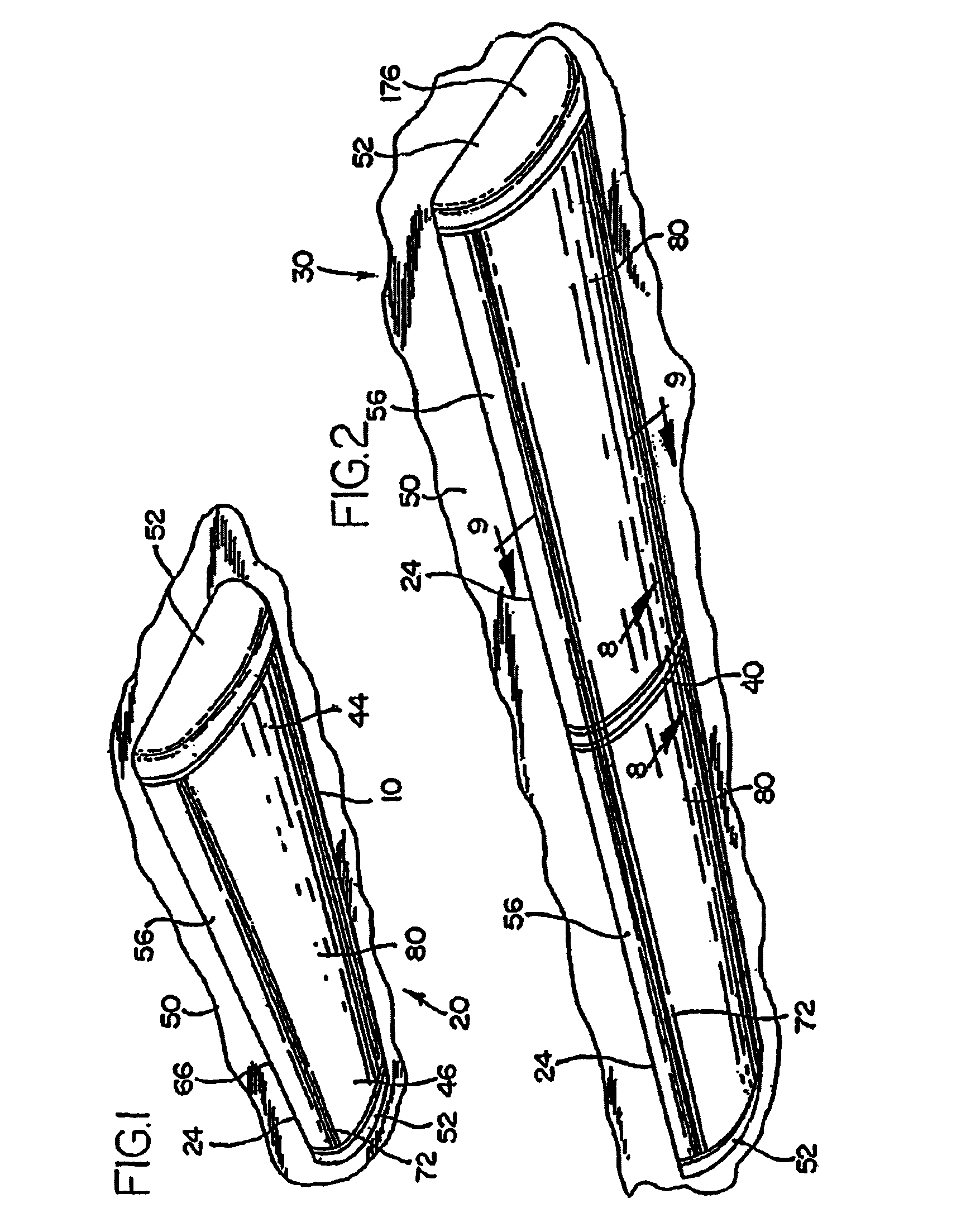

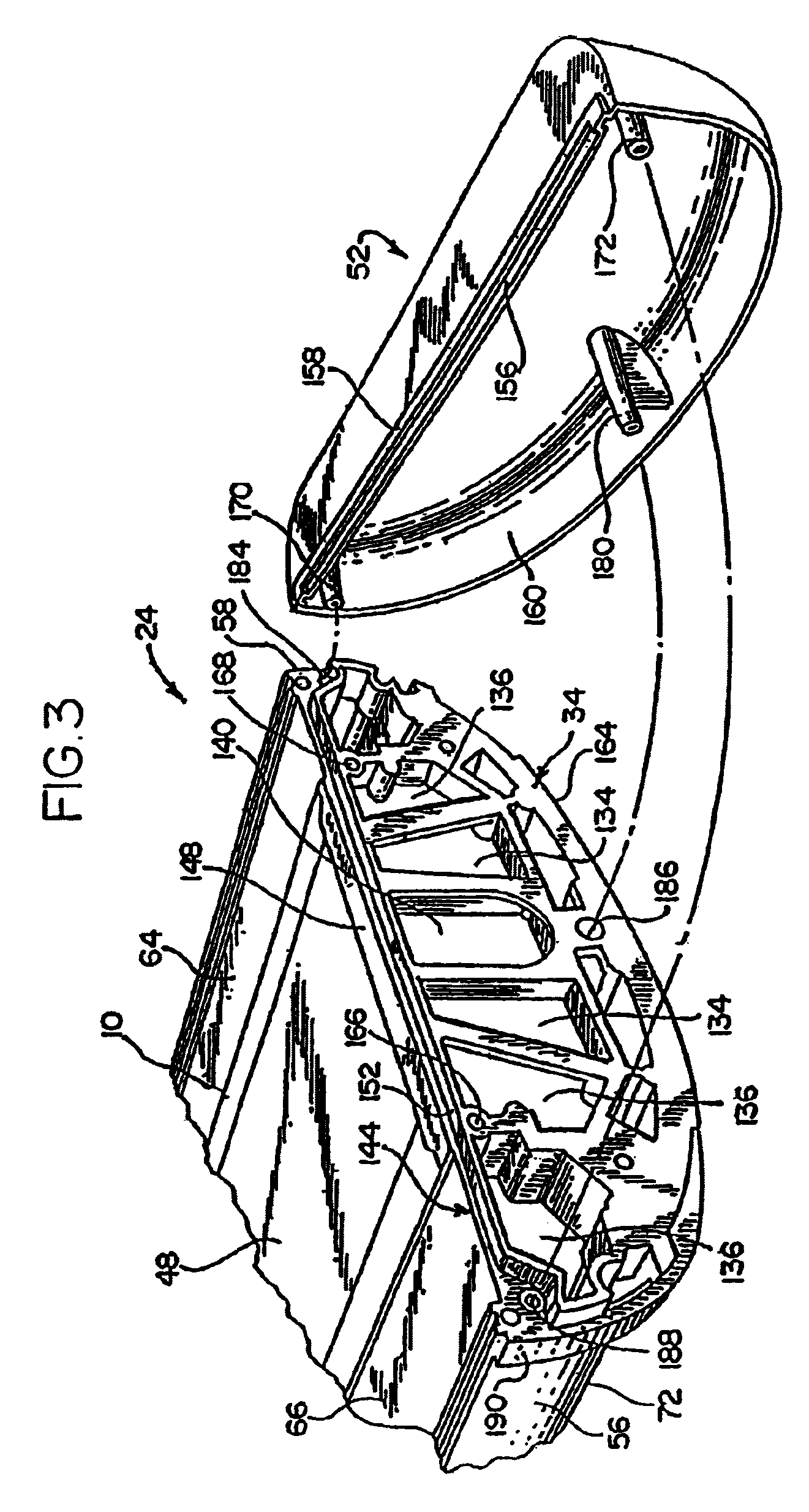

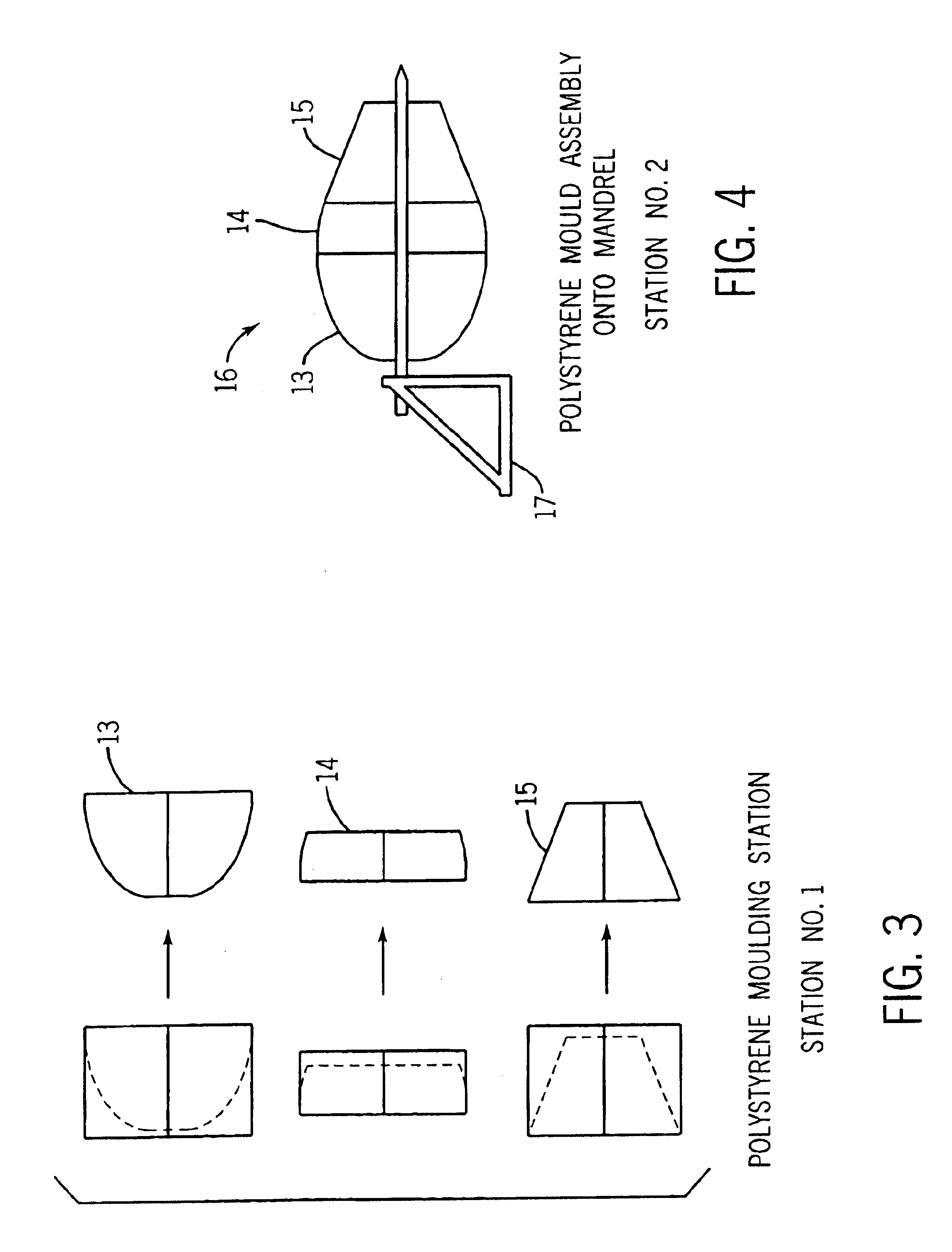

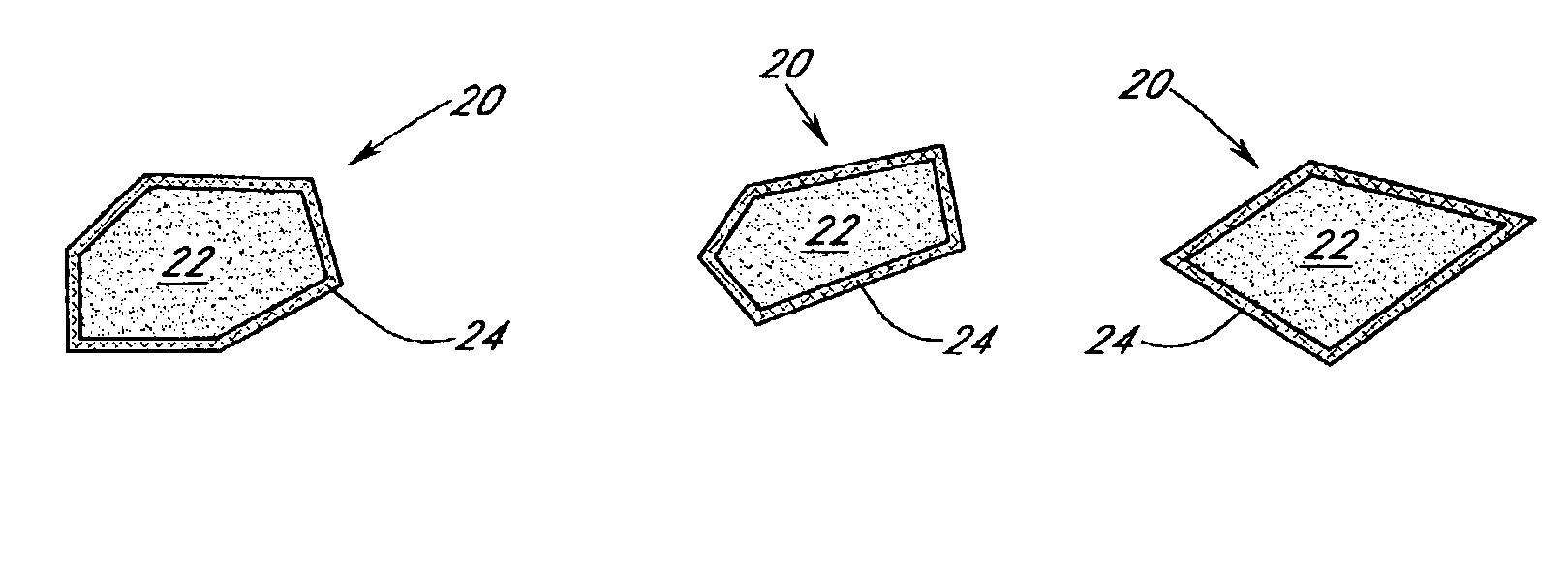

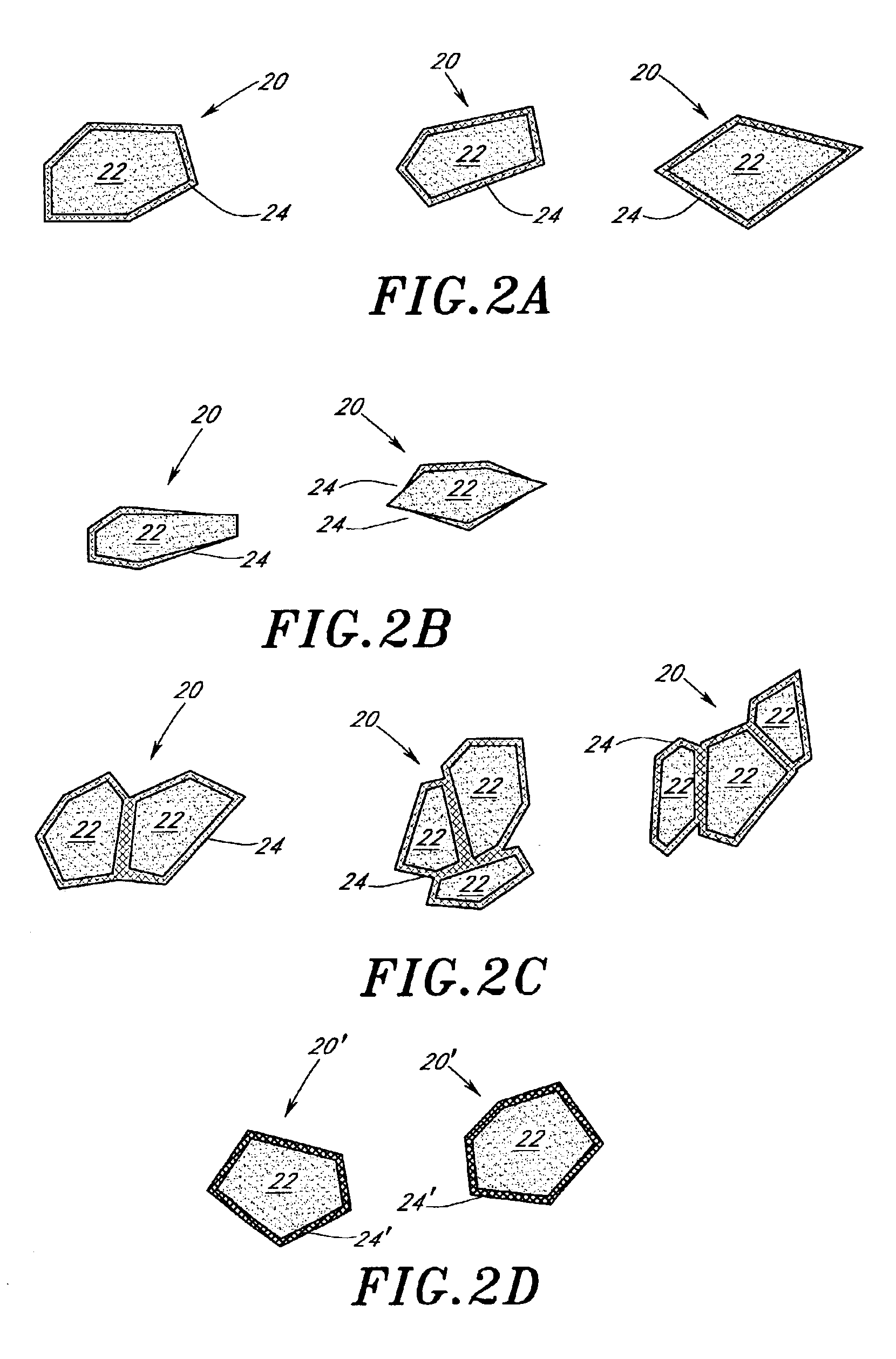

Cosmetic applicators and methods of manufacture

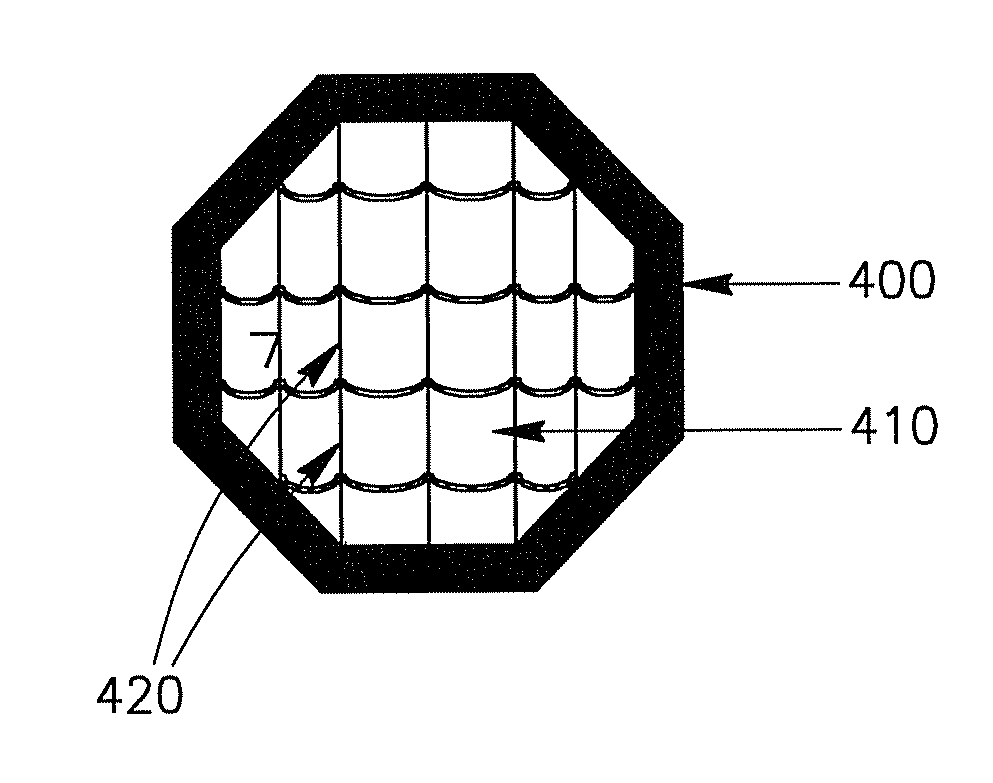

InactiveUS20080083421A1Easy to separatePromotes its utilizationCombsBristleBristleMechanical engineering

A molded plastic applicator for cosmetics, such as a mascara brush, including an integral molded plastic panel that lies substantially in a mold plane when formed and is bent out of the mold plane to surround an extended longitudinal axis when the applicator is assembled. A plurality of openings, or projections such as bristles, are formed in or on the panel so as to be oriented substantially in a common pull direction transverse to the mold plane when the panel lies in the mold plane and to be oriented substantially radially of the longitudinal axis in directions distributed around the axis when the panel is bent to surround the axis. A retainer holds the panel bent out of the plane in surrounding relation to the axis. The panel may be formed as a plurality of free-ended limbs, radiating from a hub through which the longitudinal axis extends, and bent down around the axis; alternatively, it may be generally rectangular as formed, and bent into a cylinder about the axis, or it may be formed as a band that is wound helically about the axis. A method of making the applicator includes steps of molding the panel, bending the panel about the axis, and retaining the panel in the bent configuration.

Owner:ALBEA SERVICES SAS

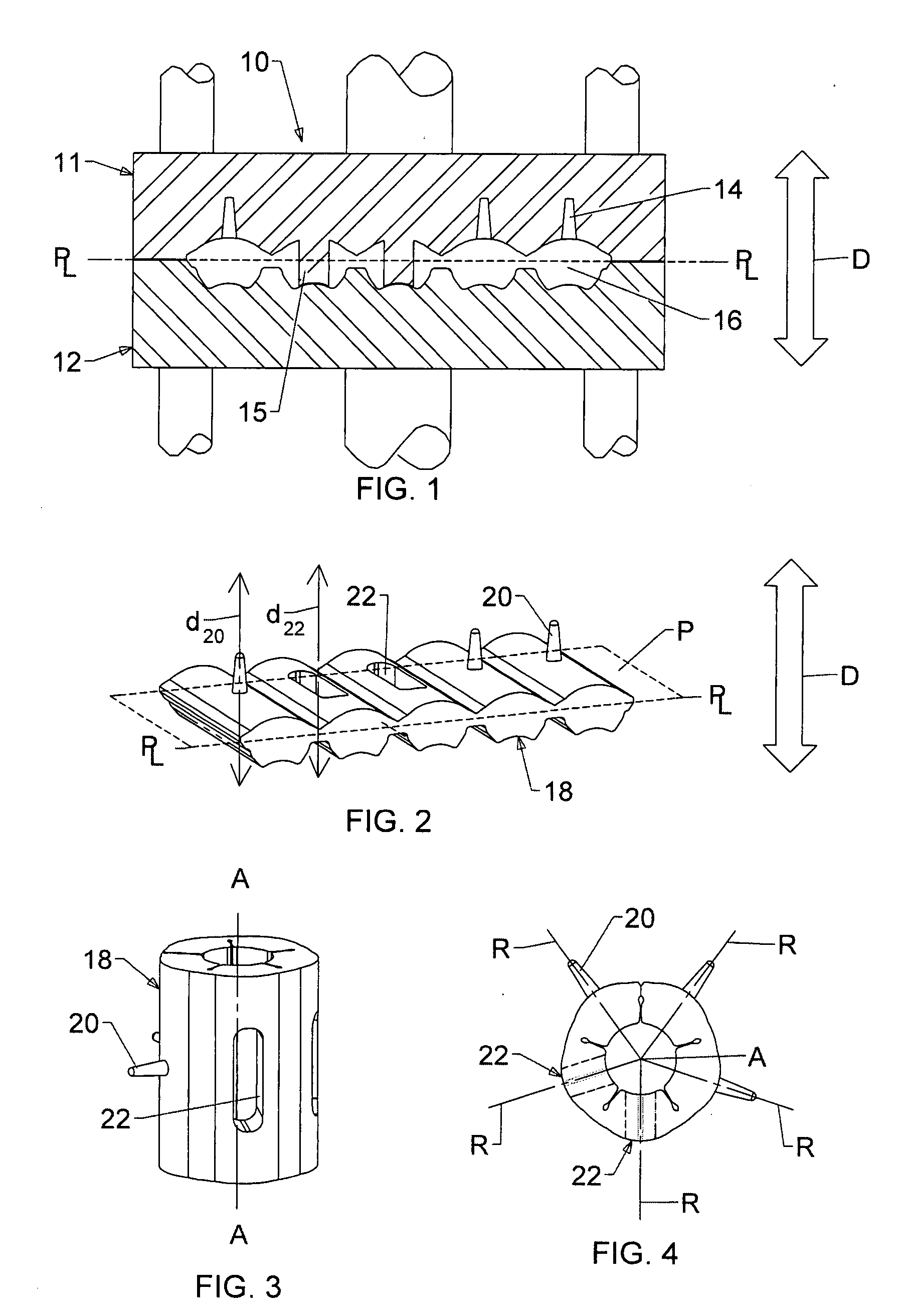

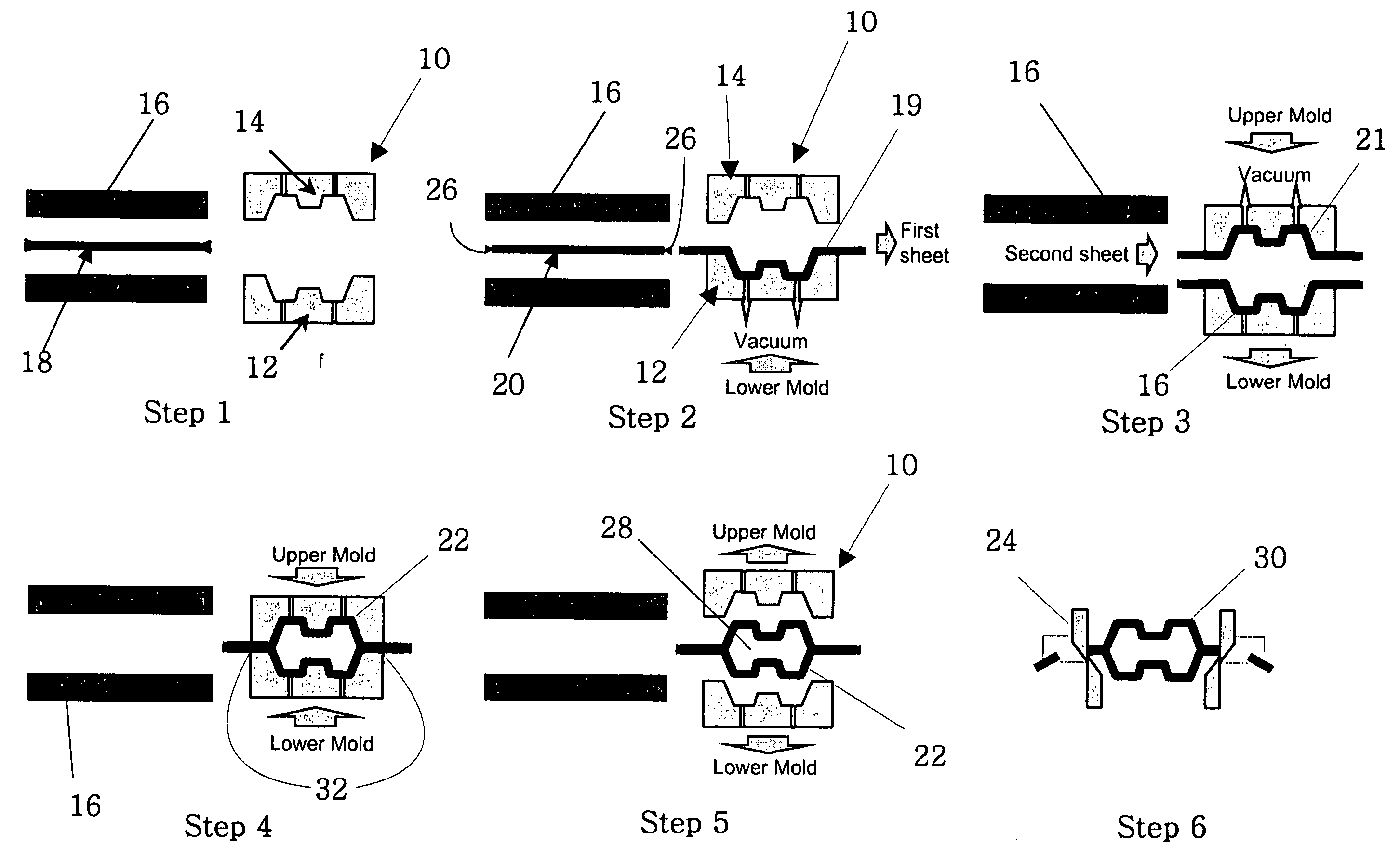

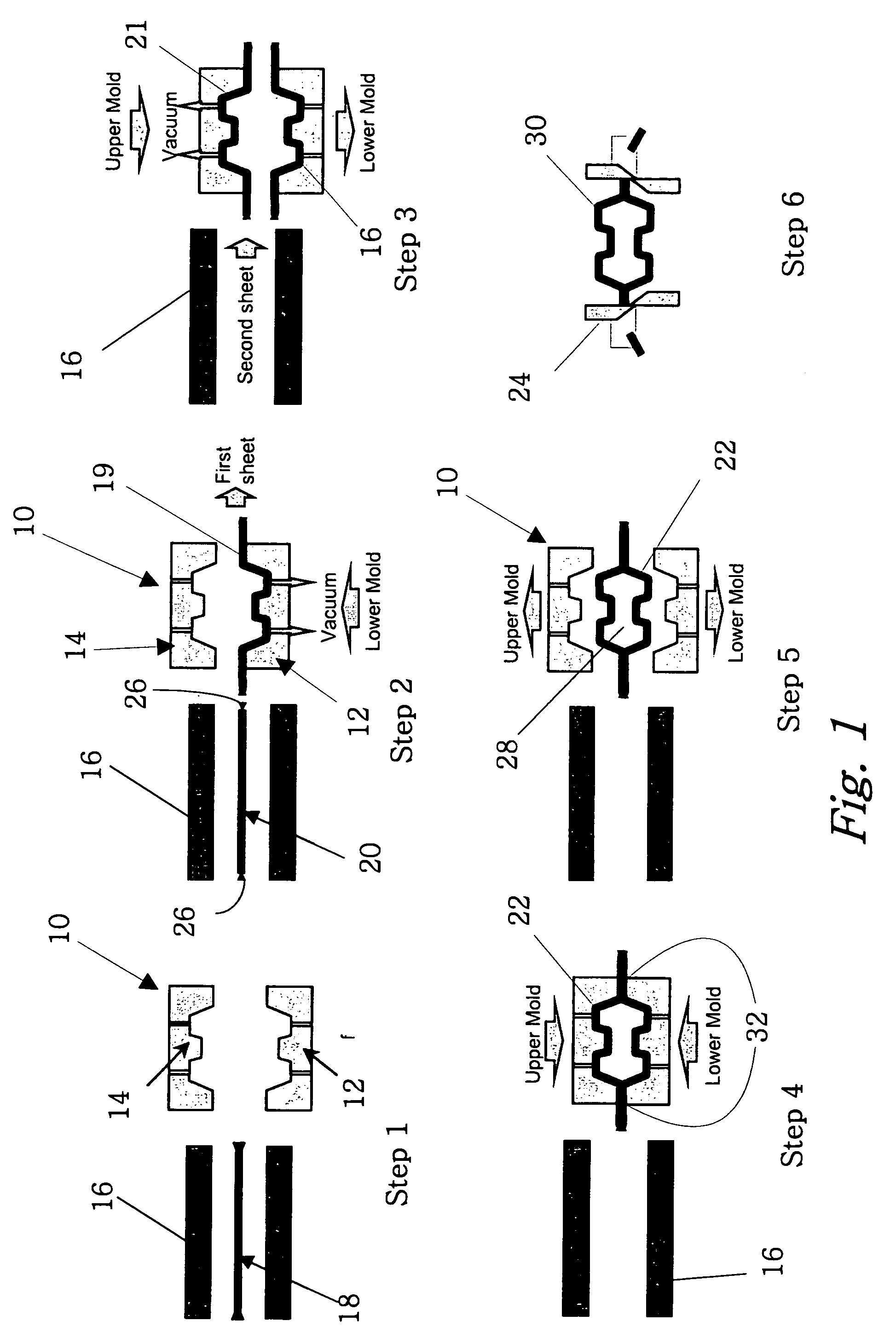

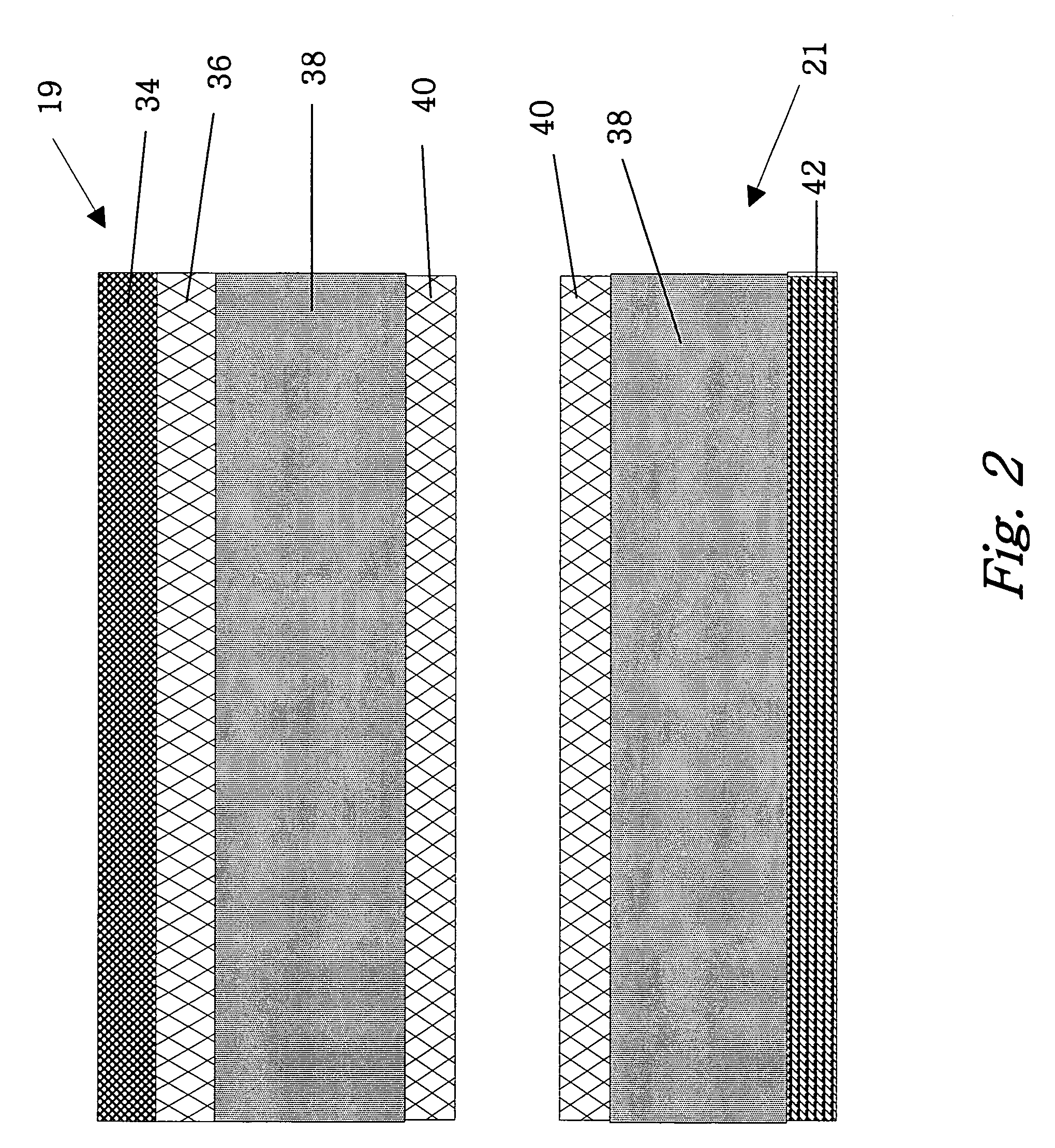

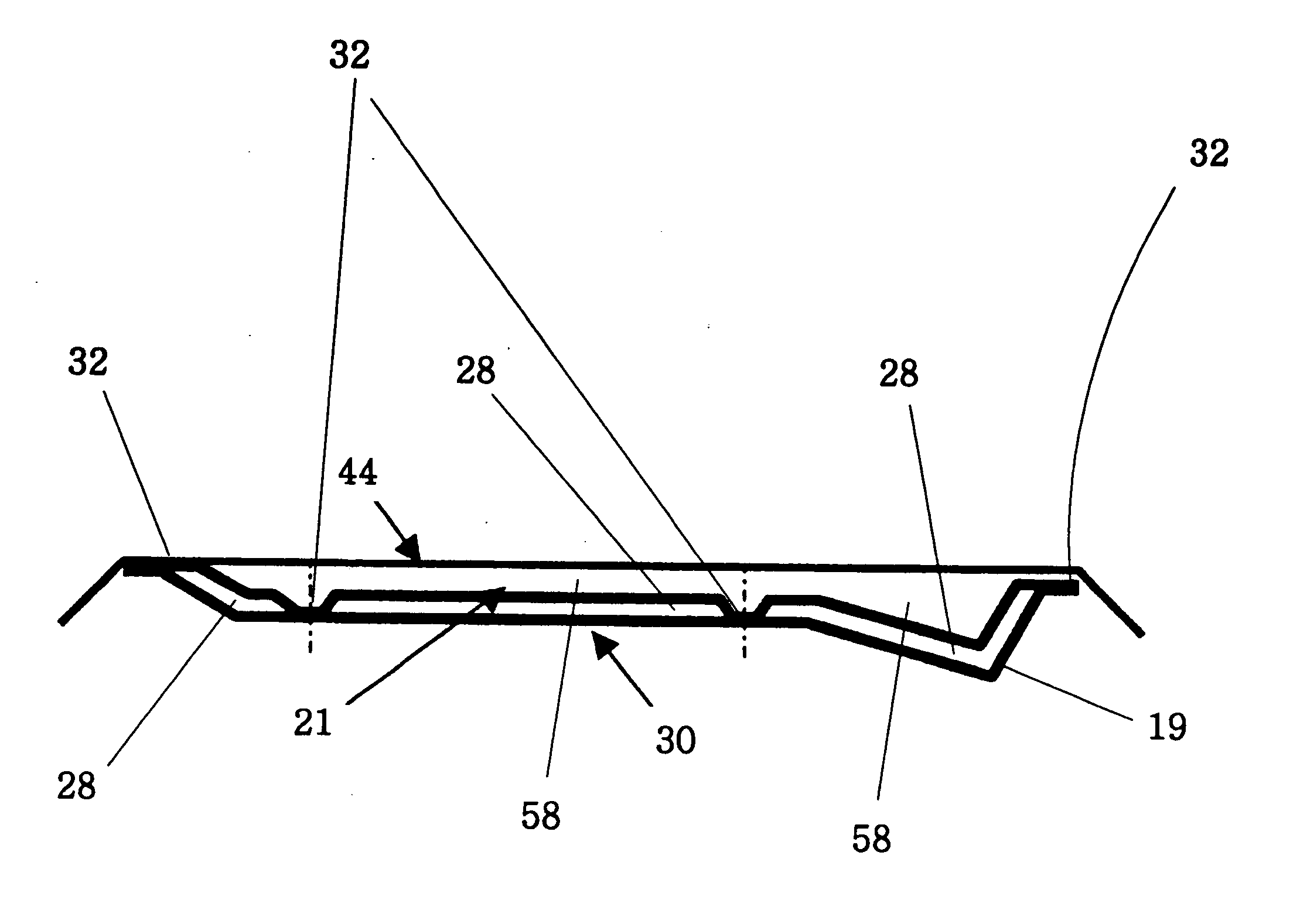

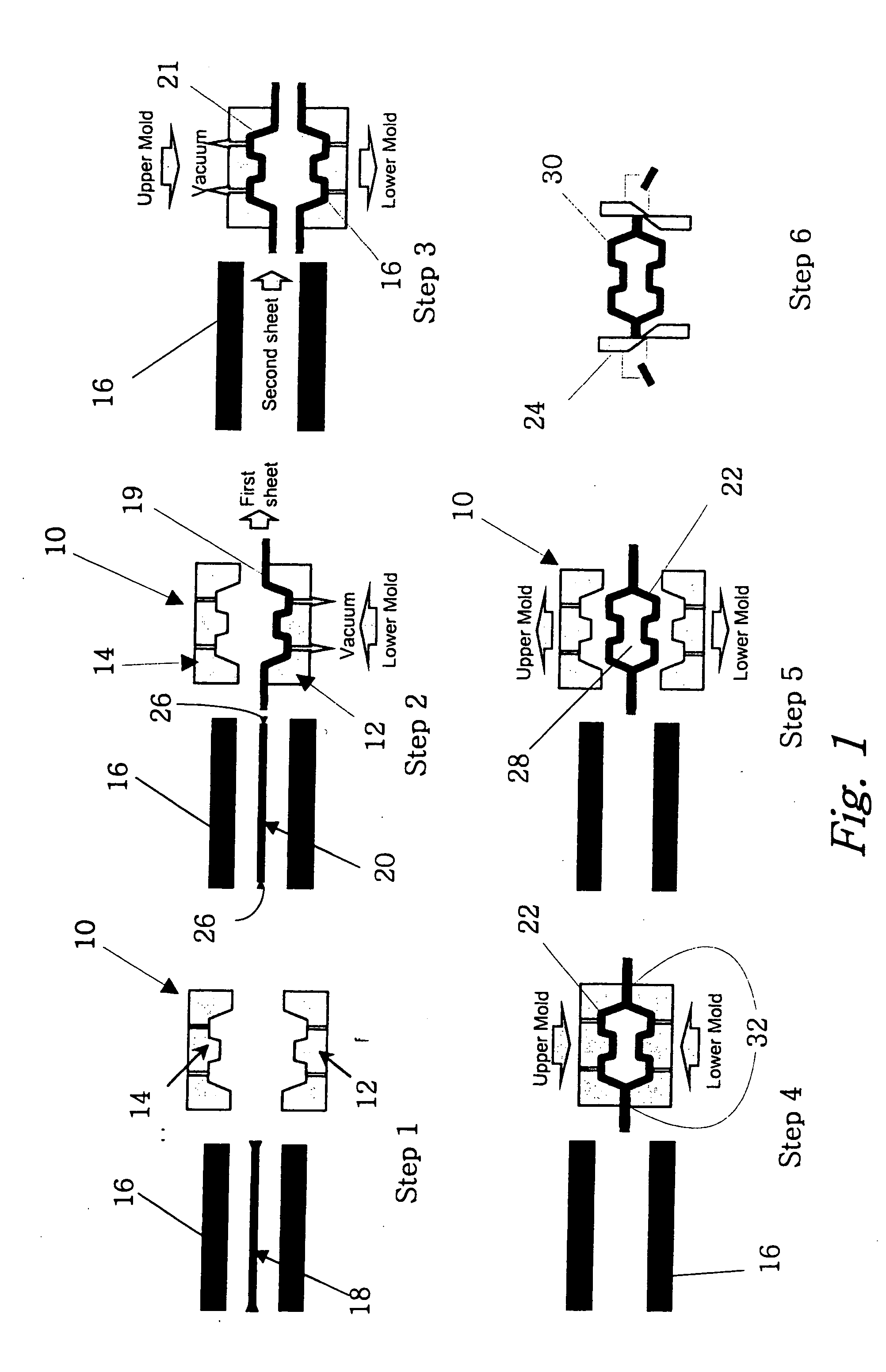

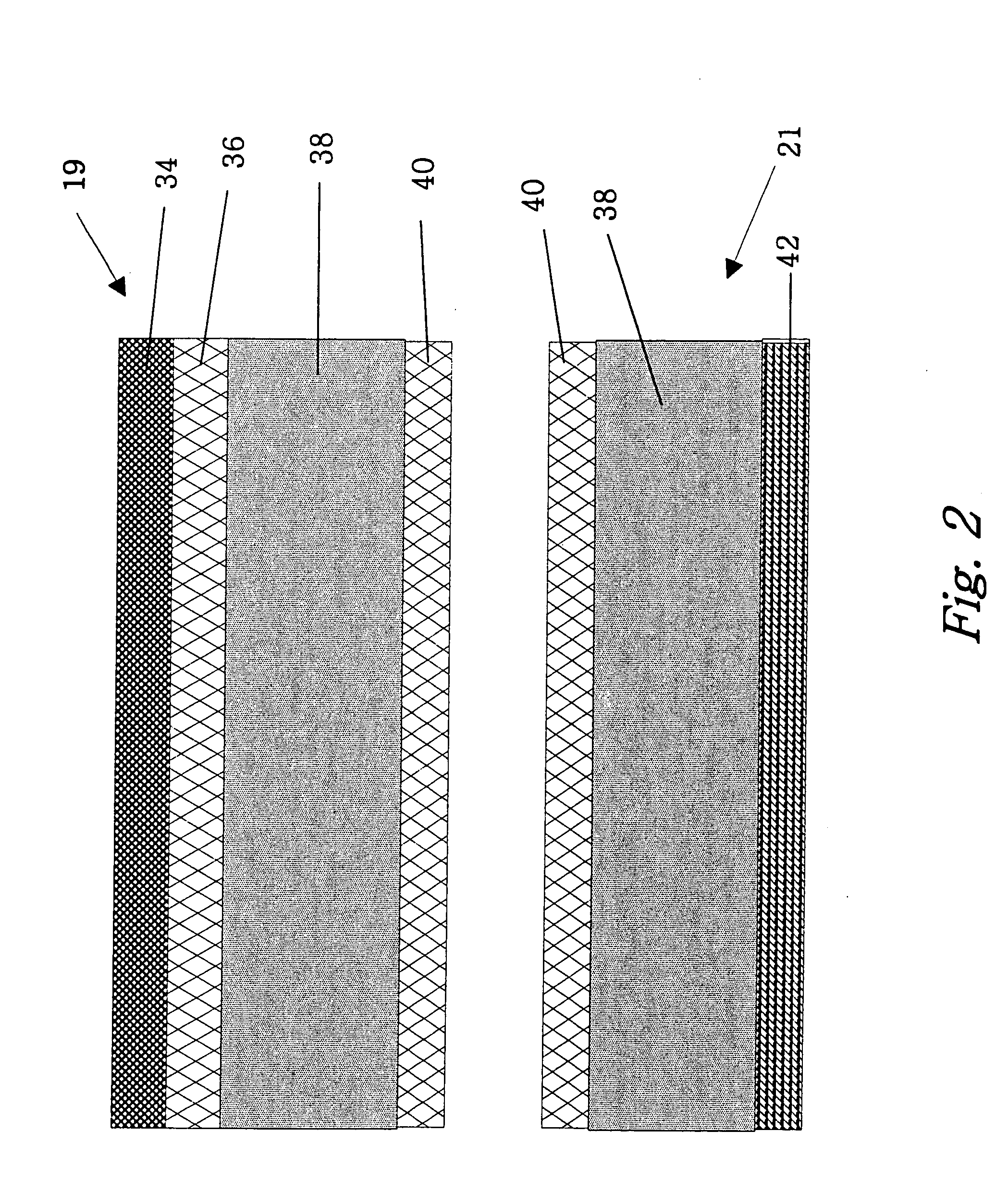

Twin-sheet thermoforming process

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

Twin-sheet thermoformed products

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

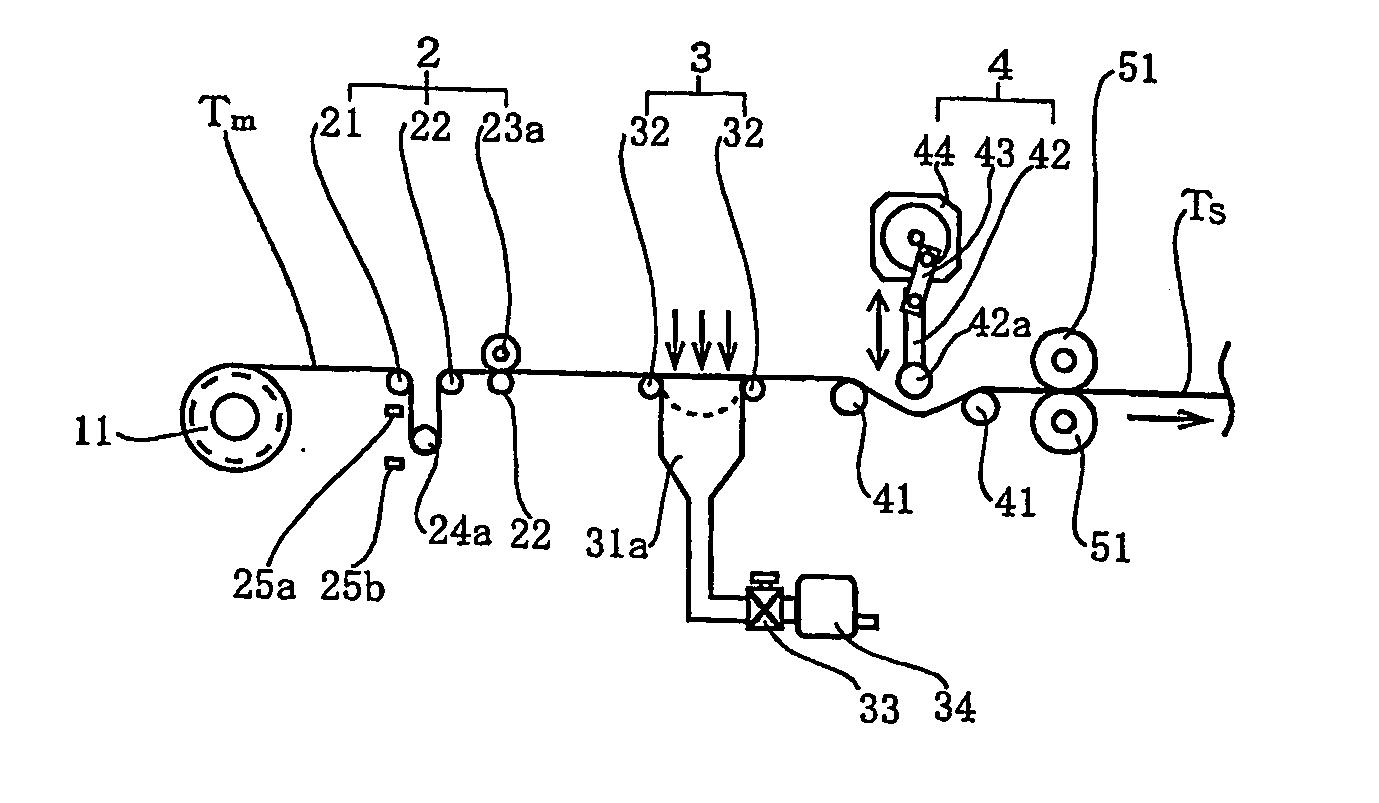

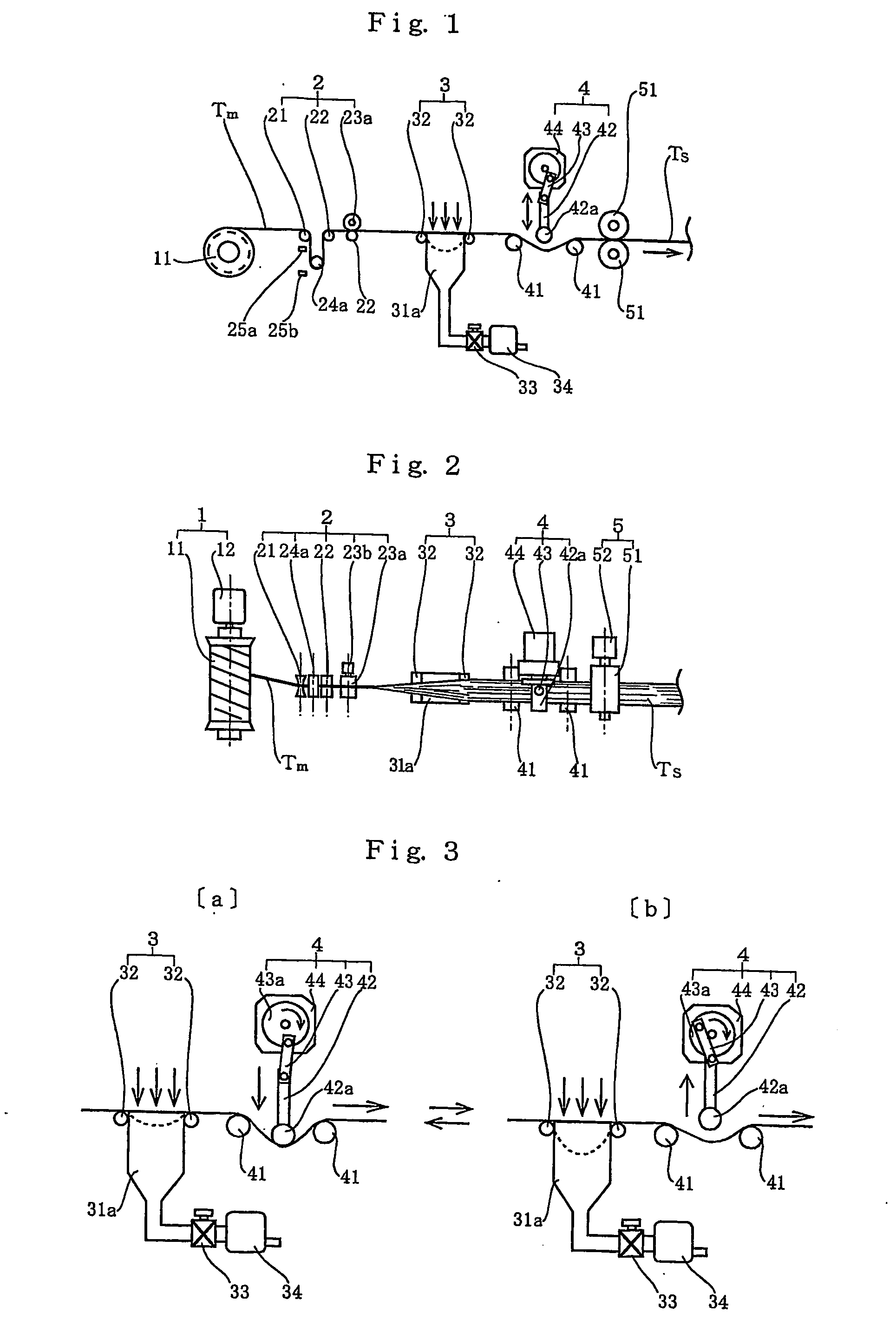

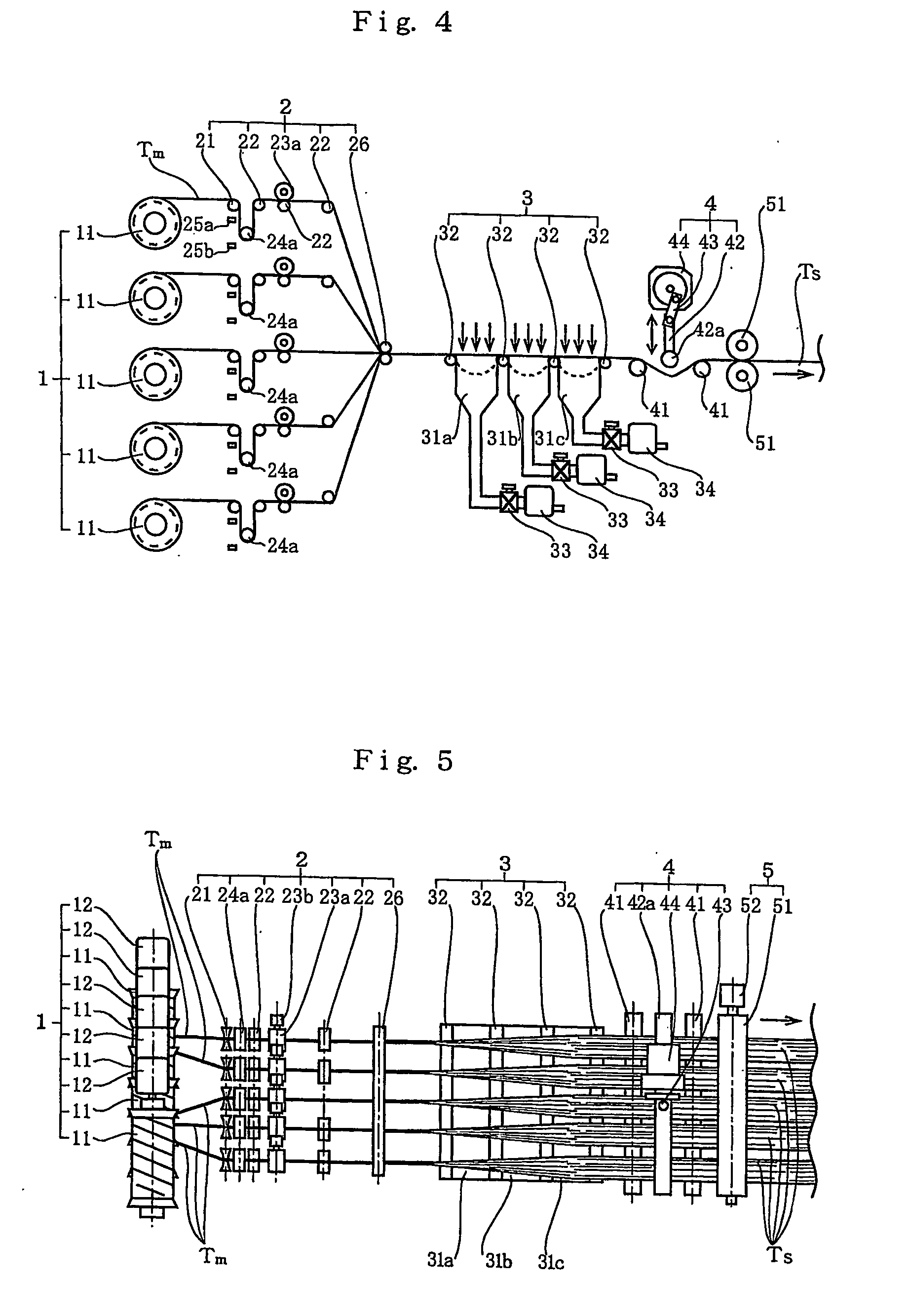

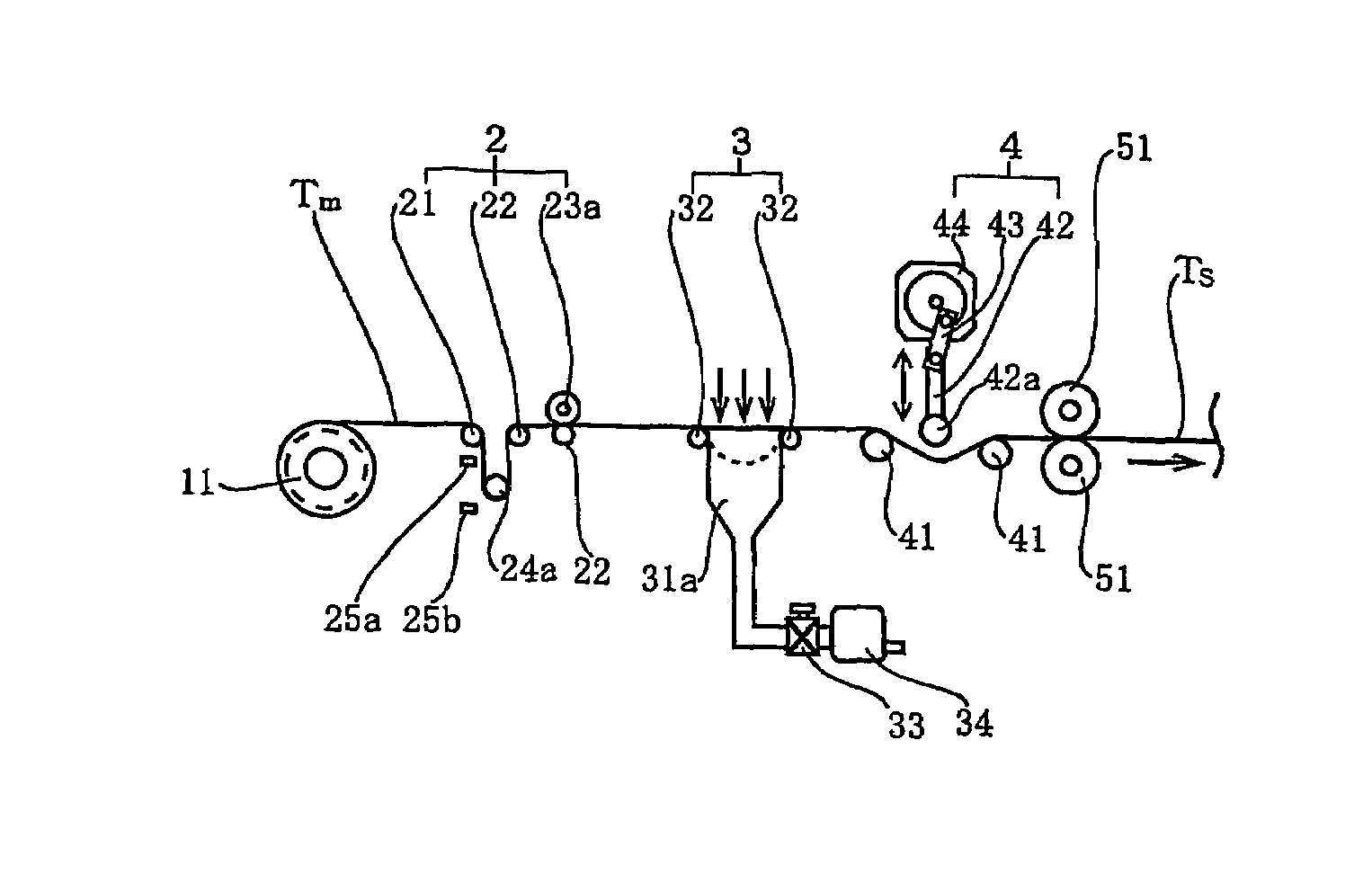

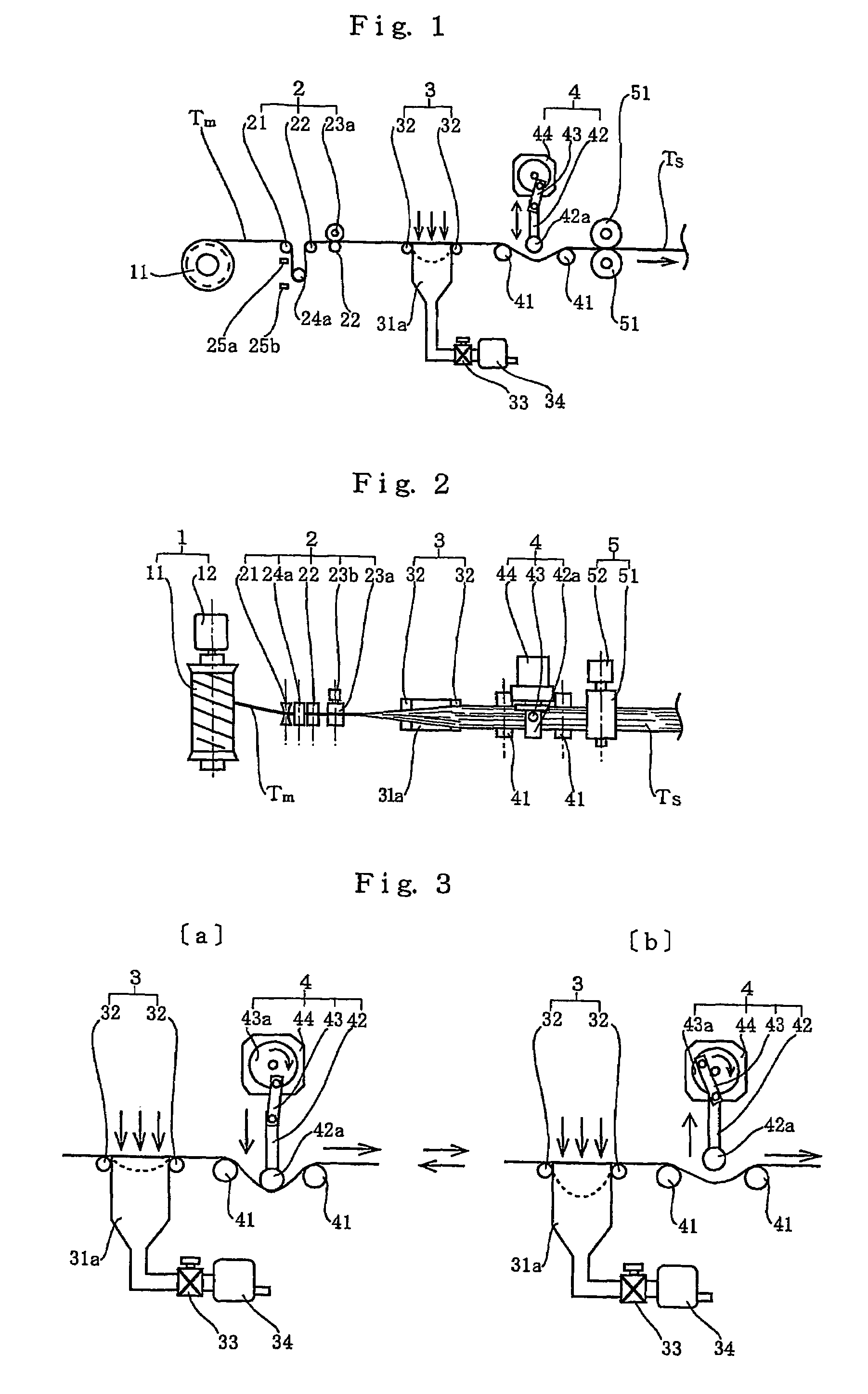

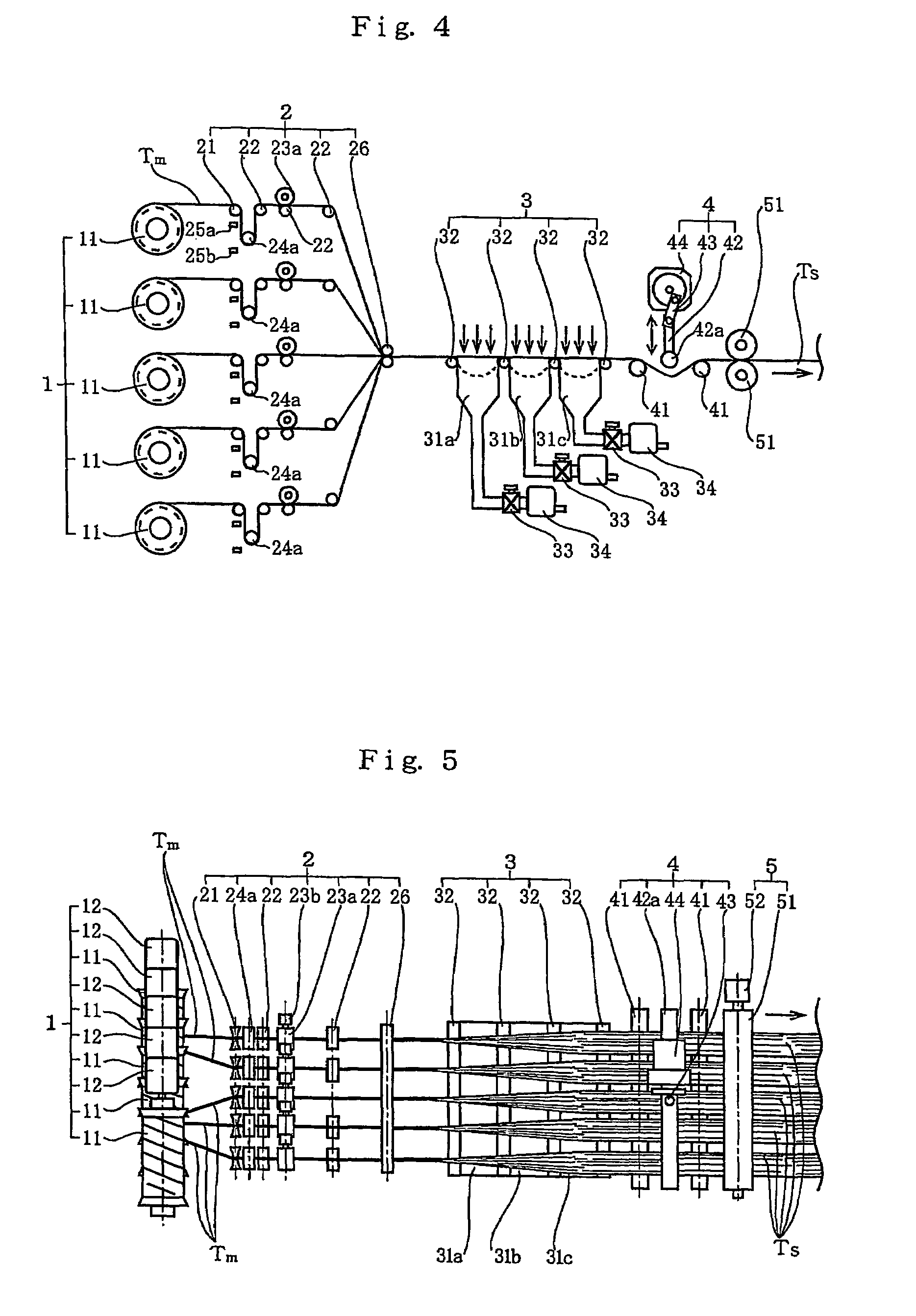

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS20060137156A1Efficient mass productionImprove efficiencyButtonsRecord carriersEngineeringVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

Selectively-extendable modular lighting fixture and method

InactiveUS6984055B2Easy to adaptEfficient implementationLighting support devicesElongate light sourcesModularityEffect light

Owner:KENALL MFG

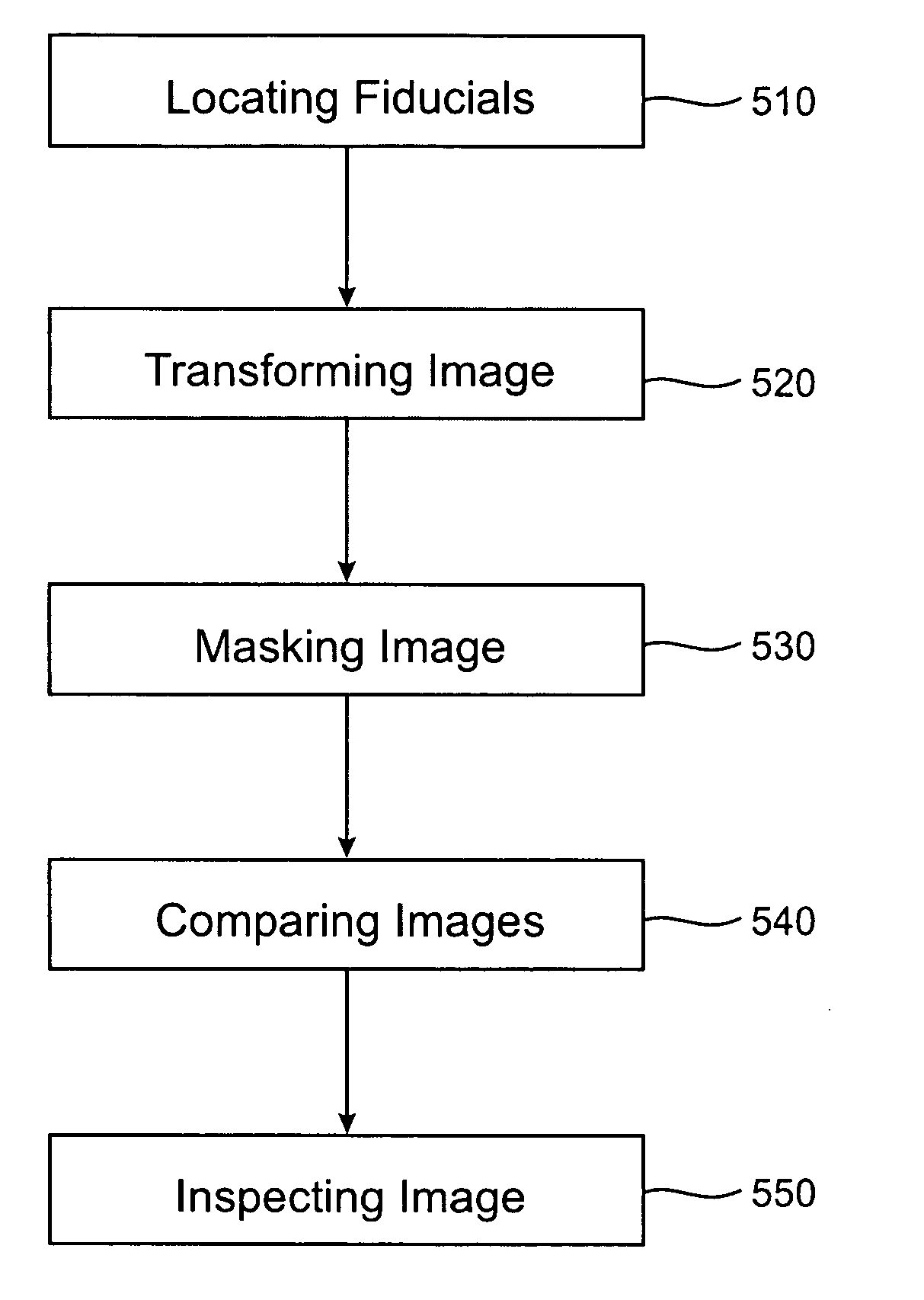

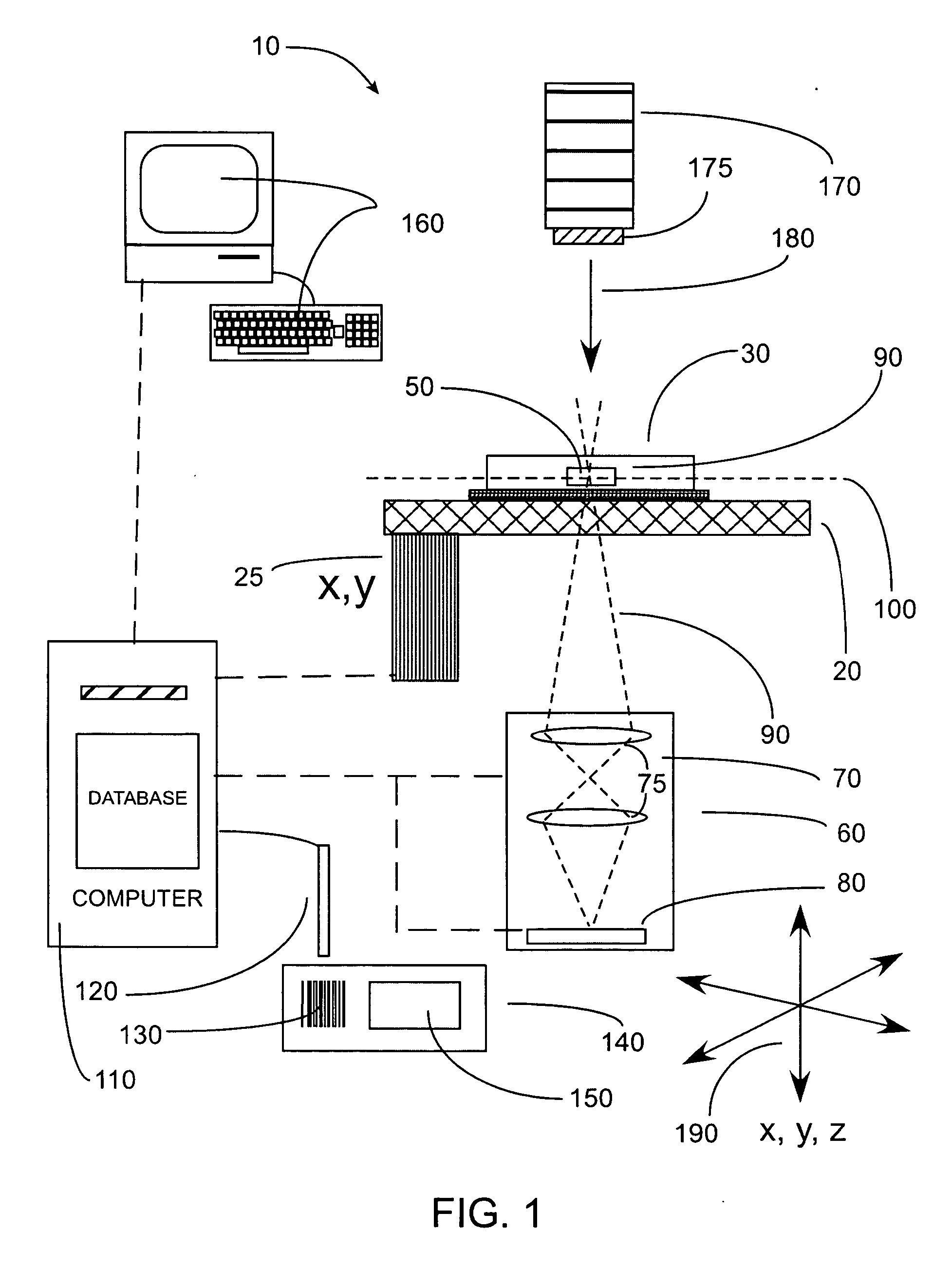

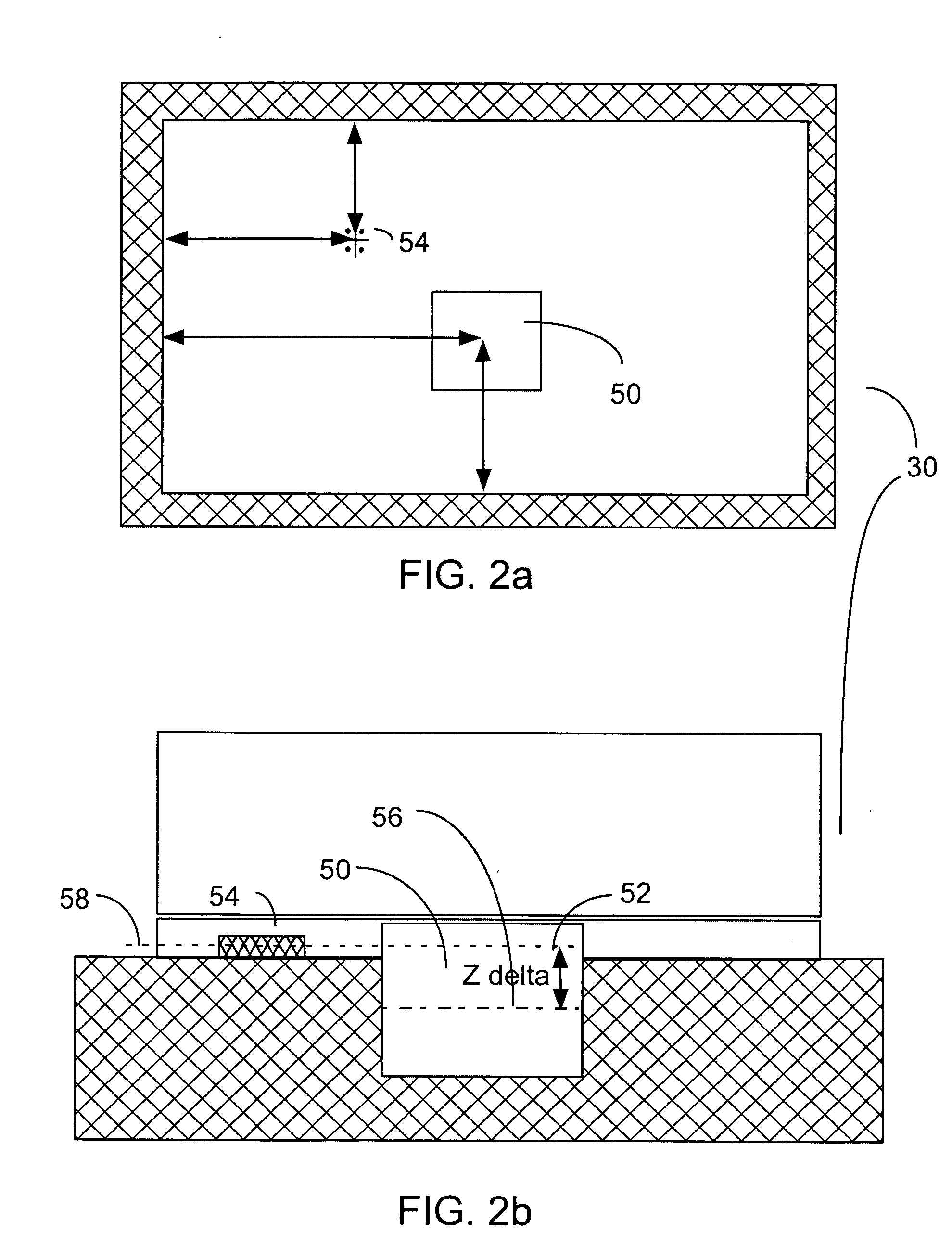

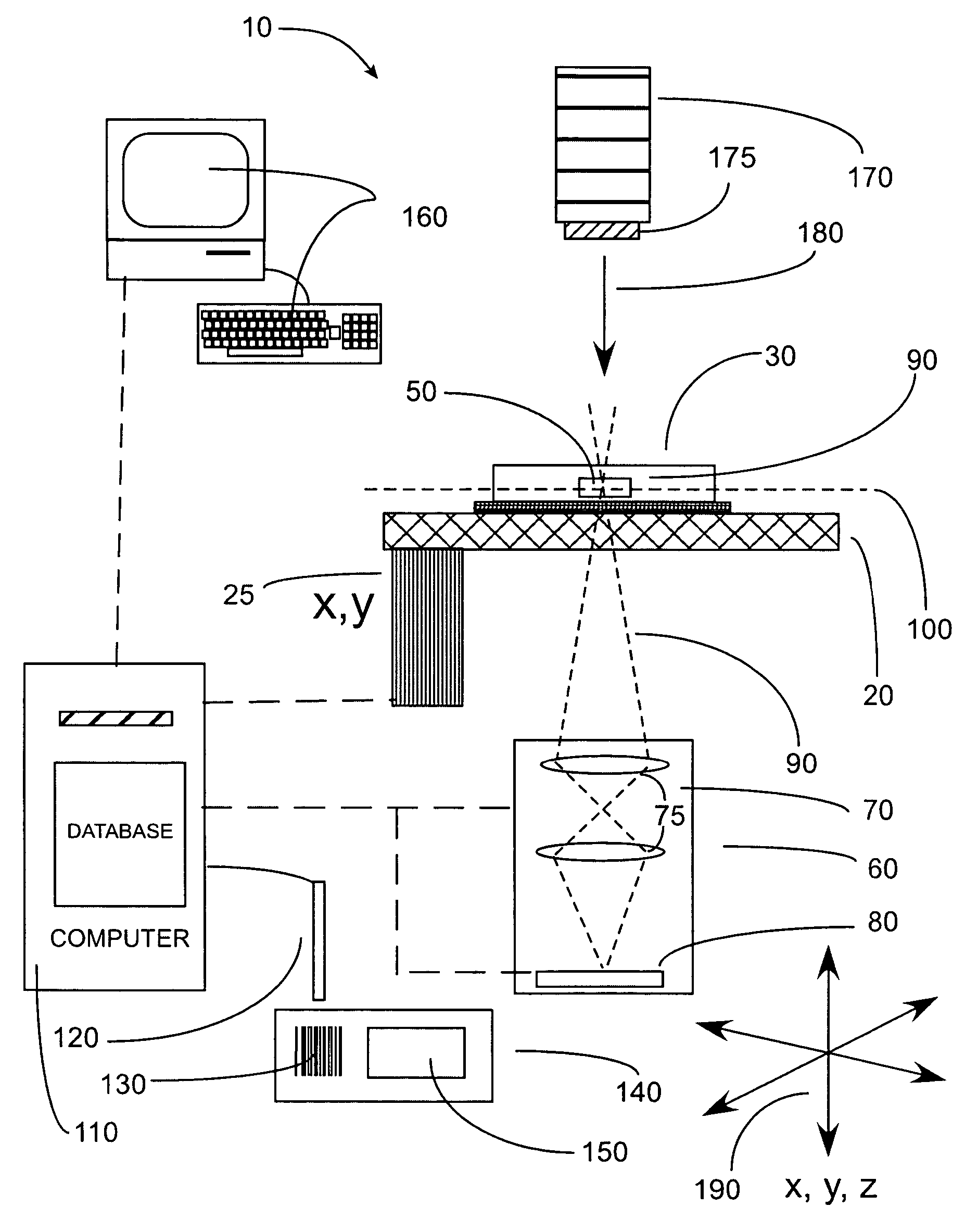

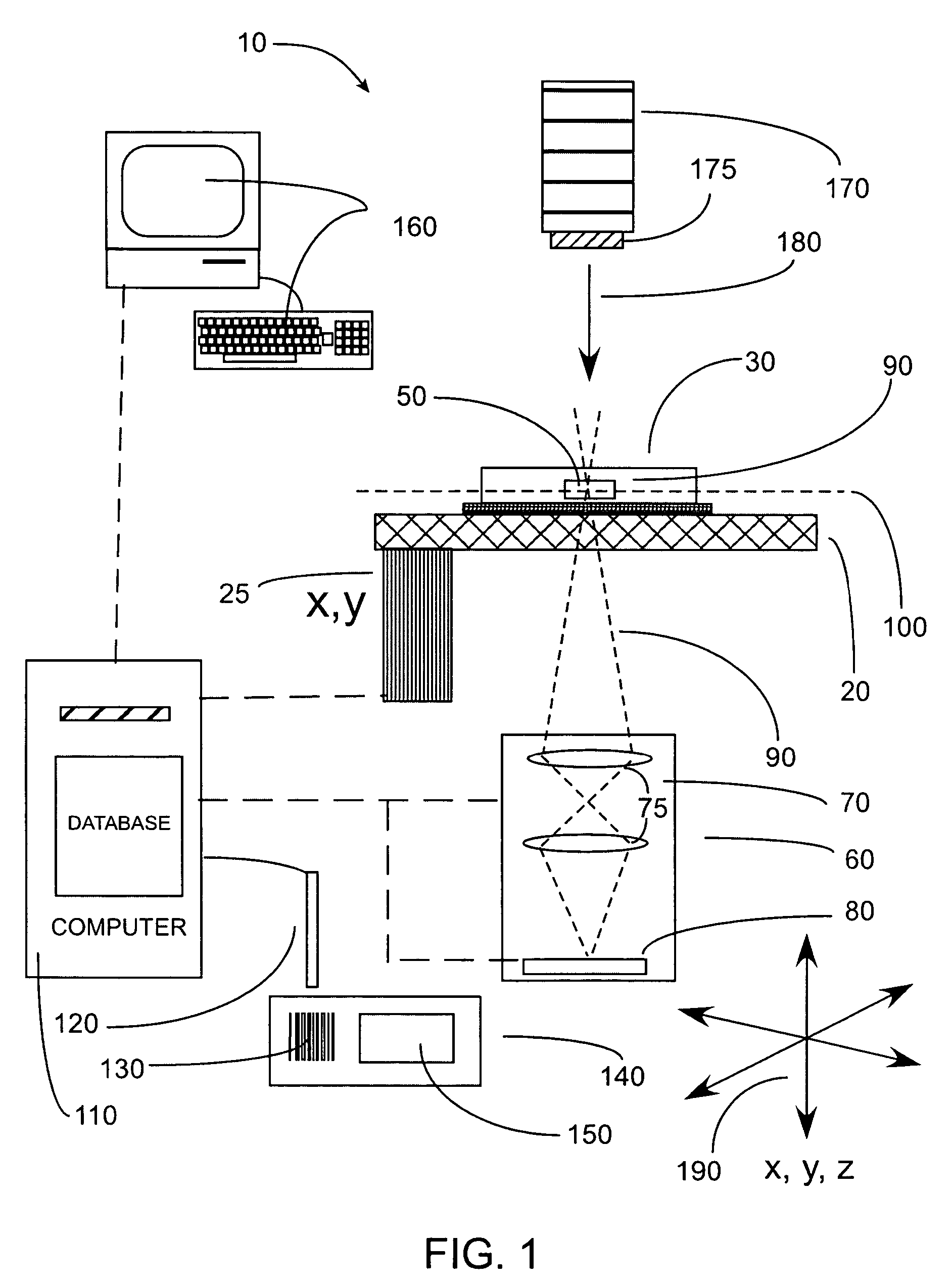

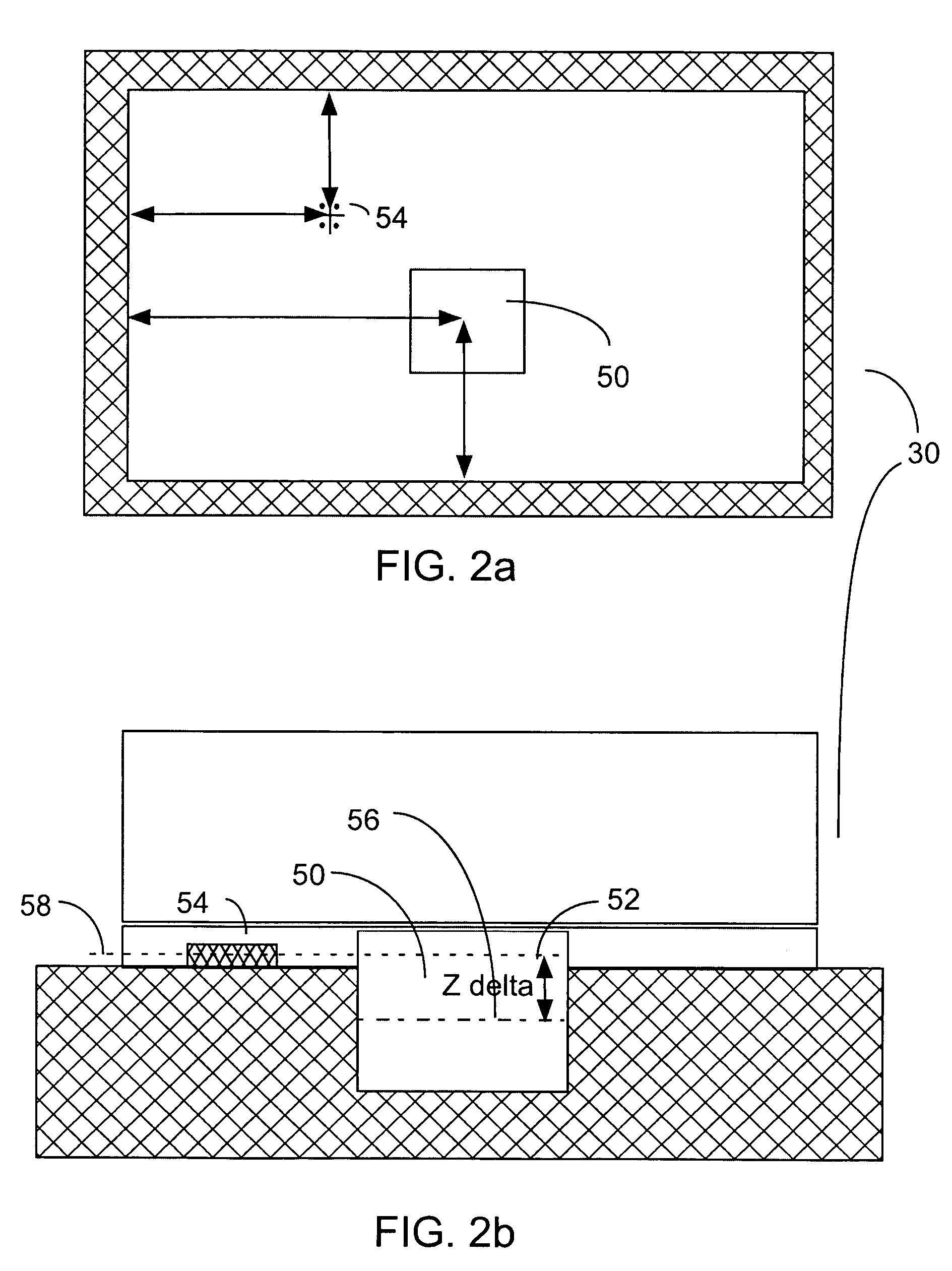

Image processing method and system for microfluidic devices

InactiveUS20050282175A1Increase speedSimple processImage enhancementButtonsImaging processingState dependent

A method for processing an image of a microfluidic device. The method includes receiving a first image of a microfluidic device. The first image corresponds to a first state. Additionally, the method includes receiving a second image of the microfluidic device. The second image corresponds to a second state. Moreover, the method includes transforming the first image and the second image into a third coordinate space. Also, the method includes obtaining a third image based on at least information associated with the transformed first image and the transformed second image, and processing the third image to obtain information associated with the first state and the second state.

Owner:FLUIDIGM CORP

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS7571524B2Efficient mass productionImprove efficiencyButtonsRecord carriersYarnVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

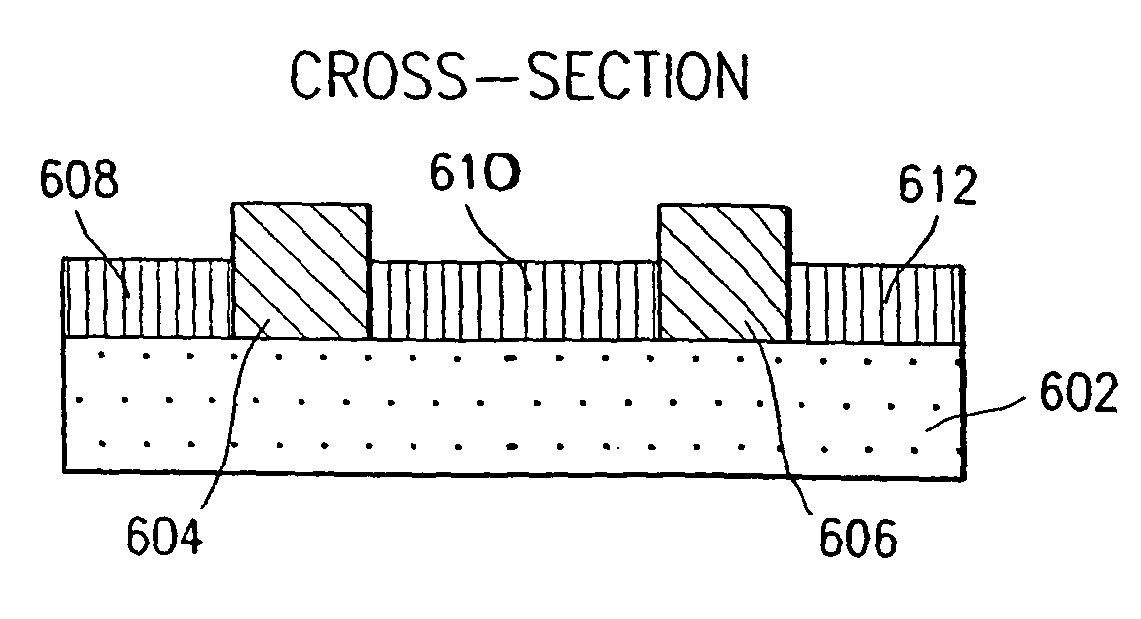

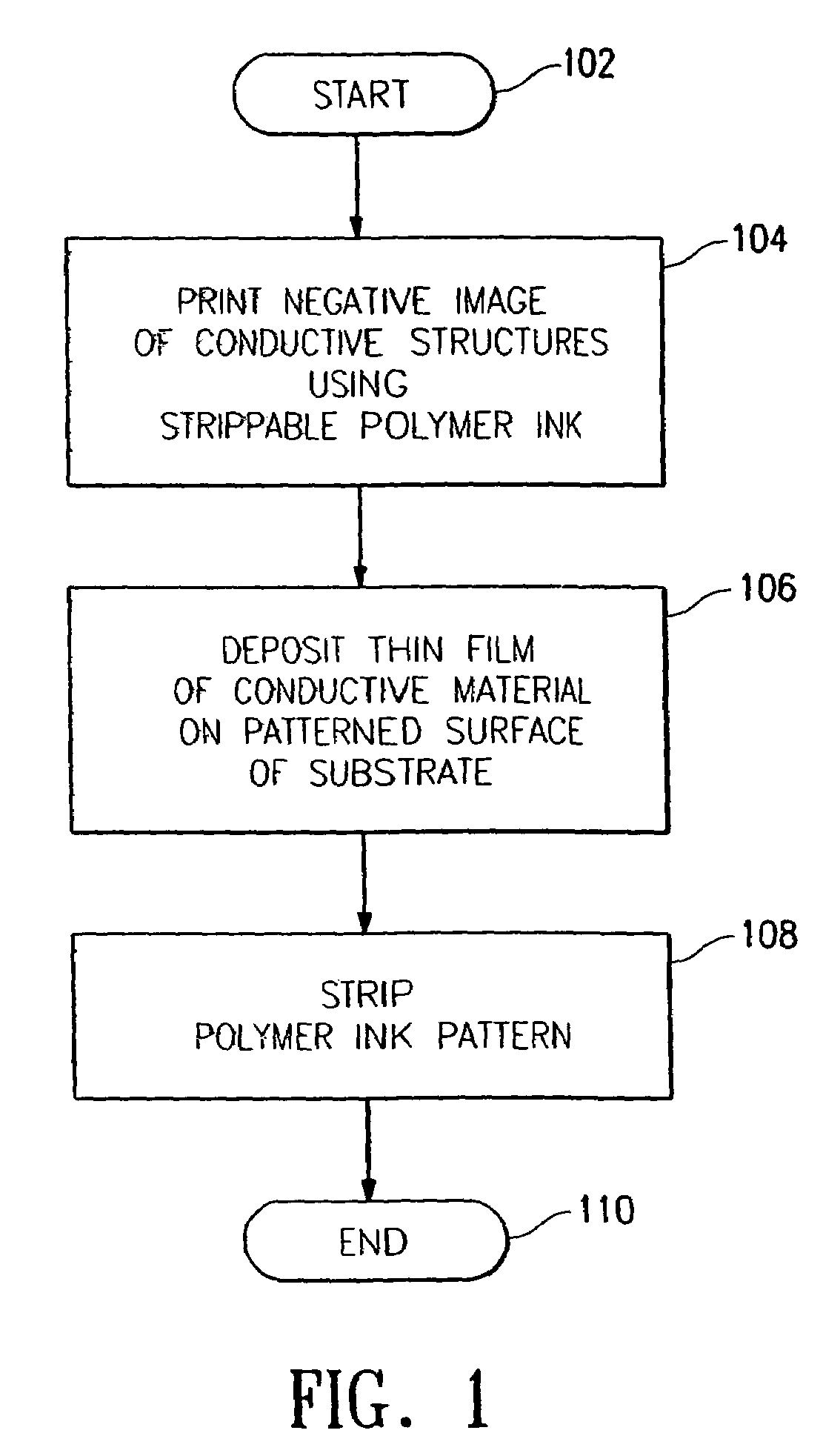

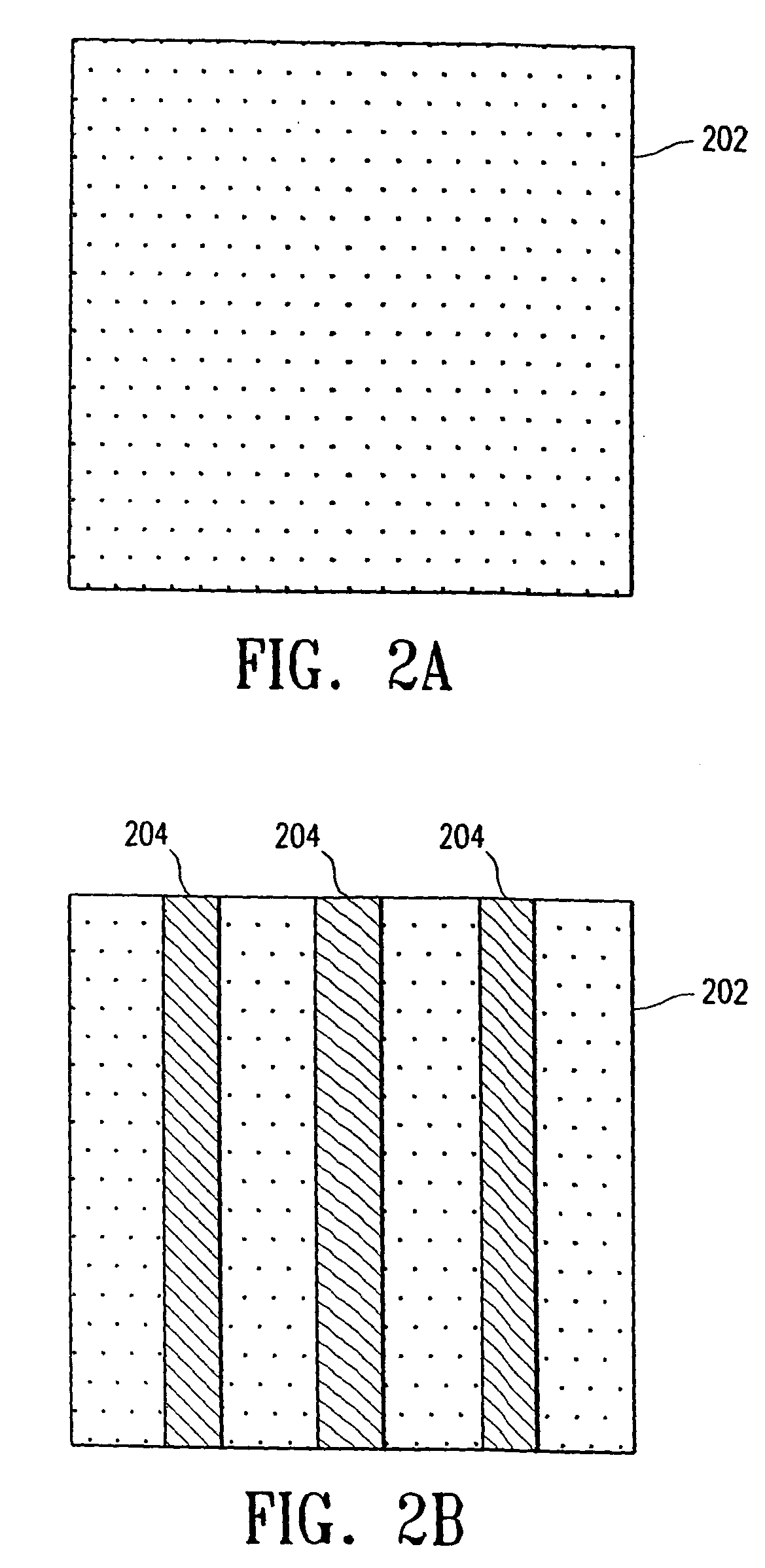

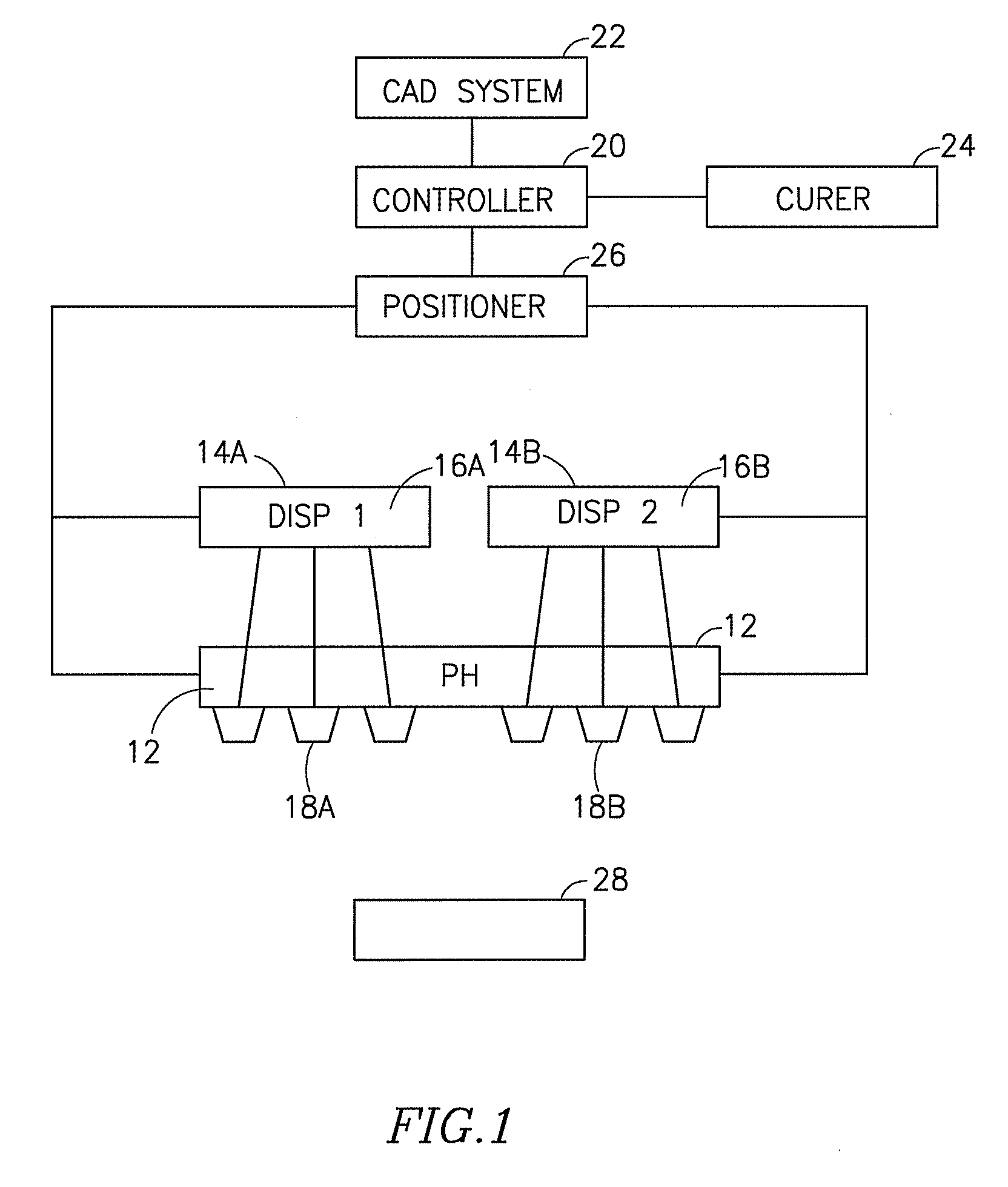

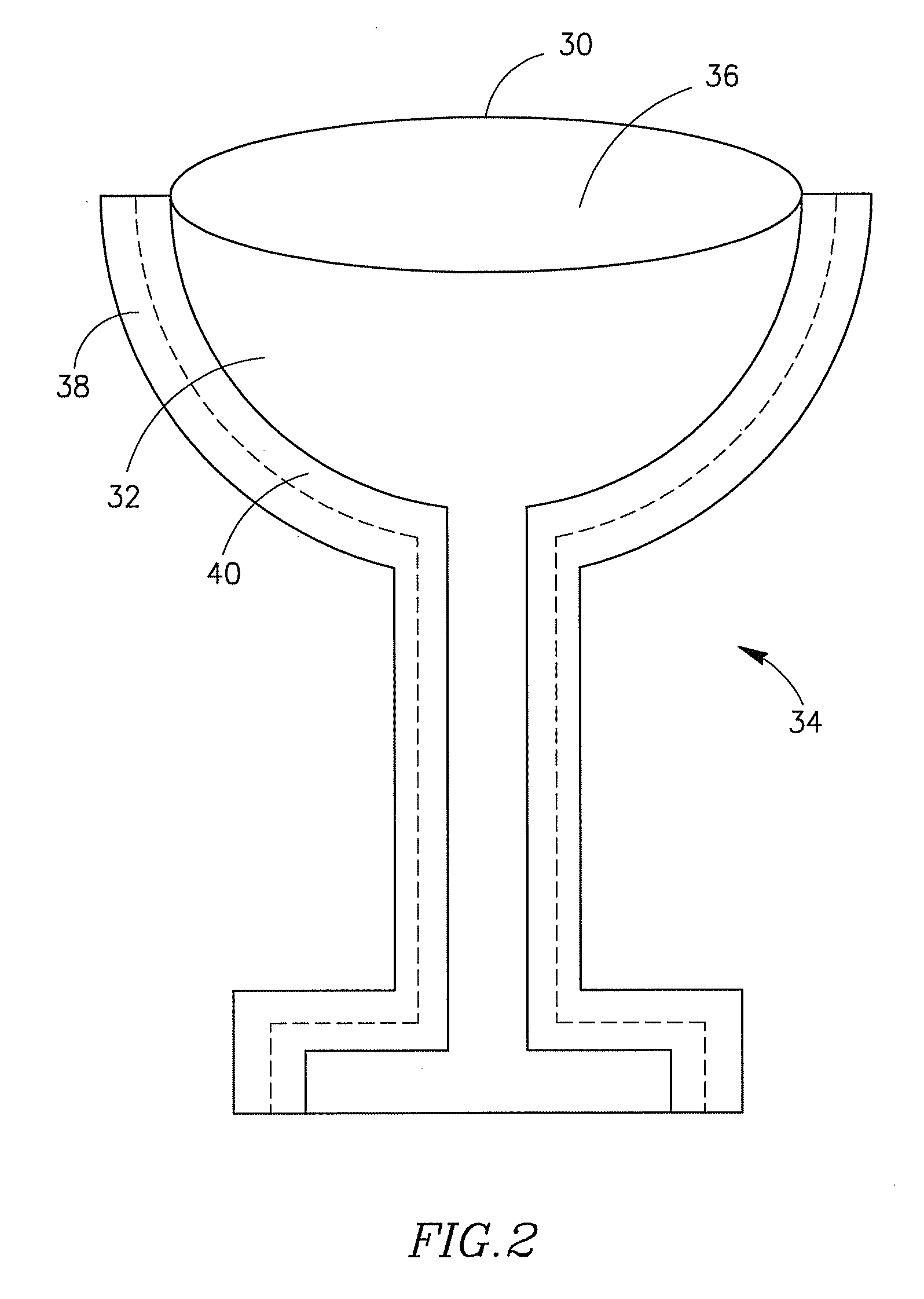

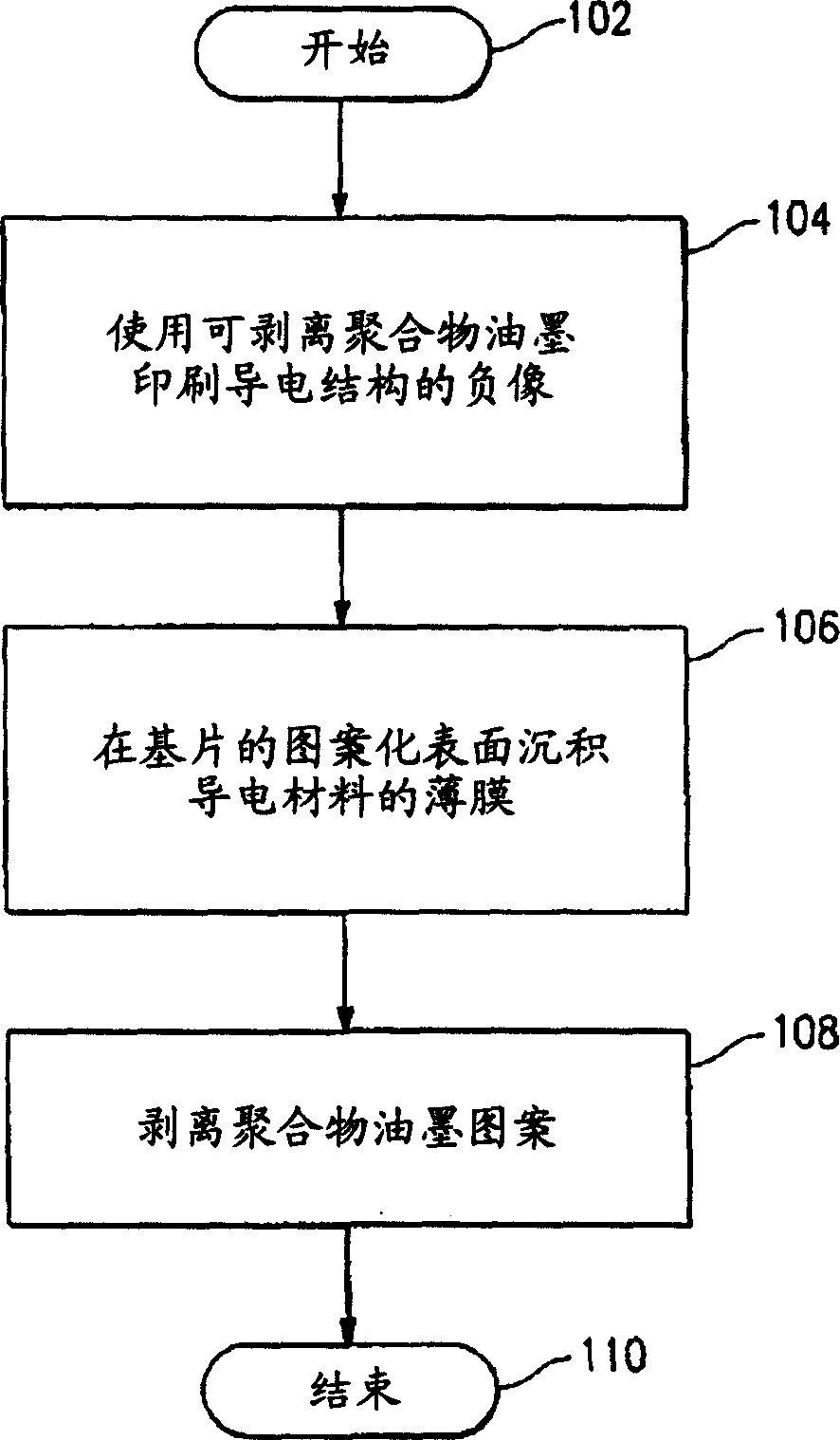

Process for forming a patterned thin film structure for in-mold decoration

A process for forming a patterned thin film structure on a substrate or in-mold decoration film is disclosed. A pattern is printed with a material, such as a masking coating or ink, on the substrate, the pattern being such that, in one embodiment, the desired structures will be formed in the areas where the printed material is not present, i.e., a negative image of thin film structure to be formed is printed. In another embodiment, the pattern is printed with a material that is difficult to strip from the substrate, and the desired thin film structures will be formed in the areas where the printed material is present, i.e., a positive image of the thin film structure is printed. The thin film material is deposited on the patterned substrate, and the undesired area is stripped, leaving behind the patterned thin film structure.

Owner:SIPIX CHEM

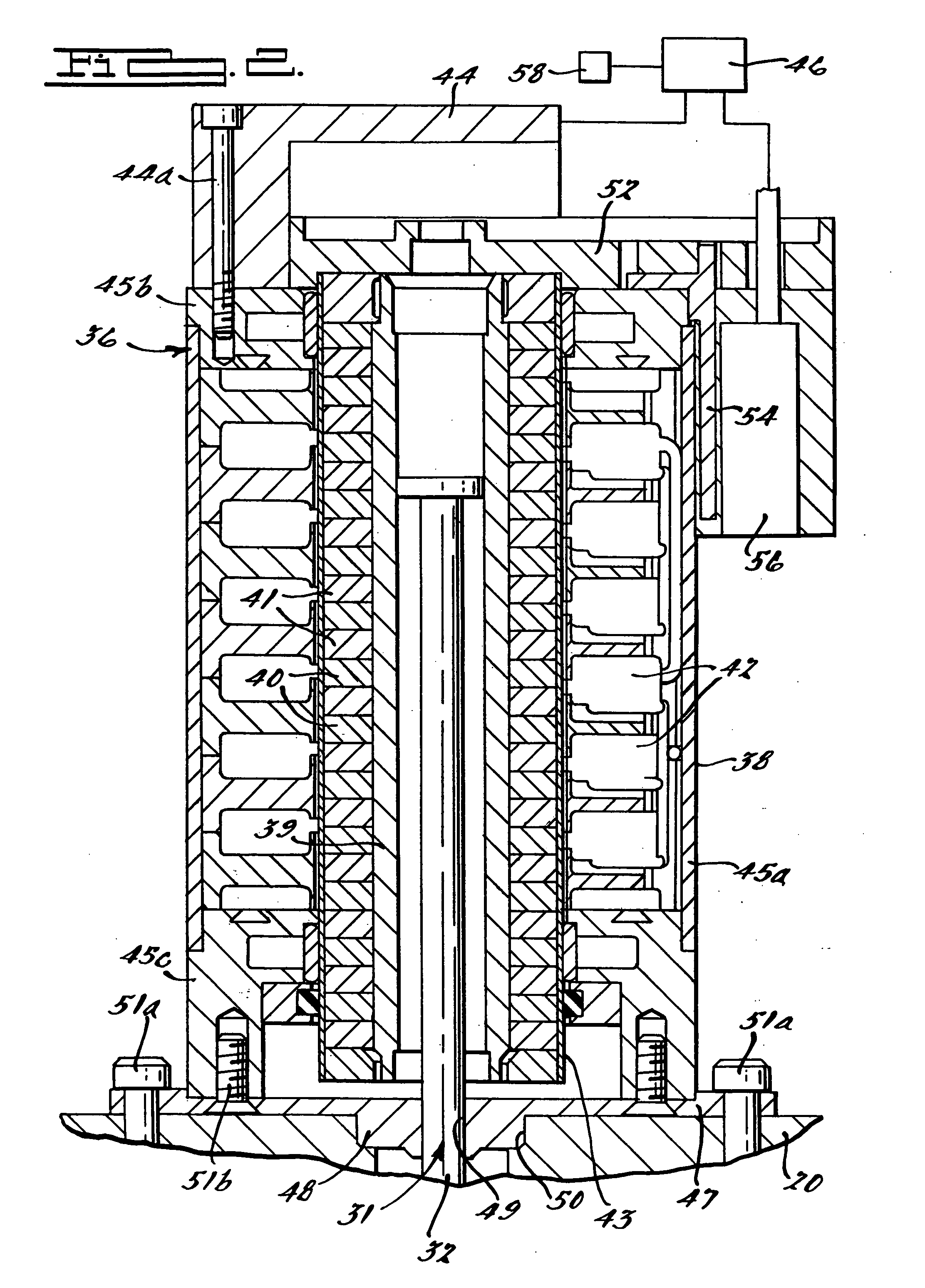

Valve gate assembly

ActiveUS20050100625A1Process controlEasy to adjustButtonsRecord carriersEngineeringMechanical engineering

A valve gate assembly for regulating a flow of molten material into a mold. The valve gate assembly includes a movable valve that can move between a fully closed position and a fully open position. The valve gate assembly further includes an actuating system operatively cooperating with the valve to move the valve and infinitely position the valve between the fully closed position and the fully open position.

Owner:PLASTIC ENG & TECHN SERVICES

Compositions and method for improving reheat rate of PET using activated carbon

ActiveUS20040249113A1Improving reheat rateMinimize impactEnvelopes/bags making machineryButtonsActivated carbonPolyester

A polyester composition, a preform, and a bottle, containing a polyester such as polyethylene terephthalate or polyethylene naphthalate and activated carbon to enhance the rate for reheating the composition is provided. Activated carbon may be added in the presence of active phosphorus containing compounds, or at any stage in the melt phase after prepolymerization and after the polyester polymer is solidified. Polyester concentrates containing activated carbon may be added to bulk polyesters to make preforms suitable for blowing into bottles.

Owner:ALPEK POLYESTER SA DE CV

Compositions and methods for use in three dimensional model printing

InactiveUS20080105818A1Similar elasticitySimilar strengthButtonsRecord carriersInvestment castingMaterials science

Embodiments of the invention are directed to a method of producing three-dimensional prototype molds for use in investment casting. The method includes dispensing modeling material and support material in a predetermined arrangement, in layers, to produce a three-dimensional mold having an outer shell. Generally, the out shell includes modeling material and the interior of the mold includes support material. Then the mold is cured.

Owner:OBJET GEOMETRIES

Process for forming a patterned thin film structure for in-mold decoration

A process for forming a patterned thin film structure on a substrate or in-mold decoration film is disclosed. A pattern is printed with a material, such as a masking coating or ink, on the substrate, the pattern being such that, in one embodiment, the desired structures will be formed in the areas where the printed material is not present, i.e., a negative image of thin film structure to be formed is printed. In another embodiment, the pattern is printed with a material that is difficult to strip from the substrate, and the desired thin film structures will be formed in the areas where the printed material is present, i.e., a positive image of the thin film structure is printed. The thin film material is deposited on the patterned substrate, and the undesired area is stripped, leaving behind the patterned thin film structure.

Owner:SIPIX CHEM

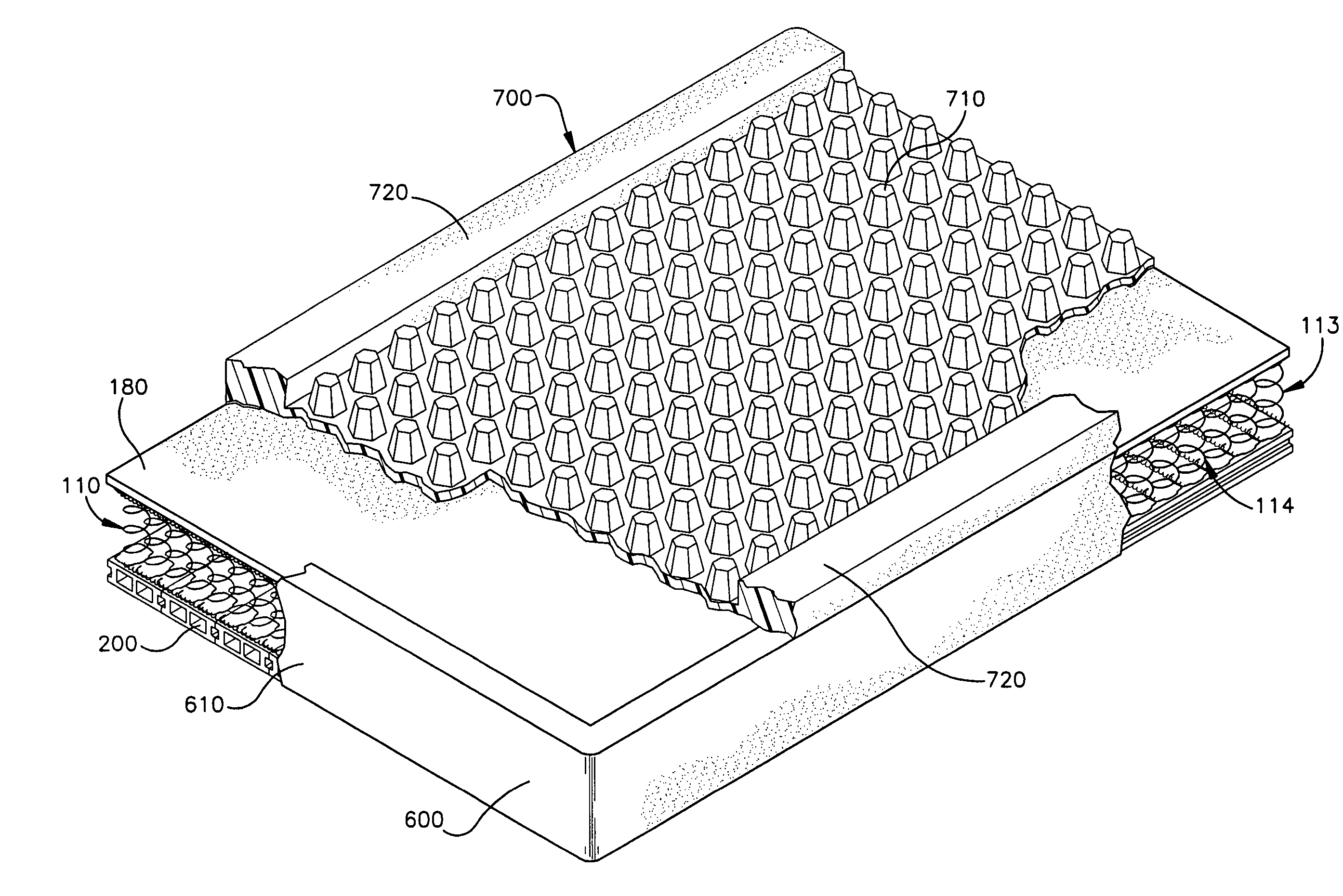

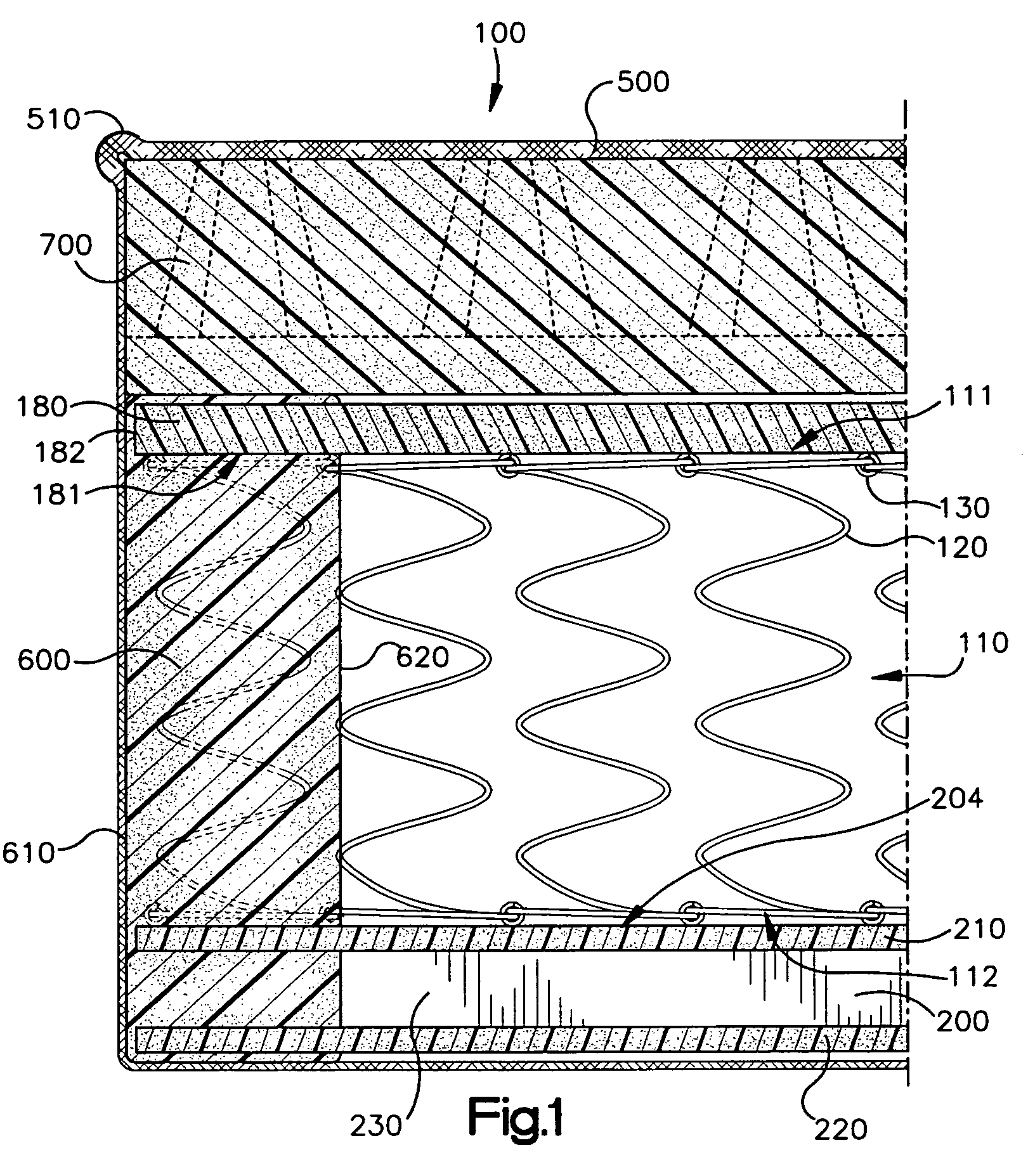

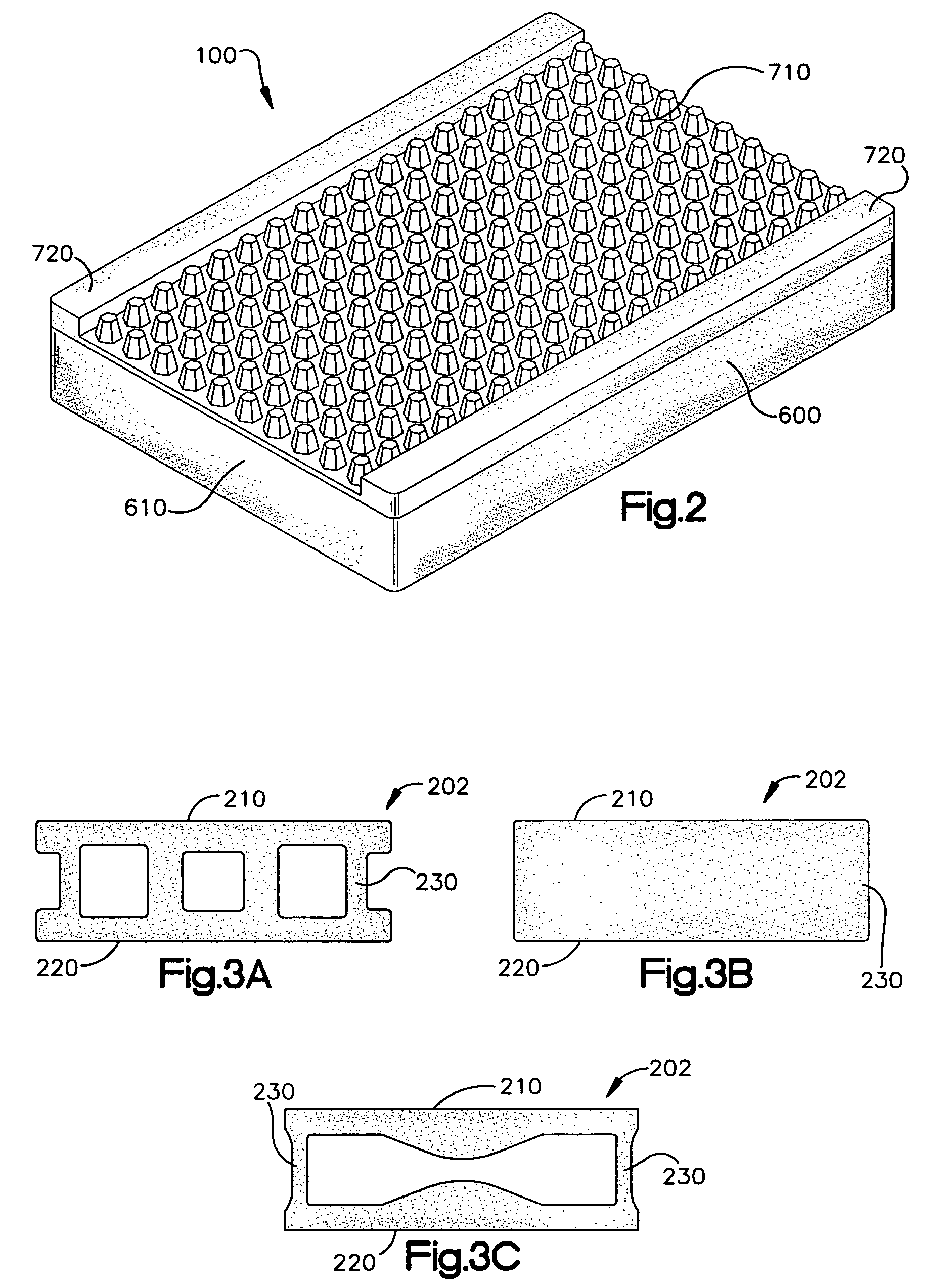

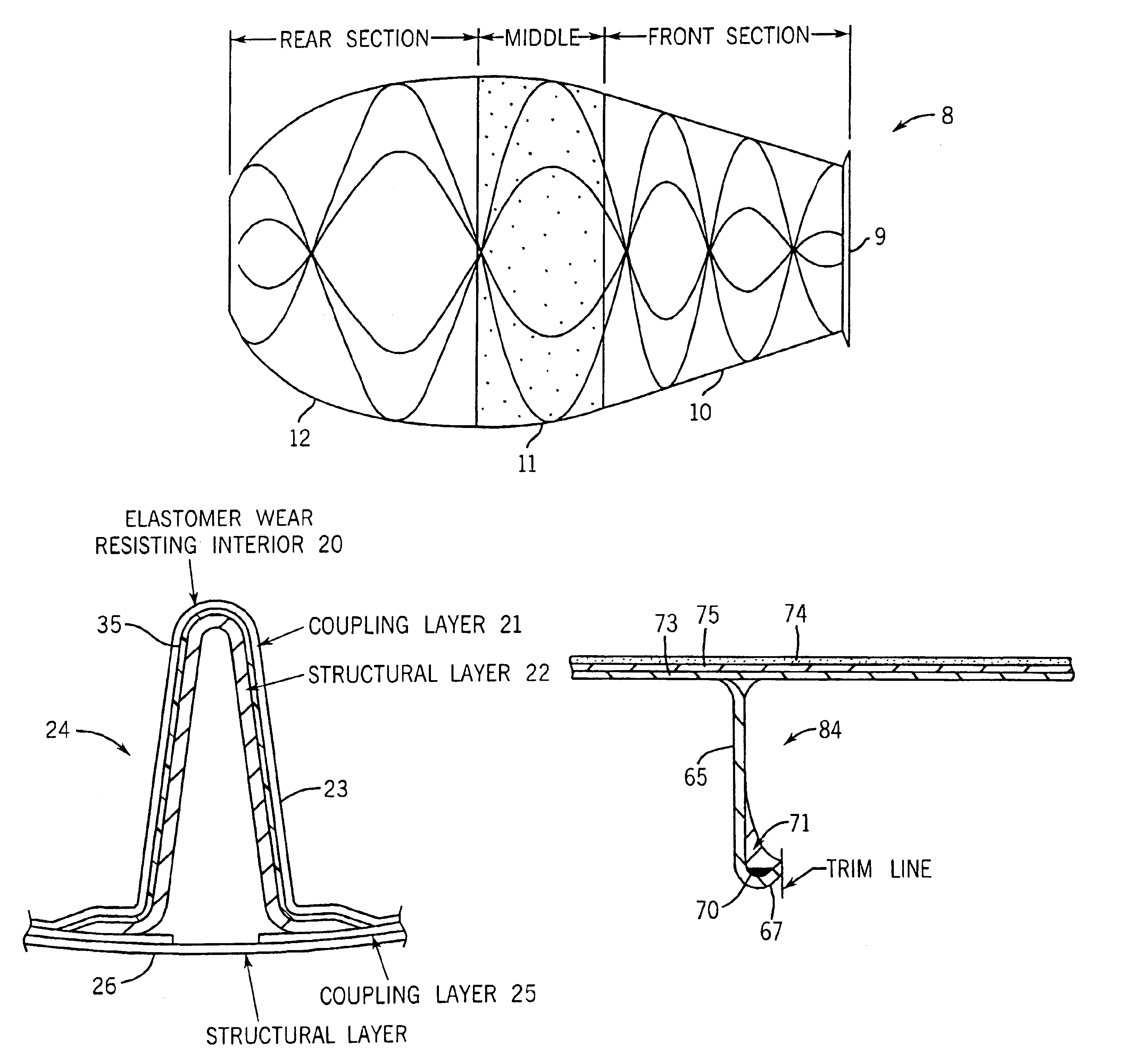

Foam encased innerspring with internal foam components (triple case)

InactiveUS7185379B2Highly variable and tunable support systemIncrease support densityButtonsRecord carriersEngineeringVolumetric Mass Density

A molded foam-encased integrated flexible support device includes an innerspring positioned upon a three-dimensional thermoplastic foam deck as a flexible foundation, and a molded foam encasement which structurally integrates the foam deck with the innerspring by attachment to perimeter coils of the innerspring. A sculpted foam topper is adhesively bonded to a support surface of the foam-encased innerspring, forming a unitized mattress or support structure with fully integrated innerspring and internal and external foam components. The sculpted foam topper is designed with varying contours and densities to provide the desired support and feel characteristics for different comfort profiles. The foam encased innerspring with internal three-dimensional foam structures is upholstered for use as a mattress, seating, or other flexible support structure.

Owner:SEALY TECH LLC

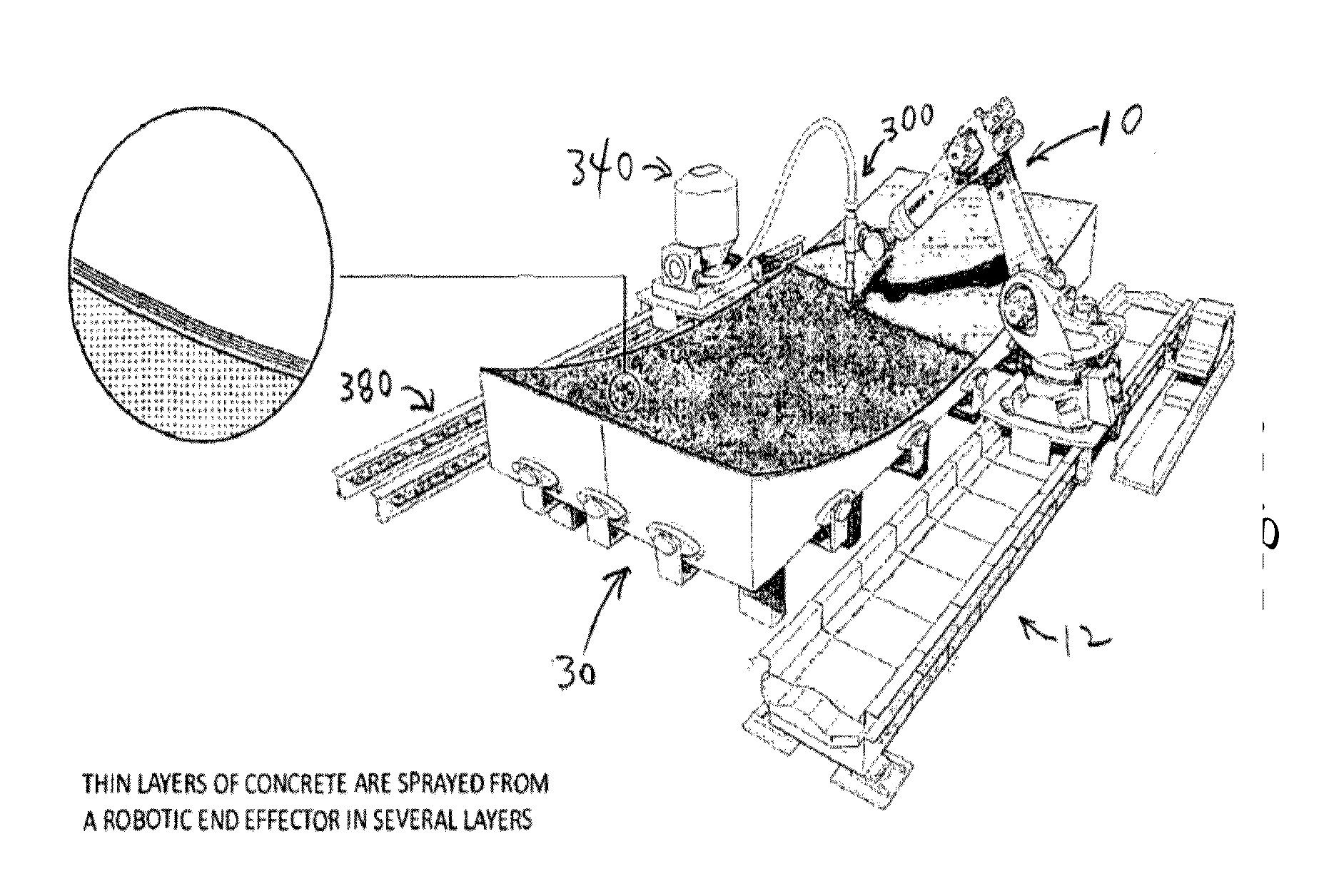

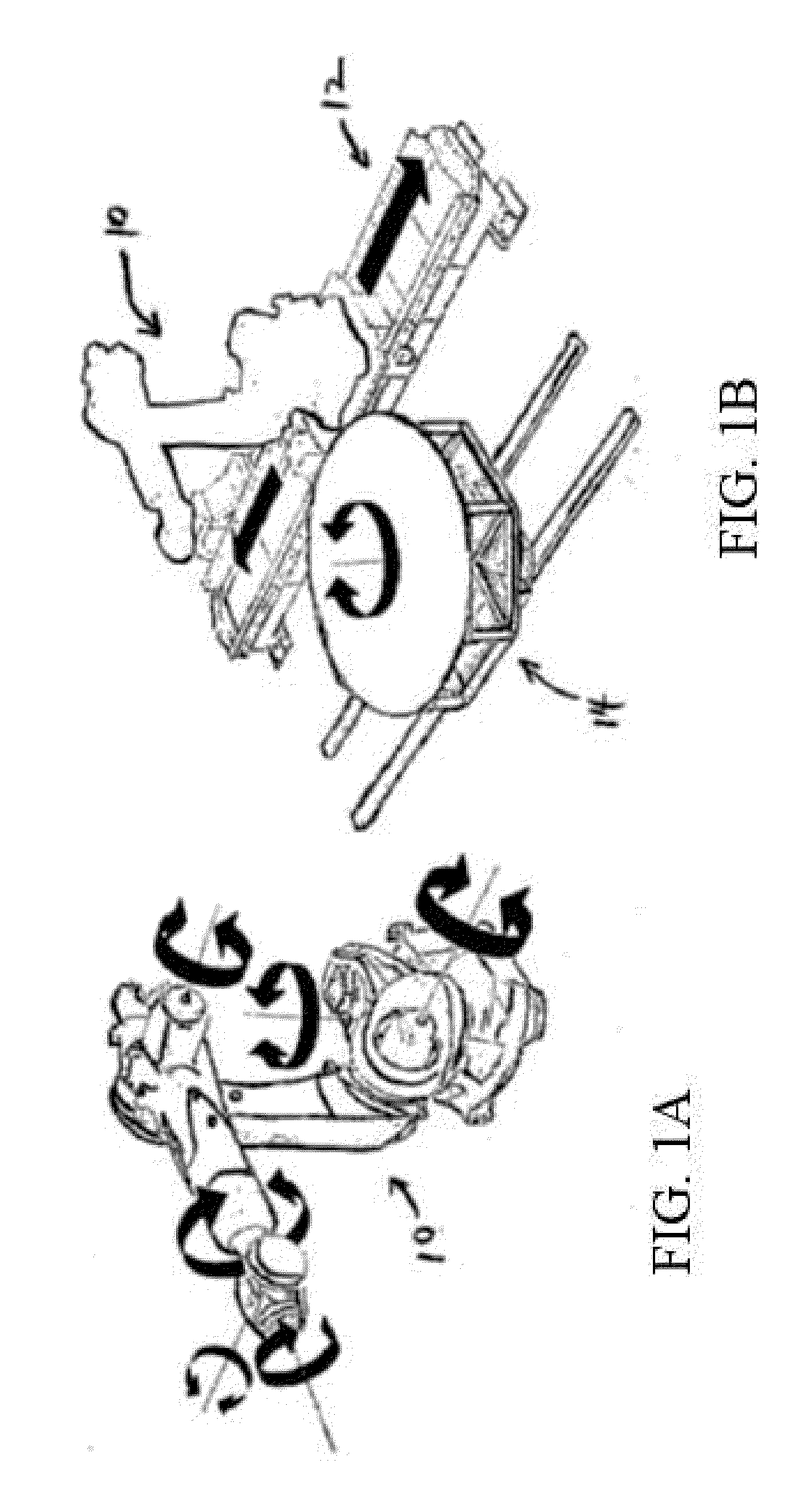

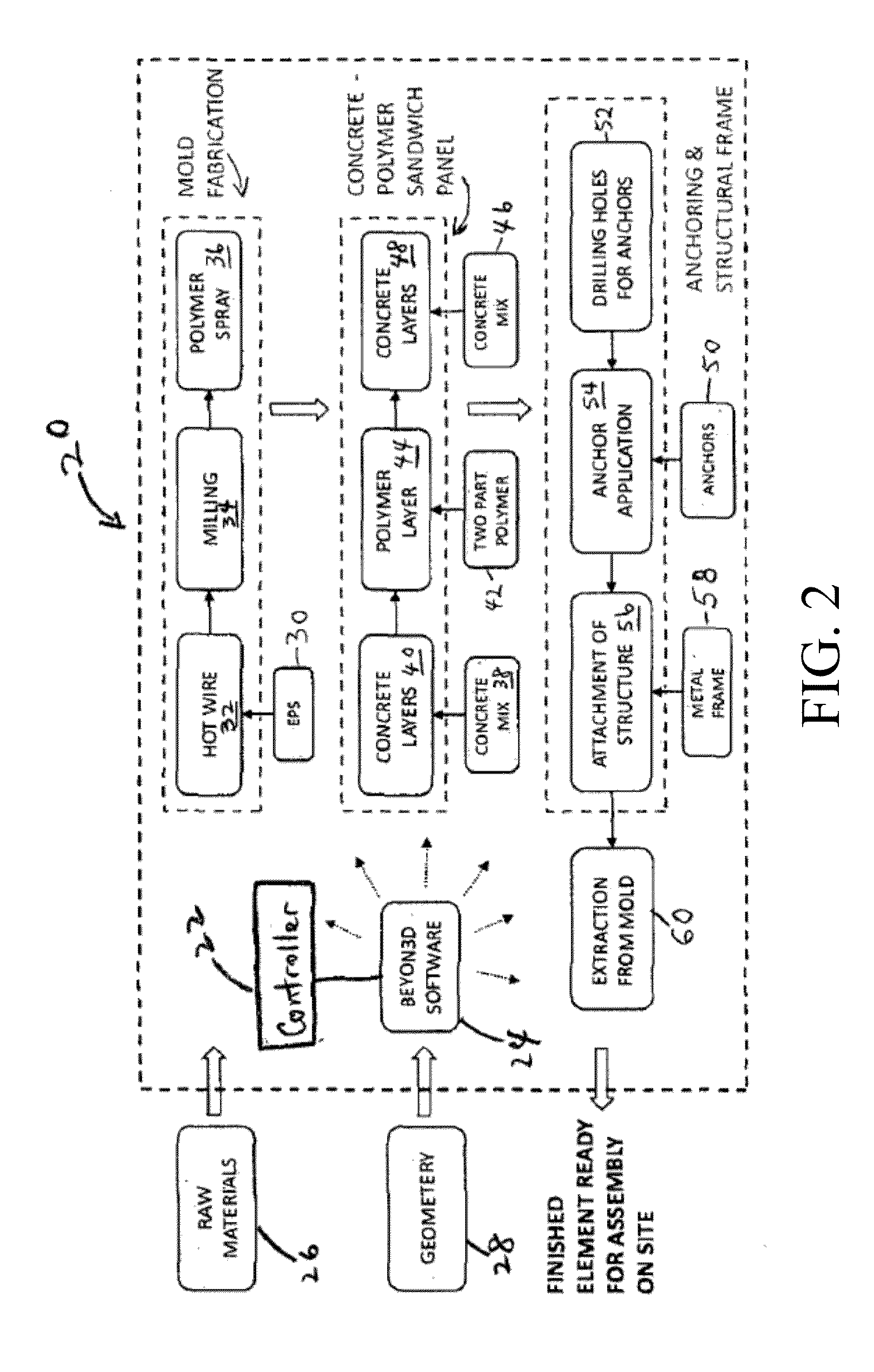

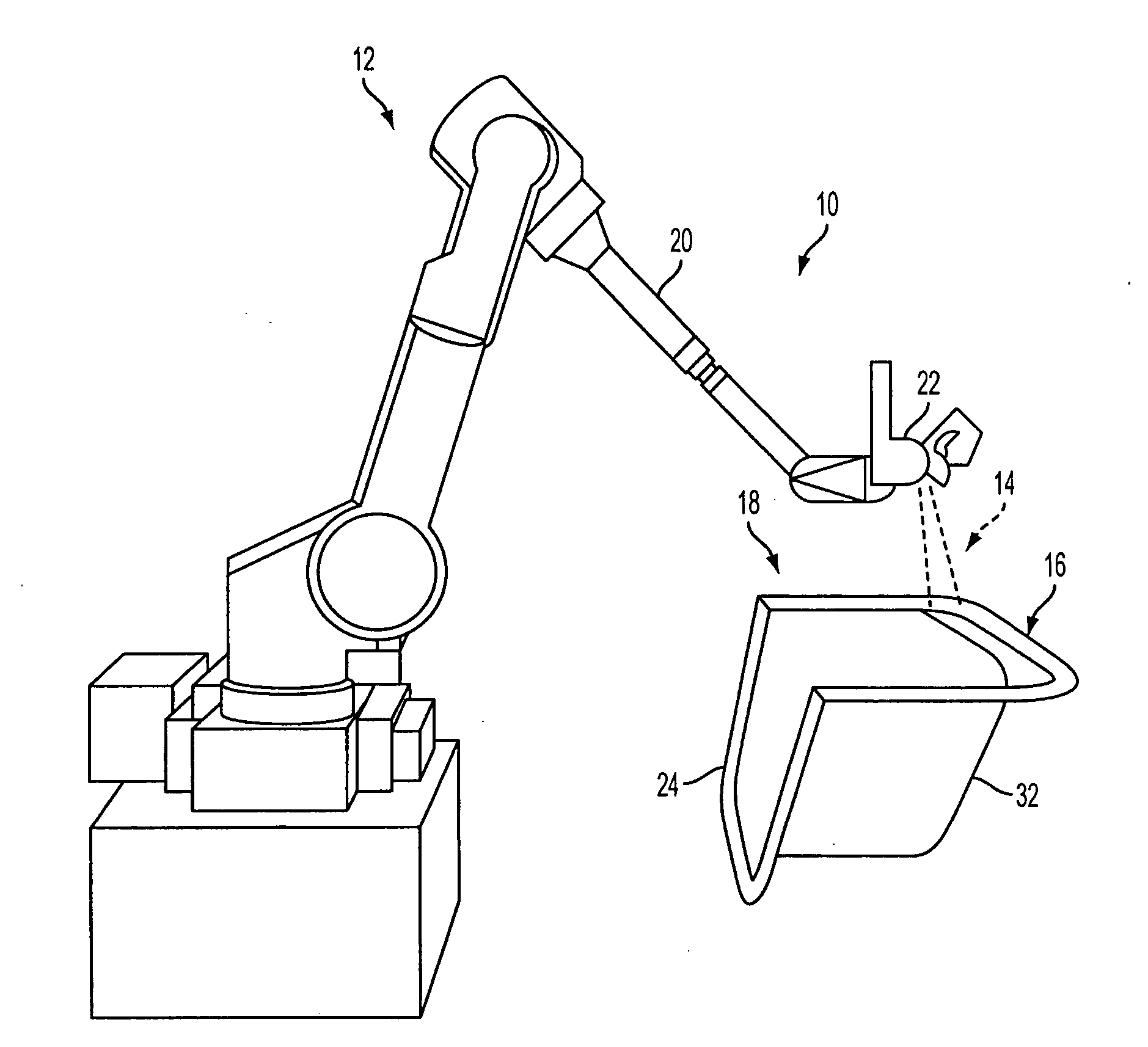

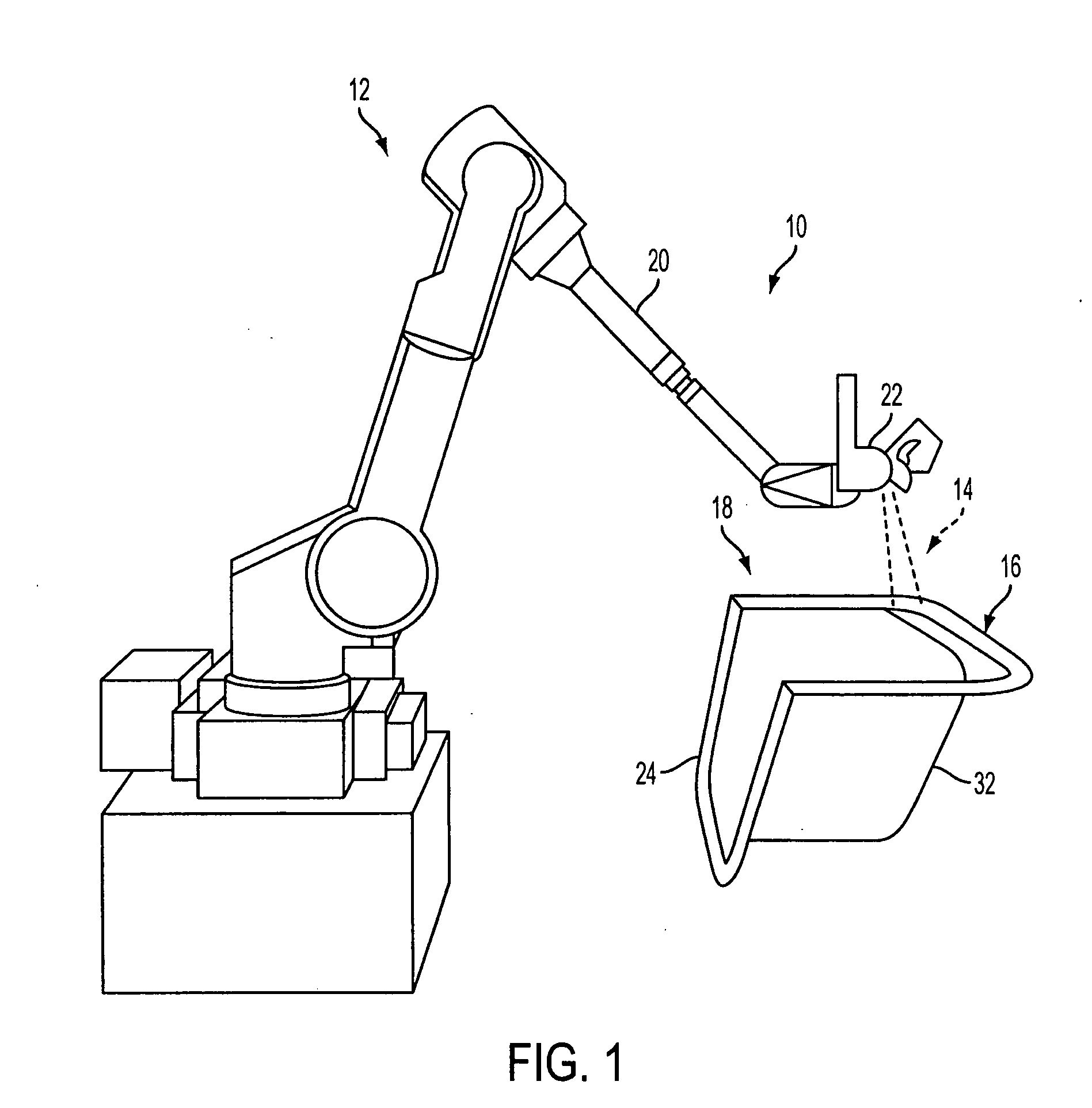

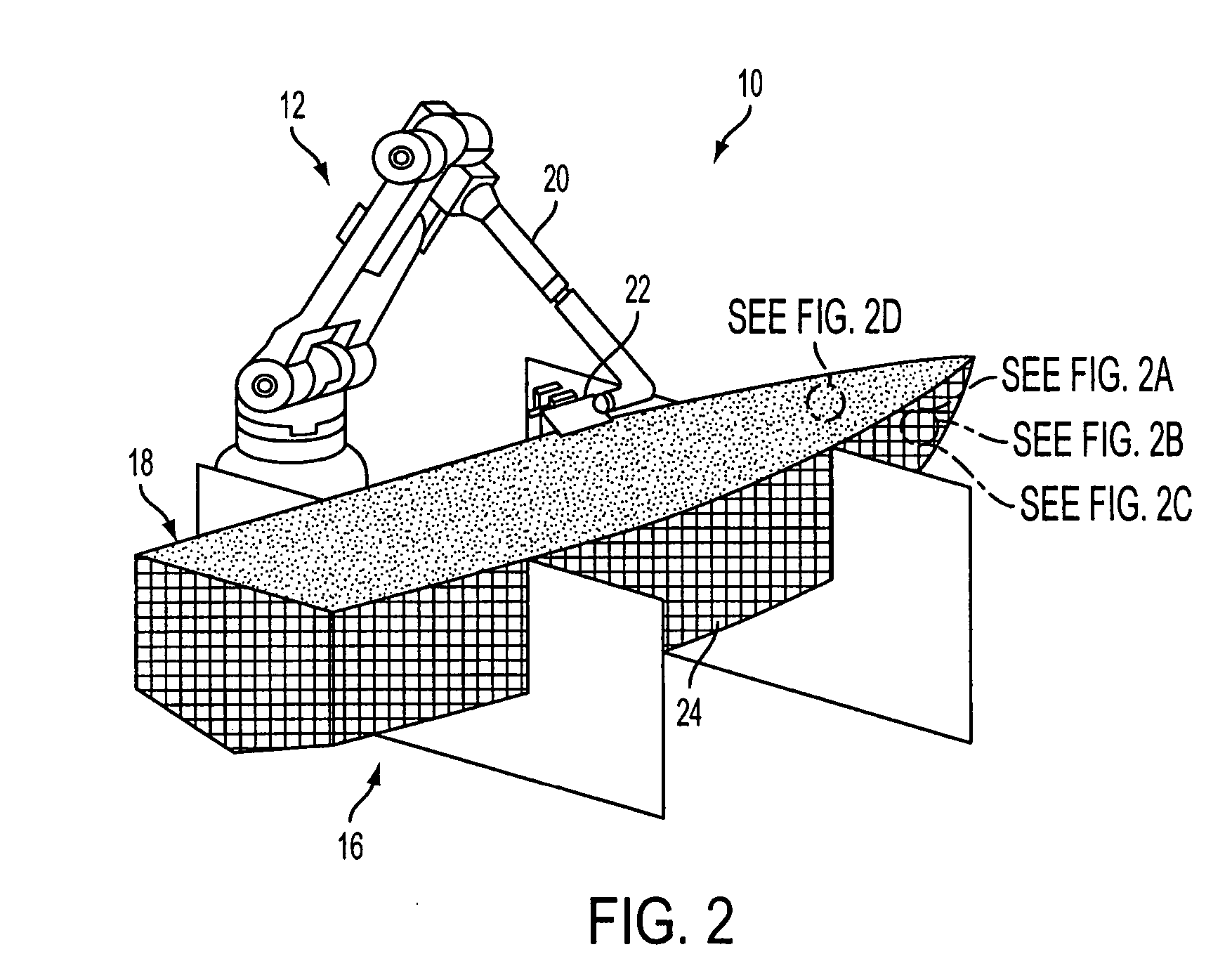

Method and system for fabrication of custom made molds and concrete architectural components

A method and system for constructing an architectural component from a three-dimensional form are disclosed. In a preferred embodiment, the system comprises a movable support table for supporting and moving a three-dimensional form; a multi-task robotic arm having a base end configured for controlled movement along a path proximate the support table and a distal end configured to extend, translate, and / or rotate relative to the base and to include an end effector for applying successive layers of material onto and / or removing material from a form on the support table; optionally, a linear rail to which said base is attached; and a computer processor for controlling a sequence of movements of the support table, the base, and the distal end of said multi-task robotic arm, and for controlling application or removal of material to or from the three-dimensional form to form an architectural component of a predetermined shape and dimension.

Owner:BEYON 3D

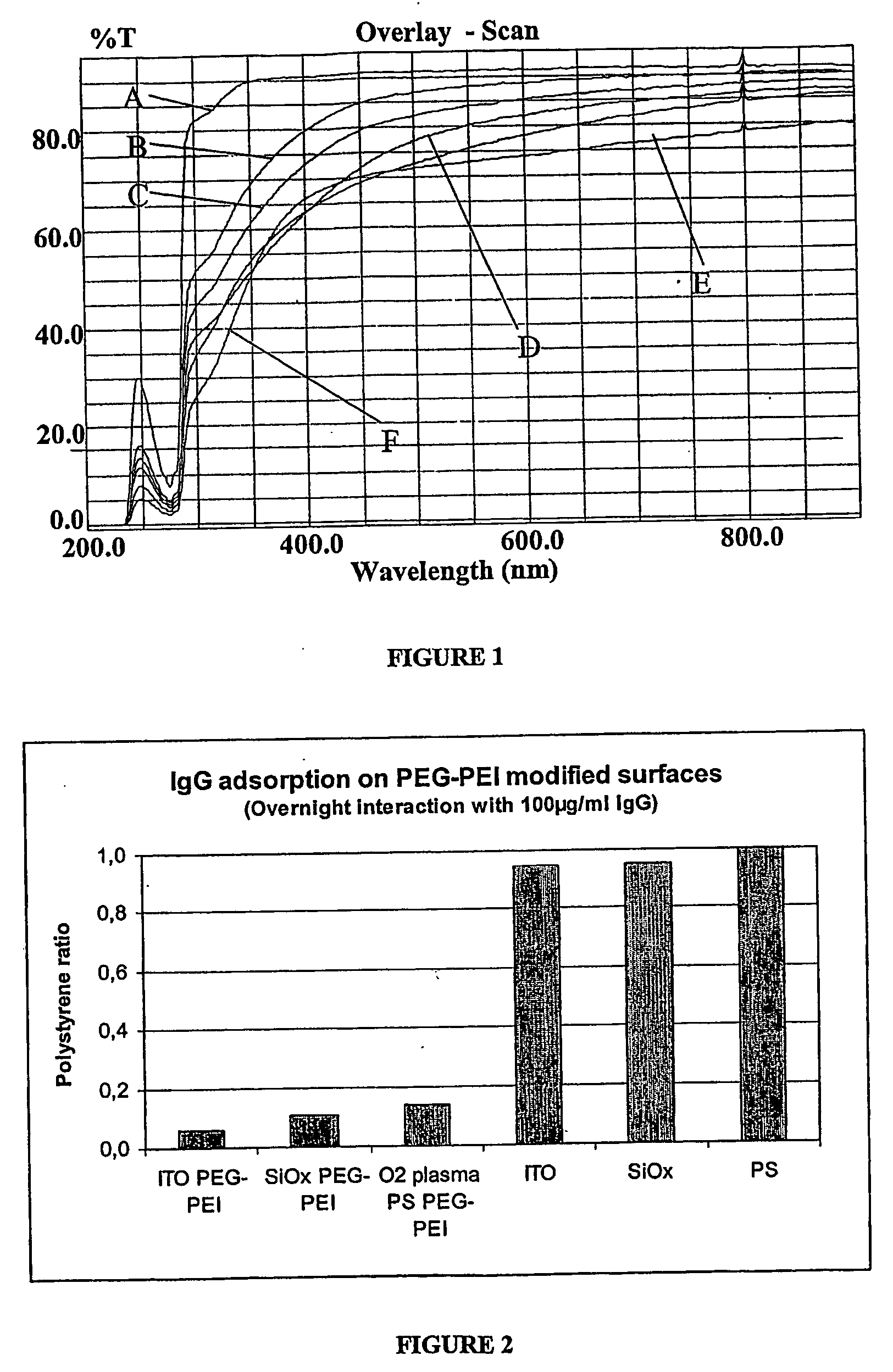

Inner walls of microfluidic devices

A microfluidic device comprising one, two, three or more enclosed microchannel structures, each of which comprises a) an inlet arrangement with an inlet opening for liquid, b)a reaction microcavity (RM1) downstream to the inlet opening, and c) an upstream section that is located between the inlet opening and the reaction microcavity (RM1) and is defined between two planar substrates made of plastic material which substrates are common for said microchannel structures. The characteristic feature is that the inner wall in said upstream section exposes a hydrophilic surface area with an underlying base layer comprising metal oxide. In one aspect the microfluidic device as such is covered.

Owner:GYROS

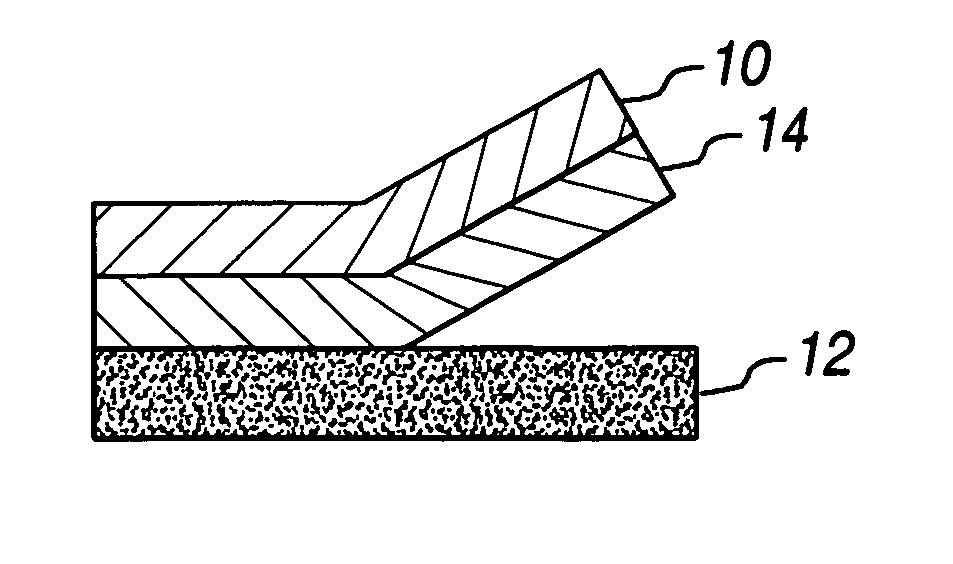

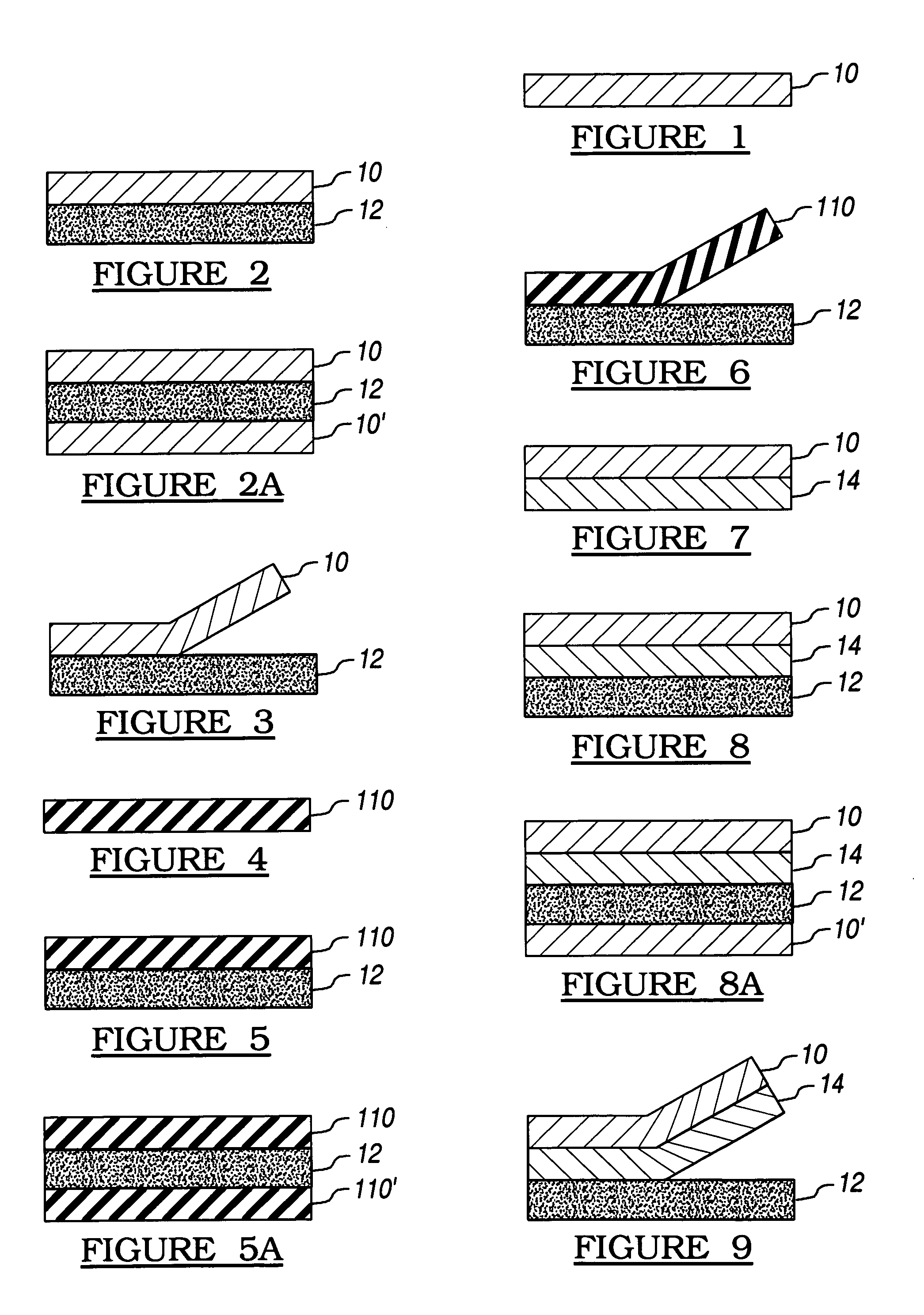

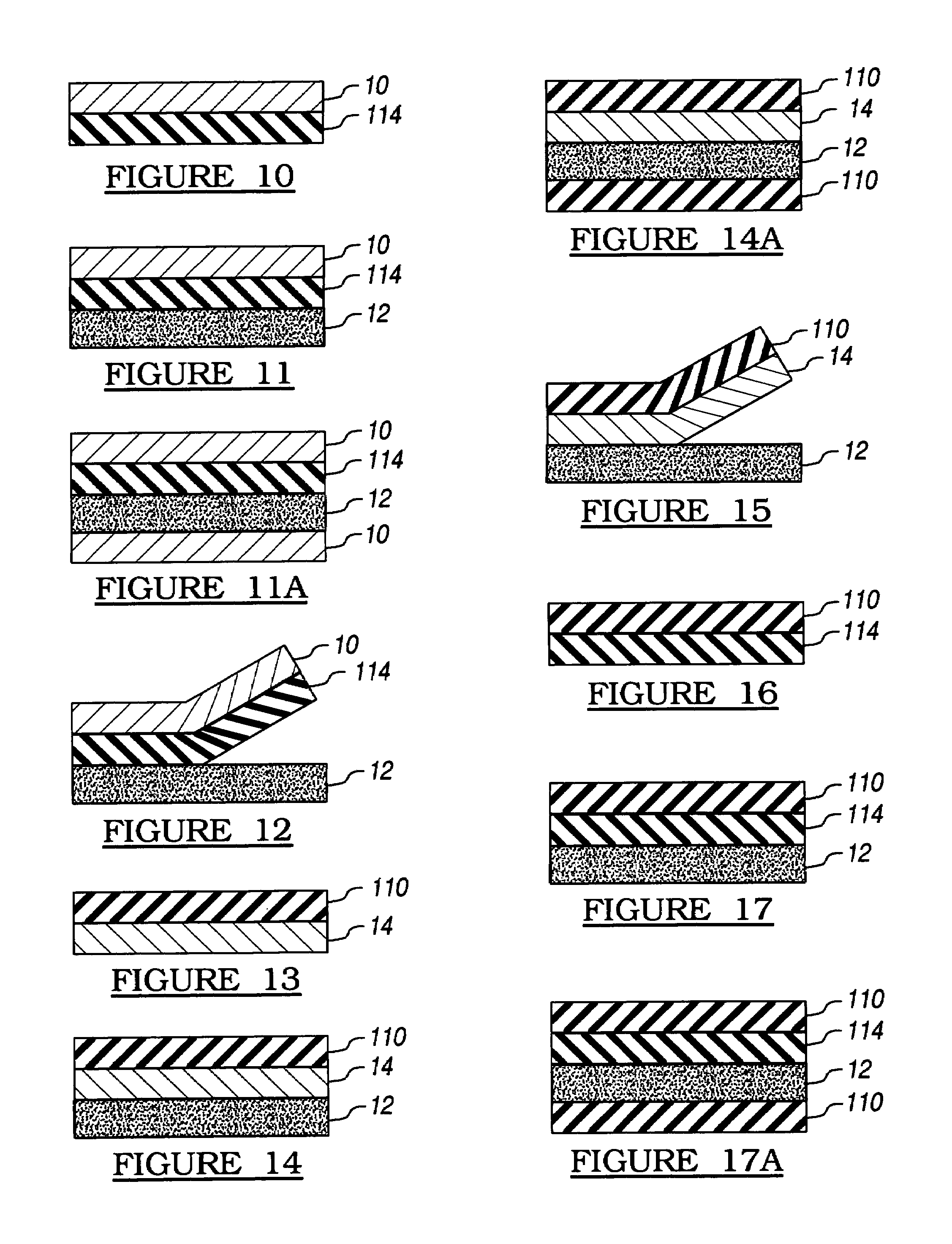

Decorative system composite and method

InactiveUS7144612B2High tensile strengthAvoid feature lossButtonsRecord carriersThermoformingCombined use

Owner:BOBS HLDG

Image processing method and system for microfluidic devices

InactiveUS7583853B2Increase speedHigh sensitivityImage enhancementButtonsImaging processingState dependent

A method for processing an image of a microfluidic device. The method includes receiving a first image of a microfluidic device. The first image corresponds to a first state. Additionally, the method includes receiving a second image of the microfluidic device. The second image corresponds to a second state. Moreover, the method includes transforming the first image and the second image into a third coordinate space. Also, the method includes obtaining a third image based on at least information associated with the transformed first image and the transformed second image, and processing the third image to obtain information associated with the first state and the second state.

Owner:FLUIDIGM CORP

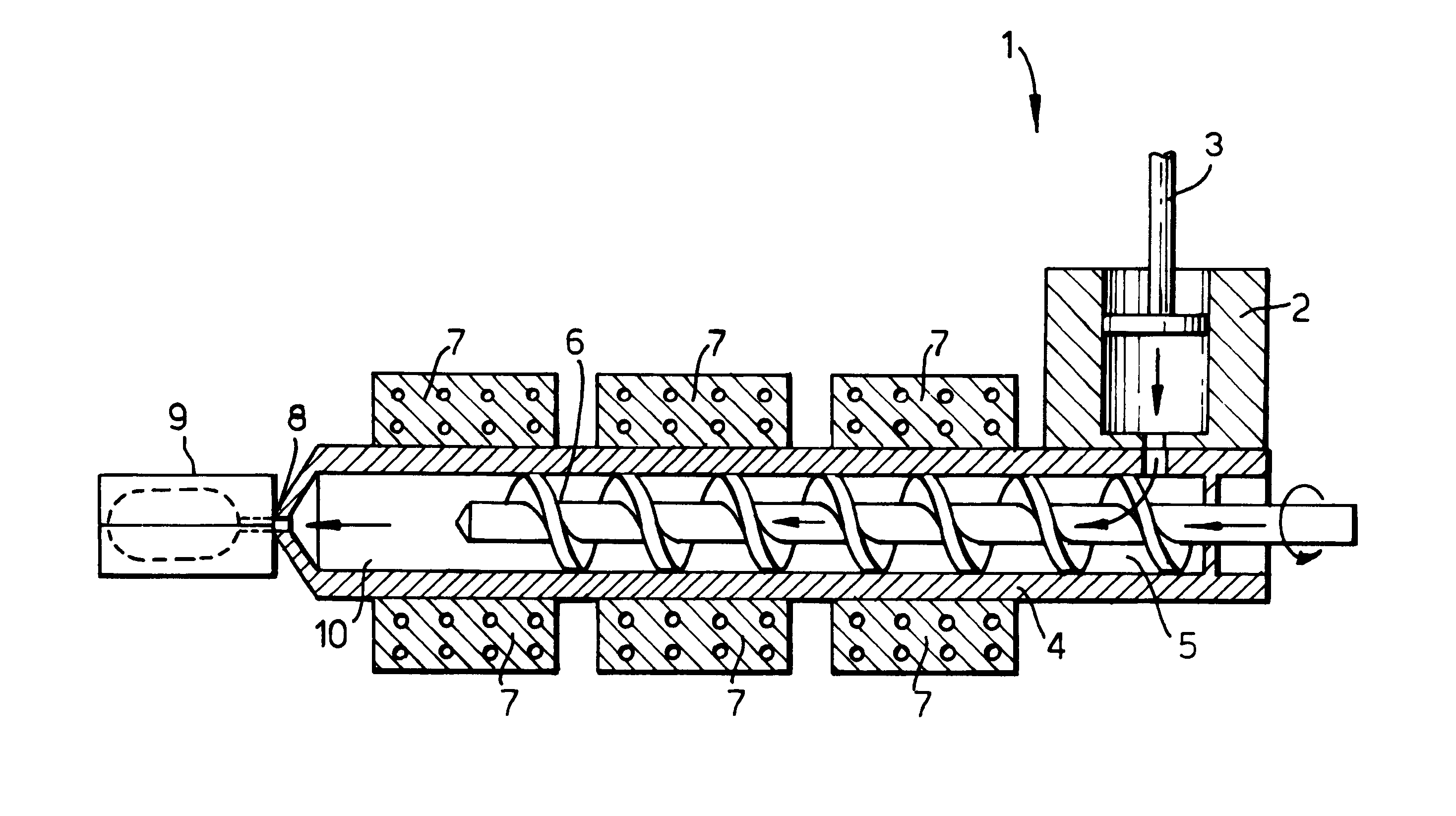

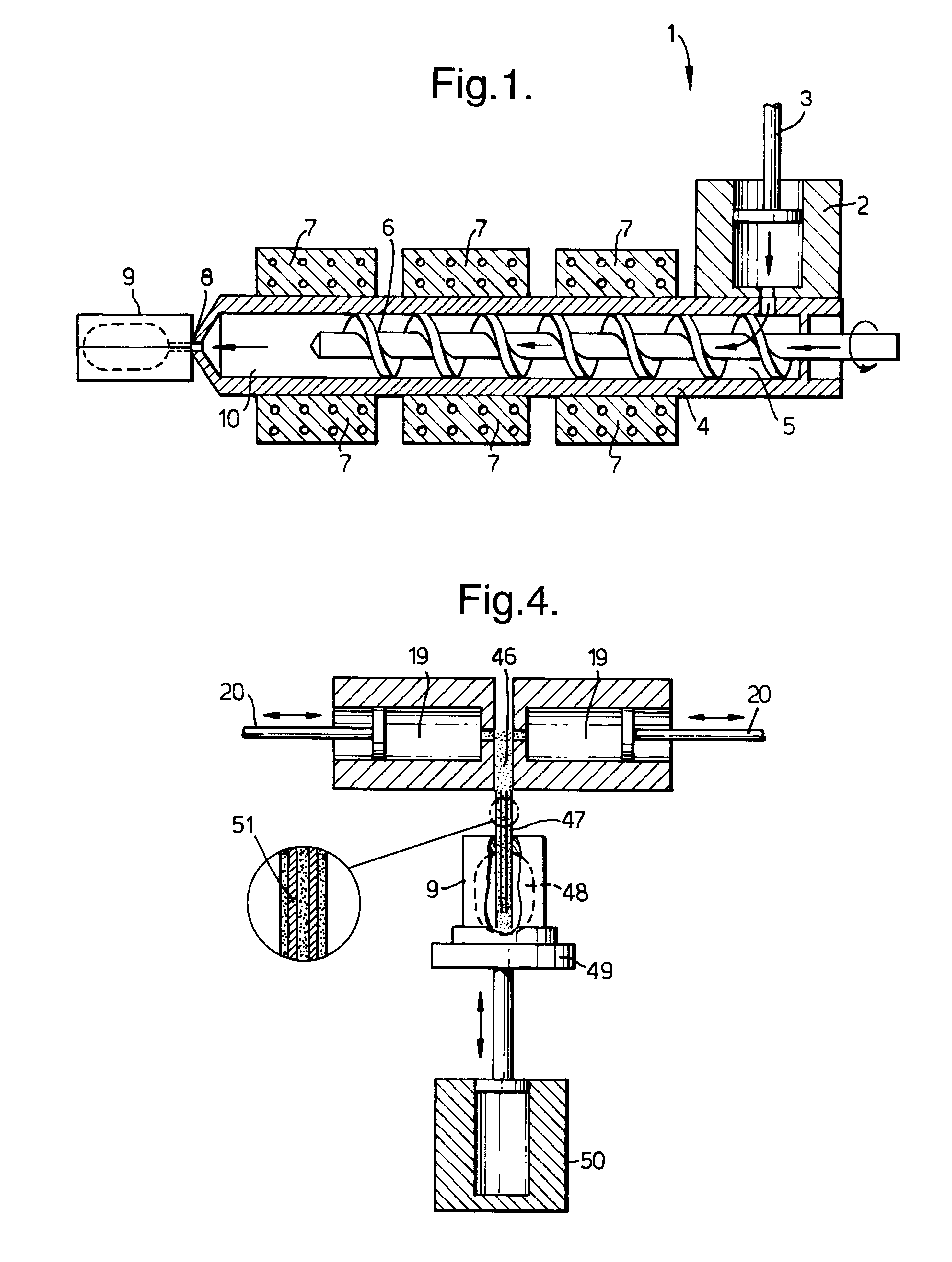

Process for molding of a detergent composition

InactiveUS6224812B1Reduce operating costsLower operating temperatureButtonsRecord carriersShell moldingSemi solid

A process for forming detergent bars by injection moulding in which a pressure is applied to a partially structured detergent composition to deliver it to a mould. The detergent composition can be delivered to the mould in a substantially semi-solid state, at a temperature below 70° C. and at a pressure at the point of injection of greater than 20 psi. Apparatus for forming detergent bars according the invention are also described

Owner:LEVER BROTHERS

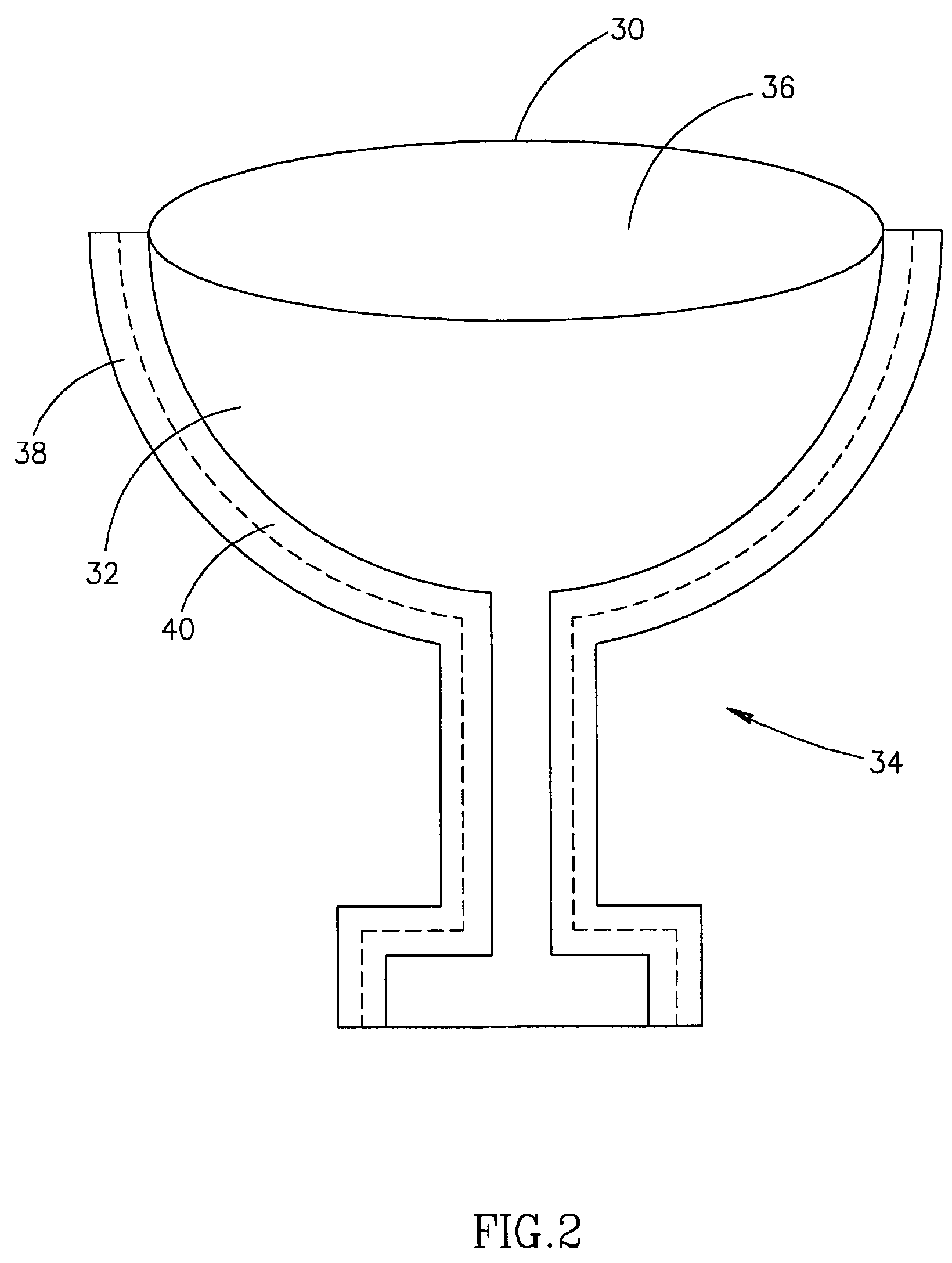

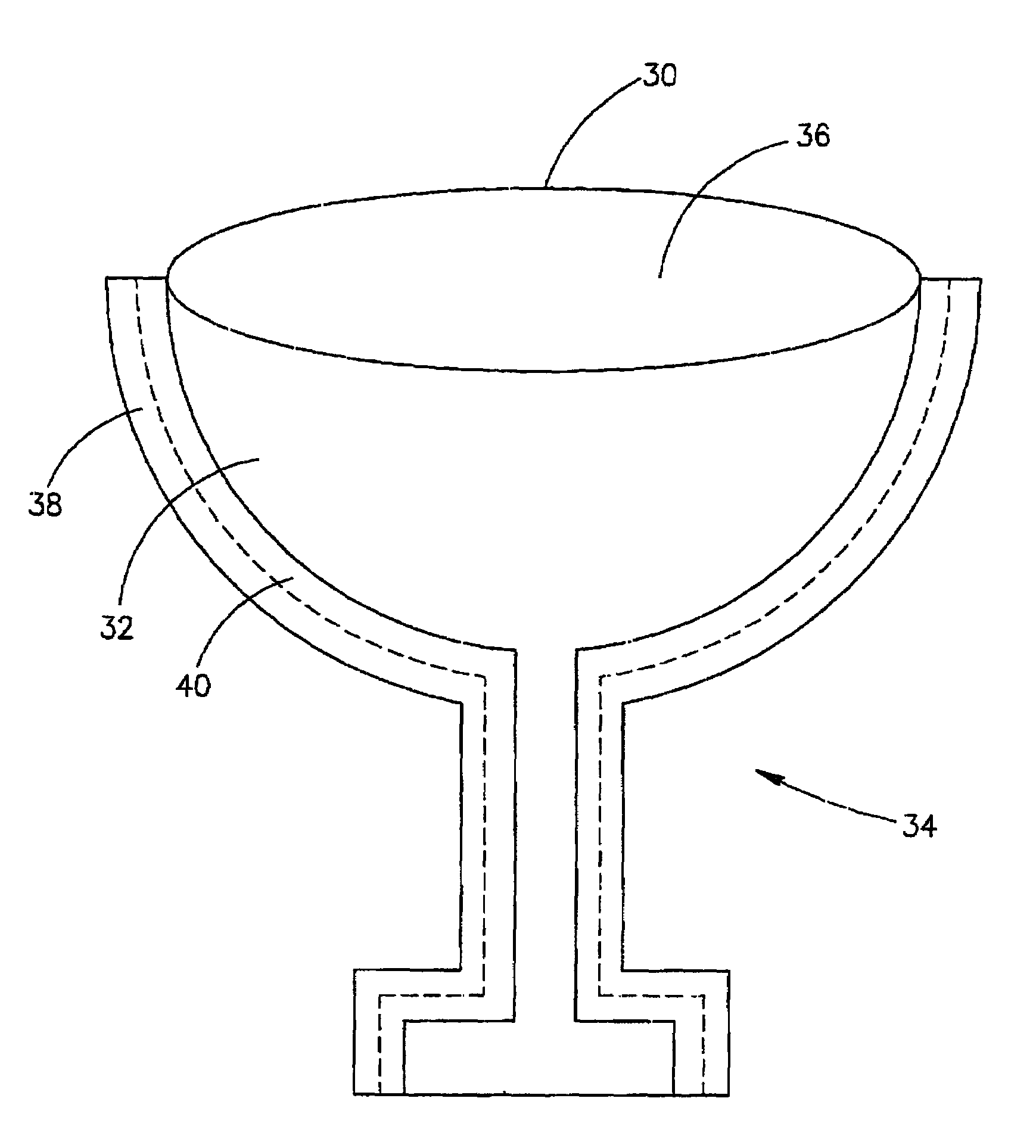

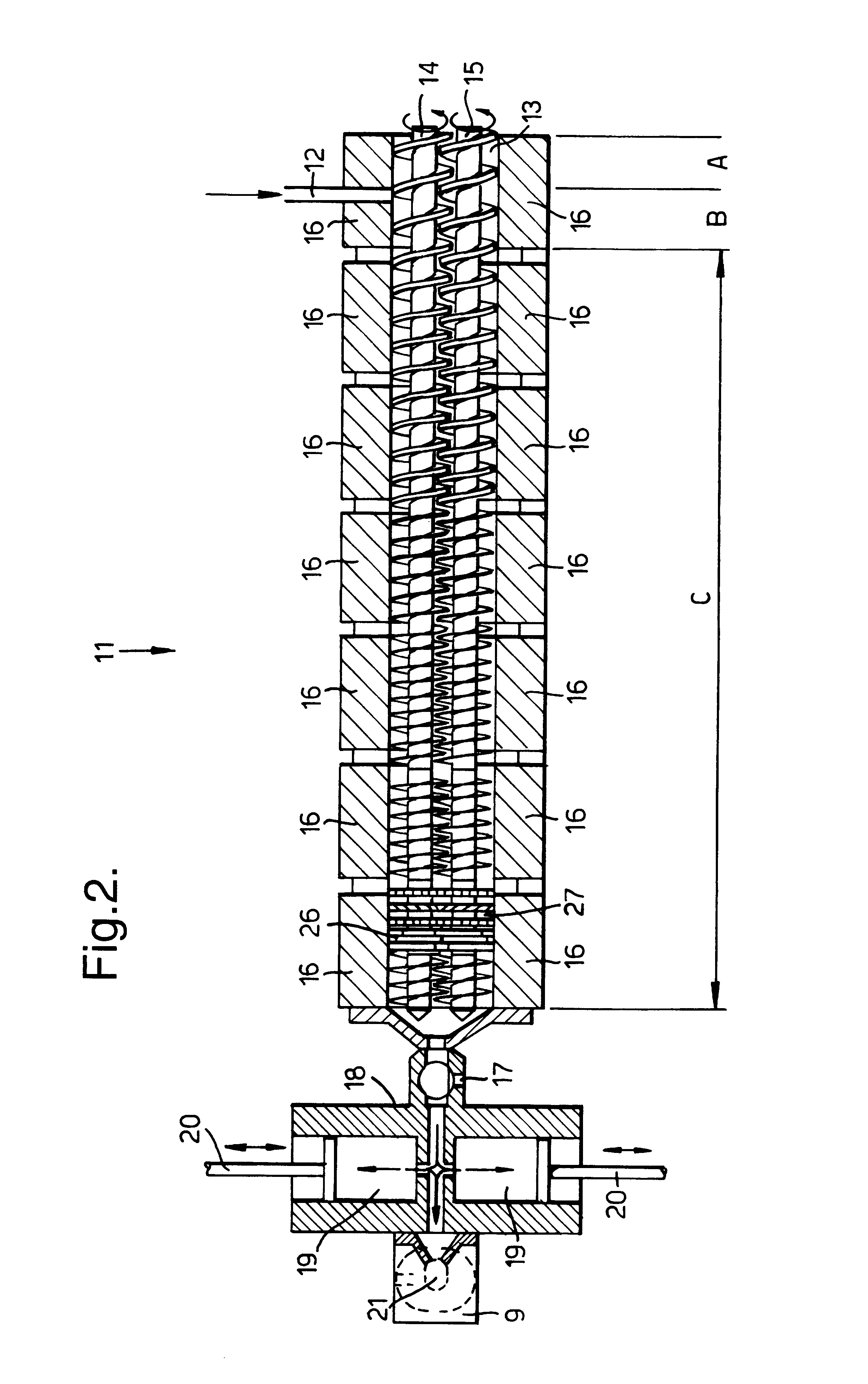

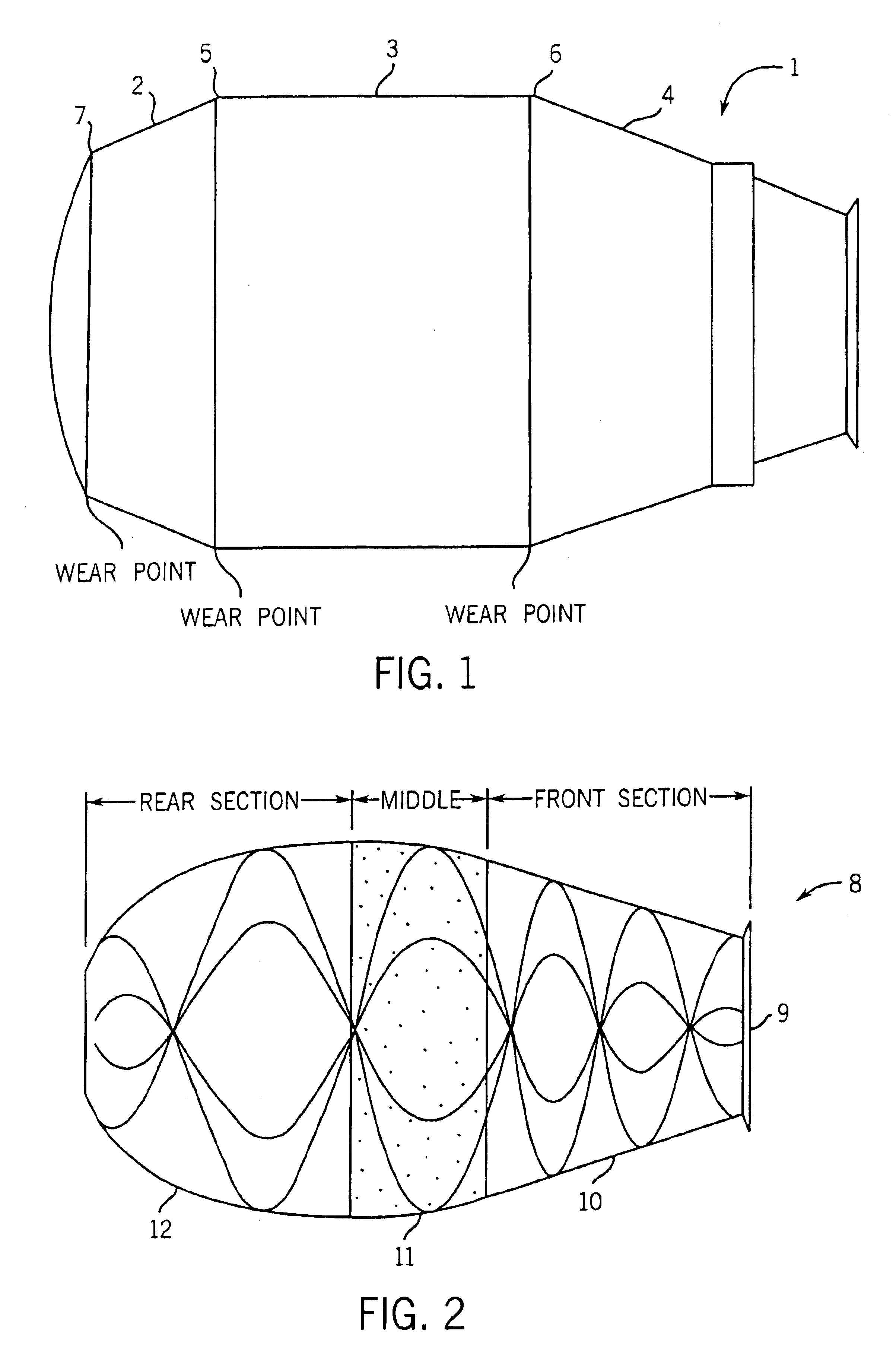

Plastics drum for concrete mixing and methods of manufacture thereof

InactiveUS6902311B1Prolong lifeGood mixing propertiesRotating receptacle mixersButtonsHeavy dutyCivil engineering

A heavy duty rotary concrete mixing drum capable of attachment to a vehicle. The drum comprises a first end which engages a vehicle powered drive assembly which rotates the drum for mixing of said concrete and a second end from which mixed concrete is discharged. The drum is manufactured from at least one layer of plastics material; wherein the drum includes a wall having integral internal formations which promote mixing and discharge of said concrete and an inner surface which promotes mixing of the concrete.

Owner:KHOURI ANTHONY

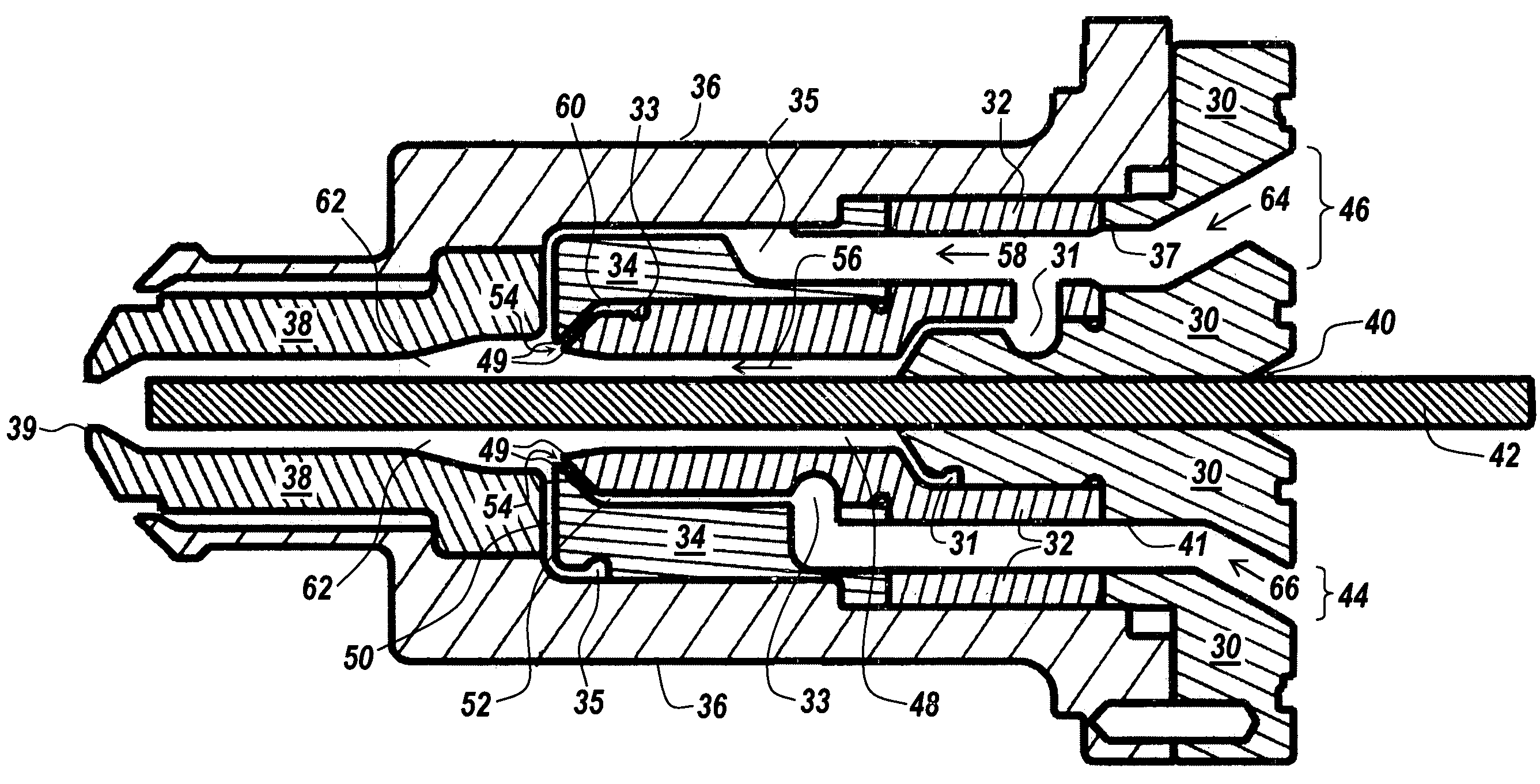

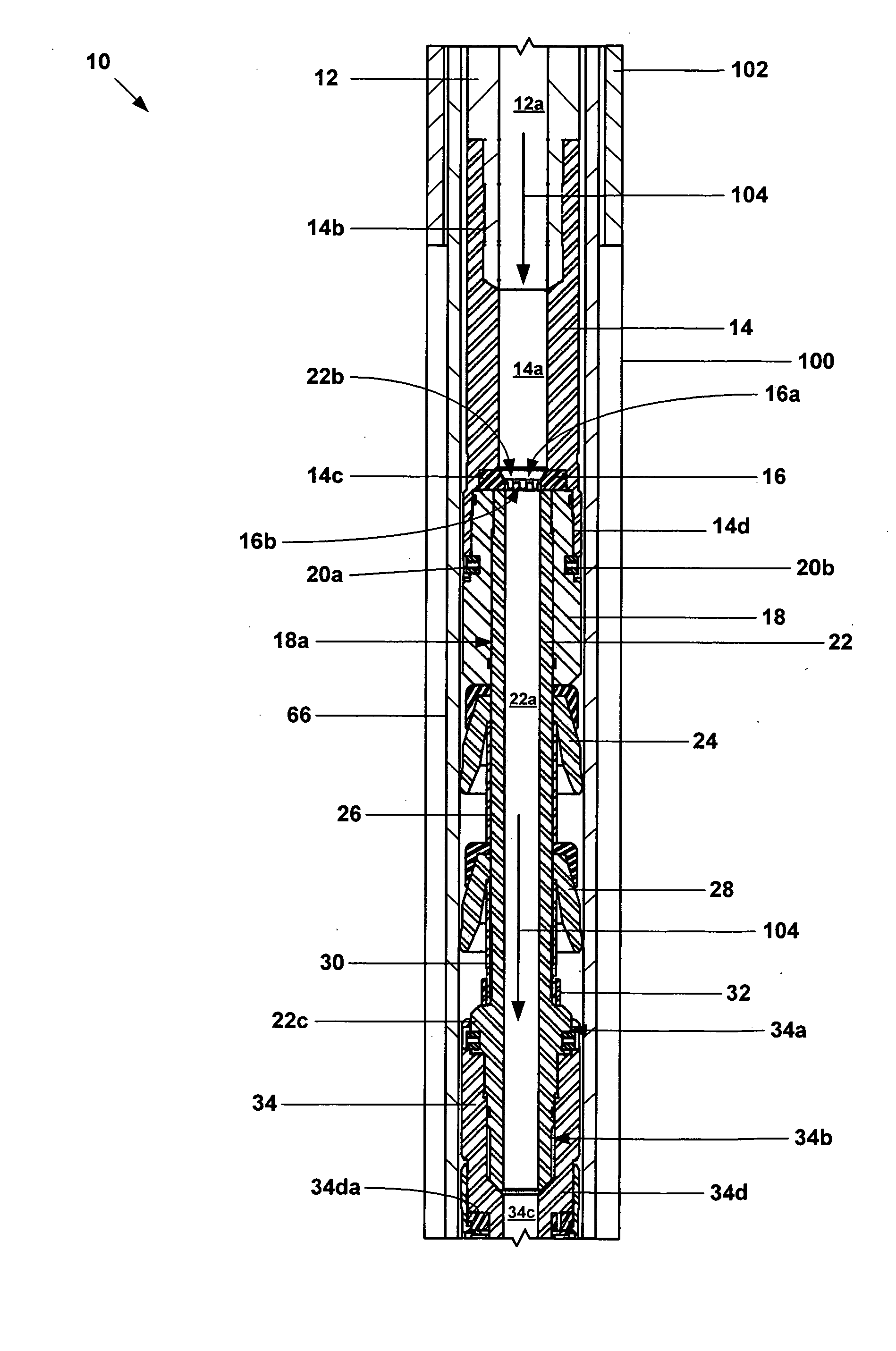

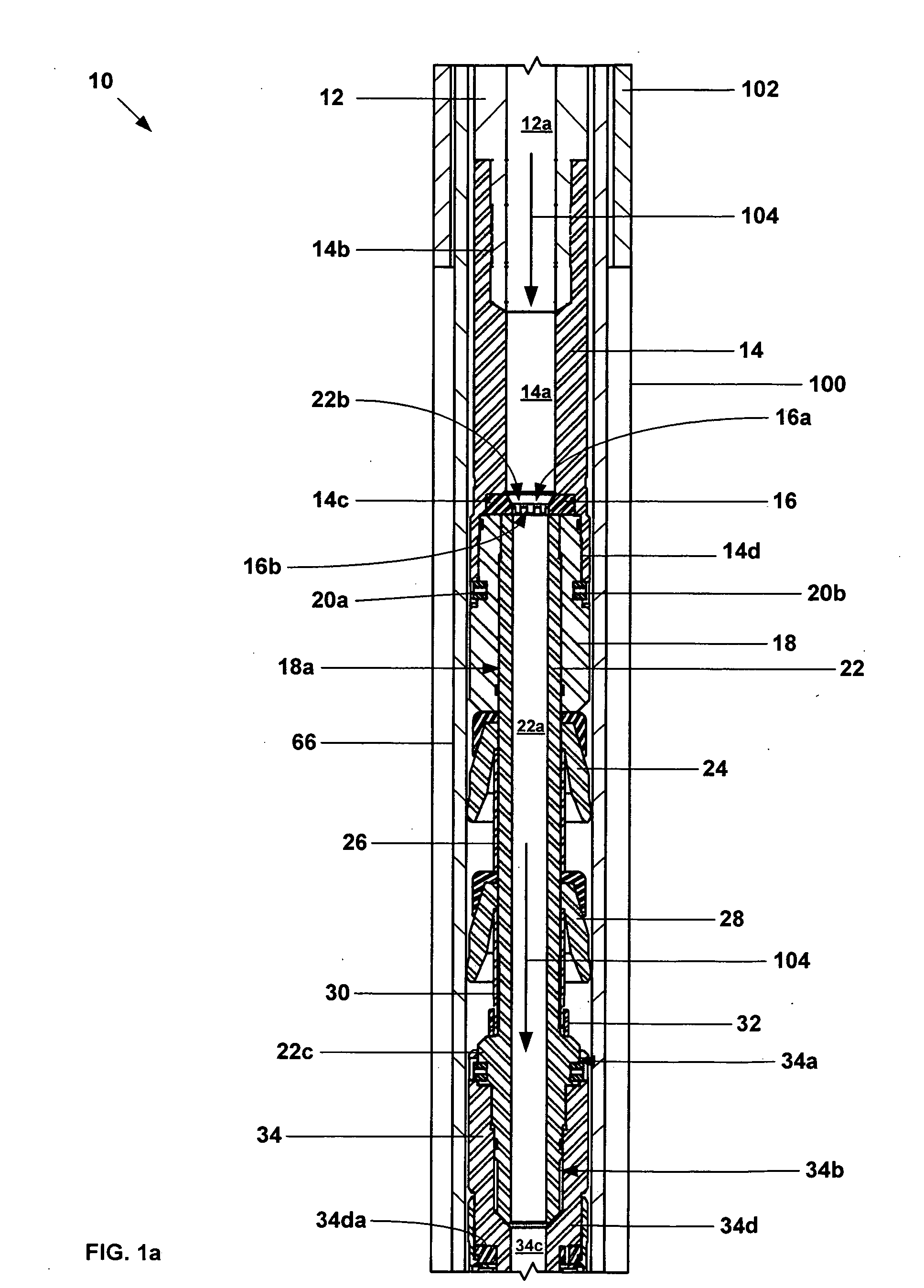

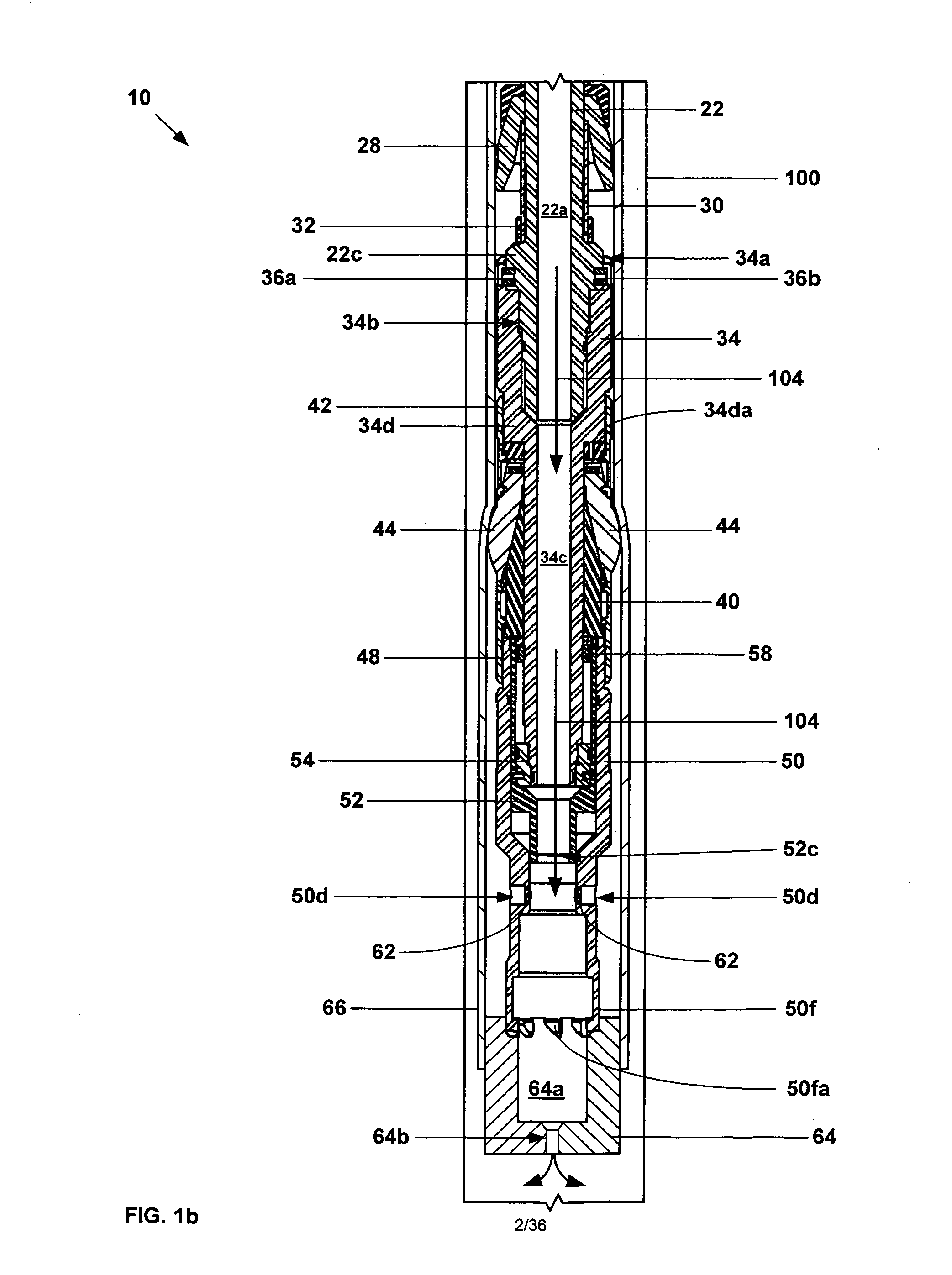

Co-injection nozzle with improved interior layer termination

ActiveUS7306446B2Easy to controlImproved barrier layer protectionButtonsRecord carriersEngineeringCo injection

Disclosed herein are a method and apparatus for combining two or more streams of a polymeric material to form a plastic object. The method and apparatus are capable of ending an interior layer of the plastic object at a desired length to avoid the need to clean selected surfaces of components used to form the plastic object. The method and apparatus increase the velocity of the polymeric material used to form the plastic object in certain components used to form the plastic object. The increase in the velocity of the polymeric material facilitates the ending of the interior layer of the plastic object.

Owner:CINCINNATI MILACRON INC

Apparatus and method for making preforms in mold

Apparatus and a method of preparing fiber preforms disperses fibers and binder on a forming support surface such that the materials are conditioned and then applied to the surface where the composite material solidifies. Reinforcing material, such as fiber, is mixed with binder, such as thermoplastic or thermoset materials, so that the materials adhere. Then, the adhesive mixture is dispersed in a controlled pre-determined weight ratio on the support surface where the mixture sticks to the support surface, cools and solidifies. The deposited mixture can be an open mat having interstices between fibers. The deposited mixture can also be shaped further into a final desired shape before complete solidification. This method eliminates the need for solvents and their associated problems. The process does not require a vacuum or plenum system to hold the reinforcing material in place. The preform can be made in any shape, including sections or asymmetric configurations and remain in mold while being processed to a composite molded article.

Owner:BRUNSWICK CORPORATION

Propane diol-based polyester resin and shrink film

ActiveUS7008698B2Improve shrinkageReadily adjustable shrink propertyWrappers shrinkageButtonsWater bathsPolymer thin films

A shrinkable polymer film including a modified polyester resin polymerized from monomers including a dicarboxylic acid and a glycol, wherein the glycol includes 2-methyl-1,3-propanediol, and wherein the polymer film shrinks at least about 50% in a main shrinkage direction after ten seconds in an 80 degree Celsius hot water bath.

Owner:MITSUBISHI POLYESTER FILM

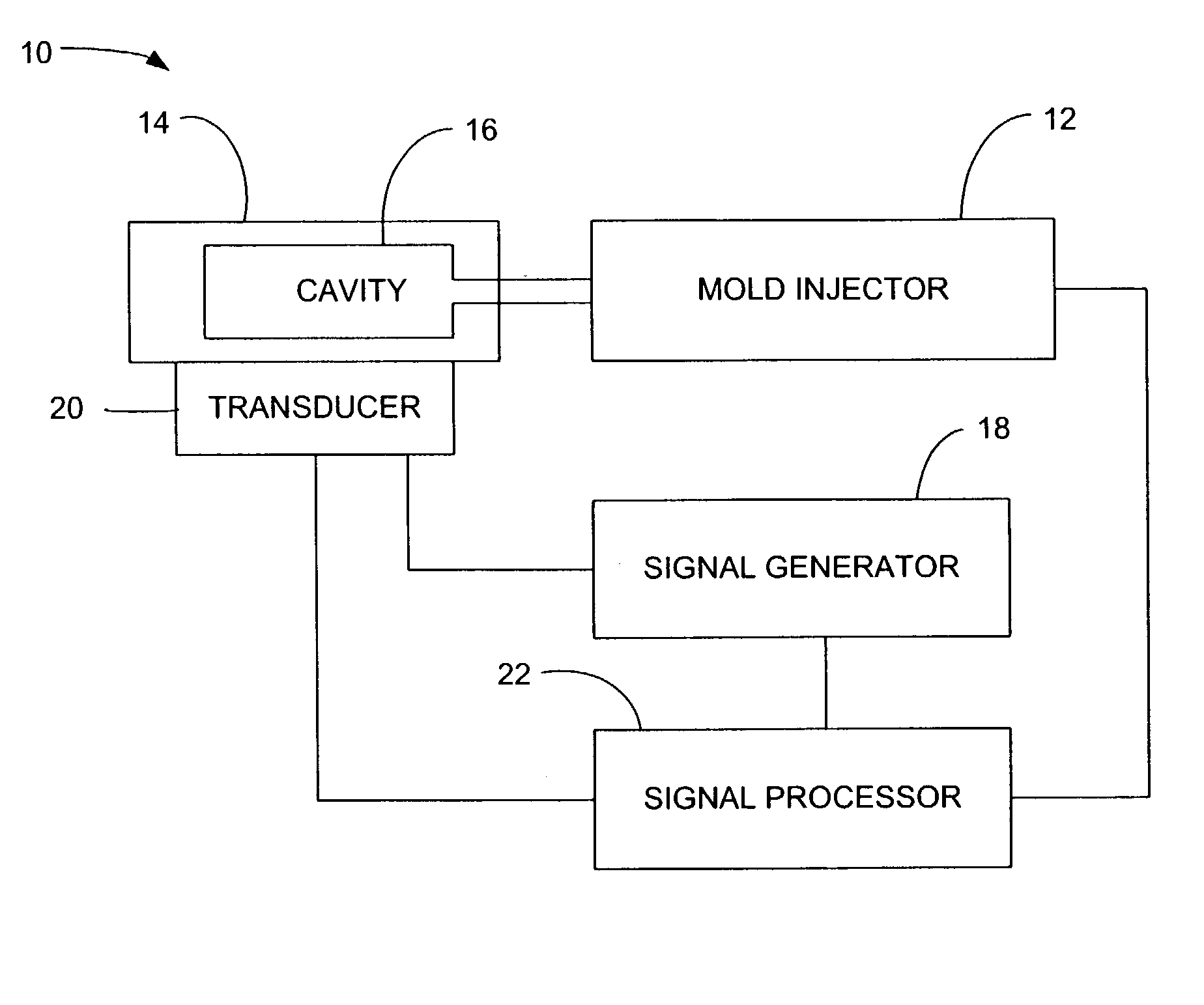

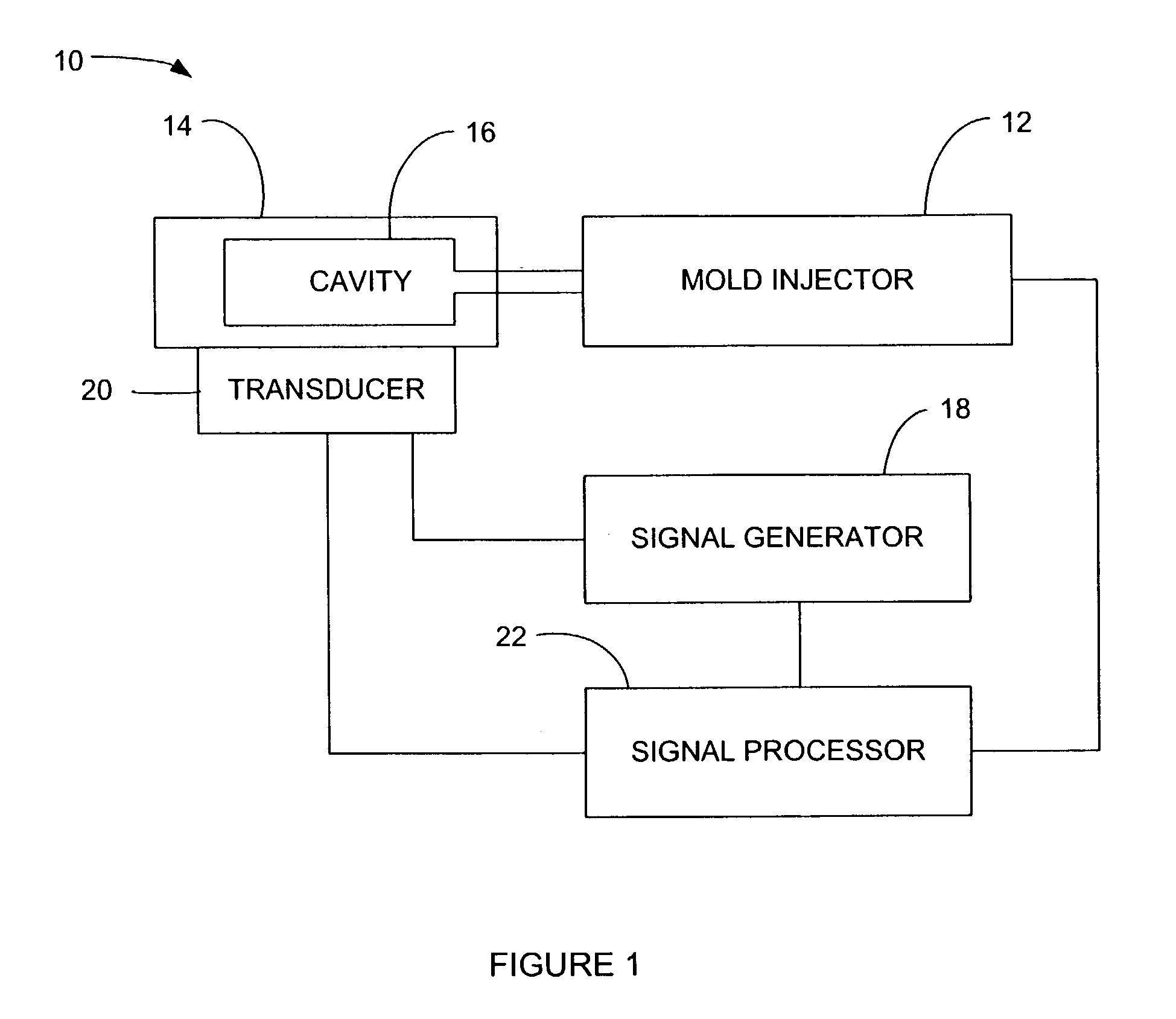

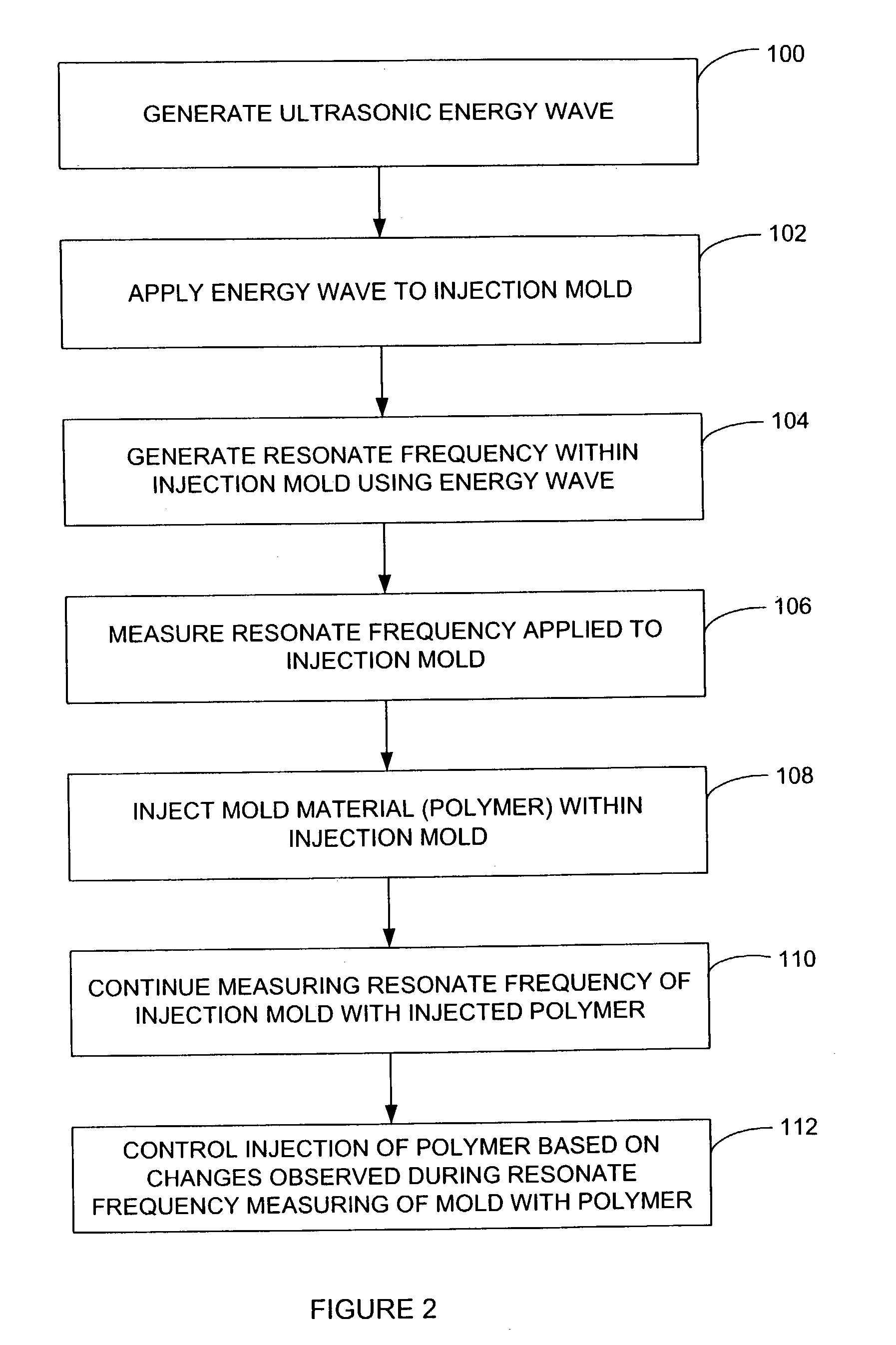

Continuous wave ultrasonic process monitor for polymer processing

An injection molding apparatus is disclosed that includes an injection mold, a mold injector, and means for monitoring the injection mold process using acoustic energy. The injection mold includes a cavity for receiving an injection mold material, such as a polymer as injected via the mold injector. The monitoring system includes an acoustic energy generator, an ultrasonic crystal, and an energy monitoring device. The acoustic energy generator produces continuous acoustic energy to be non-invasively applied to the injection mold as the polymer is delivered into the mold. The energy monitoring device monitors changes in dynamic parameters of a resulting continuous resonant frequency established by the acoustic energy generator through the ultrasonic crystal. The ultrasonic crystal serves also as a transducer to receive an output signal from the mold to be delivered to the energy monitoring device. It is this output signal that is processed to determine dynamic parameters that change based on the change of the continuous resonant frequency. This change of dynamic parameters can identify at least one characteristic of the polymer such that refined control of the injection process may be achieved by monitoring such characteristics through the continuous wave resonant frequency monitoring approach applied by the monitoring system.

Owner:UNIV OF UTAH RES FOUND

Treated rubber and products made therefrom

InactiveUS6896964B2High tensile strengthHigh elongationButtonsRecord carriersPolymer scienceUltimate tensile strength

Treated rubber is made from ground rubber and a polyurethane resin. Products made by mixing treated rubber with additional polyurethane resin, molding and curing the polyurethane have higher tensile strengths and / or elongations than similar products made from untreated rubber. The method using treated rubber uses less polyurethane binder to produce products of equivalent strengths. The molding time is also reduced because of the reduced amount of polyurethane binder used.

Owner:RYVEC

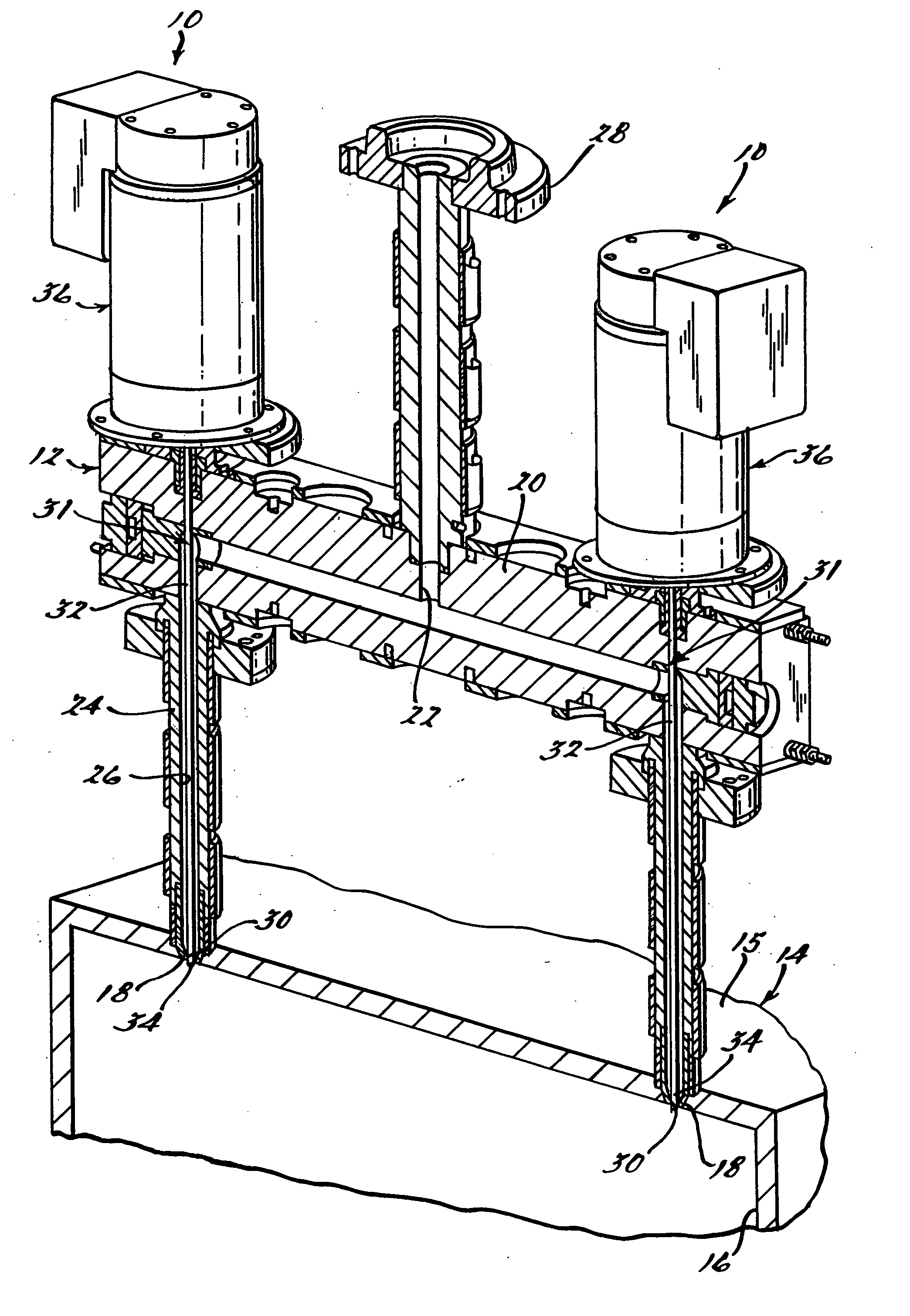

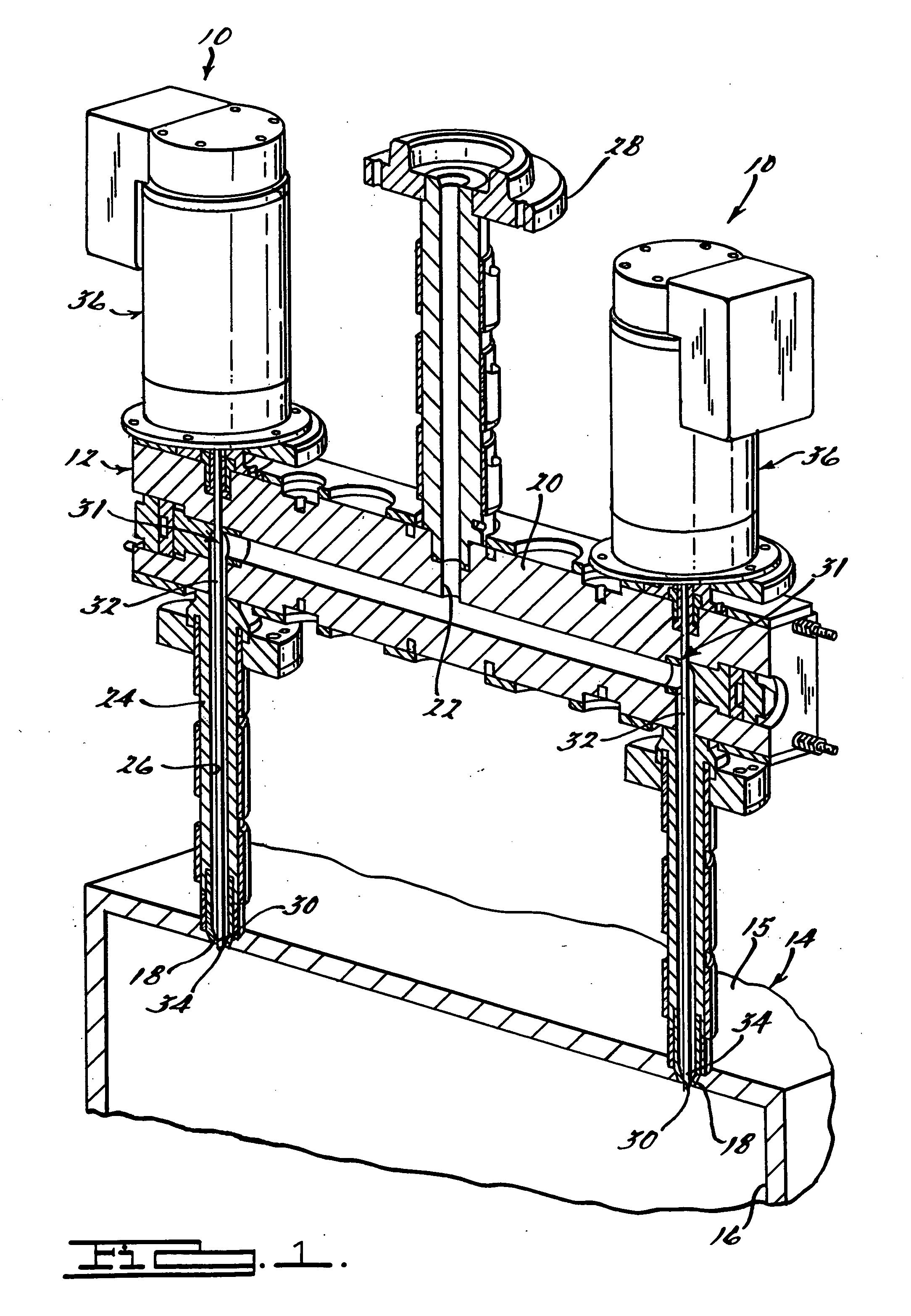

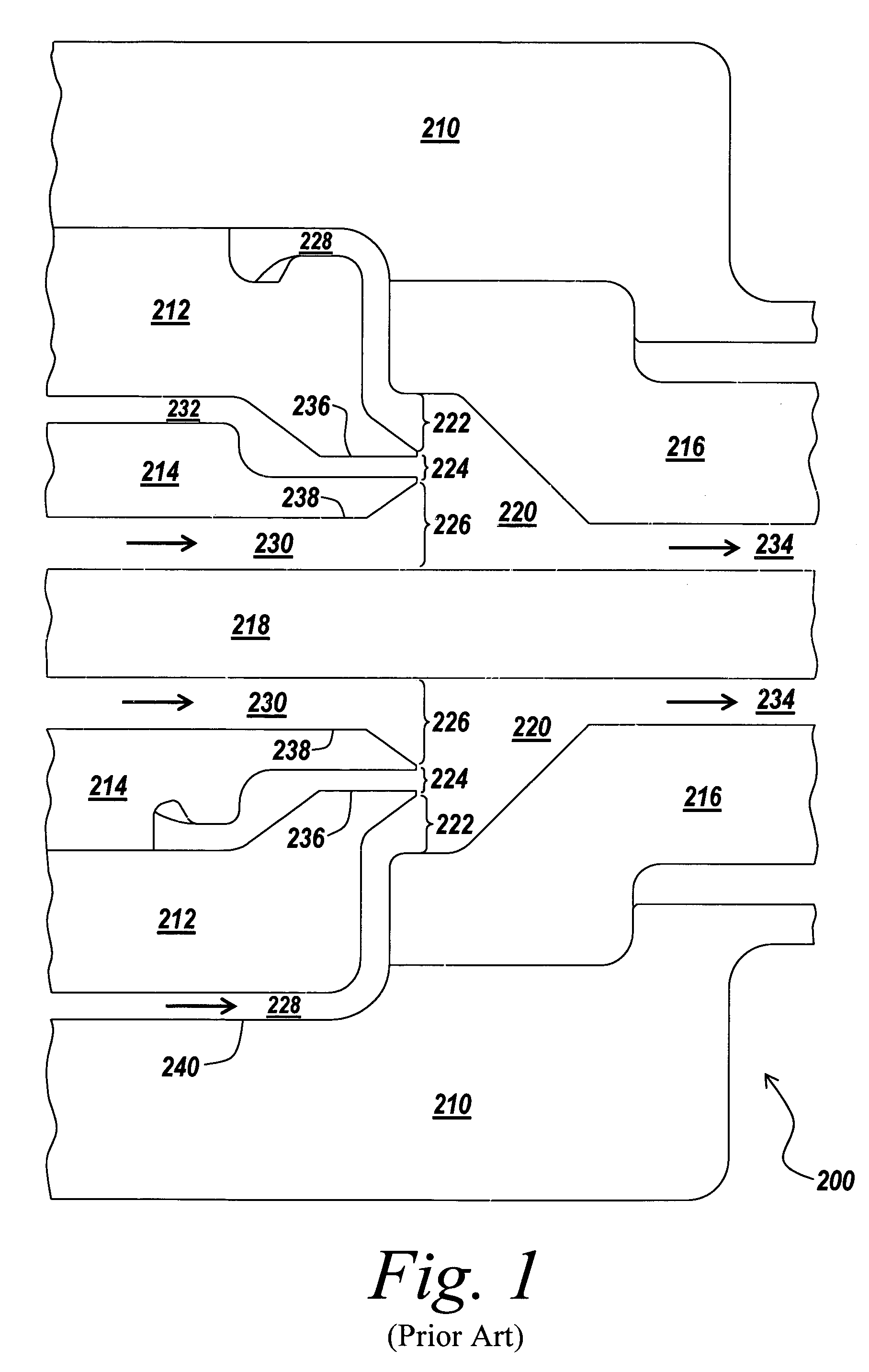

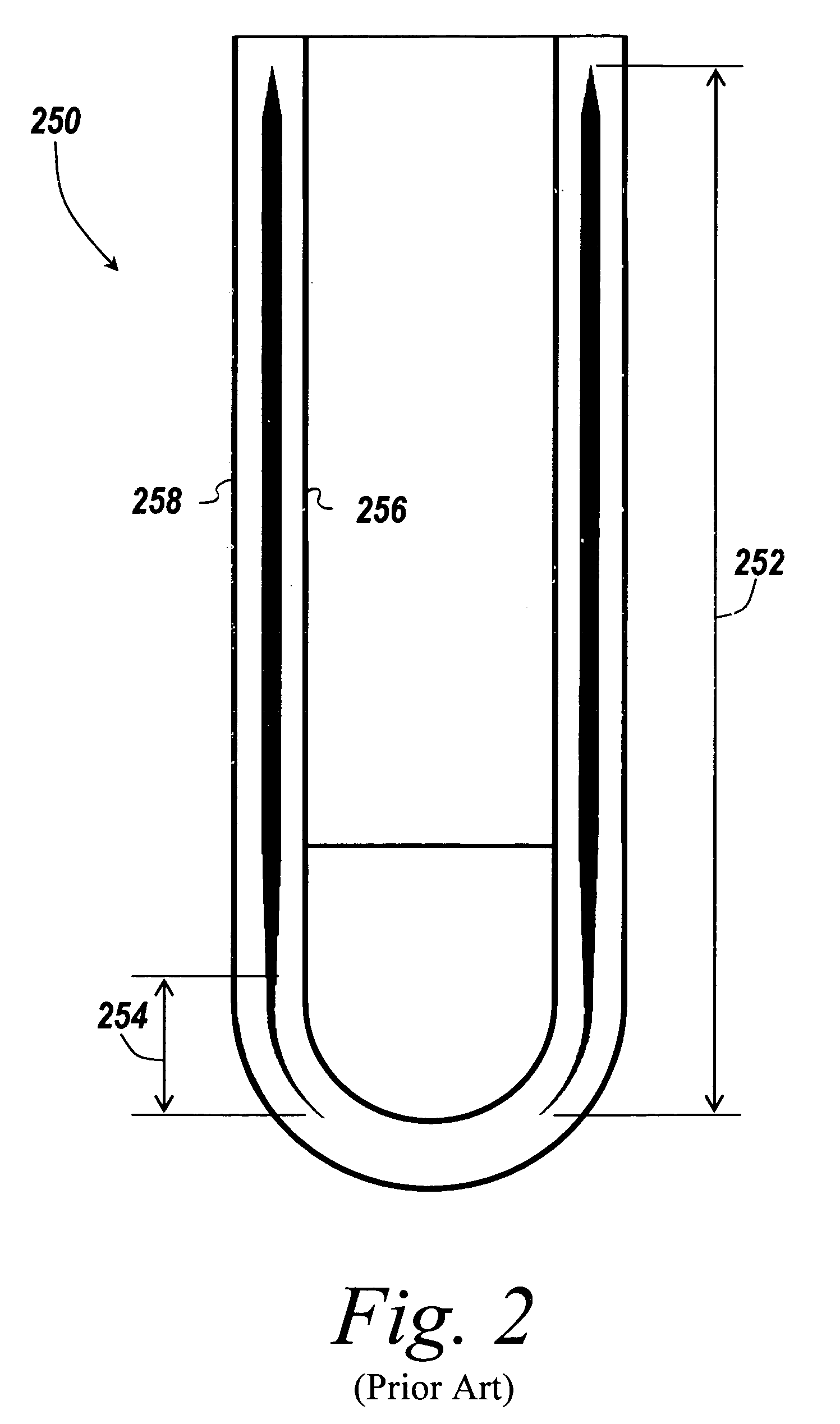

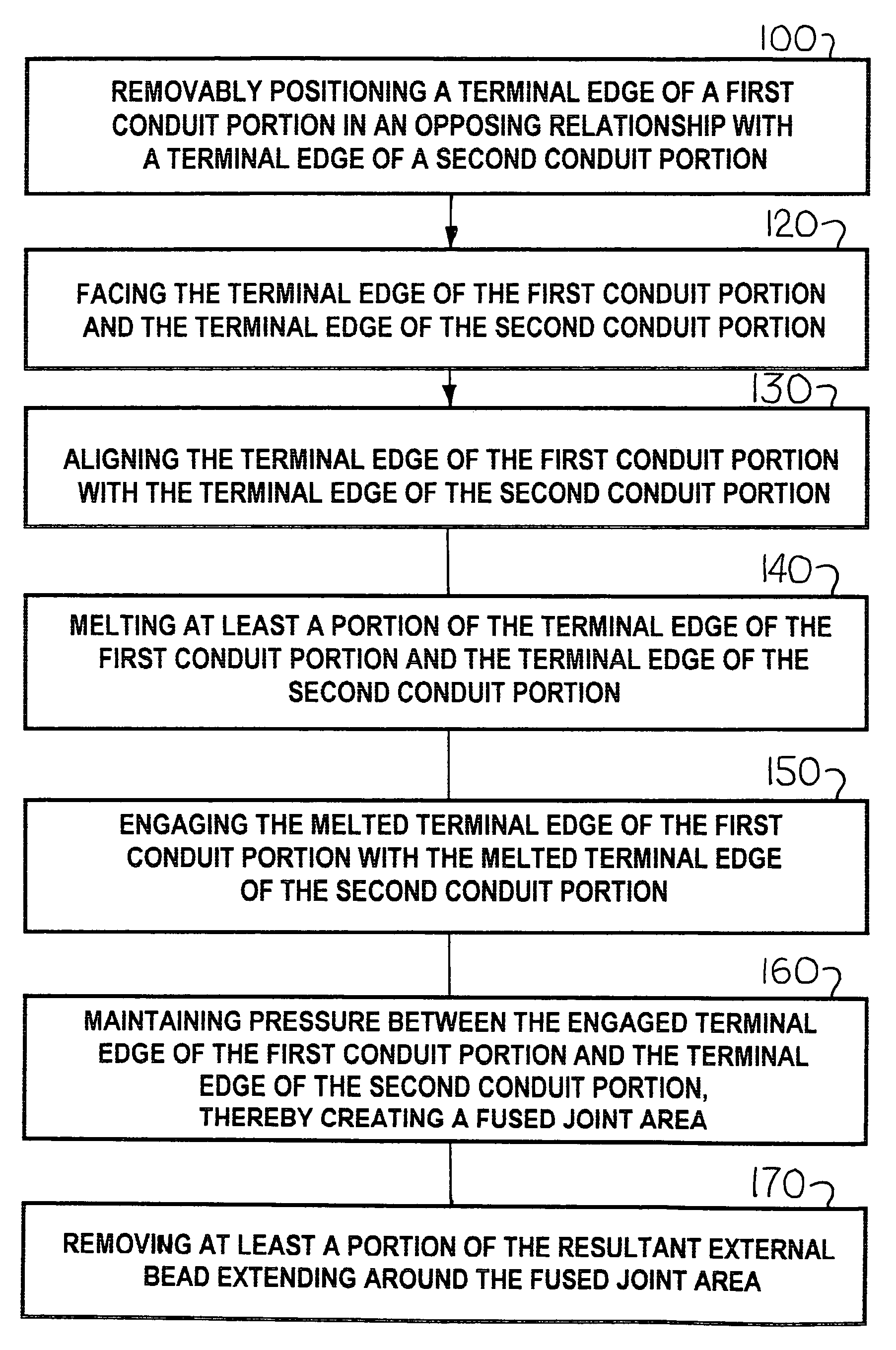

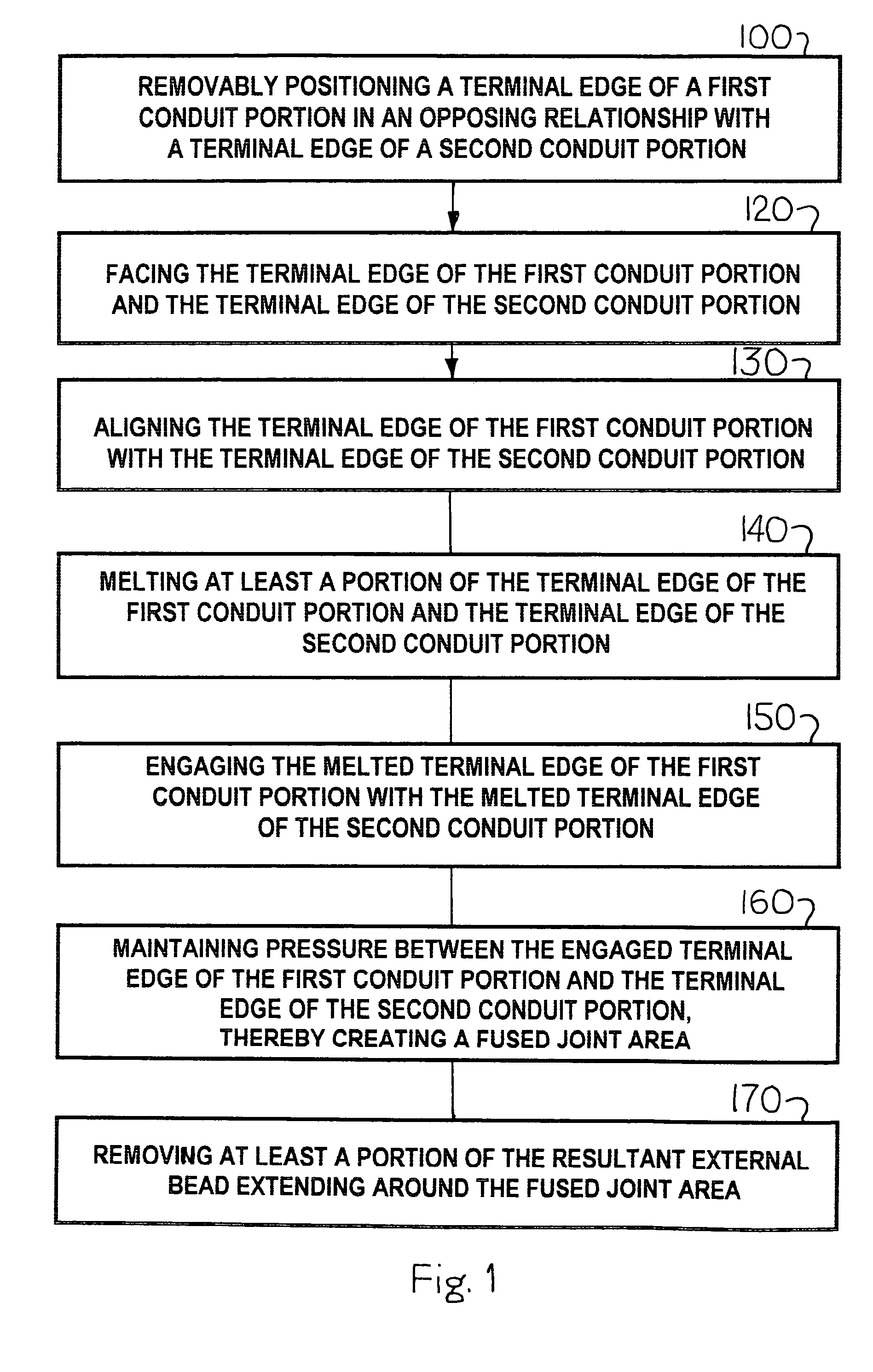

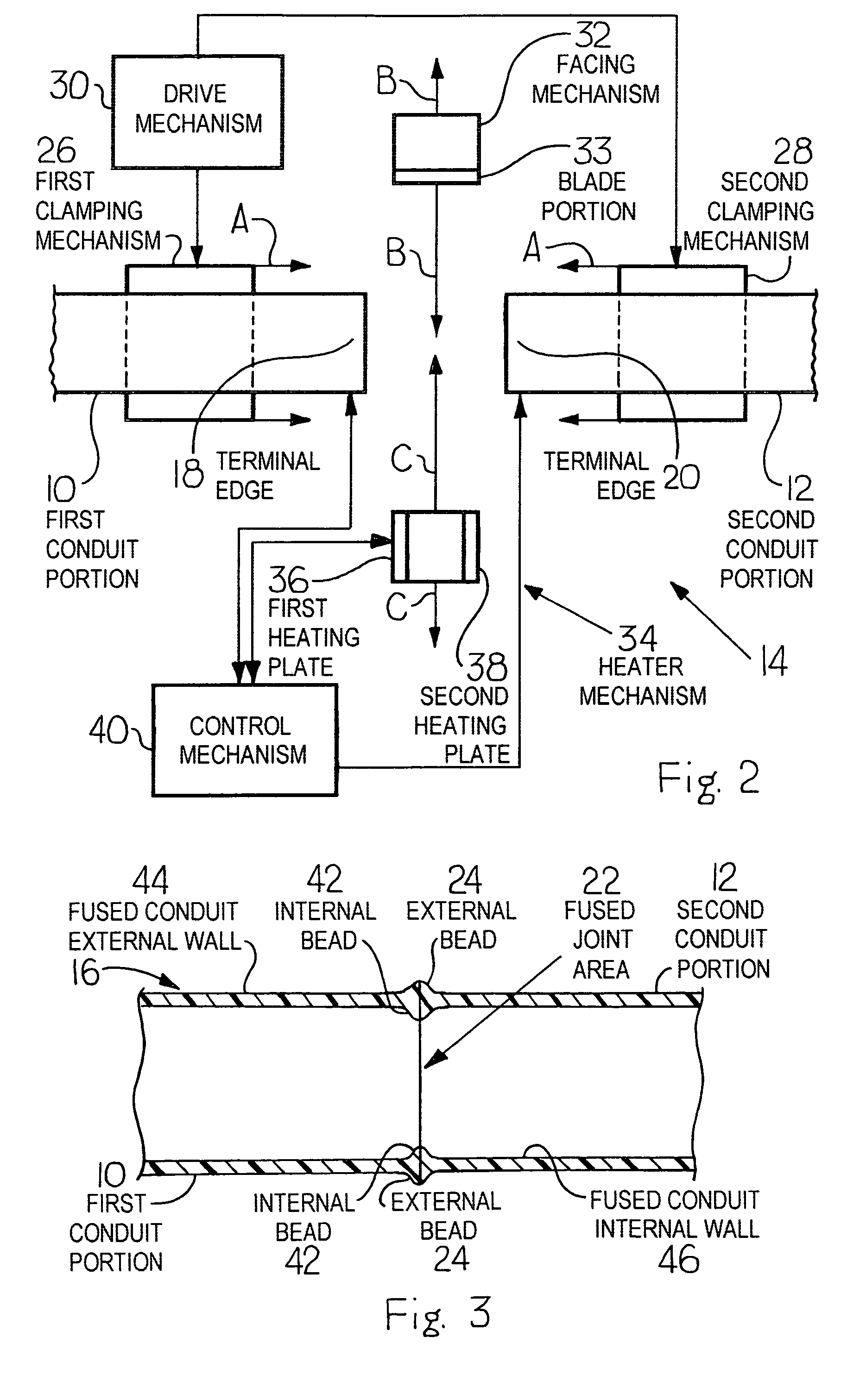

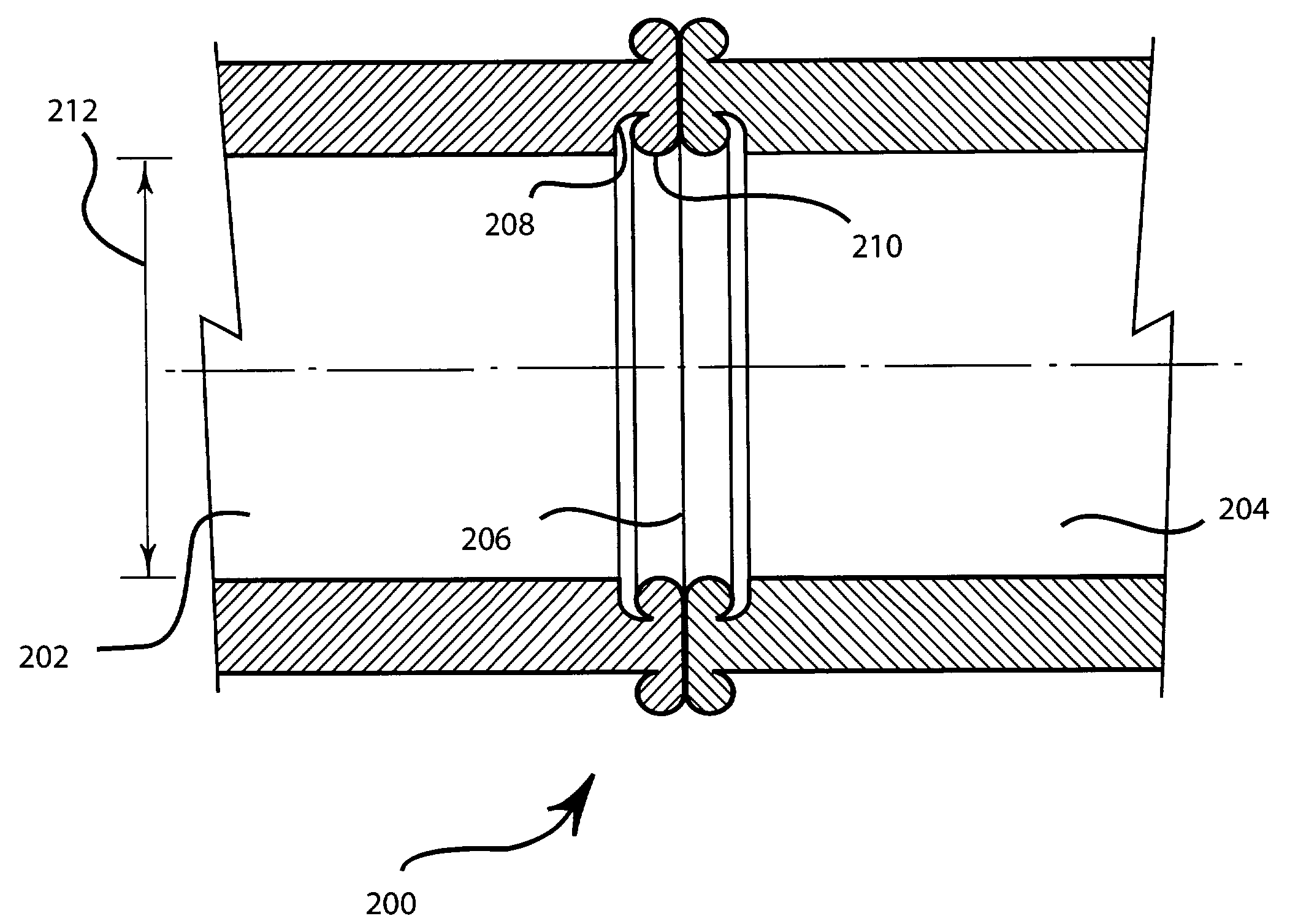

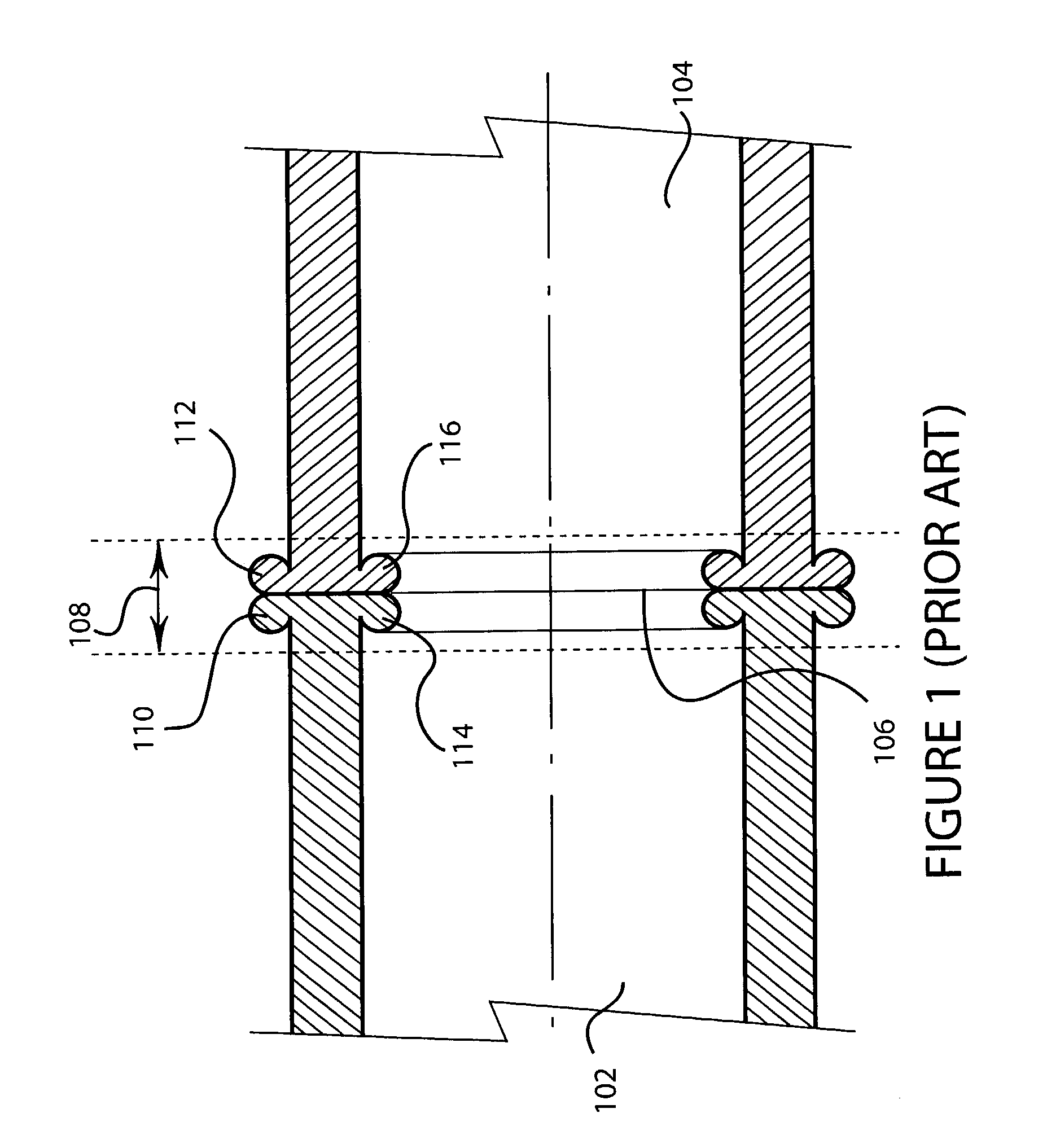

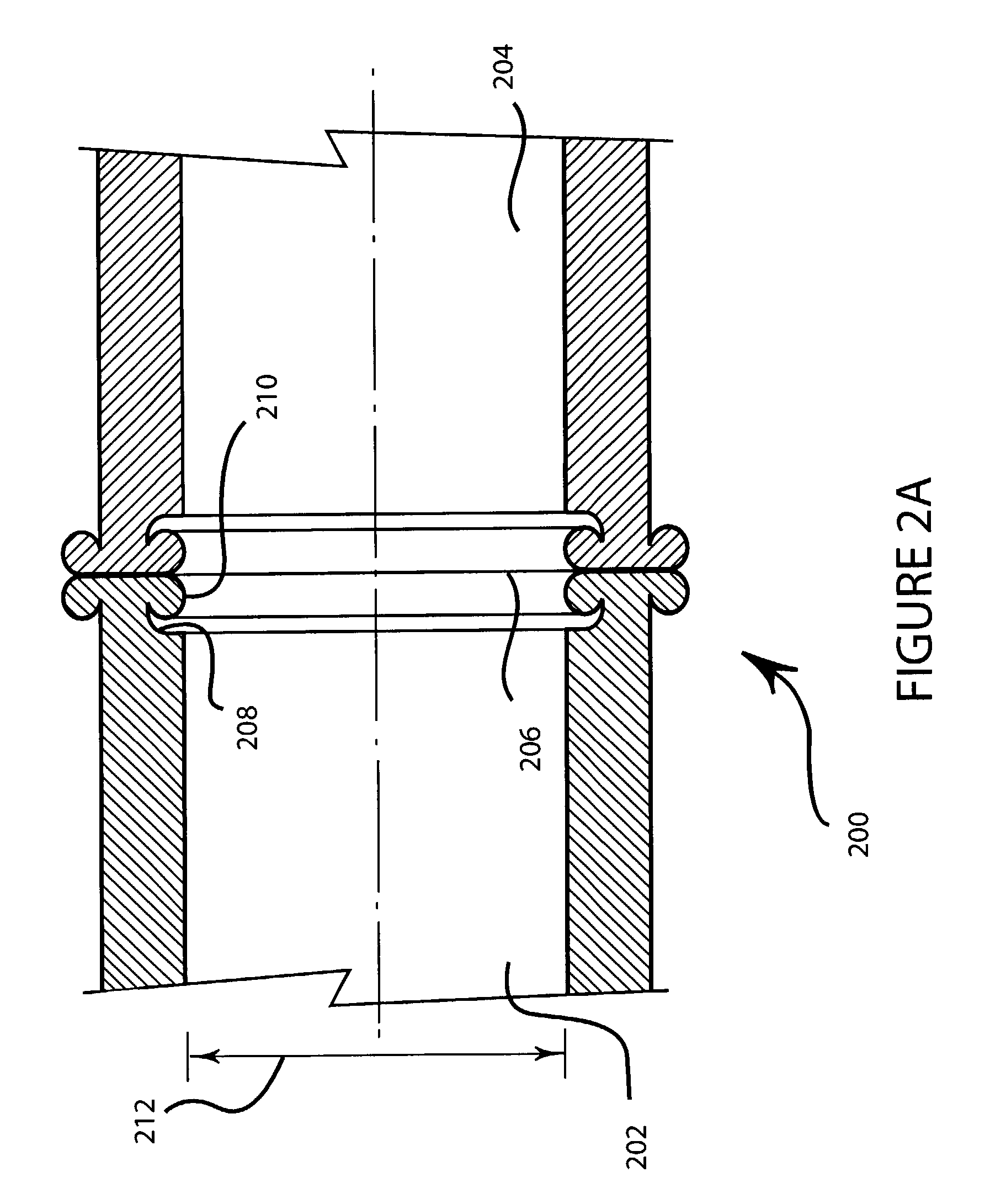

Fusion process for conduit

ActiveUS6982051B2High strength propertiesEasy to useButtonsRecord carriersEngineeringComputer terminal

Disclosed is a method and apparatus for use in a fusion process for conduit. The method includes the steps of: removably positioning a first terminal edge of a first conduit portion with a first terminal edge of a second conduit portion; facing the terminal edges of the first conduit portion and the second conduit portion; aligning the terminal edges of the first conduit portion and the second conduit portion; melting at least a portion of the terminal edges of the first conduit portion and the second conduit portion; engaging the melted terminal edge of the first conduit portion with the melted terminal edge of the second conduit portion; maintaining pressure between the engaged terminal edges, thereby creating a fused joint area; and removing at least a portion of the resultant external bead extending around the fused joint area. A fusion apparatus for employing this method is also disclosed.

Owner:UNDERGROUND SOLUTIONS INC

Collapsible expansion cone

Owner:WATSON BROCK WAYNE +1

Beveled cutter

InactiveUS6994766B2Minimize external protrusionEliminate the effects ofButtonsMechanical working/deformationEngineeringFusion welding

Disclosed is a method, apparatus, and design of a fusion welded pipe wherein the effects of an inner bead of the fusion weld are minimized. The internal shape of the pipe prior to welding may be configured in several different shapes so that the beads or lips produced by the fusion welding process are unobtrusive and do not interfere with the function of the pipe. In a likewise manner, the outer shape of the pipe prior to welding may be configured so that the lips are unobtrusive on the external surface of the pipe.

Owner:FAST FUSION

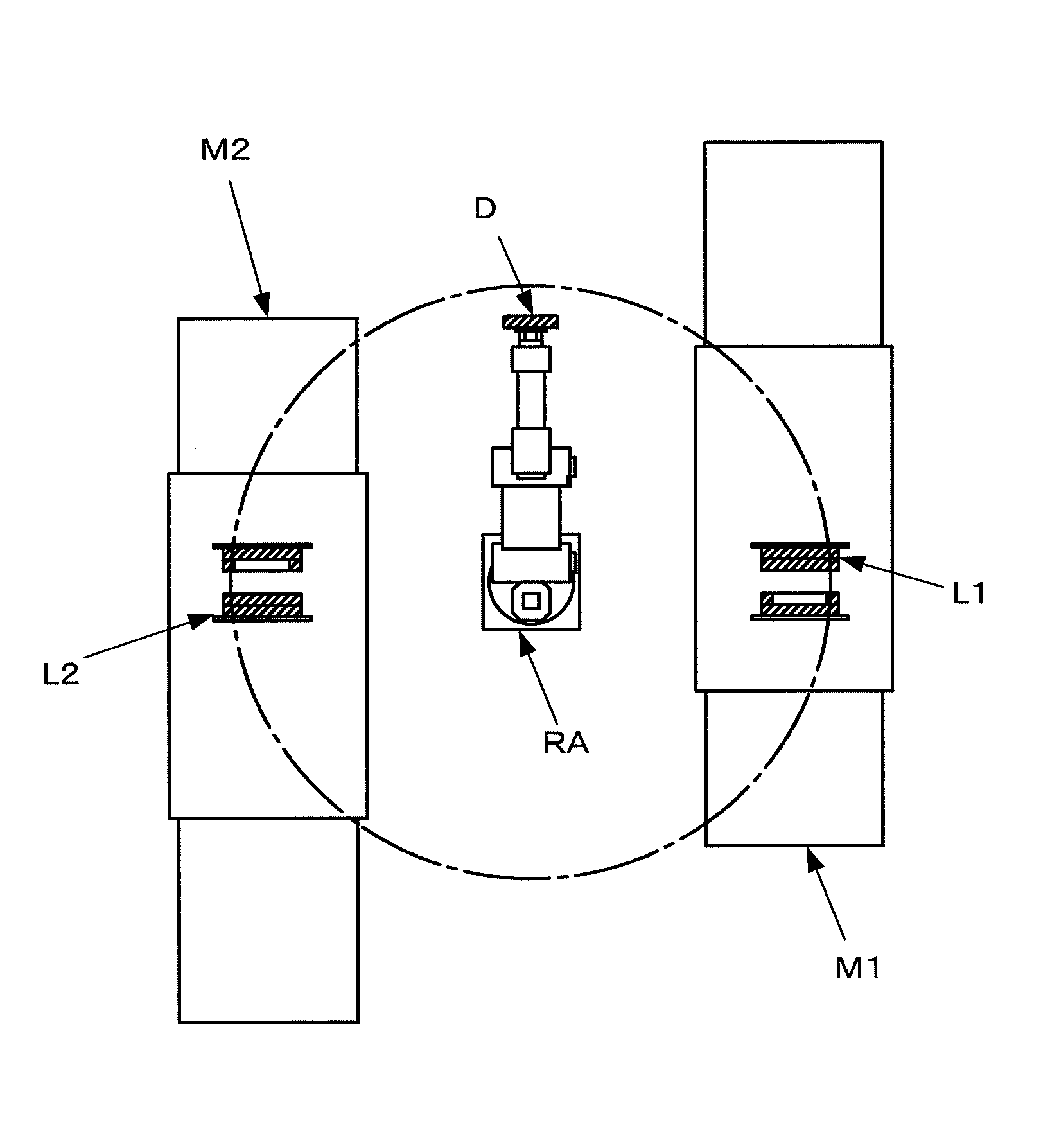

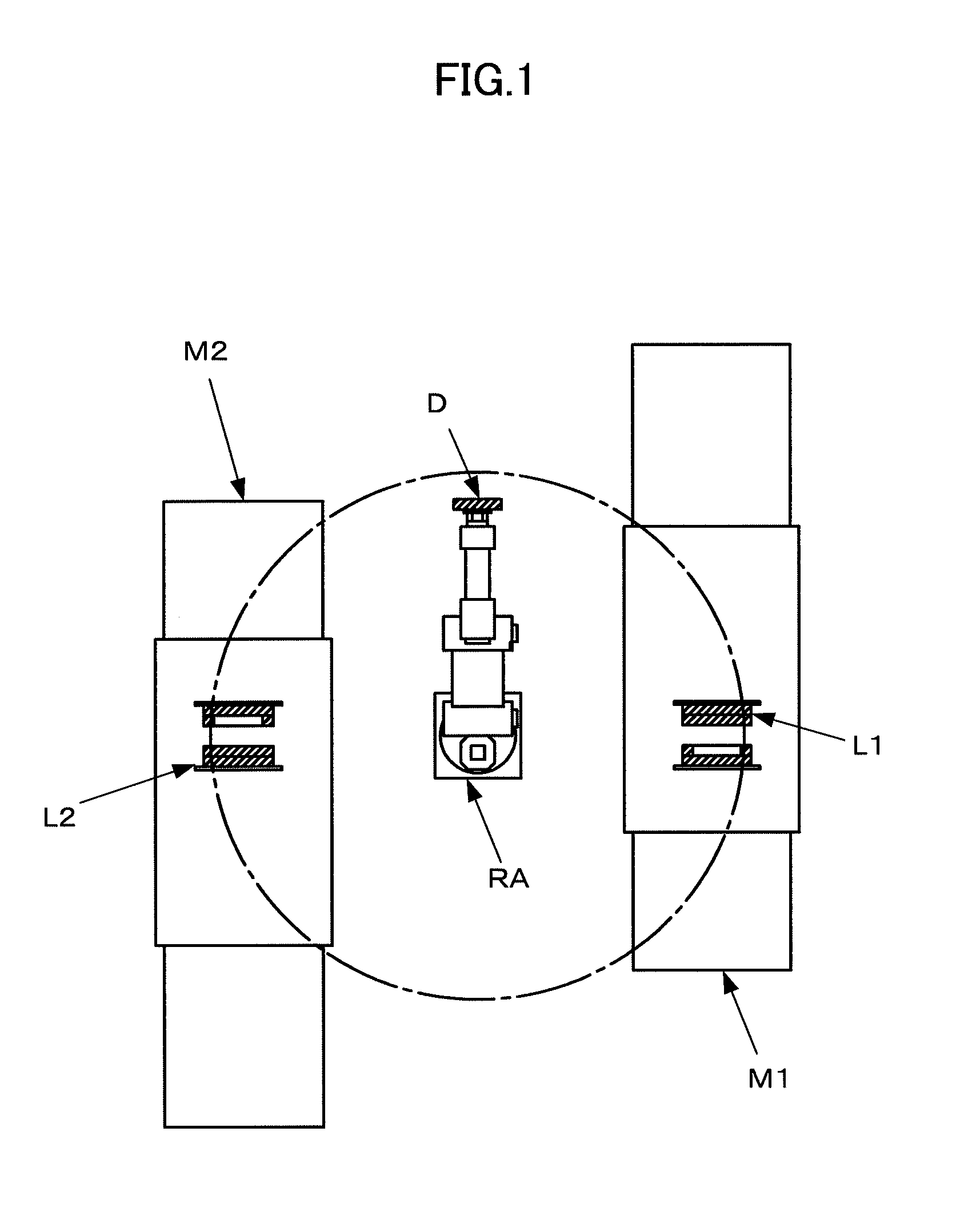

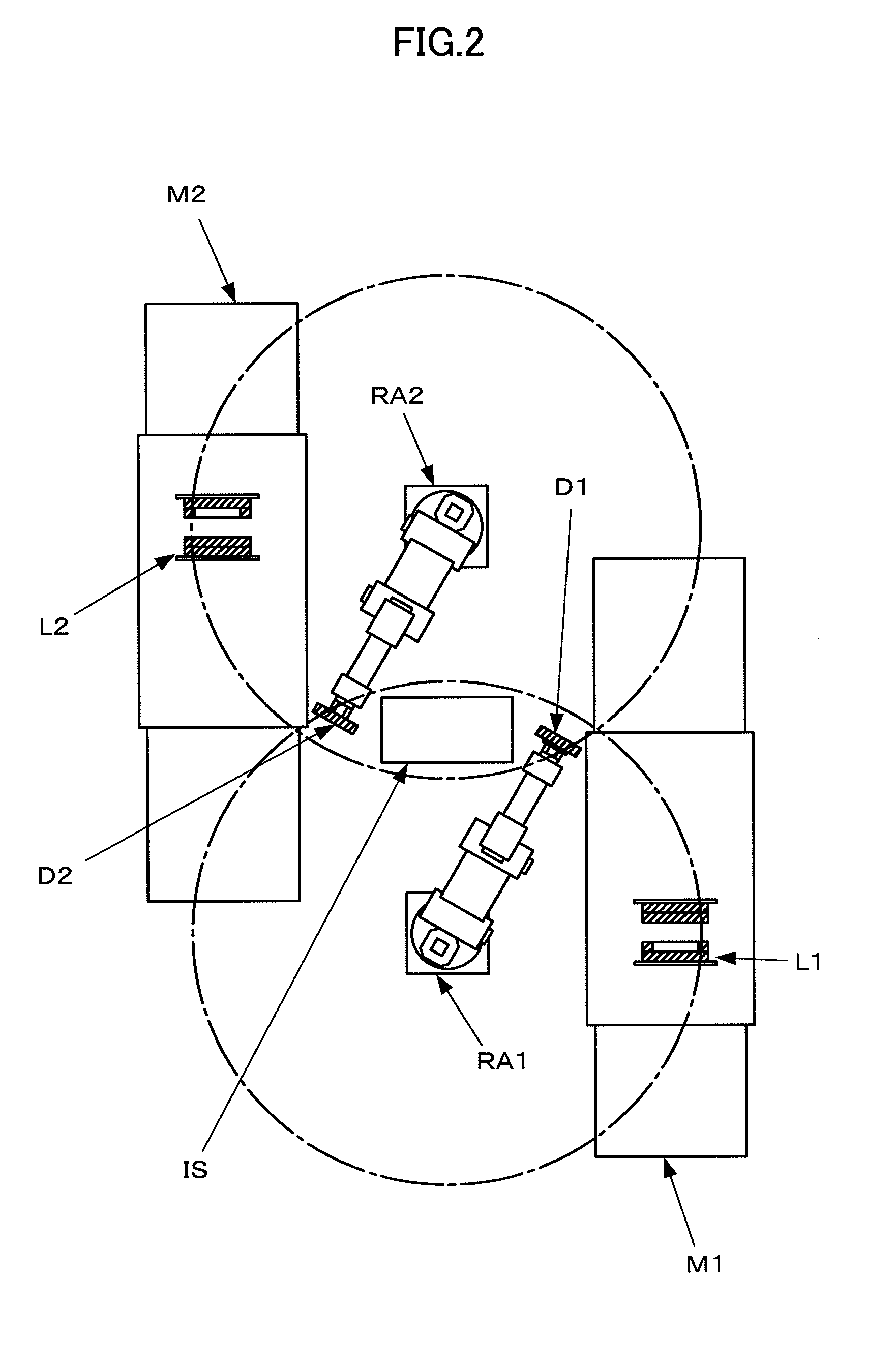

Manufacturing method and injection molding system for multi-color molded article

ActiveUS20140077410A1Preventing production of undesiredLack of versatilityButtonsRecord carriersInjection mouldingInjection molding machine

An injection molding system is configured to produce a multi-color molded article by simultaneously or sequentially injection-molding resins of a plurality of types by means of a plurality of injection molding machines. An insert mold is mounted in a mold of a first injection molding machine and a primary molded article is molded by this injection molding machine. Thereafter, a robot arm takes out the insert mold, along with the primary molded article, from the mold of the injection molding machine and attaches it to a mold of a second injection molding machine. A two-color molded article is injection-molded by the second injection molding machine and removed as a product.

Owner:FANUC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com