Air bag, automatic airing device and airing method

An air bag and equipment technology, applied in lighting and heating equipment, climate change adaptation, and preservation of seeds by drying, etc., can solve the problems of lower quality of agricultural products, difficult drying, and high labor intensity, so as to reduce the comprehensive use cost, The effect of expanding the drying area and reducing the crushing loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present embodiment takes the rectangular air bag as an example, and the above air bag is used for drying rice.

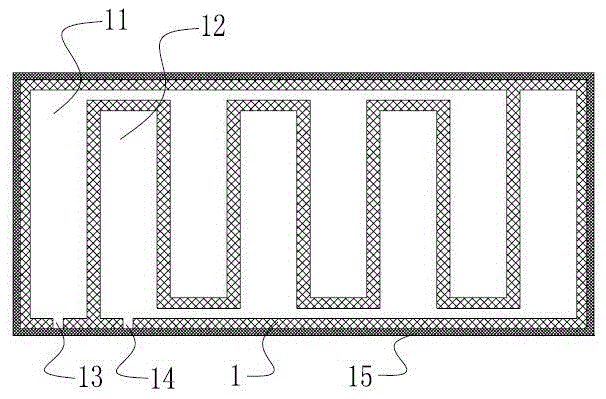

[0048] Such as figure 1 As shown, an airbag 1 is provided with a plurality of successively adjacent air cavities in the airbag 1, the adjacent air cavities are not connected, and the air passages between the spaced air cavities are connected, thereby forming two groups of unconnected air cavities. The first air cavity group 11 and the second air cavity group 12 , the first air cavity group 11 is provided with a first air flow interface 13 , and the second air cavity group 12 is provided with a second air flow interface 14 .

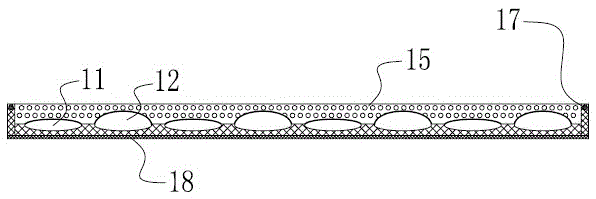

[0049] Such as figure 2 As shown, the bottom surface of the airbag 1 is connected with a protective bottom layer 18 made of plastic cloth. The protective bottom layer 18 made of plastic cloth has a waterproof effect, which enhances the adaptability of the airbag 1 to different places, and can not only be used on hard flat ground su...

Embodiment 2

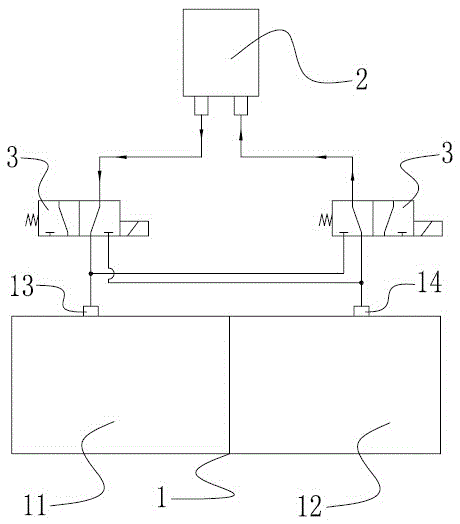

[0078] The difference between this embodiment and Embodiment 1 is that, as Figure 5 As shown, only one three-position four-way solenoid valve 3 is used to save costs.

[0079] The step S1 of the airing method of this embodiment is: deploy the airbag 1, and control the air pump 2 and the electromagnetic valve 3 to pre-inflate the two groups of air chambers through the control system, so that the two groups of air chambers reach a two-thirds full state, Then stop inflation, and paddy is laid on air bag 1.

[0080] The steps of all the other drying methods are the same as in Example 1.

[0081] The drying method in this embodiment does not need to plug and unplug the trachea, which avoids the cumbersome process of plugging and connecting the pipelines, and has a higher degree of automation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com