Wheat drying device

A drying device and technology for wheat, applied in the direction of storing seeds by drying, etc., can solve the problems of mildew and rotten wheat, economic losses of farmers, and large floor space, so as to speed up the time, increase the drying area, and increase the heating area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

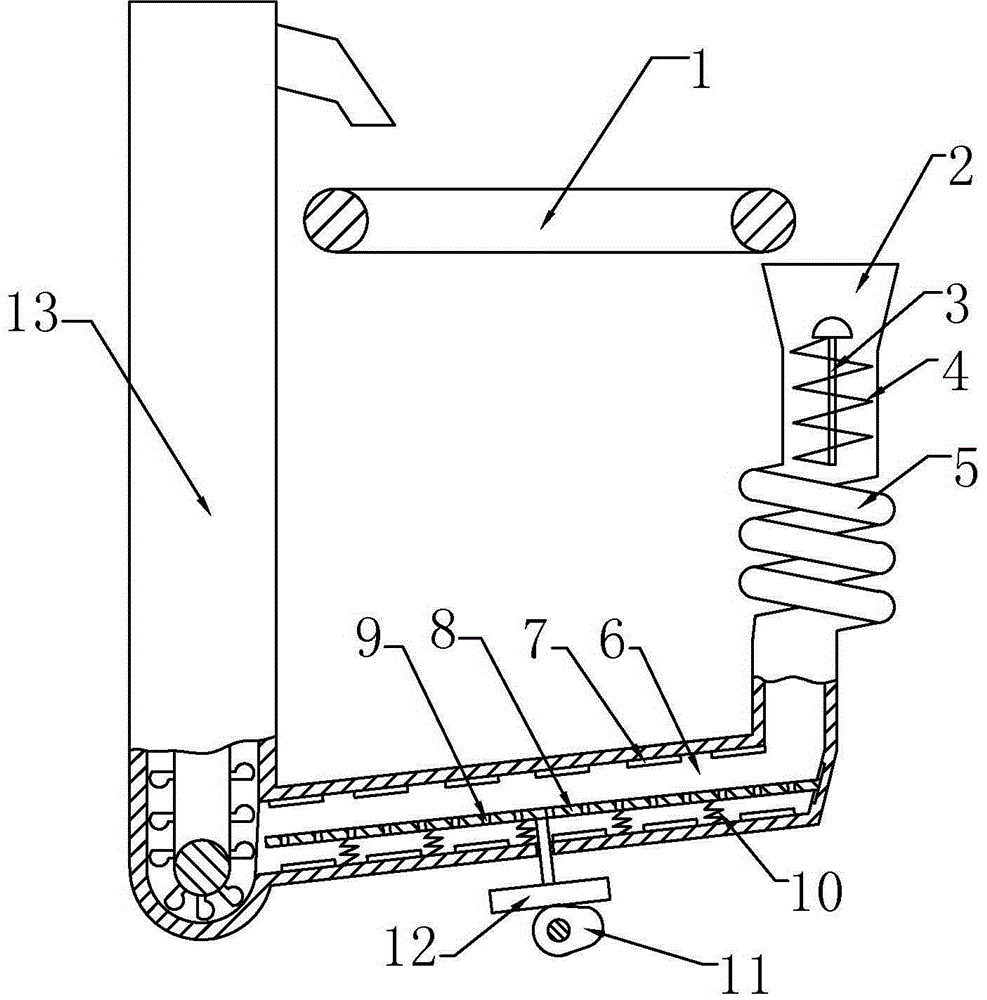

[0017] The reference signs in the drawings of the description include: belt conveyor 1, feed hopper 2, main shaft 3, spiral blade 4, spiral pipe 5, inclined pipe 6, heater 7, inclined plate 8, through hole 9, spring 10, Cam 11, connecting rod 12, bucket elevator 13.

[0018] Example basic reference figure 1 Shown: a wheat drying device, including a belt conveyor 1, the belt conveyor 1 is connected with a first motor, a drying belt is arranged on the belt conveyor 1, a feeding hopper 2 is arranged under the belt conveyor 1, and the feeding hopper 2 is provided with a main shaft 3, the main shaft 3 is connected with a second motor, the main shaft 3 is provided with a second heating wire, the main shaft 3 is fixedly connected with a spiral blade 4, and the outlet of the feeding hopper 2 is connected with a vertical spiral pipe 5, A first electric heating wire is provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com