Automatic paint spraying device for electric vehicle accessories

A technology for automatic painting and electric vehicles, which can be used in spraying devices, painting booths, and devices that apply liquid to surfaces, etc. It can solve the problems of uneven painting, consistent paint, and poor painting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

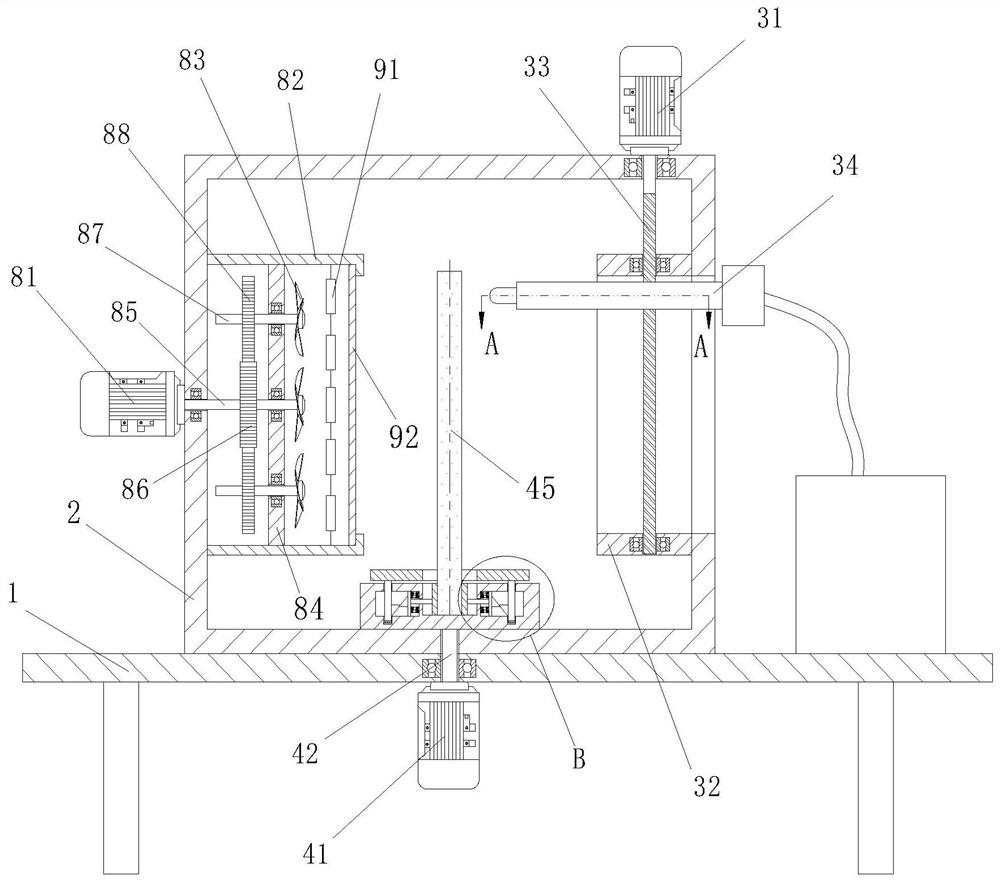

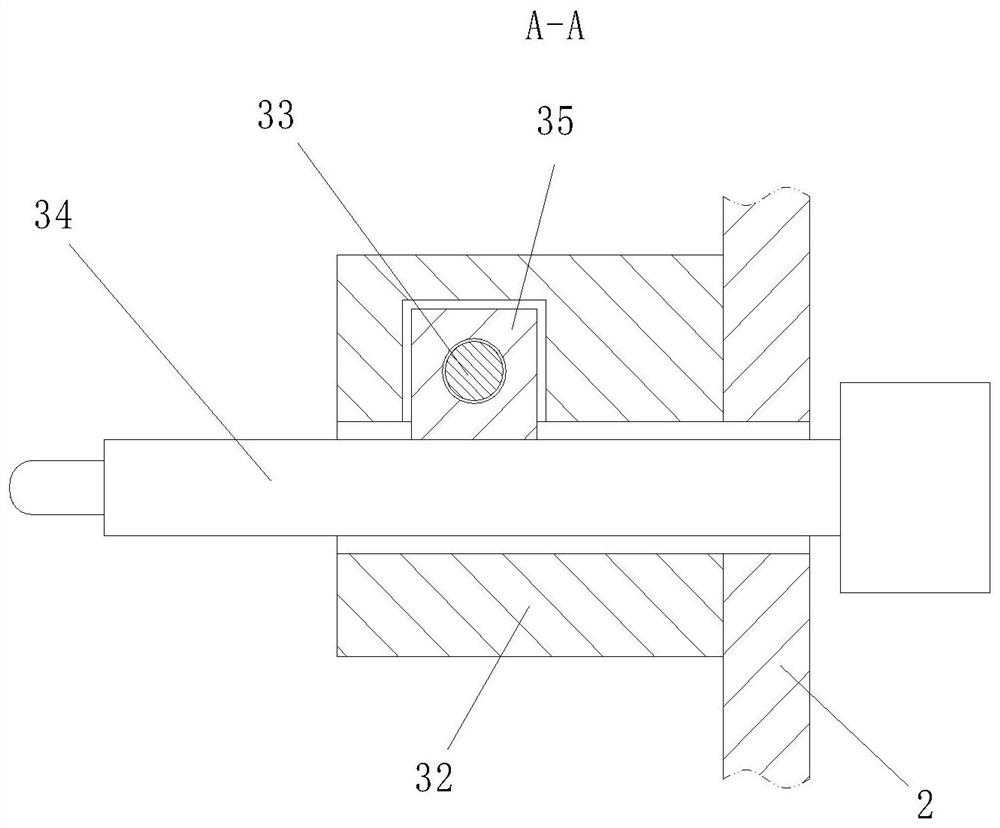

[0025] Such as Figure 1 to Figure 4 As shown, an automatic painting device for electric vehicle accessories according to the present invention includes a base 1, a paint spray box 2 and a paint spray mechanism; the paint spray box 2 is fixed on the top of the base 1, and one side of the paint spray box 2 is an opening Set; the paint spraying mechanism is arranged inside the paint spraying box 2; the paint spraying mechanism includes a No. 1 servo motor 31, a No. 1 housing 32, a threaded rod 33 and a paint spray gun 34; the No. 1 servo motor 31 is fixed on the paint spray The top of the box 2; the threaded rod 33 is affixed to the output shaft of the No. 1 servo motor 31; the No. 1 housing 32 is affixed to the inner wall of the paint spray box 2; the paint spray gun 34 runs through the paint spray box 2 and a No. 1 housing 32, and is slidingly connected inside the No. 1 housing 32; the outer wall of the spray gun 34 is fixedly connected with a connecting plate 35; the threaded...

Embodiment 2

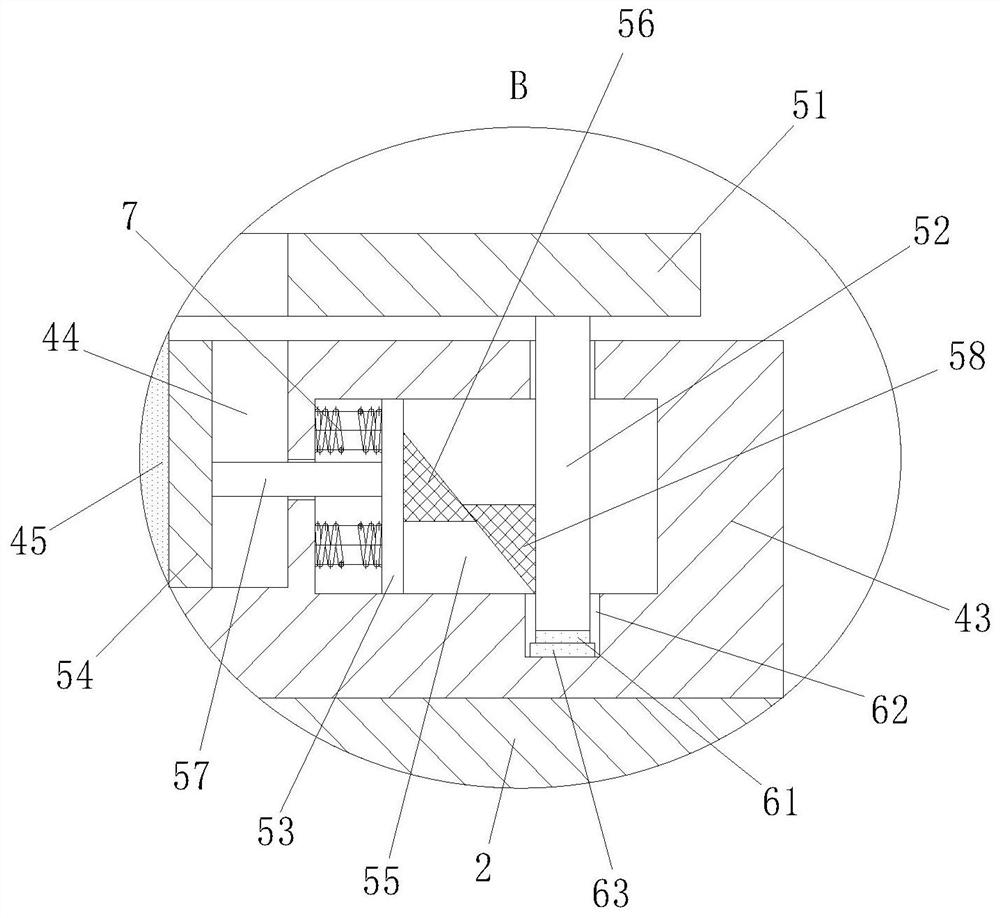

[0034] see Figure 5 , Comparative Example 1, as another embodiment of the present invention, the side of the pressure plate 54 away from the No. 1 pole 57 is fixed with a rubber layer 10; The direct contact avoids the pressure plate 54 from crushing the electric vehicle accessories 45, and at the same time the rubber layer 10 is elastic and can be deformed to a certain extent, so that the two pressure plates 54 can fully contact with the electric vehicle accessories 45 of different diameters, and realize the clamping function .

[0035] Working principle: place the electric vehicle accessory 45 in the installation hole 44, and then squeeze the annular plate 51 downward, so that the push rod 52 drives the No. 2 wedge 58 to move downward, and then makes the No. Wedge block 56, so No. 1 wedge block 56 and push plate 53 move toward the direction of mounting hole 44, and then make two pressing plates 54 clamp electric vehicle accessory 45, realize fixing electric vehicle accessor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com