Method for continuously drying polycarbonate

A technology of polycarbonate and drying method, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., which can solve the problems of reducing pressure drop and failure rate, shortening the length of airflow drying sleeve, etc., to reduce the workload , Avoid excessive local temperature and fully utilize the effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

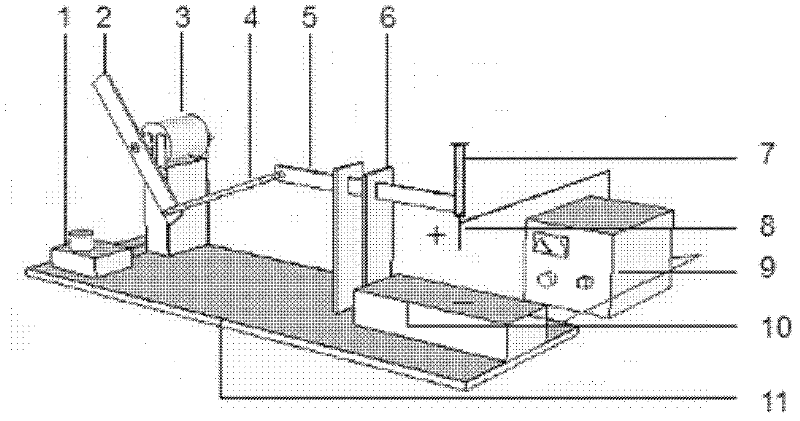

[0013] The process steps of this embodiment include air drying with superheated steam, cyclone drying, primary drying and primary cooling with air. The superheated steam whose air flow direction is perpendicular to the material direction is fed into 1 at the same time, and the two flow together in the air drying sleeve 2. The air drying sleeve 2 is a pipe with a jacket. Heat and mass transfer are carried out in the airflow drying sleeve 2, most of the solvent and moisture are removed, and the airflow drying is completed to obtain the first-step drying material; then the first-step drying material is entrained by the steam airflow and enters the cyclone at a high speed from the tangential direction At the bottom of the dryer 3, the dry material and steam rotate along the inner wall, during which intense mass and heat transfer occurs, and then the steam airflow carries the solid dry material into the cyclone separator 4 to achieve gas-solid separation. The heat of the drying pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com