Vacuum dryer for screw to convey materials and method thereof

A technology of vacuum dryer and screw conveying, which is applied in the direction of drying machine, drying solid materials, and combination of methods to dry solid materials, etc. It can solve the problems of backward enterprise management, inconformity with economies of scale, and low overall quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

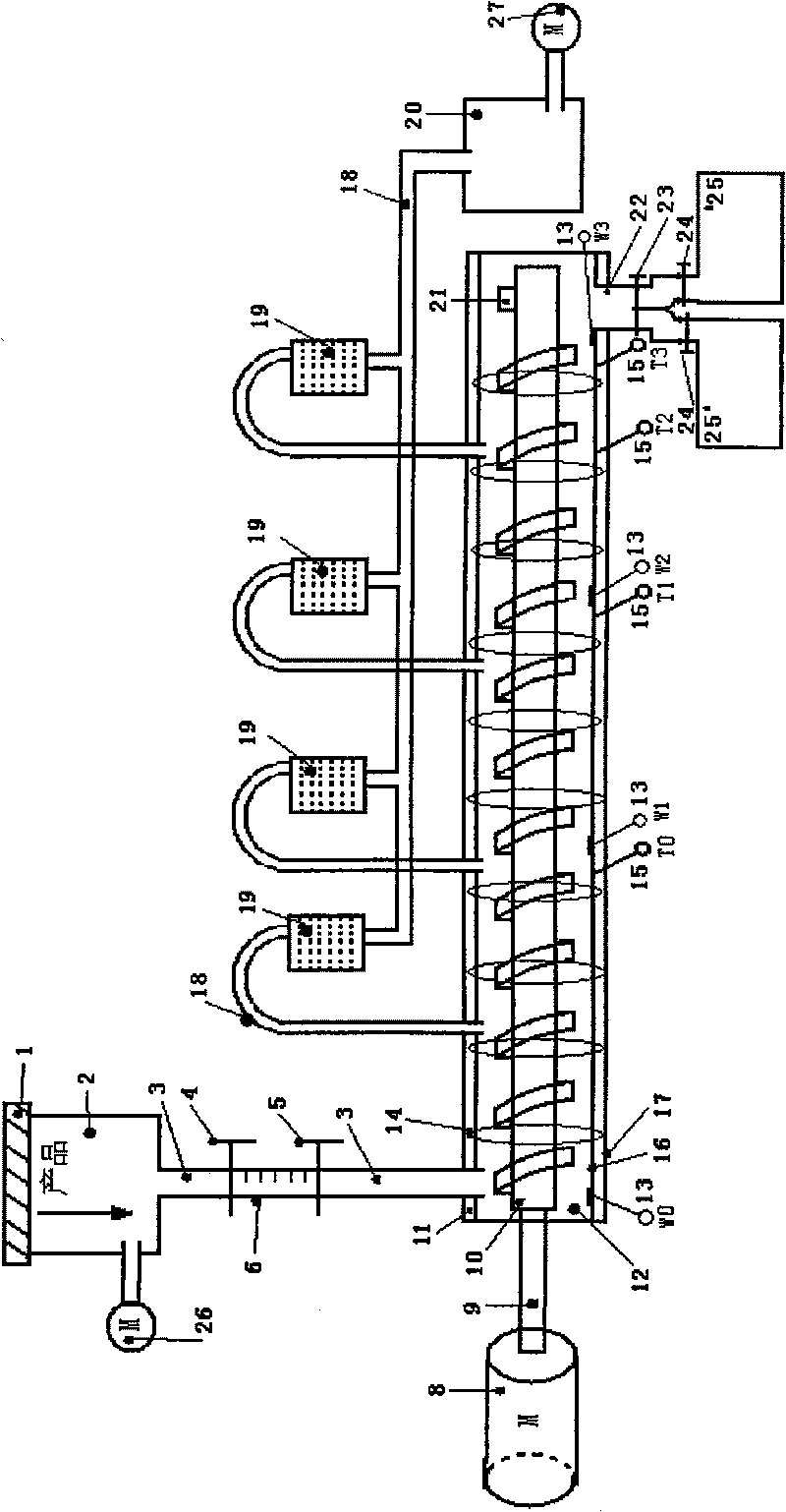

[0055] Product input part: the product is added from the material tank, and the quantitative valve and the feed valve control the product to quantitatively enter the main drying conveying pipe. The material tank is connected with the feeding pipe and the vacuum pump respectively, and the interior is fully vacuumed.

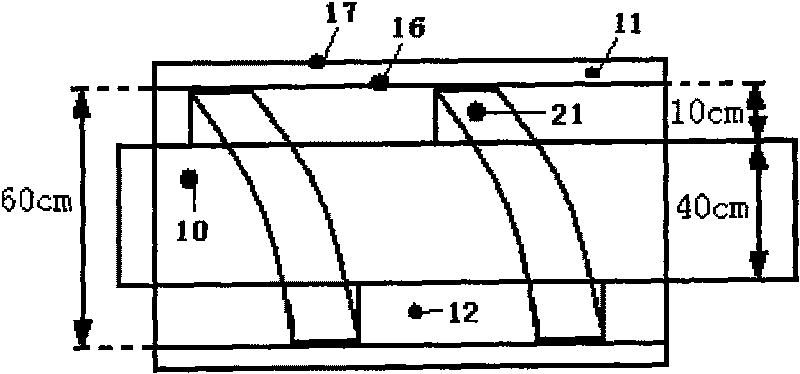

[0056] Screw driving part: the outside of the dry conveying pipeline is composed of double-layer stainless steel (model 316L) pipe walls, ten heating resistors are evenly laid between the inner and outer pipe walls, and the inside of the dry conveying pipe is a stainless steel screw with a certain thickness of threads (The diameter of the dry conveying pipe, the diameter of the screw and the thickness of the thread meet the theoretical ratio of 6:4:1); the screw is connected to the motor by a well-sealed driving bearing. The length of the dry conveying pipe is 2 meters, and the four condensation pipes are evenly distributed on the pipe, with an average of 2 / m; simi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com