Automation equipment for naturally airing kelp

An automated equipment, kelp technology, applied in applications, food science, food processing, etc., can solve the problems of low efficiency, time-consuming and energy consumption, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

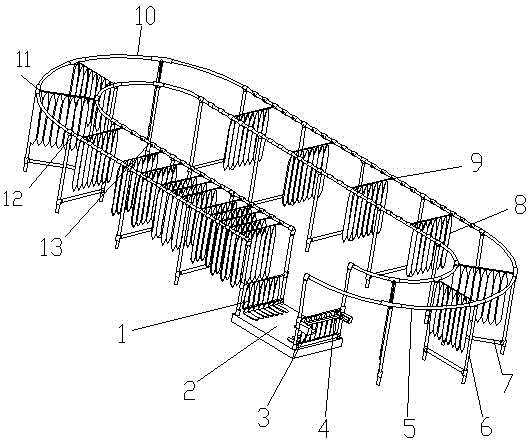

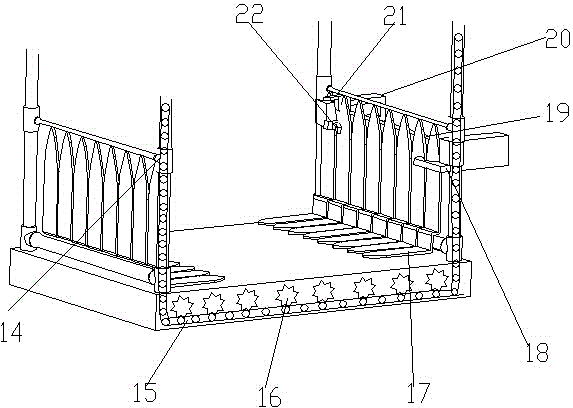

[0018] This embodiment has provided a kind of automation equipment of the kelp of two tracks airing naturally, and its structure is as follows: figure 1 As shown, it includes a drying system, a cutting system, and a workbench 2 with a built-in lubrication system. The drying system includes a chain conveyor belt 5 for hanging kelp strings, a vertical support frame 6 and a horizontal support frame 7 for fixing the chain conveyor belt 5 . The chain conveyor belt 5 is provided with a plurality of seedling rope clamping heads 11 for clamping the kelp string 8, and the seedling rope clamping heads 11 are respectively arranged on the outer side of the inner road 13 and the inner side of the outer road 12. One end of seedling rope 9 is clamped on the seedling rope clamping head of inner track, and the other end is clamped on the seedling rope clamping head of outer track. The starting end of the chain conveyor belt 5 is the feeding end 1, and the terminal is the cutting end 3. The st...

Embodiment 2

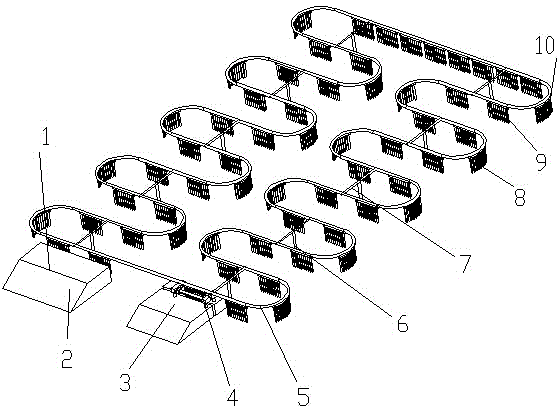

[0023] This embodiment provides a kind of single-track kelp automatic drying equipment, such as figure 2 Shown, the kelp automatic drying equipment of single track is similar to the double-track structure in embodiment 1, also comprises drying system, cutting system, workbench 2, and drying system comprises the chain conveyer belt 5 for hanging kelp string, in order to fix The vertical support frame 6 and the horizontal support frame 7 of the chain conveyor belt 5. The chain conveyor belt 5 is provided with a plurality of seedling rope clamping heads 11 for clamping the kelp strings 8, the seedling rope clamping heads are arranged on the lower side of the chain conveyor belt 5, and the seedling ropes on the kelp strings are clamped on two sides respectively. Adjacent seedling ropes are clamped on the head. The starting end of the chain conveyor belt 5 is the feeding end 1, and the terminal is the cutting end 3. The cutting end 3 is connected with a cutting system, and the ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com