Biomass fuel drying device

A biomass fuel and drying device technology, which is applied in the field of bioengineering, can solve the problems of difficult dispersion, easy agglomeration of biomass pellet fuel, and high accumulation degree of biomass pellet fuel, so as to achieve full contact, efficient and thorough drying process, and realize scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

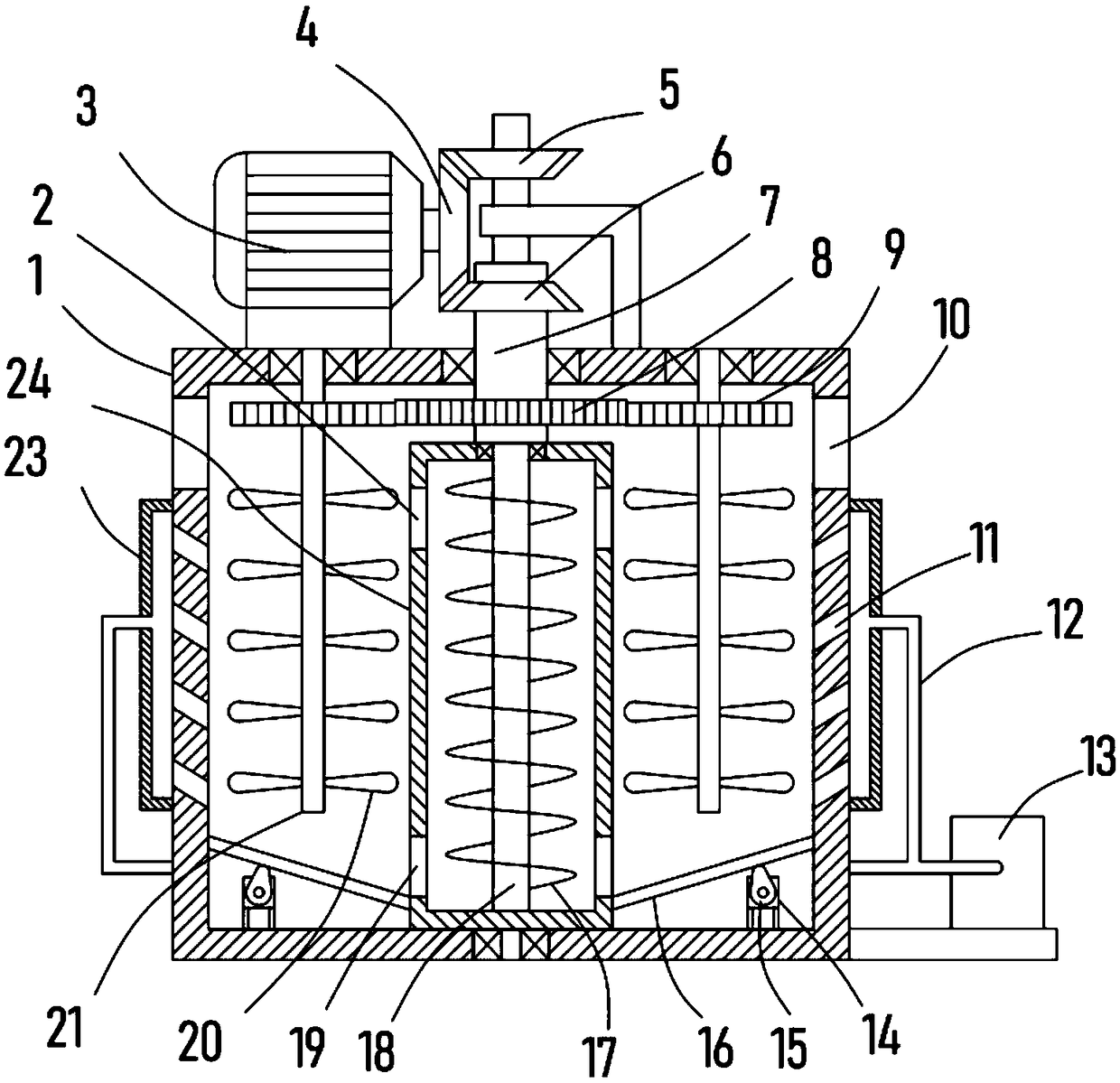

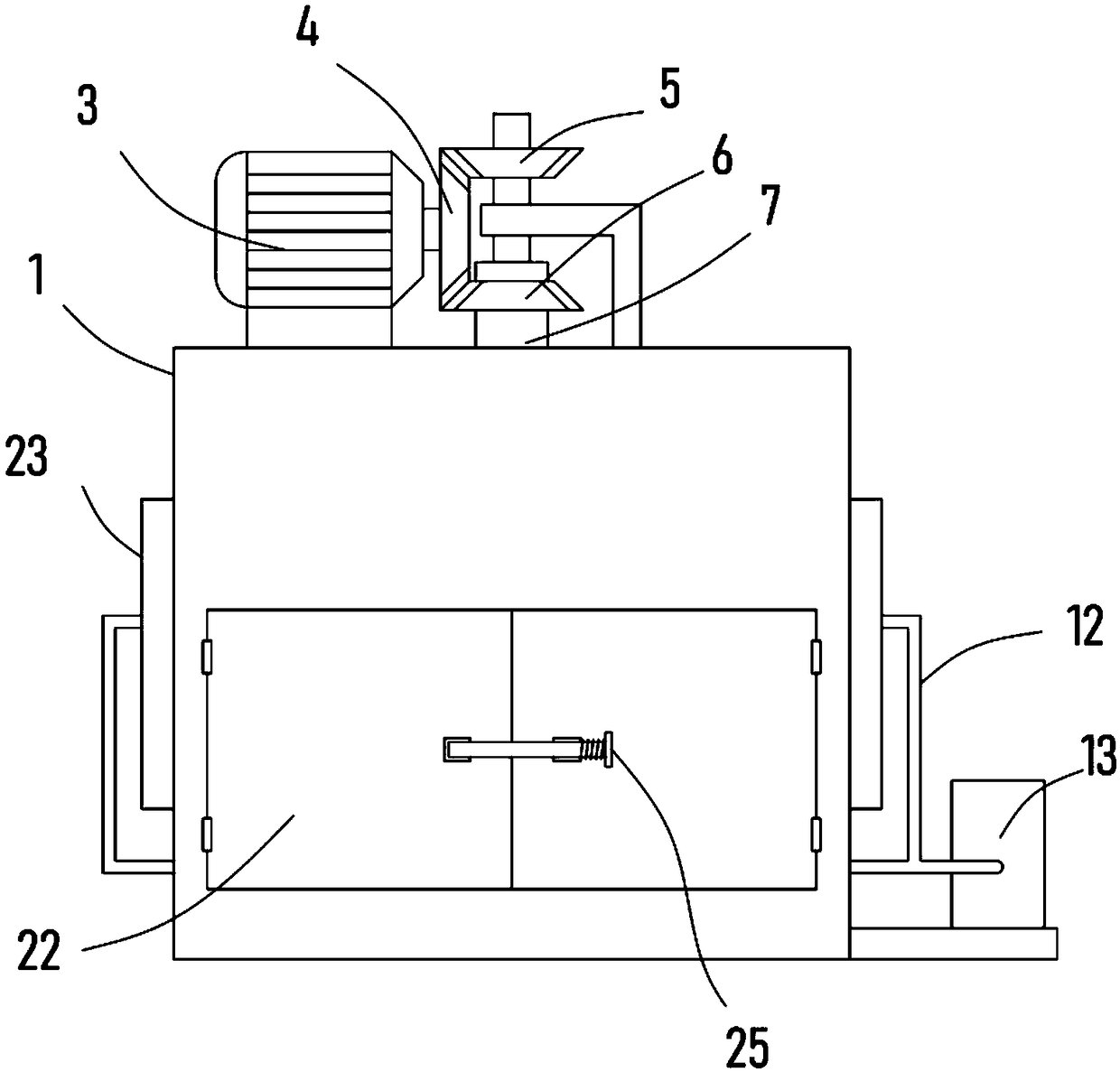

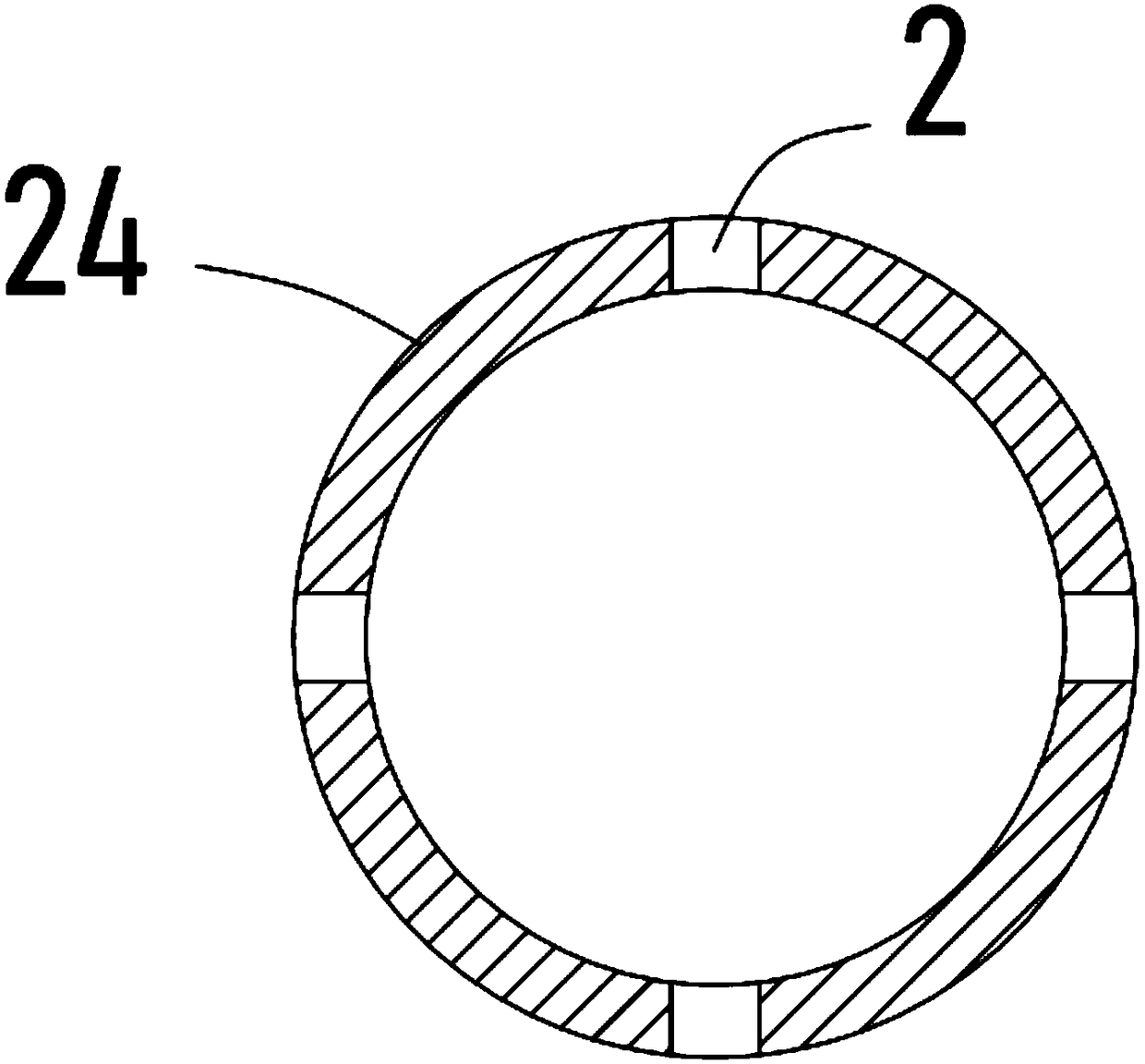

[0020] see Figure 1-3 , a biomass fuel drying device, comprising a drying box 1 and a hot air blower 13 communicating with the inside, a driving motor 3 is fixedly installed on the top of the drying box 1, and a driving bevel gear 4 is fixedly installed on the output shaft of the driving motor 3 coaxially On the drying box 1, the rotary type is vertically provided with a transmission sleeve 7, and the transmission sleeve 7 is sleeved with a driven bevel gear II6 that is meshed with the driving bevel gear 4, and the lower end of the transmission sleeve 7 is fixed with a lifting sleeve 24 , the drive motor 3 drives the driving bevel gear 4 to rotate, and the driving bevel gear 4 drives the driven bevel gear II6 to rotate through the driven bevel gear II6 meshed with it, thereby realizing the rotation of the lifting sleeve 24.

[0021] The lifting sleeve 24 is rotatably vertically provided with a lifting shaft 18 that runs through the lifting sleeve 24. The surface of the liftin...

Embodiment 2

[0026] On the basis of Embodiment 1, in addition, the driving gear 8 is sheathed and fixed on the surface of the transmission sleeve 7, and two dispersing shafts 21 are arranged vertically in a rotating manner in the drying box 1, and the driving gear 8 is sheathed and fixed on the dispersing shaft 21. 8 meshed driven gears 9, and several dispersing blades 20 are evenly fixed on the surface of the dispersing shaft 21.

[0027] The rotation of the transmission sleeve 7 drives the driving gear 8 to rotate, and the driving gear 8 drives the dispersing shaft 21 to rotate through the driven gear 9 meshed with it, and the dispersing shaft 21 drives the dispersing blade 20 to rotate to realize the rotation and dispersion of the biomass fuel. Further promotes the dispersion of fuel and improves the drying rate.

[0028] Further, an elastic material guide plate 16 is obliquely fixed in the drying box 1, one end of the elastic material guide plate 16 is fixed on the inner side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com