Hexagon head bolt hot heading forming die and machining technology thereof

A technology for forming molds and forming processes, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of complicated structure, low production efficiency, low manufacturing cost, etc., and achieve convenient and fast operation and production efficiency. High, consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the above object of the present invention, the present invention has adopted following technical scheme:

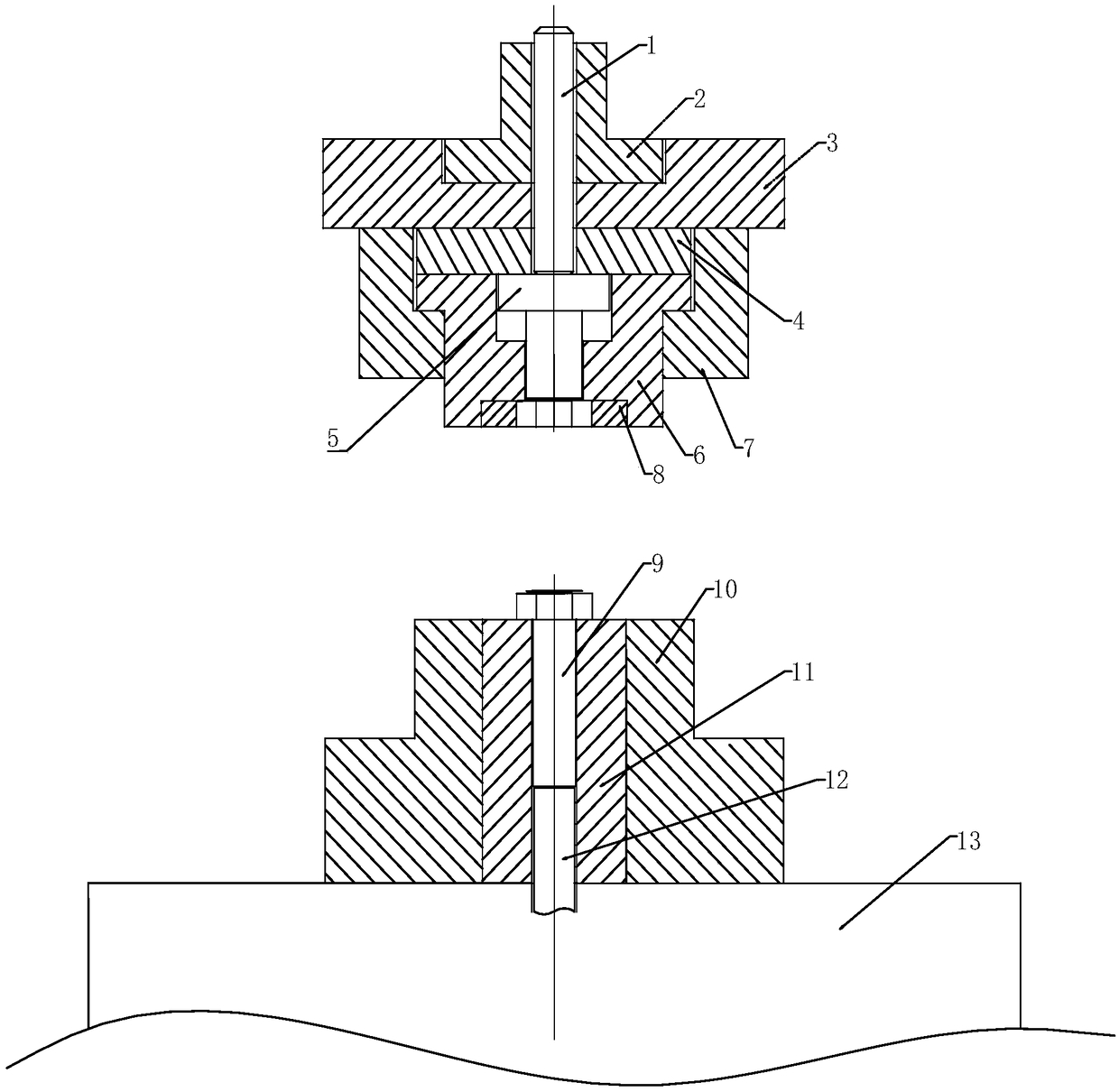

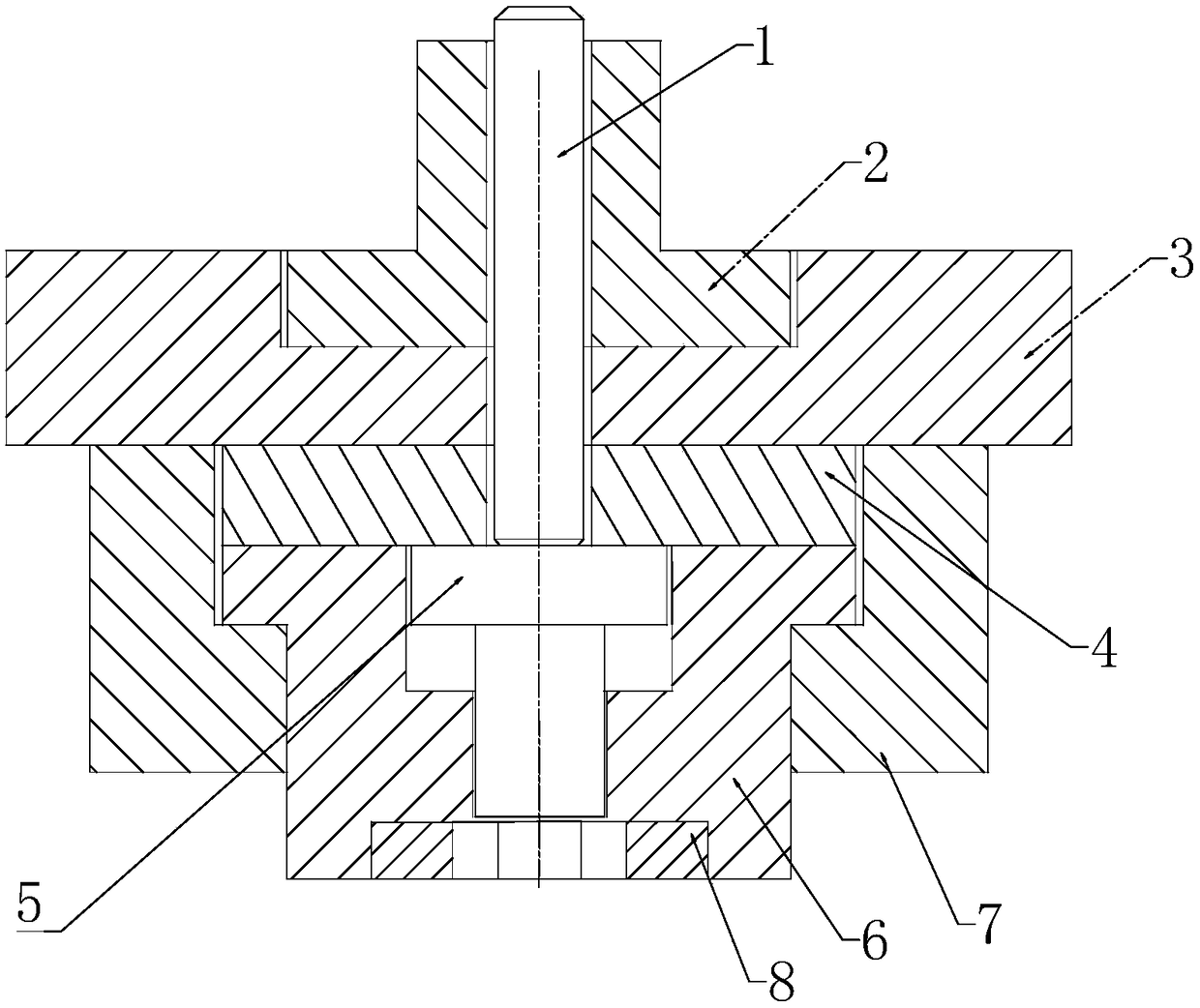

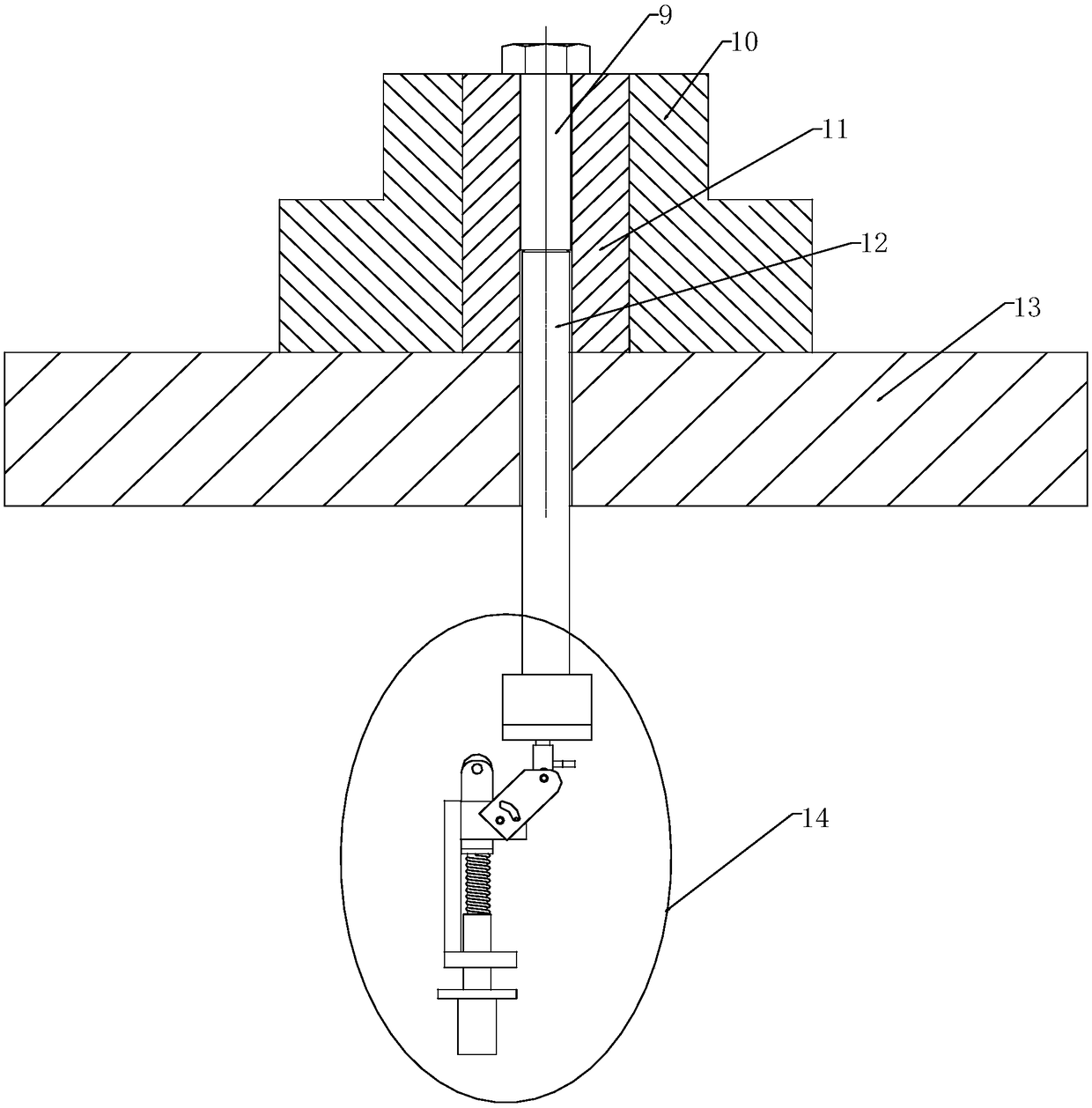

[0025] see Figure 1-Figure 4 , a hexagonal head bolt hot pier forming die, including an upper mold and a lower mold used in conjunction with each other, the upper mold includes an upper mold base 3, an upper mold handle 2 located above the upper mold base 3 and connected to it, and an upper mold located on the upper mold The forming mold fixing seat 7 below the seat 3 and connected to its lower surface, the forming mold fixing seat 7 is penetrated from top to bottom with a stepped hole with a wide top and a narrow bottom, and a "T" shaped combined forming mold is arranged in the stepped hole 6. The horizontal arm of the "T"-shaped combined forming die 6 is sleeved at the step of the stepped hole, and the vertical arm of the "T"-shaped combined forming die 6 extends out of the lower surface of the forming die holder 7; the "T"-shaped Combinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com