Battery integral installation jig

A fixture and battery technology, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of time-consuming, low work efficiency, and high labor intensity of workers, so as to reduce labor intensity of workers, save time, and improve clamping effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention provides a battery assembly fixture, which includes a bottom plate, a movable frame composed of several splints and a clamping mechanism capable of generating side sliding force on the splints to tighten the movable frame. , The movable frame is equipped with an automatic reset mechanism acting on the splint to generate a repulsive force opposite to the side sliding force of the clamping mechanism to restore the movable frame to its natural state.

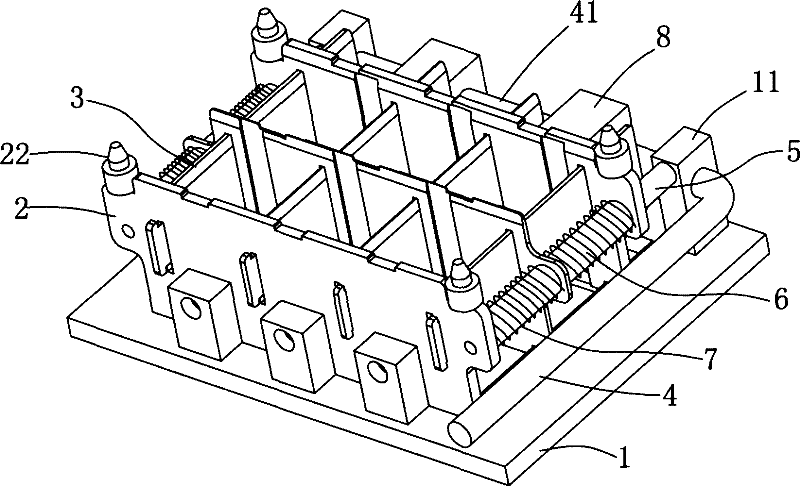

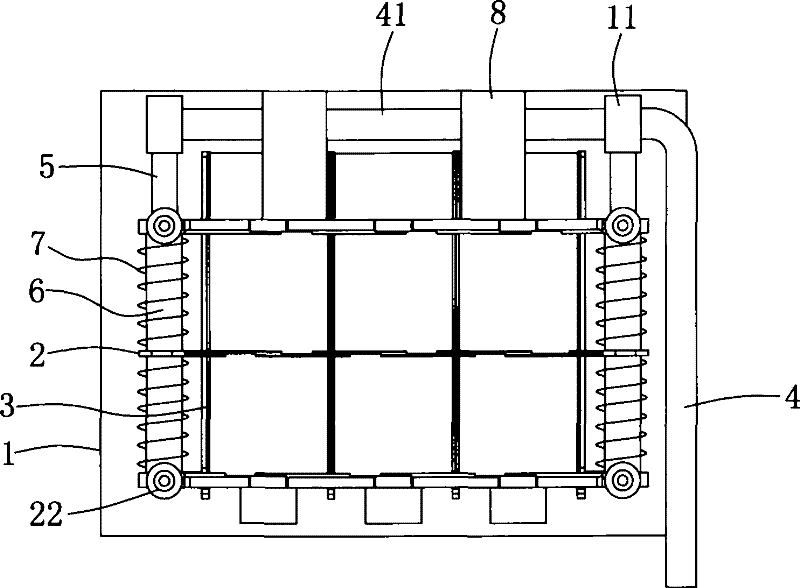

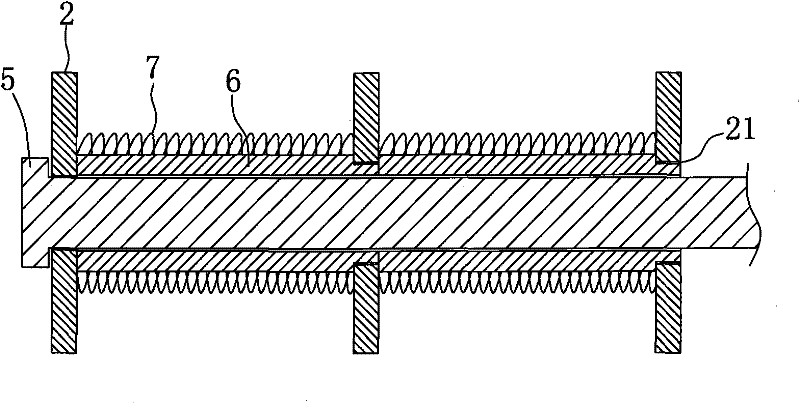

[0016] Such as figure 1 , figure 2 Shown is a preferred embodiment of the present invention, a battery assembly jig, including a bottom plate 1, a movable frame is provided on the bottom plate 1, and the movable frame is composed of four fixed splints 3 and three movable splints 2 , the movable splint 2 is slidably arranged on the fixed splint 3 and arranged alternately with the fixed splint 3 to form a well-shaped structure, and forms six cavities capable of accommodating battery cells. combine figure 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com