Radial-flow steam turbine

A steam turbine and radial flow technology, applied in the field of steam turbines, can solve the problems of low operation safety, stability and reliability, high blade processing requirements, long processing cycle, etc., to achieve safety, stability and reliability, low raw material consumption, high-speed rotation and good rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

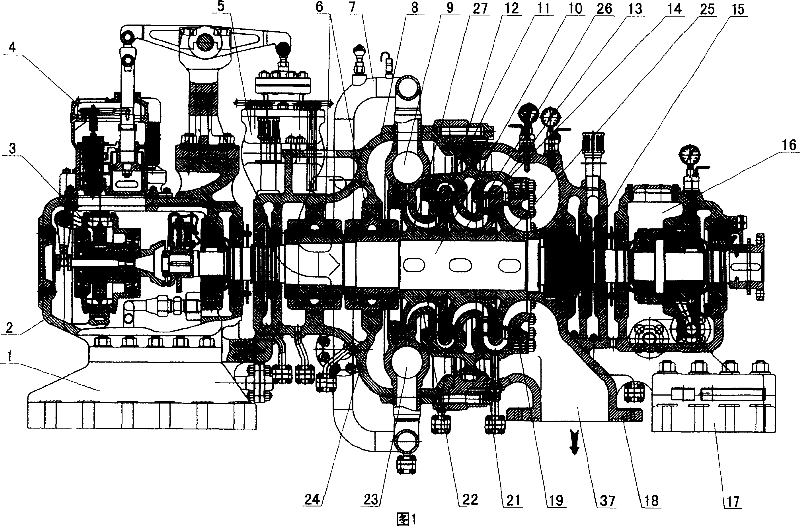

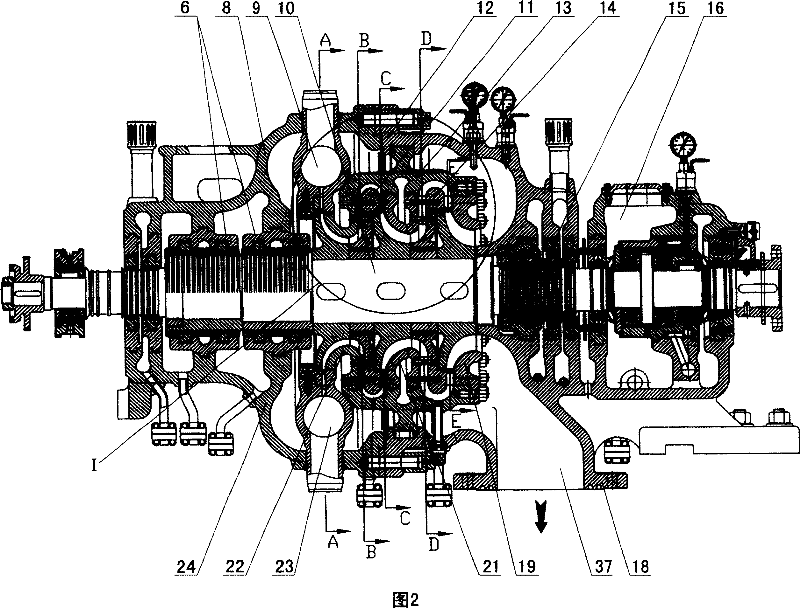

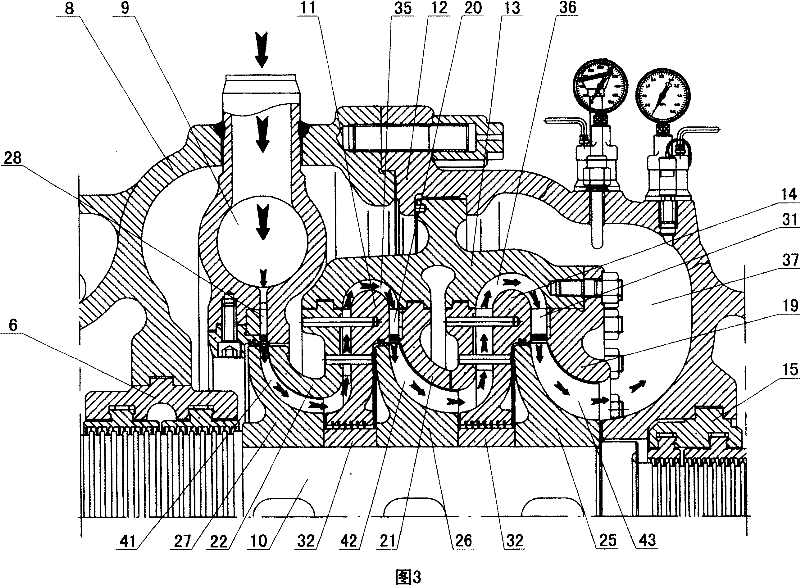

[0039] As shown in Figures 1-17, the radial steam turbine in this preferred embodiment includes a cylinder, a stator and a rotor.

[0040] As shown in Fig. 1-3, the stator and the rotor are arranged in the cylinder, and the complete steam channel formed by the cylinder, the stator and the rotor is provided in the cylinder to make the steam flow directionally, including the steam inlet pipe 7, the steam inlet chamber, centripetal energy conversion channel group, steam flow reversing channel group and exhaust chamber 37, wherein the number of centripetal energy conversion channel groups is 3, which are respectively the first centripetal energy conversion channel group 41, The second centripetal energy conversion flow channel group 42, the third centripetal energy conversion flow channel group 43, the number of steam flow reversing flow channel groups is 2, respectively the first steam flow reversing flow channel group 35, the second The steam flow reversing flow channel group 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com