Grinding device for steel rail high-speed grinding train

A technology for grinding trains and trolleys, which is applied in tracks, track laying, track maintenance, etc., can solve the problem that the operation efficiency is difficult to adapt to the grinding operation requirements of high-speed and heavy-duty railways, and achieve the effect of efficient grinding operation efficiency and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

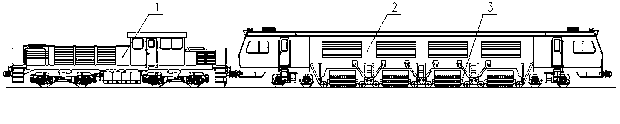

[0019] figure 1 Among them, the high-speed rail grinding train includes a power tractor 1 , a grinding operation vehicle 2 , and a grinding device 3 installed on both sides of the grinding operation vehicle 2 . The grinding device 3 can be used in combination with eight sets, and is symmetrically installed on the left and right sides of the grinding operation vehicle 2 .

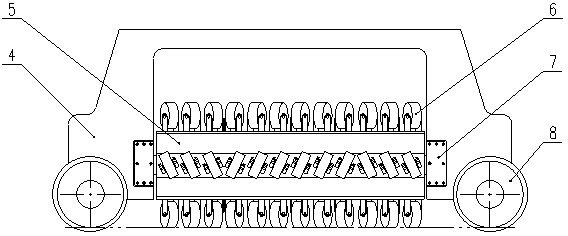

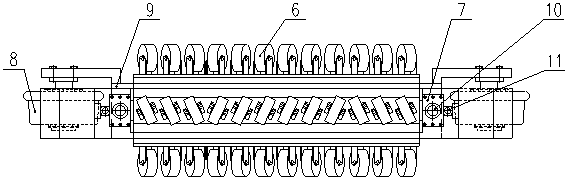

[0020] figure 2 Among them, the grinding device includes a grinding trolley 4 , a turret 5 mounted on the grinding trolley 4 , and a grinding wheel set mounted on the turret 5 . Each group of grinding wheels is a row of 12 grinding wheels 6; the grinding wheels 6 are arranged in groups at a certain angle (30°-150°) inclined to the driving direction of the grinding train; the 12 grinding wheels 6 are divided into three groups, and the middle 6 are ground Grinding wheels are a group, 3 grinding wheels on the left end are a group, and 3 grinding wheels on the right end are a group. The axis lines of the 6 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com