Hydraulic height automatic adjustment device

An automatic adjustment device, hydraulic technology, applied in axle box installation, transportation and packaging, railway car body parts, etc., can solve problems such as small deflection of bogie springs, breakage of couplers, endangering driving safety, etc., to increase transportation Economic benefits, improving the force of wheel and rail parts, and easing the effect of vertical impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

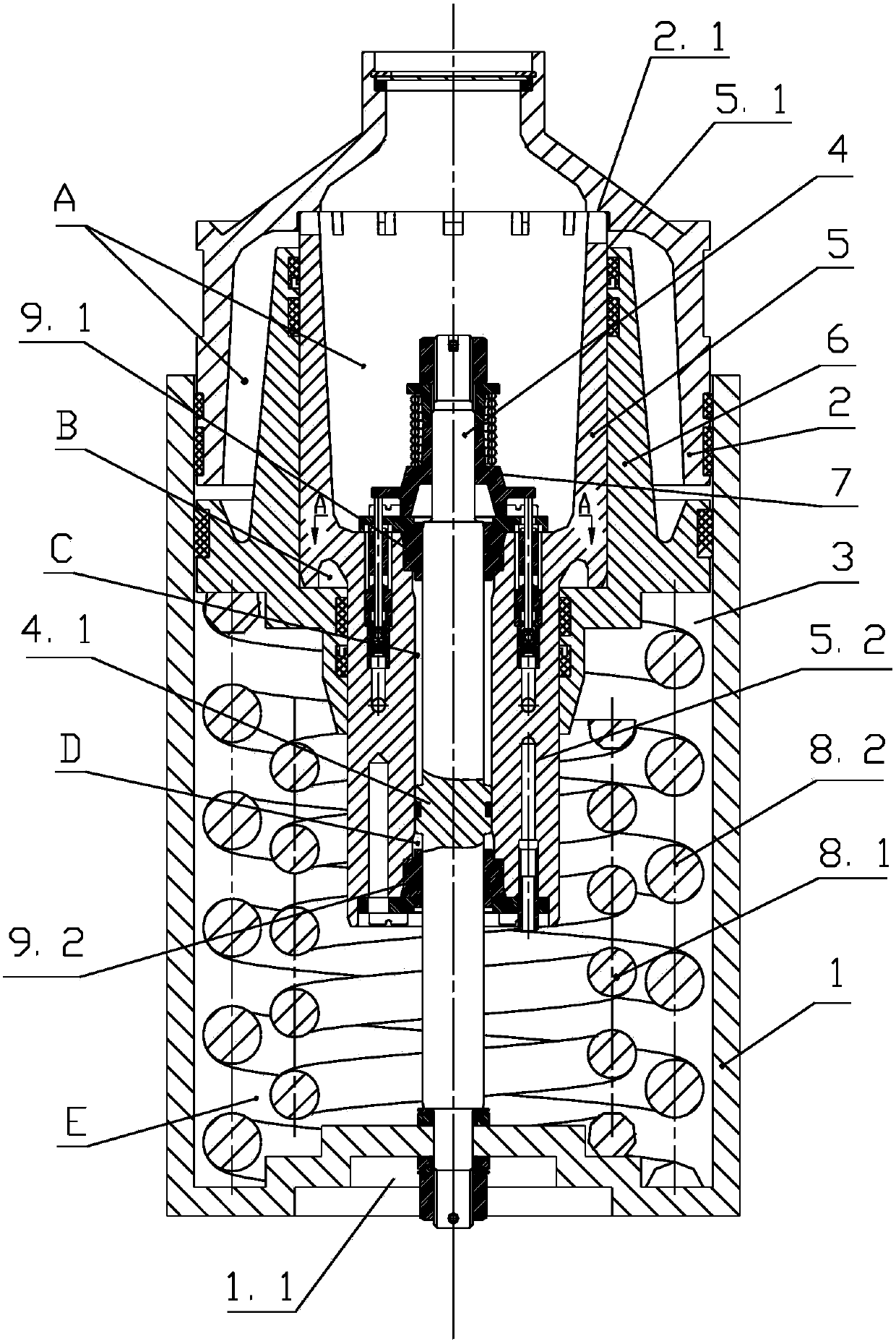

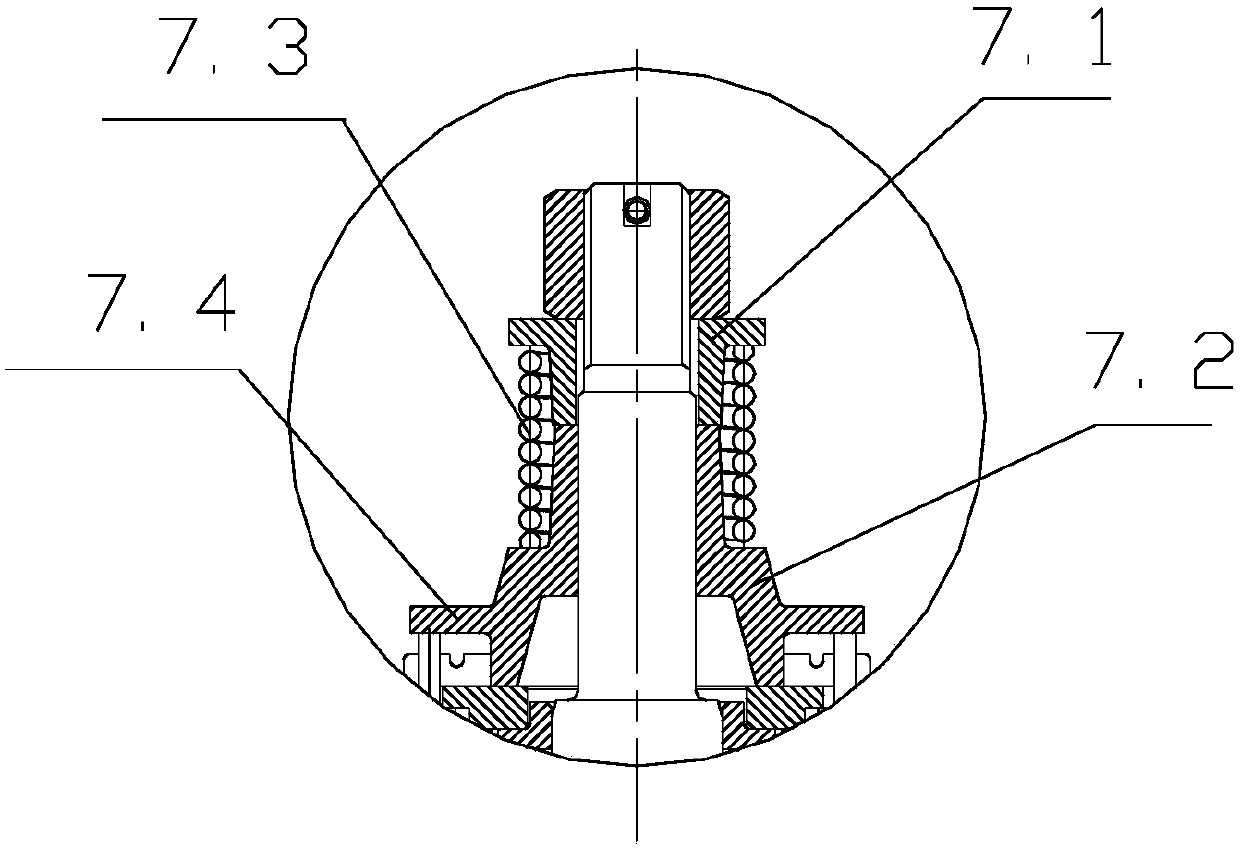

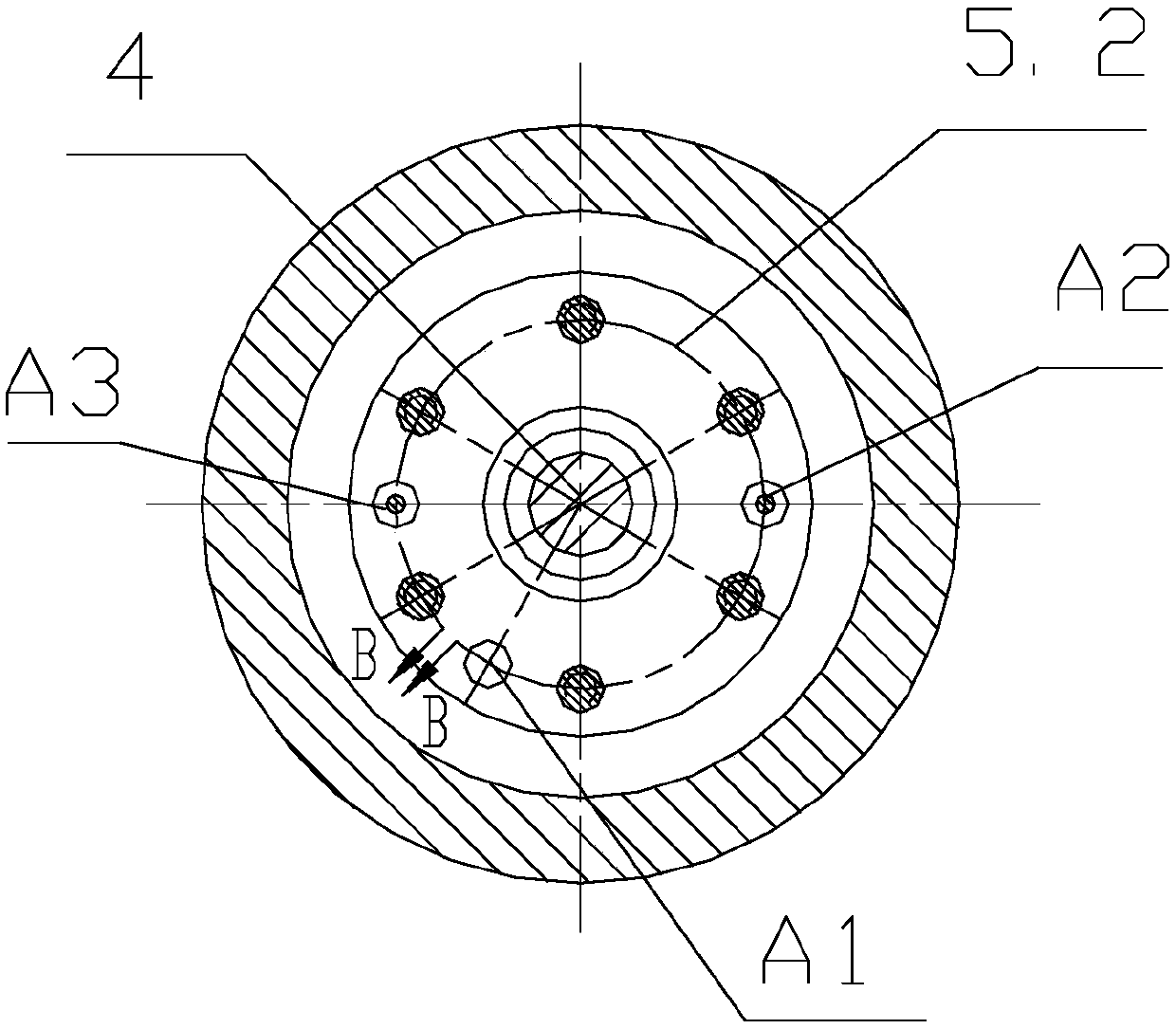

[0045] The hydraulic automatic height adjustment device shown in the figure includes a cylindrical base 1, a hollow structure top cover 2 that is arranged on the top of the base 1 and can slide up and down along its inner wall, the inner wall of the base 1 and the top cover 2 The outer wall fits together to form a sealed accommodation chamber 3; the accommodation chamber 3 is provided with a rod-shaped integral piston 4 vertically arranged with the bottom end surface of the base 1, and the outer periphery of the integral piston 4 is provided with a plunger body 5 that slides and fits with it. The top and bottom of the plunger body 5 are respectively provided with an upper seal cover 9.1 and a lower seal cover 9.2 that match the integral piston 4, the top of the plunger body 5 also extends upwards to form an annular boss 5.1, and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com