Chassis assembly and vehicle body comprising same

A technology of an underframe and a body is applied to the field of the underframe and the vehicle body including the underframe, so as to achieve the effects of improving transportation efficiency, reducing load and reducing self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following describes the implementation of the present invention in detail with reference to the examples, but they do not constitute a limitation of the present invention, but are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand by illustrating the advantages.

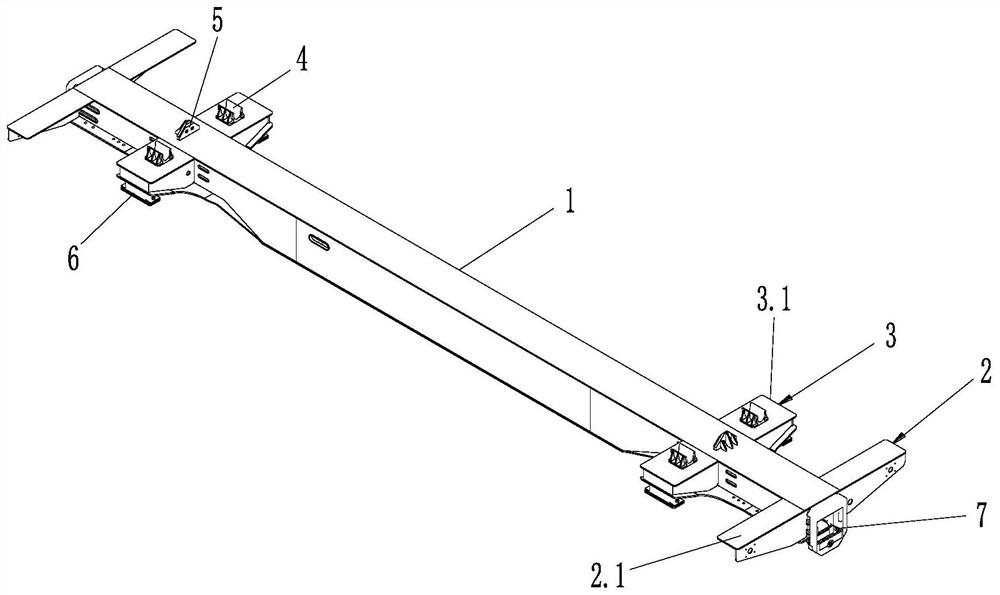

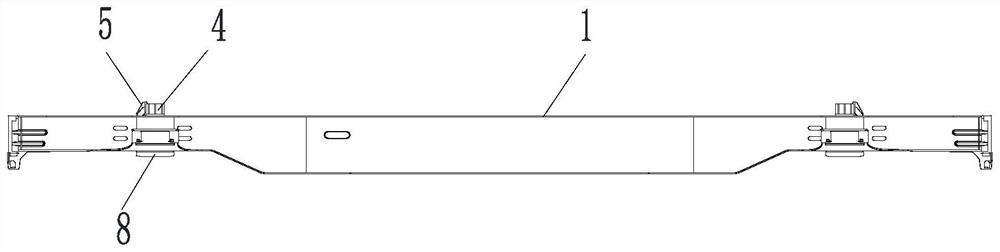

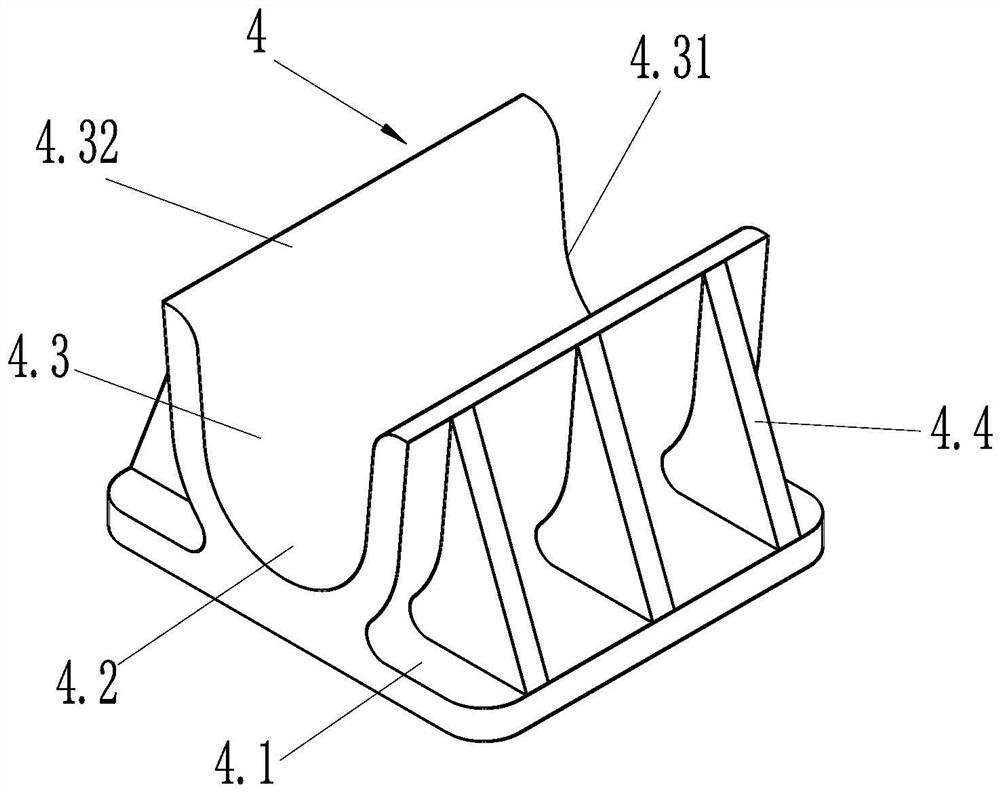

[0035] like figure 1 and figure 2 An underframe composition shown includes a middle beam composition 1, two groups of end beam compositions 2 arranged on both sides of the end of the middle beam composition 1, and two groups of corbels disposed on the middle beam composition 1, a composition 3, and two The group bolster composition 3 is located between the two groups of end beam compositions 2; each group bolster composition 3 includes two bolster bodies 3.1 symmetrically arranged on both sides of the middle beam composition 1, and the top of each bolster body 3.1 is provided with a rotating shaft The mounting seat 4, the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com