High-speed grinding train for rails

A technology for grinding trains and rails, applied in tracks, laying tracks, track maintenance, etc., can solve the problems of inability to achieve full rail surface grinding, unadjustable grinding posture, and deviation of the grinding belt position, so as to eliminate fire hazards and save energy. The effect of manpower and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

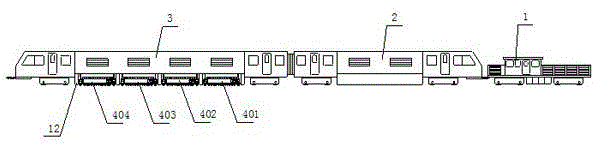

[0033] Such as Figure 1 to Figure 6 As shown, a rail high-speed grinding train includes a power tractor 1 connected in series, a monitoring operation vehicle 2, and a grinding operation vehicle 3 equipped with a grinding device 4. The grinding device 4 can be used in four groups and is installed in the compartment of the grinding operation vehicle 3. 8 bottom. A camera for monitoring the grinding condition is installed on the grinding operation vehicle 3 , and a monitoring display screen is provided on the monitoring operation vehicle 2 . Grinding work vehicle 3 is also provided with emery wheel spare parts warehouse, is provided with hoisting manipulator in emery wheel spare parts warehouse.

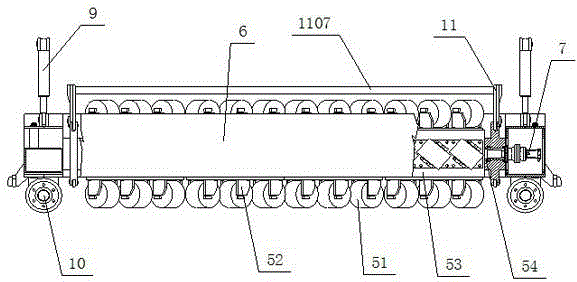

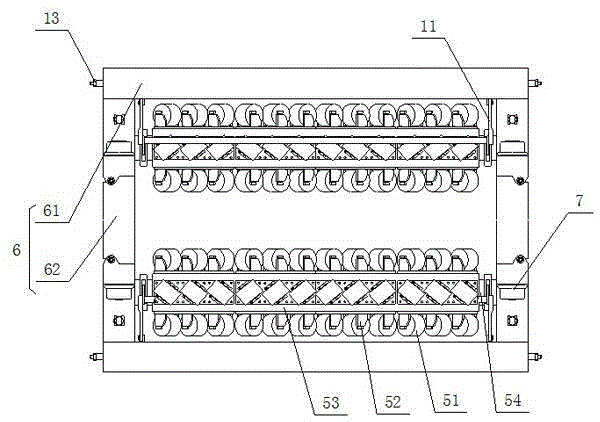

[0034] Such as figure 2 with image 3 As shown, the grinding device 4 includes a grinding assembly 5 and a grinding frame 6. The grinding assembly 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com