Auxiliary support for electric control cabinet installation

A technology for installation assistance and electric control boxes, applied in transportation and packaging, cargo handling equipment, ships, etc., can solve problems such as the difficulty of installing tower accessories and increase the internal space of the tower, so as to improve core competitiveness and reduce tower body space, interchangeability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

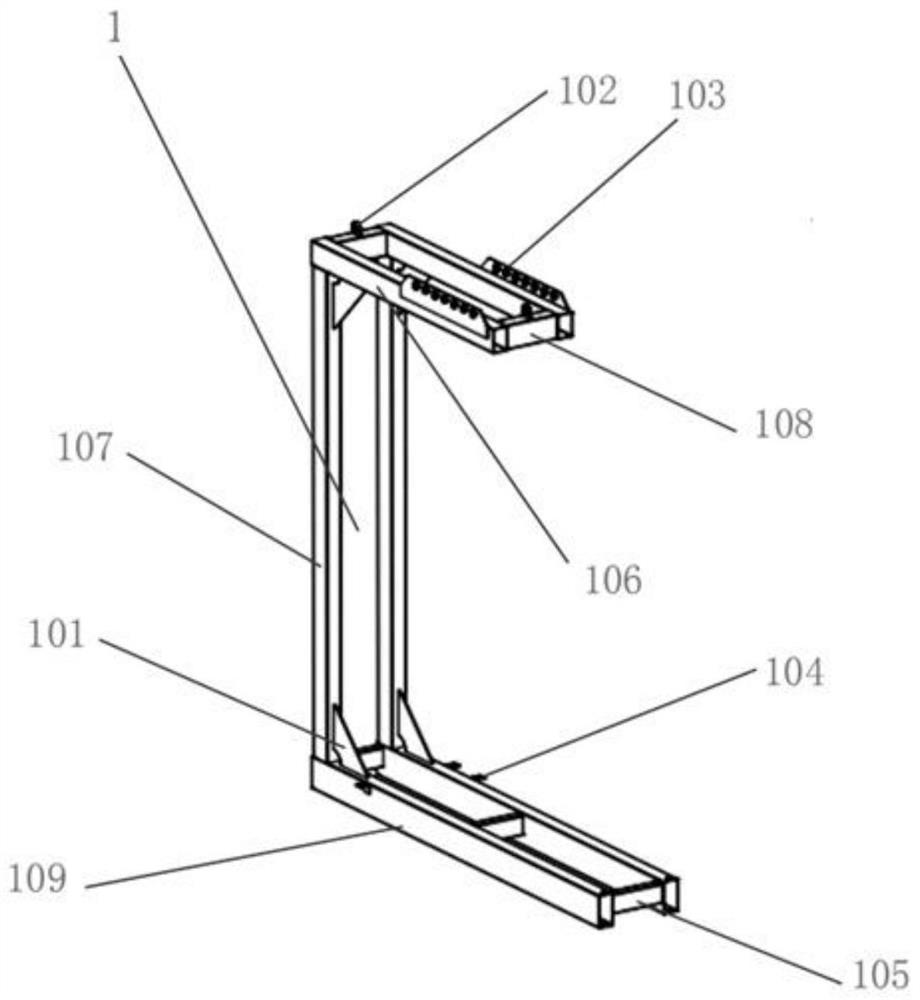

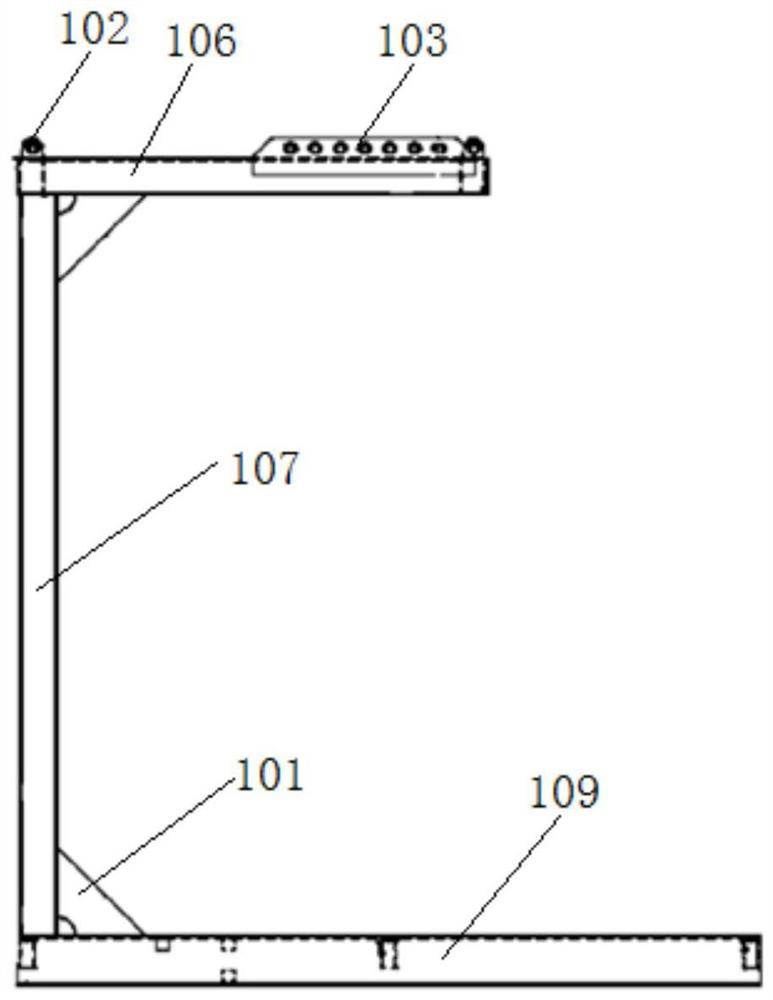

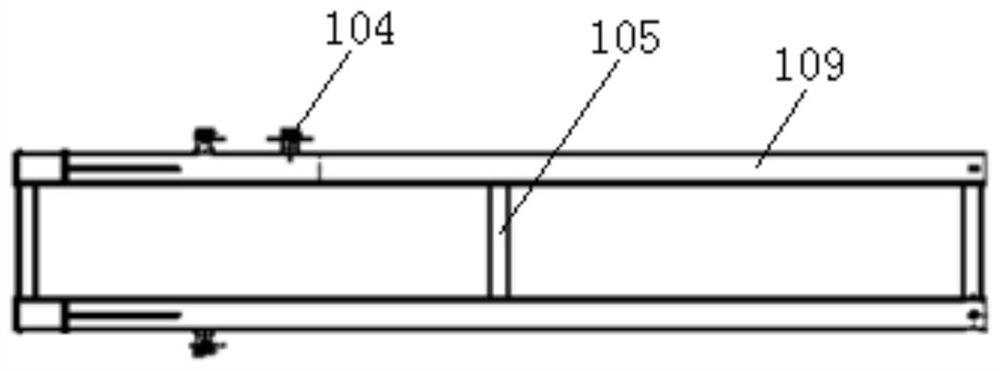

[0035] An auxiliary bracket for installing an electric control box, mainly composed of a lifting mobile bracket 1 and an electric control box fixing bracket cooperating with the lifting mobile bracket 1. Control box lateral support 3.

[0036] Such as Figure 1 to Figure 3 As shown, the lifting mobile support 1 is a first frame structure surrounded by a plurality of rods, a set of lifting holes is set on the top of the first frame structure, and a set of connecting pieces is set on the bottom. Specifically, the first frame structure is composed of a top rectangular frame, a bottom rectangular frame and two columns 107, and the top rectangular frame is welded to the bottom rectangular frame through the two columns 107, resulting in the first frame structure being welded by several small rectangular steel Compared with solid web beams of the same section, it has the advantages of light weight, less consumables, good bending resistance, etc., and has a compact structure and good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com