Full-automatic forming equipment for producing freeze-dried bird's nests

A molding equipment and fully automatic technology, which is applied in food molding, application, cleaning devices, etc., can solve the problems of bird's nest contamination, damage, and increase the labor burden of staff, so as to improve stability, reduce interference, and improve transportation The effect on processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

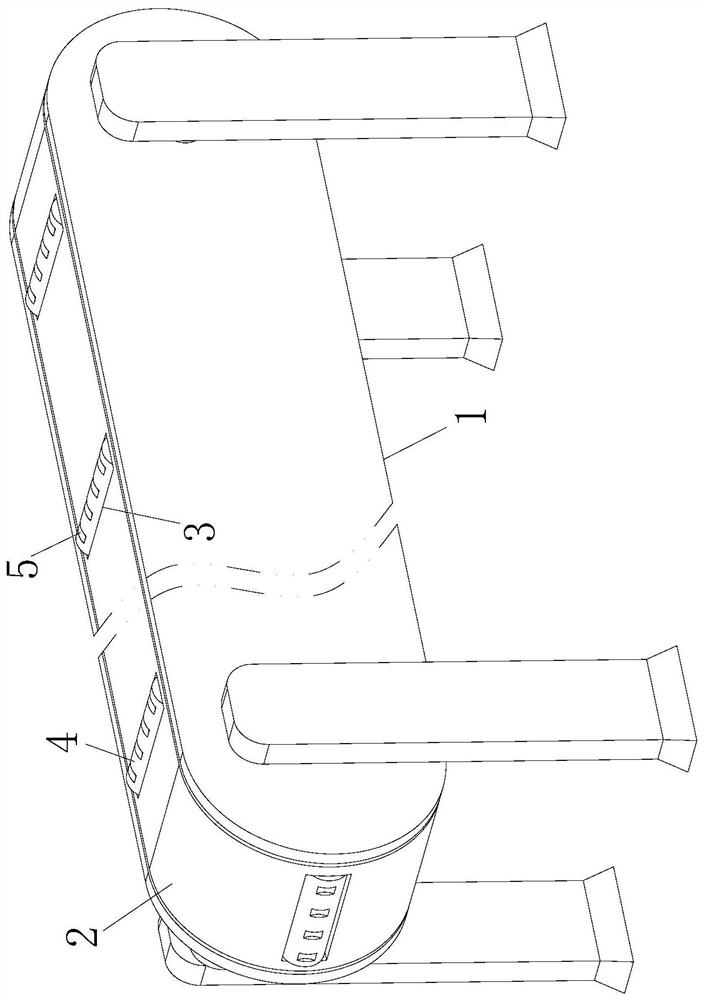

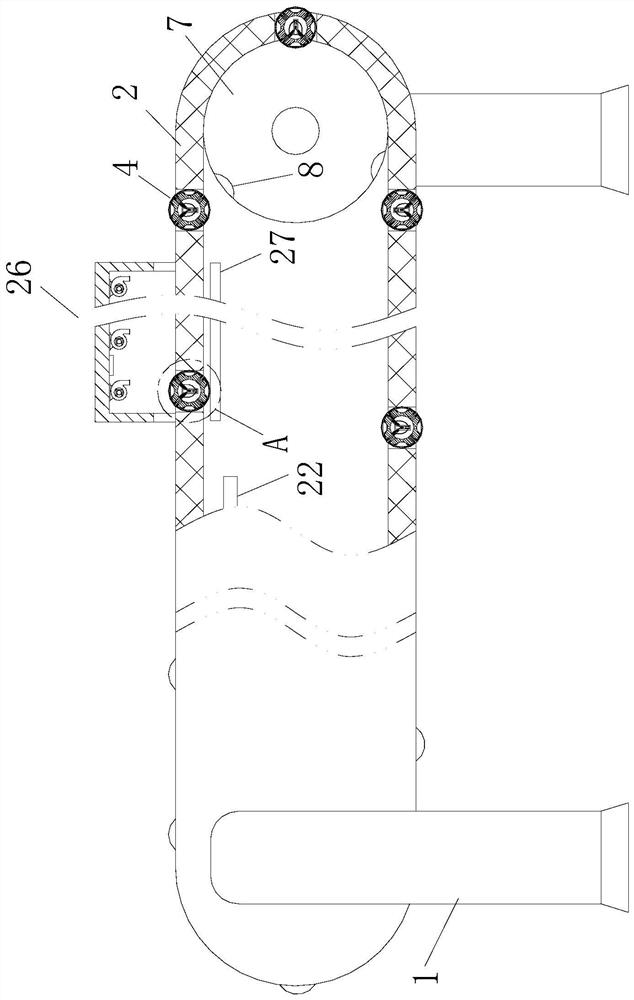

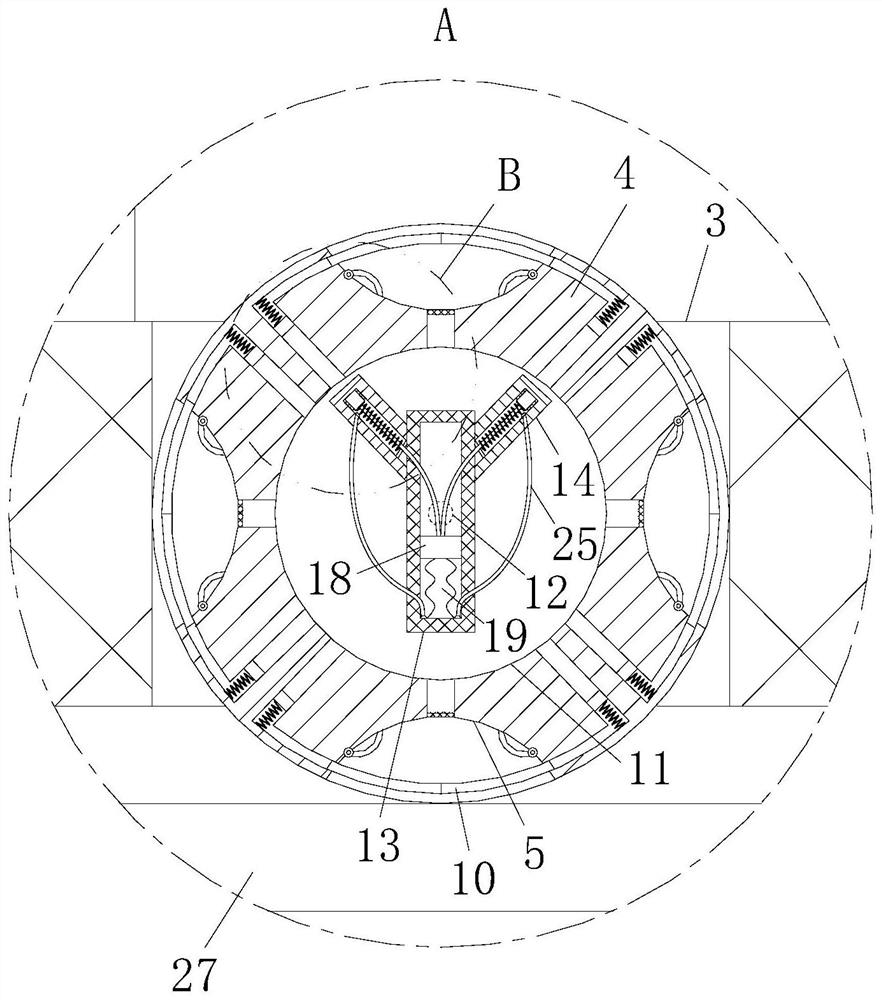

[0032] see Figure 1-4 As shown, a kind of fully automatic molding equipment for freeze-dried bird's nest production according to the present invention includes a workbench 1; a conveyor belt 2 is provided on the workbench 1, and one end of the workbench 1 is provided with a conveyor belt 2 capable of driving The driving assembly of the operation, the inside of the conveyor belt 2 is provided with a number of conveying chambers 3, and the side walls of the conveying chambers 3 are rotatably connected with cylindrical conveying columns 4, and the side walls of the conveying pillars 4 are provided with several along the axial direction. A ring-shaped delivery trough 5 evenly distributed, the inside of the delivery trough 5 is provided with a clamping assembly 6; when the freeze-dried bird's nest in the prior art is produced, when the impurities or feathers inside the bird's nest are manually removed, it is often necessary to remove the The bird’s nest raw materials before and af...

Embodiment 2

[0040] see Figure 5 As shown, the inner wall of the workbench 1 corresponding to the inner end of the conveying cavity 3 is symmetrically connected with a fitting plate 30 matching the shape of the conveying column 4, and the side of the fitting plate 30 close to the conveying column 4 is set as a rough surface; When the bird's nest is manually cleaned of feathers or impurities, the staff presses the conveyor belt 2 so that the conveying column 4 and the rough surface of the bonding plate 30 are extruded and bonded. The rotation of the conveying column 4 is limited to a certain extent, reducing the random shaking of the conveying column 4 when workers clean up impurities in the bird's nest, and improving the stability of the equipment during bird's nest processing.

[0041] A group of clamping blocks 31 are connected to the side wall of the delivery column 4, and a side wall of the bonding plate 30 close to the delivery column 4 is provided with a draw-in groove 32 matched wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com