Sintering molding process of electromagnetic coil of electrical equipment

A technology of sintering and forming electromagnetic coils, which is applied in the direction of coils, coil manufacturing, transformer/inductor coils/windings/connections, etc. It can solve problems such as increasing the size of winding or coil structures, increasing the thickness of insulating materials, and prolonging the production cycle. Achieve the effects of reducing the overall size, improving the electrical strength of the insulation, and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

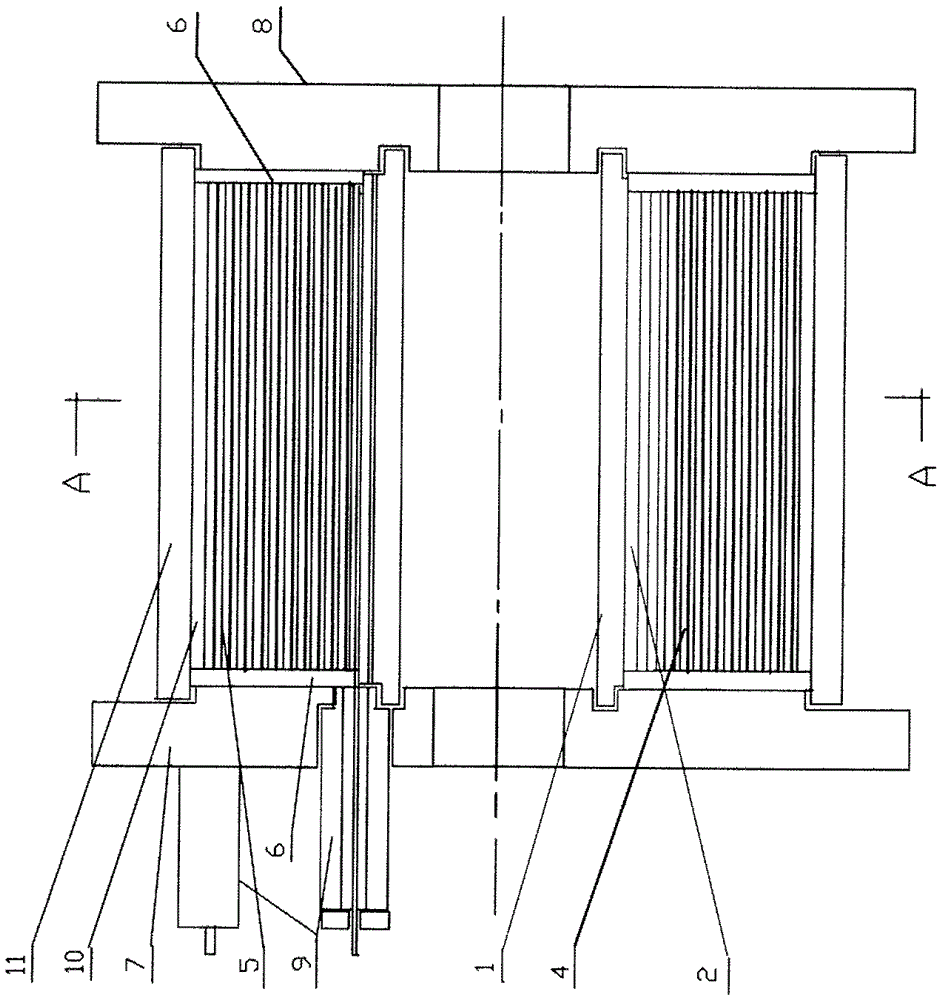

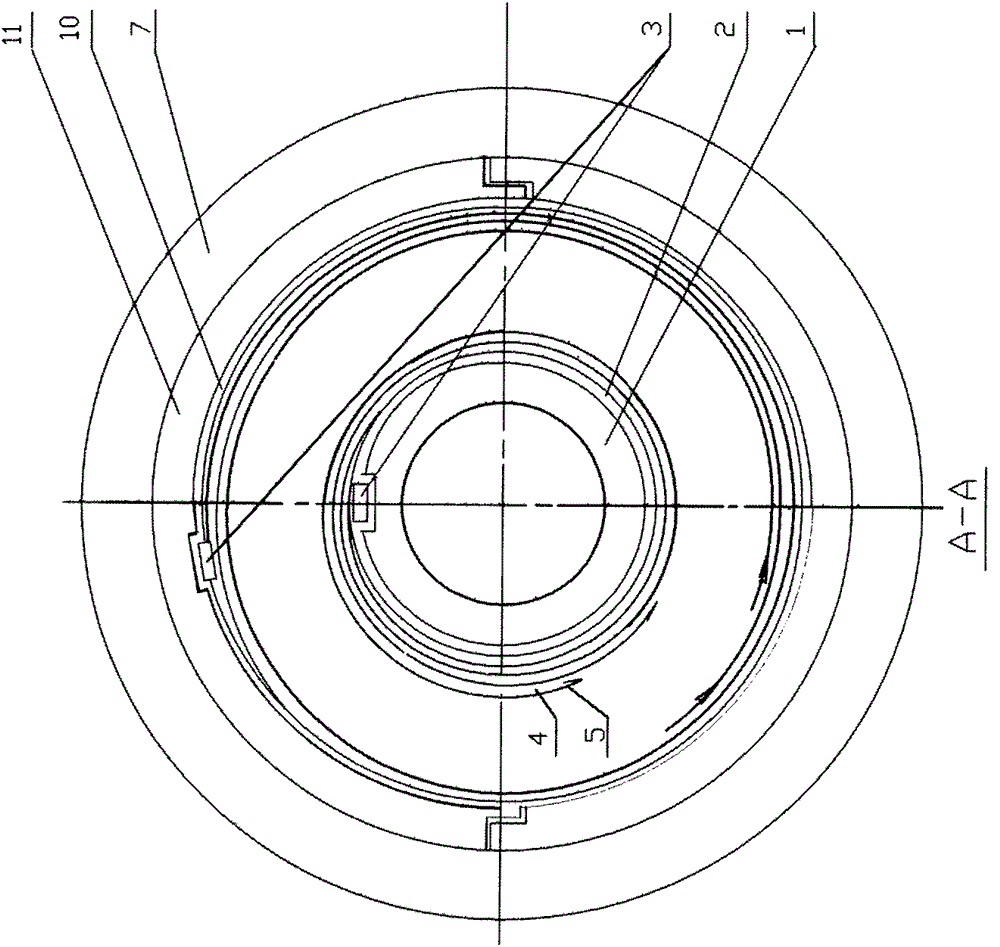

[0033] Prepare a capacitive additional winding for a single-phase compliant isolation transformer. The conductor is two layers of aluminum foil with a thickness of 0.03mm and a width of 400mm. The interlayer insulation is 2 * 0.025mm thick and 420mm wide polypropylene film. The end seal insulation is 1 * 0.03mm thick and 10mm wide polypropylene film tape. The lead wire is 0.03*20mm copper strip, the total thickness of the inner and outer main insulation layers is 1mm, the total thickness of the winding is 30mm, and the outer diameter is 350mm.

[0034] First, the upper end cap 8, the lower end cap 9 and the mold core 1 of the metal mold are fixed on the winding shaft of the wrapping machine, and the inner main insulating layer 2 and the outer metal conductor 4 of the welding lead 3 are wound on the metal mold core 1 , interlayer insulation layer 5, end seal insulation layer 6 and outer main insulation layer 7, adopt traditional winding or coil winding procedures and methods, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com