Porous inner gusset plate of supporting ring of converter

A converter support ring and porous technology, applied in the field of iron and steel industry, can solve the problems of converter support ring cracking, poor cooling of the support ring, large thermal stress, etc., and achieve the effects of increasing the cooling area, reducing the cooling conditions, and improving the cooling conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

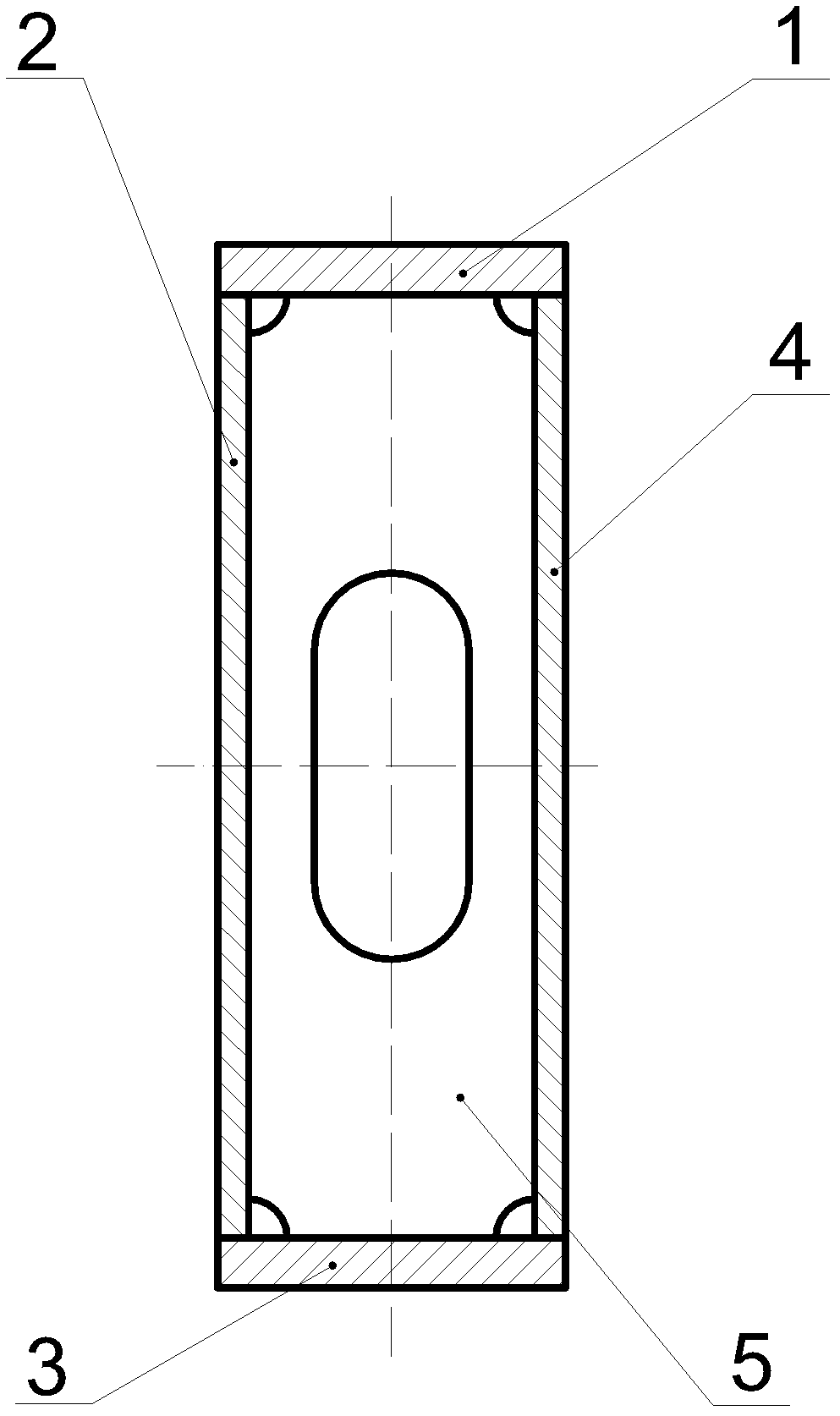

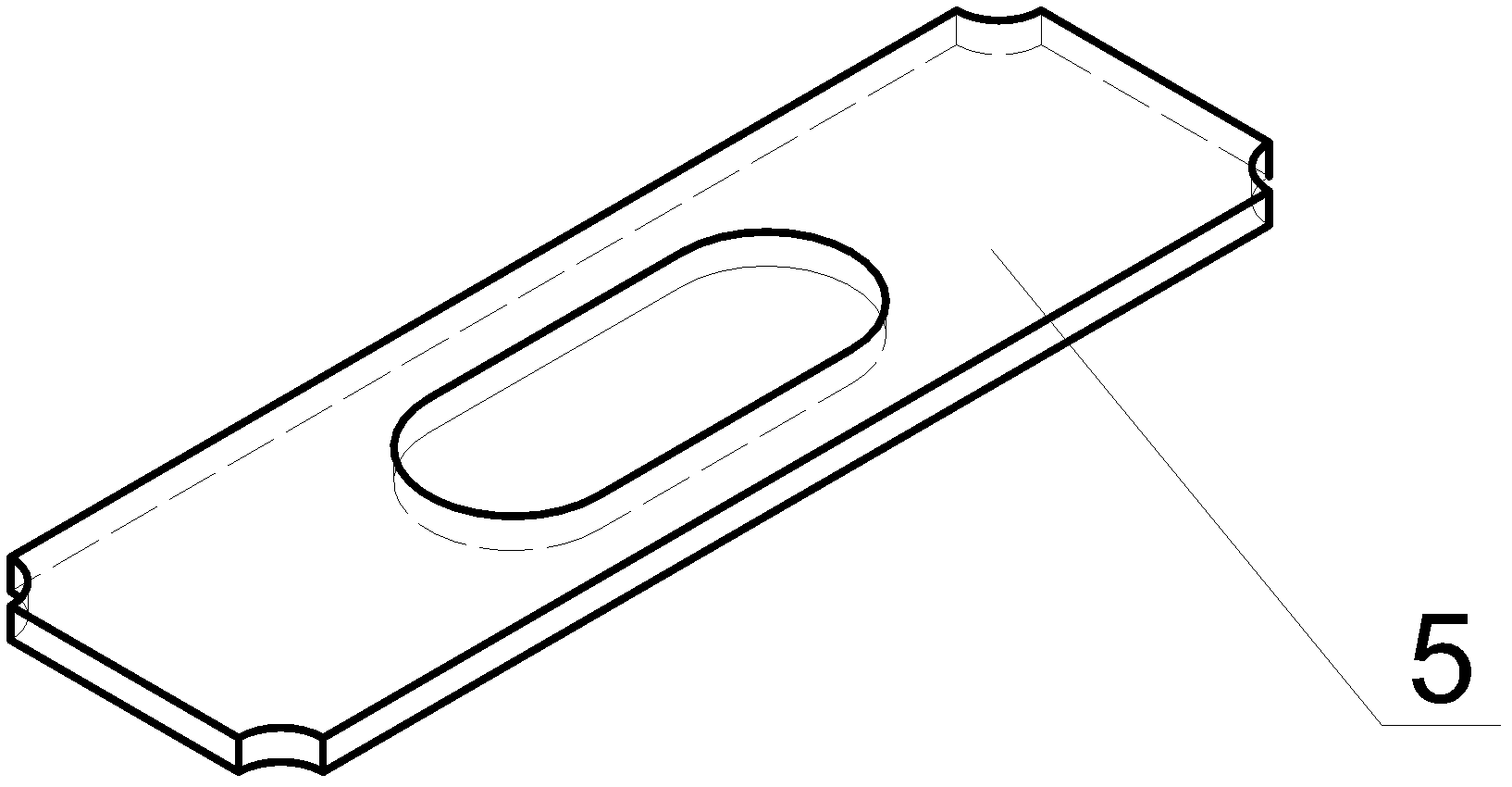

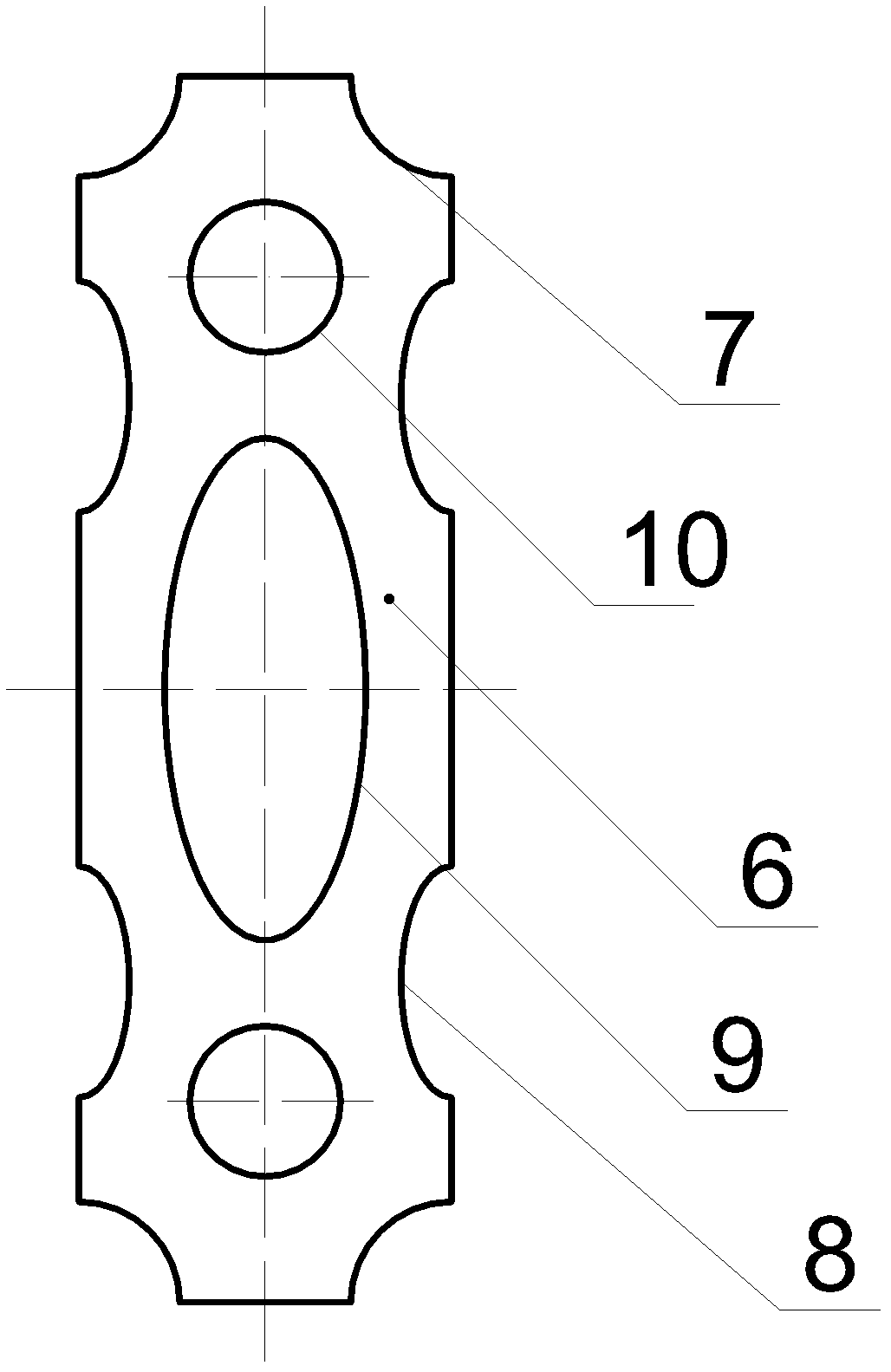

[0022] For a better understanding of the present invention, below in conjunction with the attached Figure 3-5 And embodiment the present invention is described further.

[0023] The inner rib plate 6 of the porous converter support ring is made of a rectangular steel plate, and the four corners of the inner rib plate 6 are symmetrically dug to form 1 / 4 round holes 7 to form four missing corners, and the center of the inner rib plate 6 is provided with a large hole; it is characterized in that: Two semi-elliptical holes 8 are dug symmetrically on the long sides on both sides where the inner rib plate 6 is connected with the inner and outer plates 3 and 4 of the support ring, and the major axes of the semi-elliptical holes 8 on each side are the long sides of each side; the inner rib plate The radius ≥ R160mm of the 1 / 4 circular hole 7 that the four corners of 6 are dug to establish. By enlarging the opening radius of the 1 / 4 circular hole at the four corners of the inner rib ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com