Method for improving proportion of steel slag in blended ore

A technology of mixing ore and steel slag, which is applied in the field of steelmaking, can solve the problems of low utilization rate of steel slag, loss and waste of iron elements, etc., achieve the effect of saving ingredients cost, improving mixing degree, and solving the effect of steel slag accumulation and resource occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

[0017] The steel slag used in the following examples is produced in the steelmaking process of Sichuan Desheng Group Vanadium and Titanium Co., Ltd., the applicant of the present invention, and its specific chemical composition is:

[0018] SiO 2 %

CaO% MgO% Al 2 o 3 %

TiO 2 %

V 2 o 5 %

P 2 0 5 %

Total iron (TFe)% 8-13 37-42 6-7 2-3 1.8-2.5 2.5-4 1.8-2.4 45-52

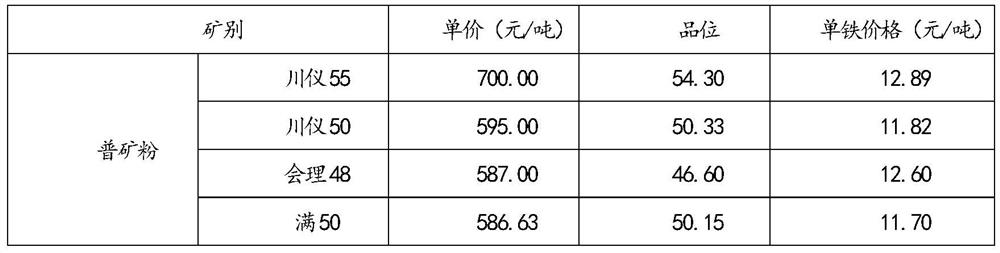

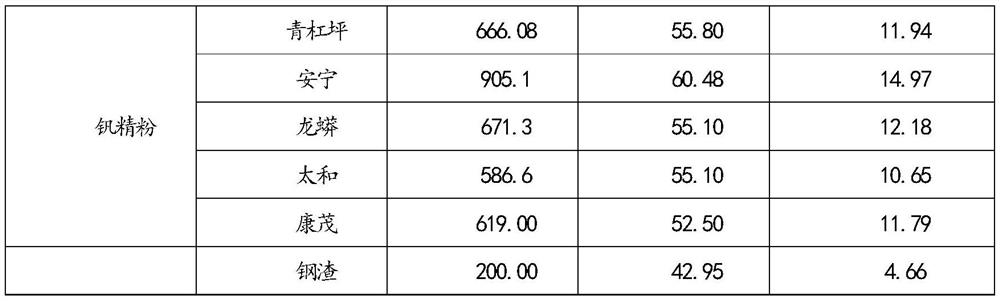

[0019] The ingredients used in the production of mixed ore are shown in the table below:

[0020]

[0021]

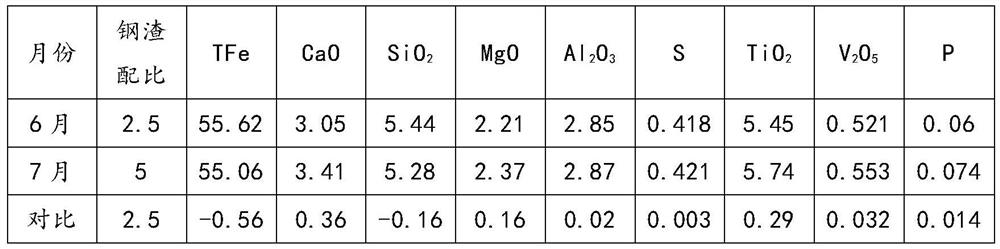

[0022] Theoretically, every 1% increase in the proportion of steel slag can reduce the proportion of ordinary ore powder or vanadium concentrate powder by 1%. Considering the price-performance ratio of single iron, the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com