Soil modifier, and preparation and application method thereof

An application method and modifier technology are applied in the field of preparation and application of soil modifiers, which can solve problems such as shortening construction period and reducing maintenance time, and achieve the effects of shortening construction period, excellent durability and simple construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

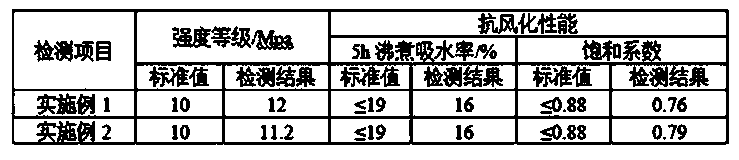

Embodiment 1

[0020] Weigh 10g of acrylamide, 9g of polyvinyl alcohol, 5g of sodium dodecylbenzenesulfonate, 8g of calcium chloride and 68g of water to prepare an aqueous solution.

[0021] Initiator (NH 4 ) 2 S 2 o 8 / NaHSO 3 (0.0015g / 0.0015g), after mixing, immediately mix with 350g of cement and 4550g of crushed soil (removing organic matter such as grass roots), and compact the soil into bricks with an ordinary non-burning brick machine, then 280w microwave radiation for 5min. The soil modified building material is obtained.

Embodiment 2

[0023] Weigh 8g of acrylamide, 8g of polyvinyl alcohol, 4g of sodium dodecylbenzenesulfonate, 10g of calcium chloride and 70g of water to prepare an aqueous solution.

[0024] Initiator (NH 4 ) 2 S 2 o 8 / NaHSO 3 (0.0012g / 0.0012g) was added to the above-mentioned prepared aqueous solution, and immediately mixed with 400g of cement and 4500g of crushed soil (removing organic matter such as grass roots) after mixing, and compacted the soil with an ordinary unburned brick machine. After the bricks were irradiated with 119W microwave for 8 minutes, the soil modified building materials were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com