Waterborne epoxy primer and preparation method thereof

A water-based epoxy and primer technology, applied in the field of coatings, can solve the problems of poor corrosion resistance and weather resistance, high cost of ingredients, poor stability, etc., and achieve the effects of good salt spray resistance, good gloss retention, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

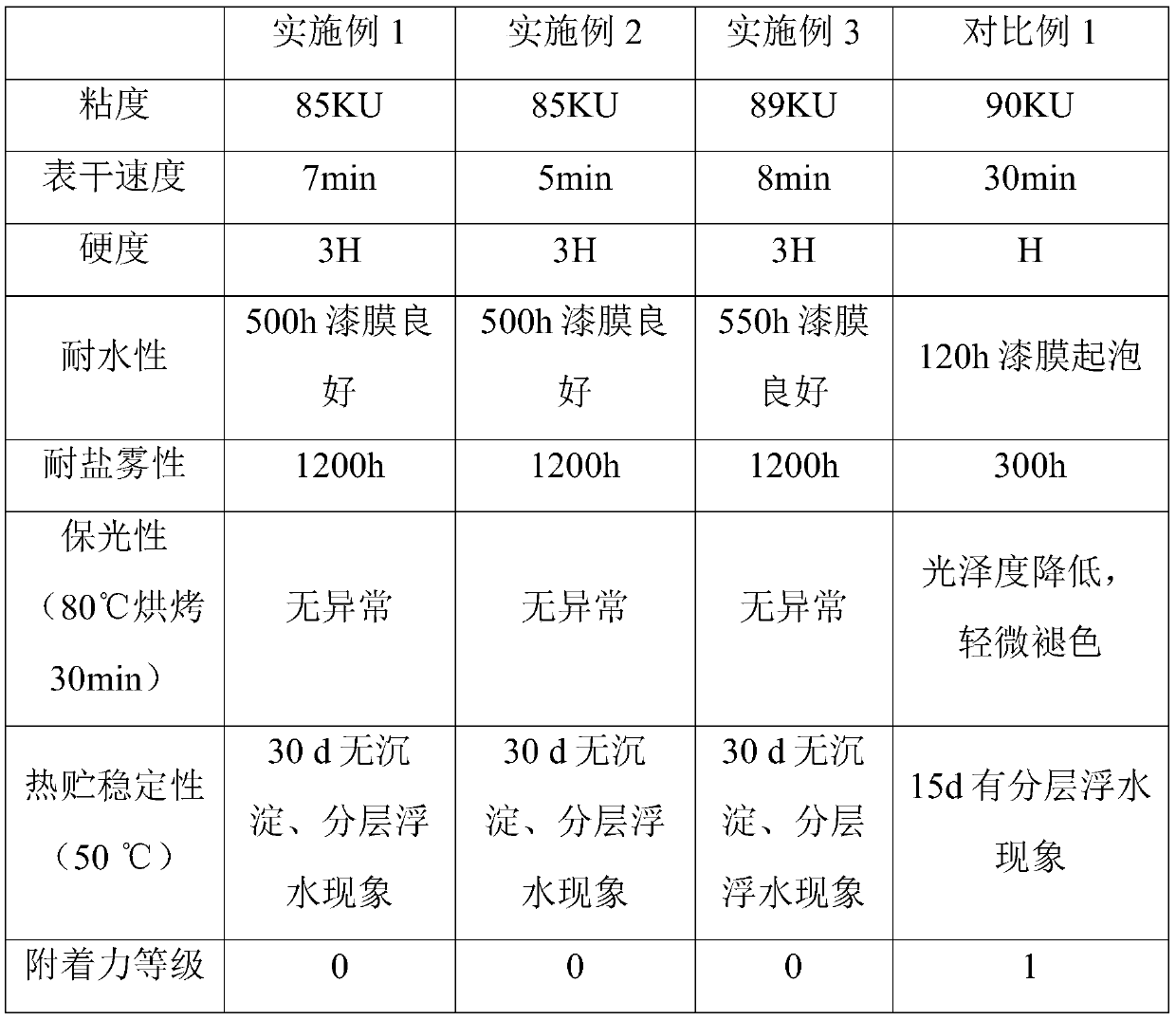

Examples

Embodiment 1

[0028] A water-based epoxy primer, comprising A component and B component;

[0029] A component includes the following components in mass percentage:

[0030] Waterborne Epoxy Emulsion 25%,

[0031] Waterborne Epoxy Acrylic Emulsion 6%,

[0032] Defoamer 0.3%,

[0033] Dispersant 2%,

[0034] Pigment and filler 50%,

[0035] Substrate wetting agent 0.5%,

[0037] Thickener 3%,

[0038] Anti-rust additive 0.1%,

[0039] Anti-settling agent 0.5%,

[0040] Deionized water 9.6%;

[0041] Component B includes components in the following mass percentages:

[0042] Cartley's NX-8101 23%,

[0043] Huntsman's Aradur 3986 37%,

[0044] Deionized water 40%;

[0045] The mass ratio of component A to component B in the waterborne epoxy primer is 6:1.

[0046] Among them, the water-based epoxy emulsion is WG827 from Meiguowang Co., Ltd.; the water-based epoxy acrylic emulsion is GK-HY2509 from Norbert Chemical; the defoamer is BYK-024 from France...

Embodiment 2

[0054] A water-based epoxy primer, comprising A component and B component;

[0055] A component includes the following components in mass percentage:

[0056] Waterborne Epoxy Emulsion 28%,

[0057] Waterborne Epoxy Acrylic Emulsion 5%,

[0058] Defoamer 0.3%,

[0059] Dispersant 2.5%,

[0060] Pigment and filler 53%,

[0061] Substrate wetting agent 0.8%,

[0062] Anti-rust pigment 4%,

[0063] Thickener 2%,

[0064] Anti-rust additive 0.3%,

[0065] Anti-settling agent 0.8%,

[0066] Deionized water 3.3%;

[0067] Component B includes components in the following mass percentages:

[0068] Cartley's NX-8101 30%,

[0069] Huntsman's Aradur 3986 40%,

[0070] 30% deionized water;

[0071] The mass ratio of component A to component B in the waterborne epoxy primer is 5:1.

[0072] Among them, the water-based epoxy emulsion is WG827 from Meiguowang Co., Ltd.; the water-based epoxy acrylic emulsion is GK-HY2509 from Norbert Chemical; the defoamer is BYK-024 from France...

Embodiment 3

[0080] A water-based epoxy primer, comprising A component and B component;

[0081] A component includes the following components in mass percentage:

[0082] Waterborne Epoxy Emulsion 30%,

[0083] Waterborne Epoxy Acrylic Emulsion 4%,

[0084] 0.4% defoamer,

[0085] Dispersant 3%,

[0086] Pigment and filler 55%,

[0087] Substrate wetting agent 1%,

[0088] Anti-rust pigment 2%,

[0089] Thickener 1%,

[0090] Anti-rust additive 0.5%,

[0091] Anti-settling agent 1%,

[0092] Deionized water 2.1%;

[0093] Component B includes components in the following mass percentages:

[0094] Cartley's NX-8101 37%,

[0095] Huntsman's Aradur 3986 43%,

[0096] Deionized water 20%;

[0097] The mass ratio of component A to component B in the waterborne epoxy primer is 4:1.

[0098] Among them, the water-based epoxy emulsion is WG827 from Meiguowang Co., Ltd.; the water-based epoxy acrylic emulsion is GK-HY2509 from Norbert Chemical; the defoamer is BYK-024 from France; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com