Water-borne acrylic-modified alkyd resin emulsion and preparation method thereof

A technology of alkyd resin emulsion and water-based acrylic, applied in coatings, anti-corrosion coatings, etc., can solve the problems of promoting ester bond decomposition and unfavorable resin storage stability, achieve good color retention, overcome poor storage stability, and broaden applications field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with embodiments.

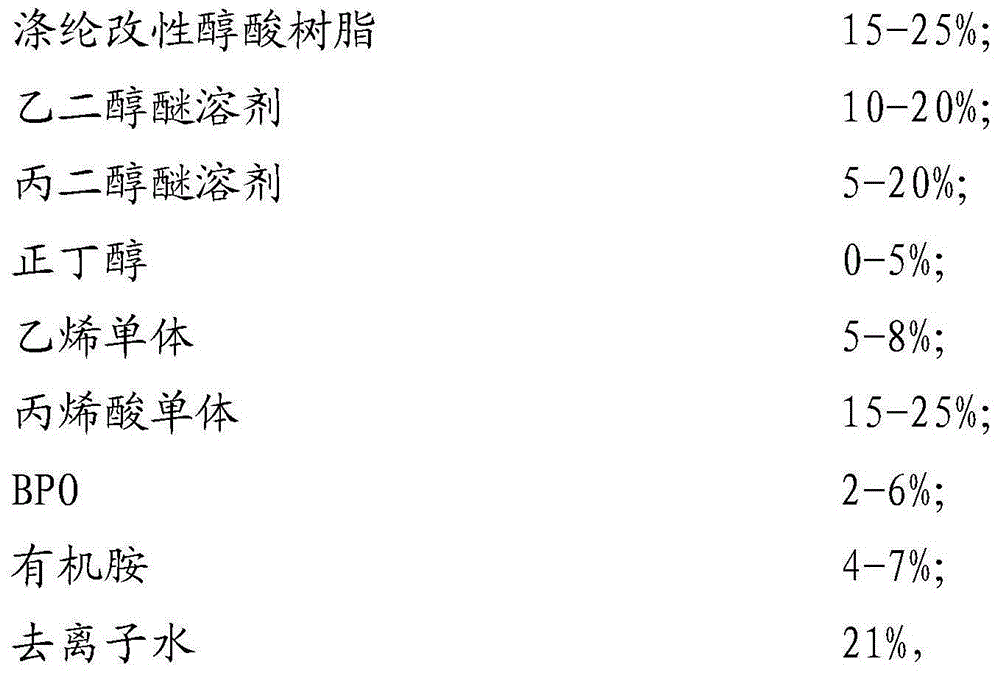

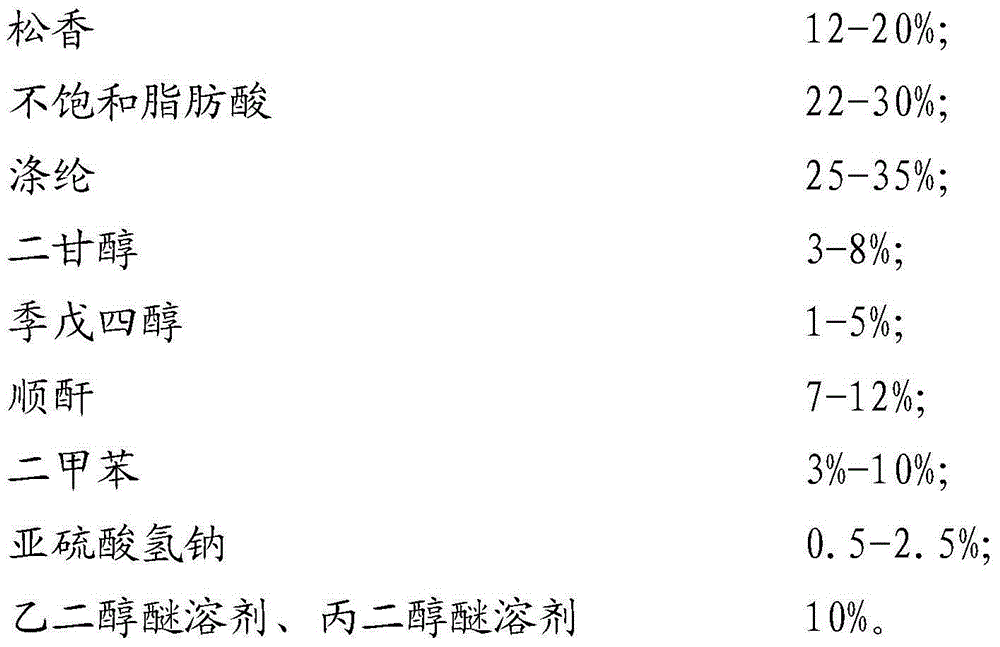

[0030] A water-based acrylic modified alkyd resin emulsion of the present invention comprises the following components according to its weight percentage: 15-25% of polyester modified alkyd resin; 10-20% of ethylene glycol ether solvent; 5-20% of propylene glycol ether solvent %; n-butanol 0-5%; vinyl monomer 5-8%; acrylic acid monomer 15-25%; BPO 2-6%; organic amine 4-7%; The modified alkyd resin comprises the following components according to its weight percentage: 12-20% of rosin; 22-30% of unsaturated fatty acid; 25-35% of polyester; 3-8% of diethylene glycol; 1-5% of pentaerythritol; Anhydride 7-12%; Xylene 3%-10%; Sodium bisulfite 0.5-2.5%; Ethylene glycol ether solvent, propylene glycol ether solvent 10%.

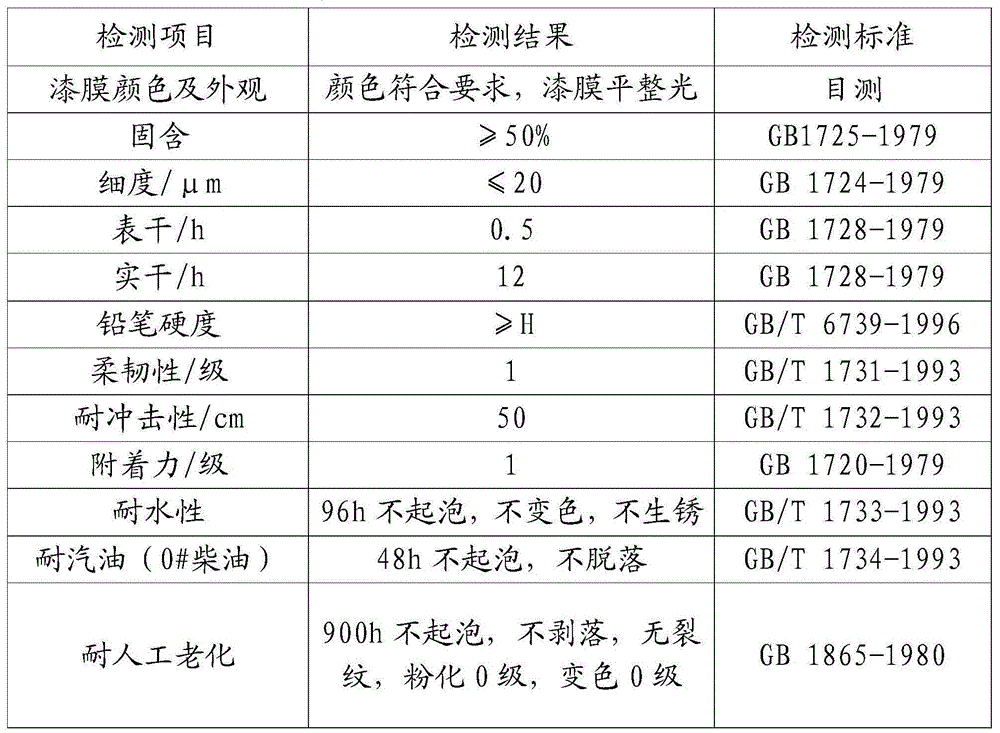

[0031] The coating performance test is as follows:

[0032]

[0033] The water-based acrylic modified alkyd emulsion system improves the air-drying and flexibility of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com