Liquid-cooling liquid homogenizing device and liquid-cooling radiator applying same

A liquid homogenizer and radiator technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., which can solve the problem of affecting the heat dissipation effect of the cooling system, the operation quality of heating elements, and the inability to concentrate and evenly spray heating elements , The liquid working medium is not fully utilized, etc., to achieve the effect of improving heat dissipation, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

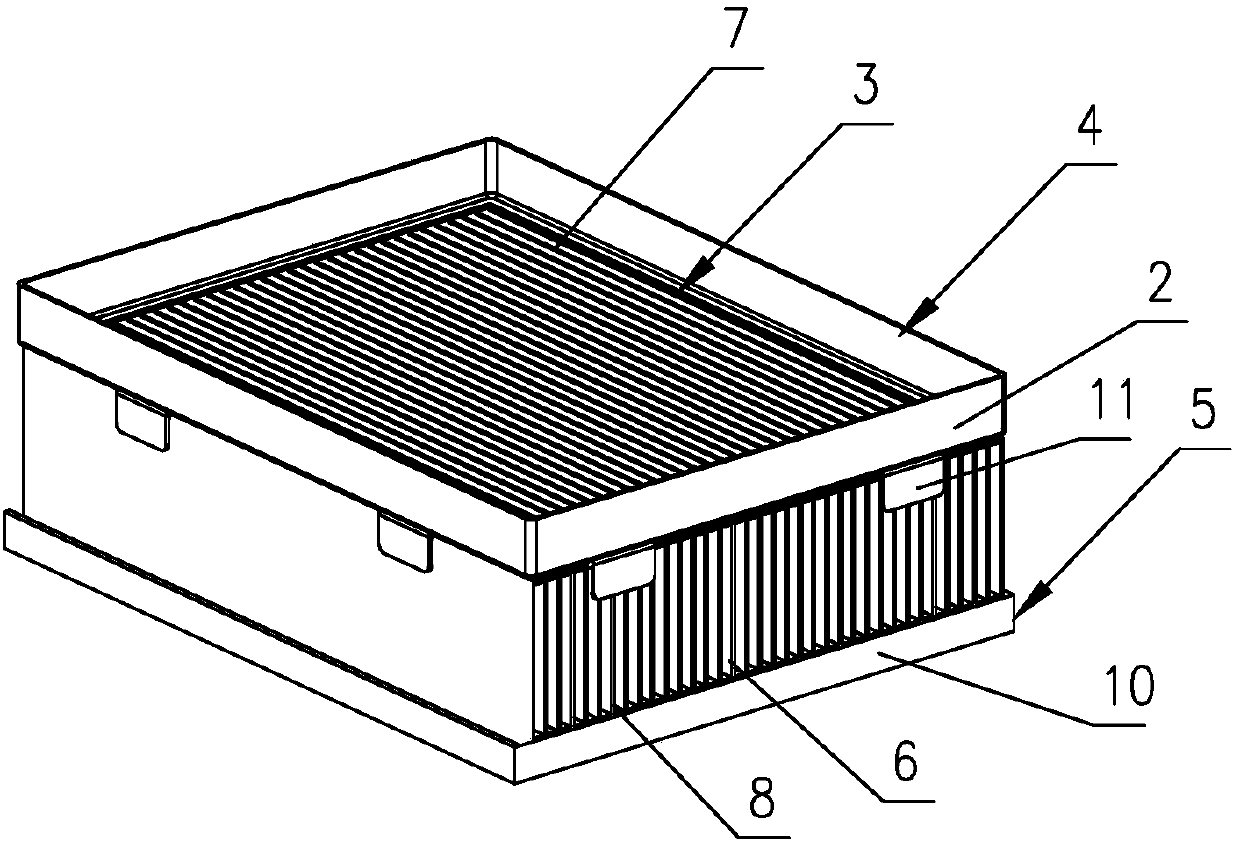

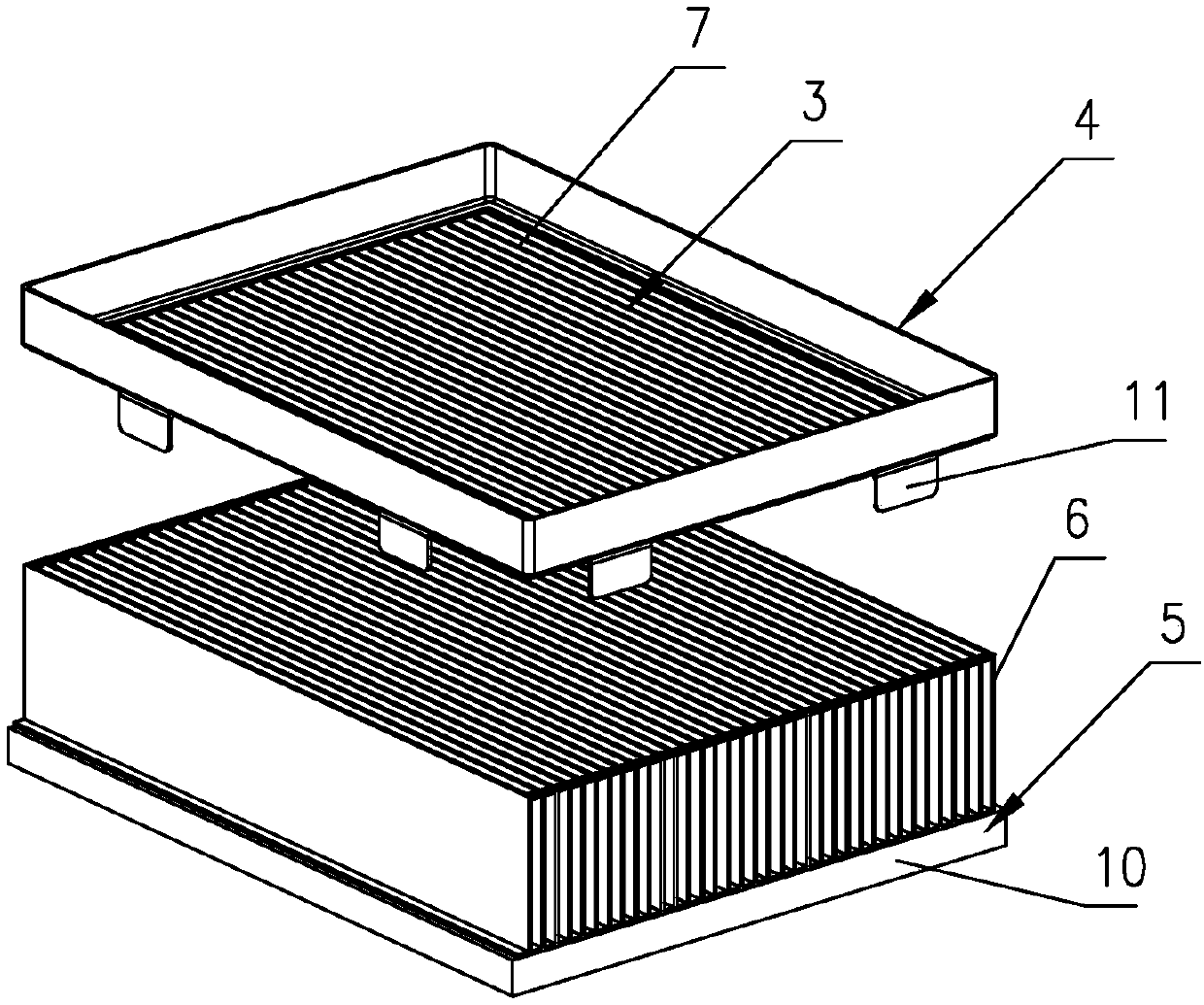

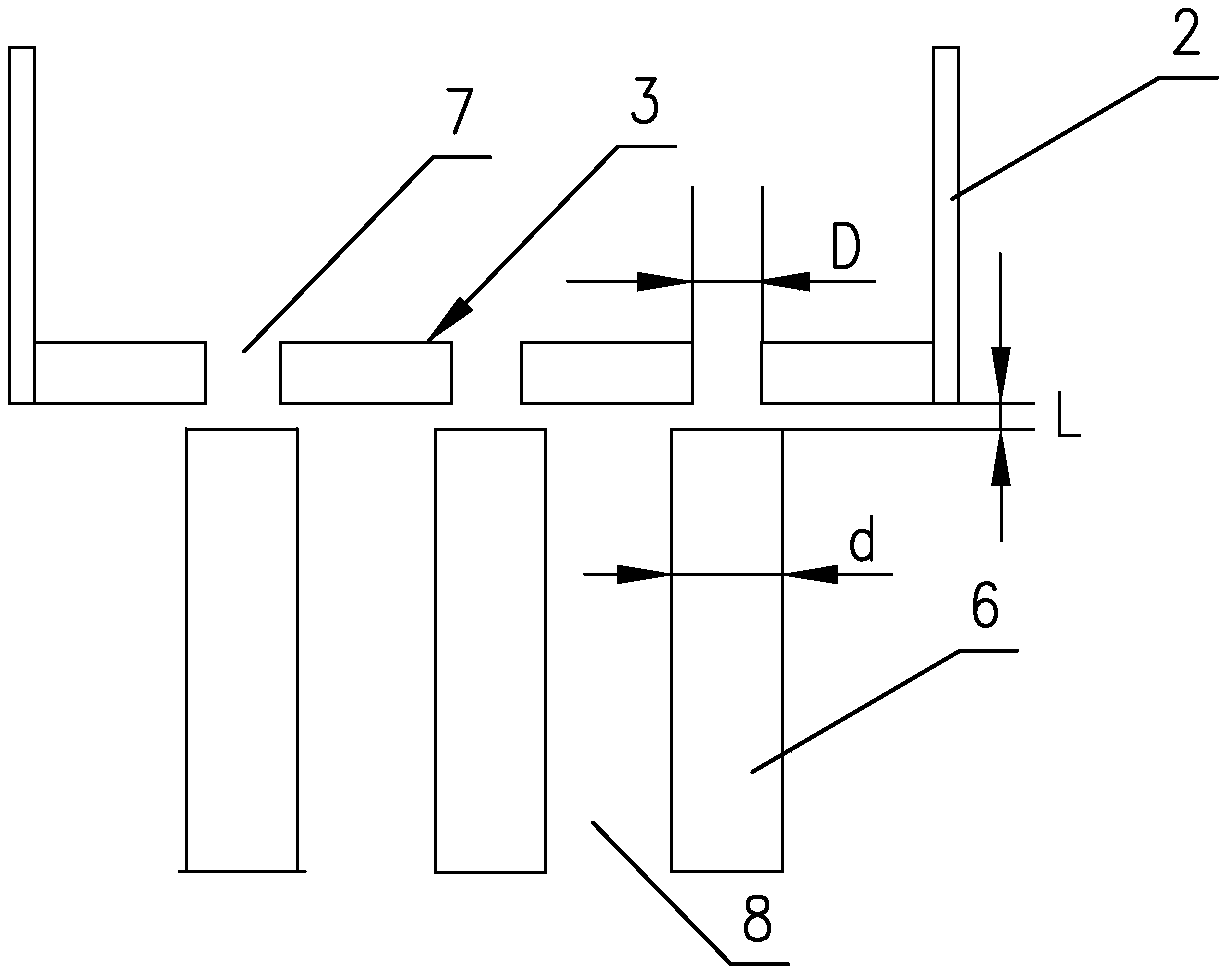

[0028] like Figure 1~4 As shown, it is a liquid-cooled homogenizer 4 of the present invention, which includes an open liquid collection box 2 for collecting liquid cooling working medium 1. The liquid collection box 2 is a rectangular box made of plastic material, and the liquid-cooled homogenizer The device 4 is used to be arranged directly above the heat dissipation fins 6 of the radiator 5 of the heating element, and the liquid collection box 2 is provided with a fixing part for fixing on the radiator 5 of the heating element. The bottom plate of the liquid collection box 2 is used for uniform The capillary homogeneous plate 3 for liquid cooling working fluid 1, the capillary homogeneous plate 3 is sealed and installed at the bottom of the liquid collection box 2, the capillary homogeneous plate 3 is plate-shaped and has a capillary structure with many pores, the capillary homogeneous plate 3 It is a key component of the liquid-cooled homogenizer 4. In this embodiment, th...

Embodiment 2

[0034] like Figure 5 As shown, the difference between this embodiment and embodiment 1 is that the structure of the capillary liquid equalizer is different. In embodiment 1, capillary through holes need to be opened on the capillary liquid equalizer, and it needs to be determined according to the arrangement of the cooling fins. The pore position of the capillary homogeneous plate is relatively complicated to manufacture. In this embodiment, the capillary leveling plate 3 is mainly composed of at least one layer of capillary porous material. When there are more than two layers of capillary porous material, the capillary leveling plate 3 is formed by stacking multiple capillary porous materials in sequence. The pores are the pores of the capillary porous material itself, which can simplify the manufacturing process, and use the block capillary porous material to replace the capillary homogeneous plate with capillary through holes. The thickness of the capillary equalizing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com