Multiphase dielectric layer capacitive pressure sensor with microstructure and preparation method thereof

A pressure sensor and microstructured technology, applied in the field of sensors, can solve the problems of high cost, flexible sensor sensitivity to be improved, sensitivity to be improved, etc., and achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

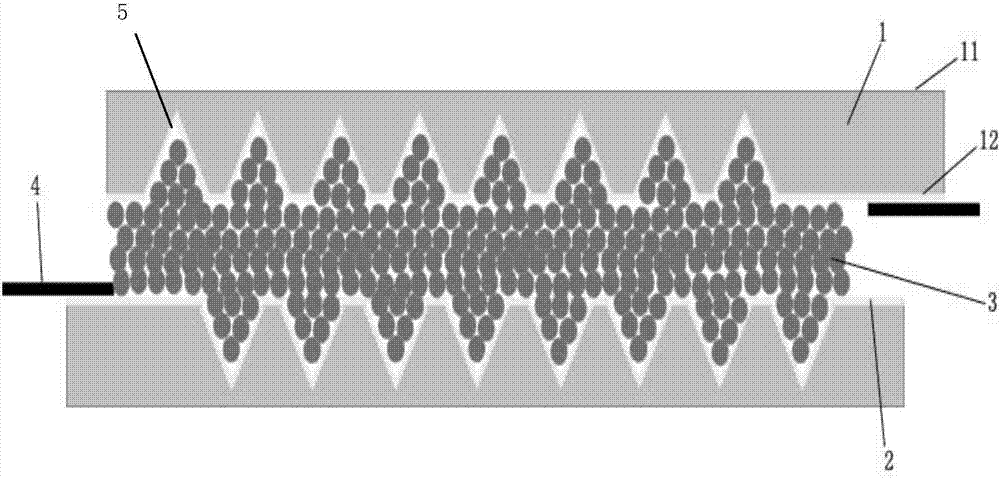

[0065] The structure of a capacitive pressure sensor with a microstructured multi-phase dielectric layer involved in some more specific embodiments of the present invention can be as follows figure 1 As shown, the preparation process may include: providing two flexible substrates with inverted pyramid microstructures, the flexible nano-electrodes are placed on the flexible substrates with inverted pyramid microstructures by thermal evaporation, printing, and spraying. The first surface of the bottom is used to form electrodes, and lead wires are drawn out; at least two flexible electrodes are respectively electrically contacted with the multi-phase dielectric layer, and the at least two flexible electrodes are arranged at intervals; in some more specific embodiments In this method, two flexible substrates covered with an air-microsphere two-phase dielectric layer are stacked face to face to obtain the microstructured multiphase dielectric layer capacitive pressure sensor. The ...

Embodiment 1

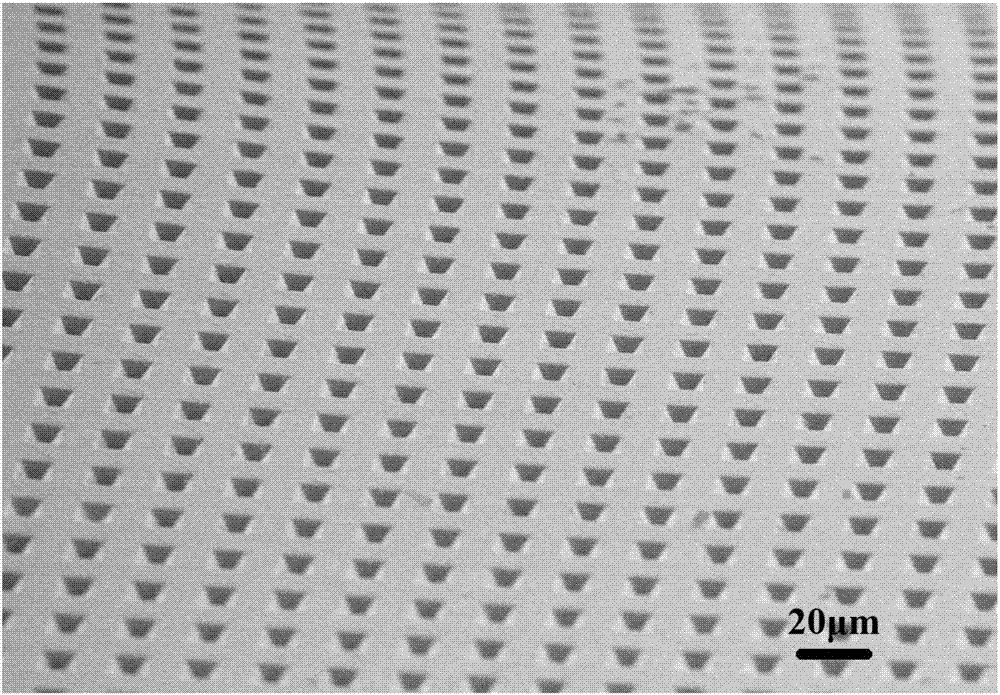

[0081] Weigh 10g of polydimethylsiloxane prepolymer and 1g of cross-linking agent, stir for 20min, remove air bubbles, use silicon wafer as template, spin coat, cure, and reshape to obtain a flexible substrate with an inverted pyramid.

Embodiment 2

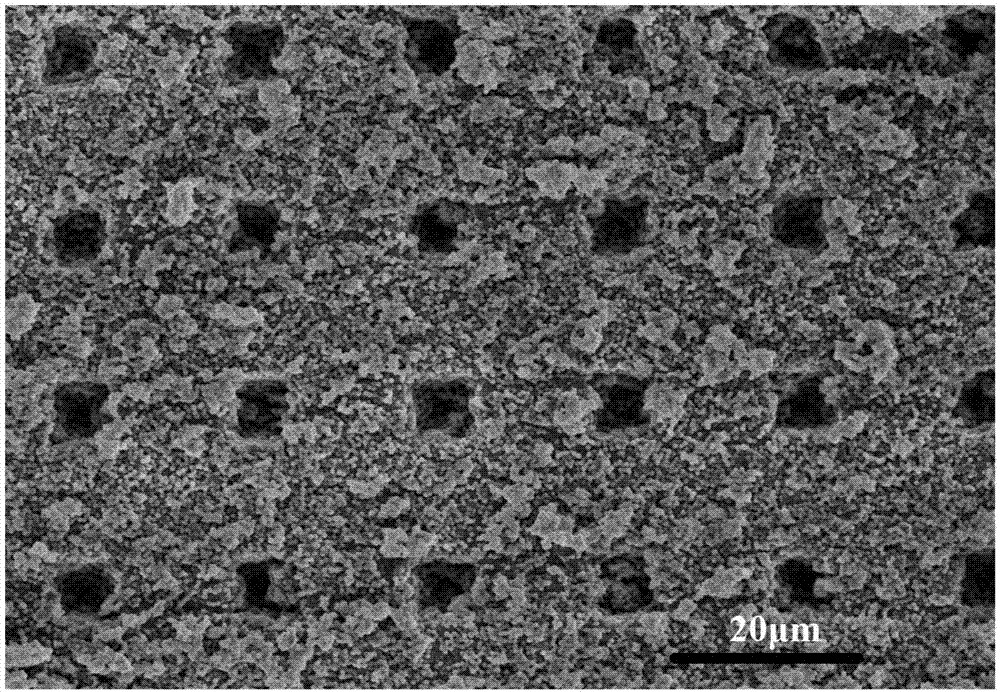

[0083] Spray 0.05g / L SWNTs / DMF solution on the flexible substrate, remove the solvent at 80-150°C to obtain flexible electrodes, and draw out leads. Spray PS / ethanol solution on the above-mentioned flexible substrate, remove the ethanol solvent, and obtain an air-microsphere multiphase dielectric layer with a thickness of 3-12 μm; stack the upper and lower flexible substrates face to face, and place them on the edge of the flexible substrate A capacitive pressure sensor with a microstructured multiphase dielectric layer is prepared by coating a biocompatible flexible encapsulation layer. The results show that there is a large amount of air between the microspheres, which is beneficial to the mutual transformation of the air and the microspheres in the dielectric layer, so as to achieve the change of the dielectric constant and improve the sensitivity of the sensor. On this basis, by drawing two electrodes on the surface of the flexible substrate, and coating the edge of the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com