LED display screen formed by transparent film and manufacturing method thereof

An LED display, transparent film technology, applied in instruments, electrical components, circuits, etc., can solve the problem that non-flexible materials cannot meet the requirements of lightness, thinness, rewinding, freedom of design, complex LED smart glass manufacturing process, and high PI material cost. problems, to achieve the effect of design freedom, uniform brightness, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] The production of an LED display composed of a transparent film includes two steps:

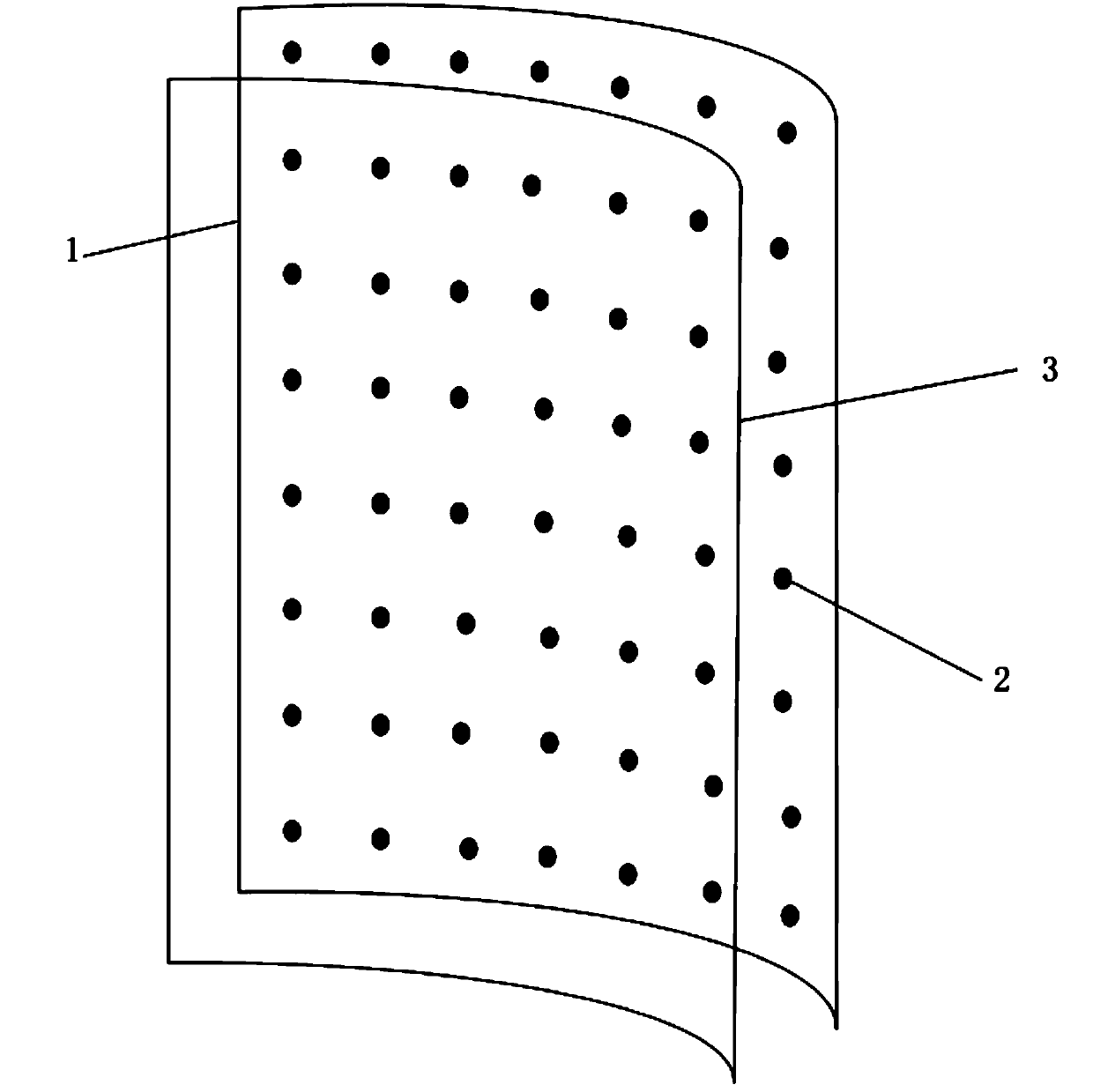

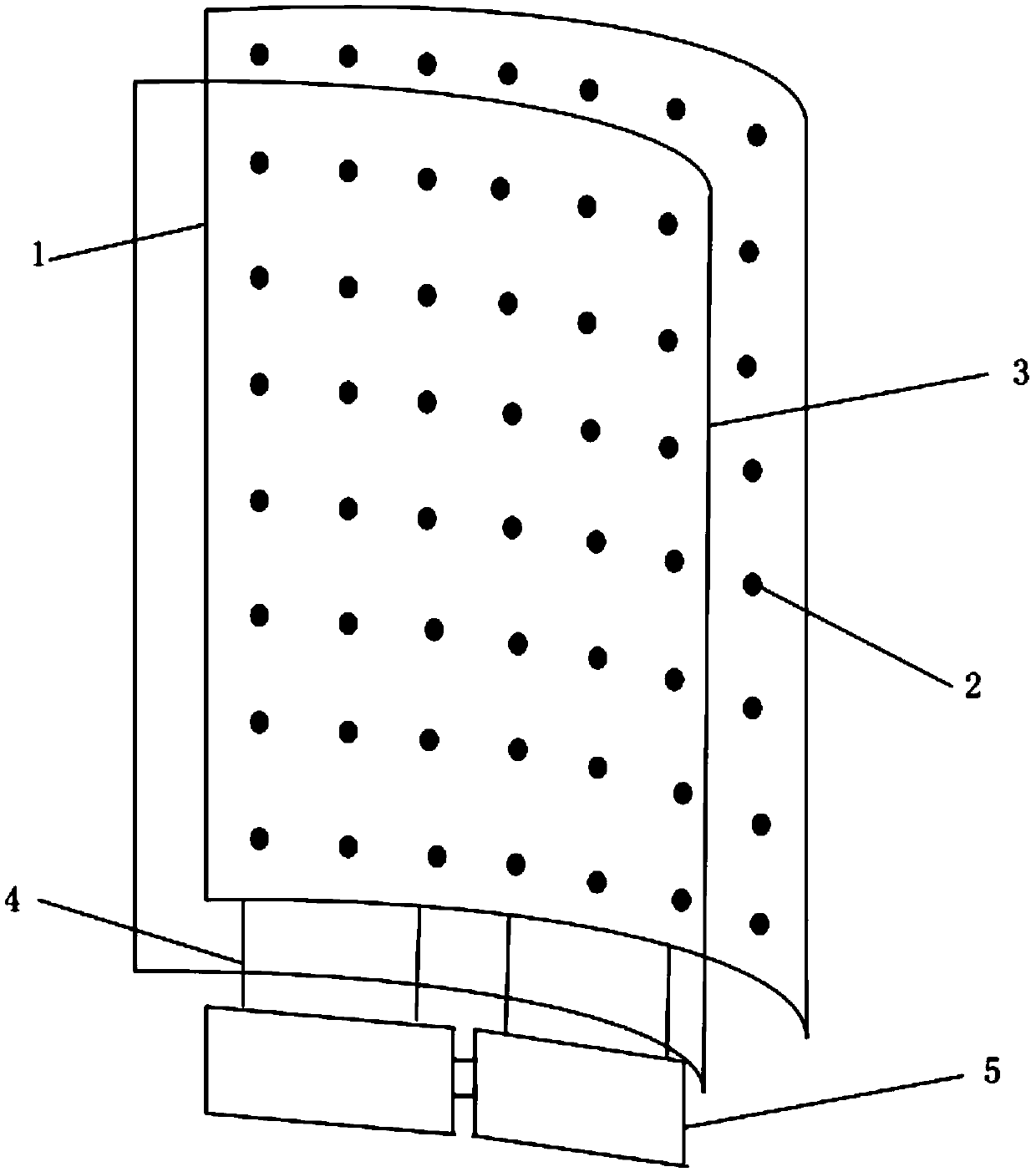

[0025] The first step is the production of flexible and transparent LED flexible display, such as figure 1 As shown, it includes a layer of flexible transparent film 1 , a layer of conductive film circuit plated on the flexible transparent film 1 and several LED chips 2 . The LED chip 2 is connected to the flexible transparent film 1 on which the conductive film circuit has been coated and etched through ITO conductive electrodes or conductive ink. Its specific implementation process is: a layer of conductive film such as ITO indium tin oxide conductive film is plated on one side of flexible transparent film 1, the thickness of conductive film will be far less than the thickness of flexible transparent film 1 (the present invention controls the thickness of conductive film un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com