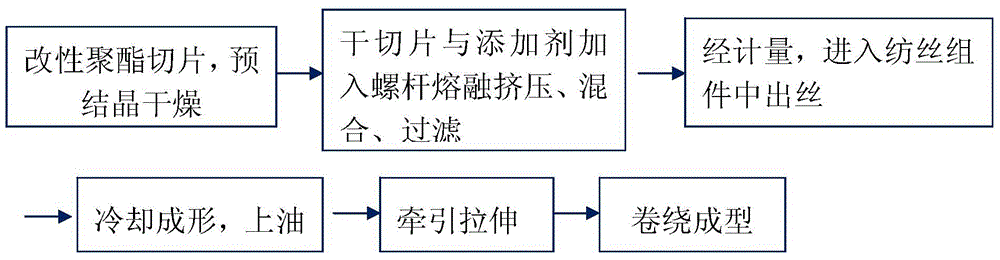

Production process of high-elasticity-feature terylene pre-oriented fibers

A technology of pre-oriented fiber and production process, which is applied in fiber processing, complete sets of equipment for the production of artificial threads, and bundles of newly sprayed silk, etc., can solve the problem of inability to produce polyester pre-oriented yarn, poor dyeing performance and effect, and product quality. Poor stability and other problems, to achieve the effect of high added value, high oil absorption and cleaning function, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Modified polyester chips are dried and pre-crystallized

[0040] The slice drying process needs to be heated to 160-170°C. The softening point of ordinary slices is very low, and it is easy to stick into pieces to block the drying device or the feeding pipe. Pre-crystallization improves the crystallinity of the slices, so that the softening point can reach above 200°C, which is beneficial Drying went on smoothly. When drying, it is transported from the bottom of the drying tower to the drying tower to contact with the slices in reverse to make the slices dehydrate quickly, and the dry air takes the moisture out from the top of the drying tower.

[0041] The pre-crystallization temperature is 170°C, the residence time is 35min; the drying temperature is 170°C, the drying time is 4h, and the ventilation volume is 250Nm 3 / h, the dry air inlet dew point is -80°C. The production capacity is 300KG / h, and the moisture content of dry slices is ≤0.003%. The main performan...

Embodiment 2

[0069] 1. Modified polyester chips are dried and pre-crystallized

[0070] The pre-crystallization temperature is 180°C, the residence time is 25min; the drying temperature is 180°C, the drying time is 6h, and the ventilation rate is 300Nm 3 / h, the dry air inlet dew point is -80°C. The production capacity is 400KG / h, and the moisture content of dry chips is 0.0025%.

[0071] 2. Melting and spinning

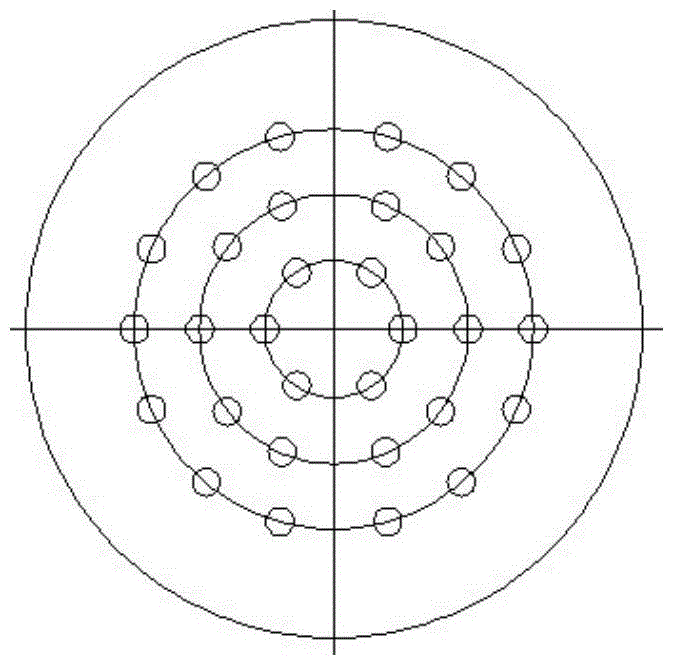

[0072] In this embodiment, the blended spinning of acrylate with a mass fraction of 2% is added, and the micropores of the spinneret are evenly distributed and arranged; the spinning temperature is 292°C, the specification of the spinneret is Φ95, and the micropores of the spinneret are 0.28*0.54*36, the component composition is 20 / 280+40 / 240 mesh / g, and the initial pressure of spinning is 160bar.

[0073] 3. Combination cooling and forming, and oiling

[0074] In this embodiment, the combined cooling method of slow cooling and side blowing is adopted in the cooling forming p...

Embodiment 3

[0080] 1. Modified polyester chips are dried and pre-crystallized

[0081] The pre-crystallization temperature is 176°C, the residence time is 28min; the drying temperature is 173°C, the drying time is 5.5h, and the ventilation rate is 300Nm 3 / h, the dew point of the dry air inlet is -80°C, and the moisture content of the dry slice is 0.0025%.

[0082] 2. Melting and spinning

[0083] In this embodiment, the blended spinning of acrylate with a mass fraction of 1% is added, and the micropores of the spinneret are evenly distributed and arranged; the spinning temperature is 289°C, the specification of the spinneret is Φ95, and the micropores of the spinneret are 0.28*0.54*36, the component composition is 20 / 280+40 / 240 mesh / g, and the initial pressure of spinning is 145bar.

[0084] 3. Combination cooling and forming, and oiling

[0085] In this embodiment, the combined cooling method of slow cooling and side blowing is adopted in the cooling forming process, the speed of sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com