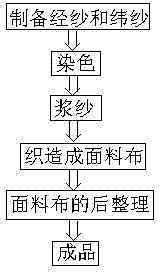

Production process of cotton-hemp blended yarn-dyed woven fabric

A preparation process and fabric technology, applied in the field of fabric fabrics, can solve the problems of hemp fiber being difficult to spin, dye and weave, etc., and achieve the effect of soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The specific implementation steps are as follows:

[0018] a) Preparation of warp yarn and weft yarn: cotton fiber and hemp fiber are selected as raw materials for warp yarn and weft yarn. Before spinning, the hemp fiber is pre-combed to remove some thick fibers and improve the yarn quality, and then add a certain amount of softener to the hemp for health treatment to improve its spinnability, the amount of softener It’s enough to just cover the hemp. Cotton / hemp is spun by vortex spinning at a ratio of 65:35, and the fineness of both warp and weft is 14.8tex.

[0019] b) Dyeing: The dyeing process mainly includes: pretreatment, dyeing, color fixing and drying. Among them, the pretreatment process adopts low-alkali high-temperature oxygen bleaching and gentle process to remove pectin and lignin in the hemp fiber without destroying the strength of the fiber. The process condition is 110°C×45min, and the amount of caustic soda is 1.5g / L; The dyeing is carried out on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com