Dyeing and finishing technology for cuprammonium-linen interwoven fabric and cuprammonium-linen interwoven fabric

A technology of interweaving cloth and linen, applied in the field of fabrics, can solve the problems of easy wrinkling, many flax impurities, rough hand feeling, etc., to achieve the effect of high comfort, low cost, and overcoming rough hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment provides a dyeing and finishing process of cupro ammonia linen interwoven cloth, which comprises the following steps:

[0024] (1), pre-shrinking

[0025] Pre-shrinking is carried out in an open-width two-dipping and two-rolling pre-shrinking machine, and the temperature of the first water tank is controlled at 70°C, and the temperature of the second water tank is controlled at 90°C. Straight crepe prints are formed in the overflow dyeing machine.

[0026] (2), refining

[0027] Refining is carried out in the overflow dyeing machine, the refining bath ratio is controlled as 1:21, the composition of the refining solution is: liquid caustic soda 35g / l, refining agent 1g / l, Yuzhongbao 1.5g / l and the rest are water, controlled refining The temperature was 80°C, and the temperature was kept for 120 minutes.

[0028] (3), washing

[0029] After refining, discharge the refining solution, add water, heat to 70°C, wash with water for 20 minutes, drain,...

Embodiment 2

[0040] According to the dyeing and finishing process of the cupro ammonia linen interwoven cloth of the present embodiment, it is basically the same as the embodiment 1. No, the composition of the dyeing solution used in this example is: L-3G Navy Blue 1.85%; L-3R Yellow 2.47%; L-4B Red 0.96%, Yuanming Powder 70g / l; liquid caustic soda 0.8g / l ;Soda ash 7g / l, Yuzhongbao 1.5g / l and the rest is water. The color of the final interwoven fabric is brown.

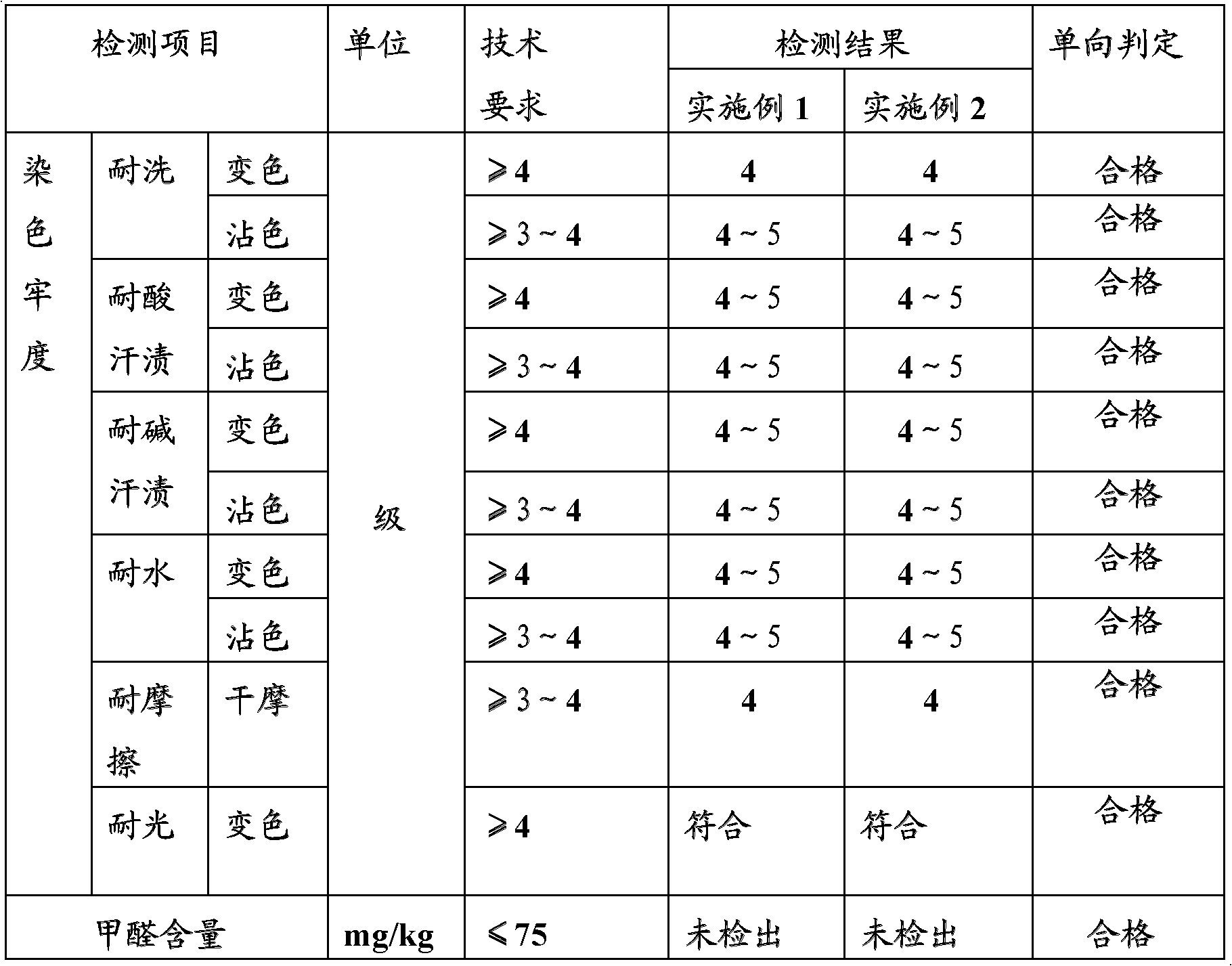

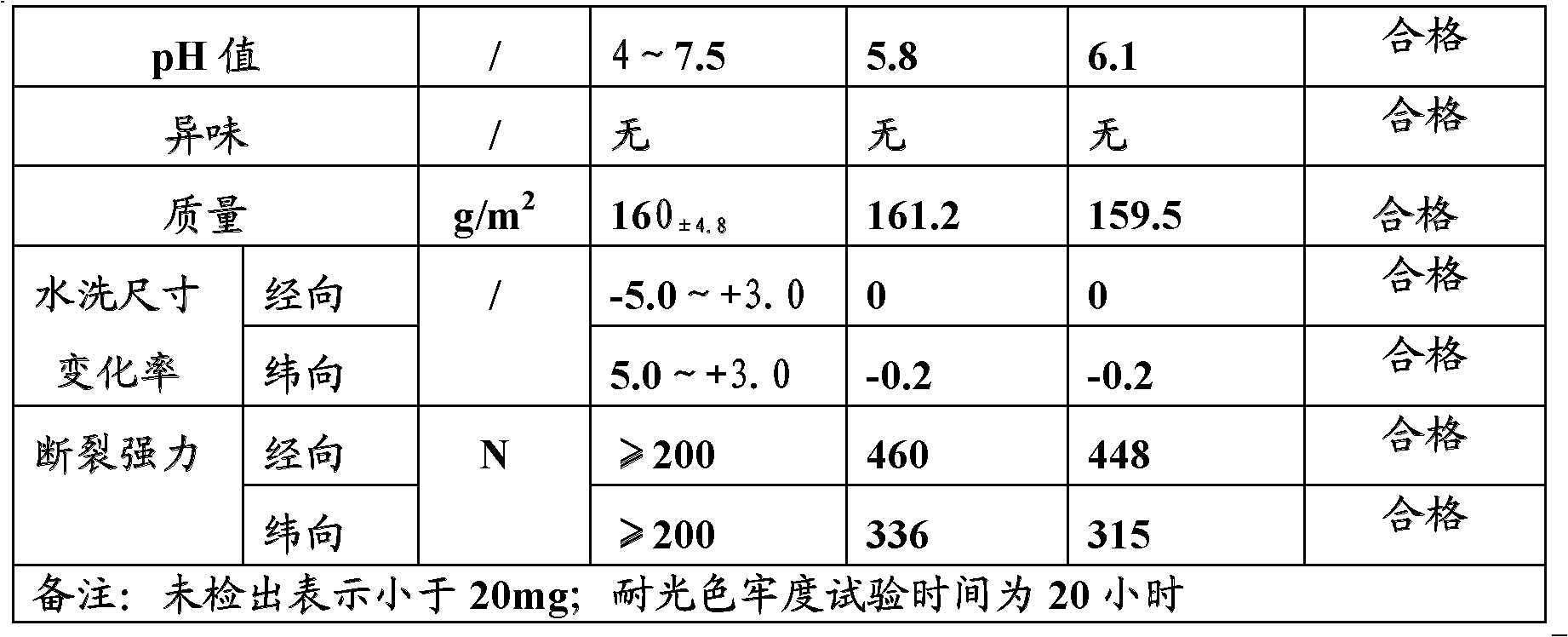

[0041] The cupro-ammonia linen interwoven fabrics of Example 1 and Example 2 were inspected, and the inspection basis was GB / T16605-2008 "Regenerated Cellulose Silk Fabric" and GB18401-2003 "National Basic Safety Technical Specifications for Textile Products" Class B, the result See Table 1. The results show that all the items meet the requirements of the superior product specified in the GB / T16605-2008 standard, and meet the requirements of the B category specified in the GB18401-2003 standard.

[0042] Table 1 Performance ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com