Simulated linen fabric

A technology of fabrics and raw materials, applied in the field of textile fabrics, can solve the problems of moisture absorption and ventilation without hemp, and achieve the effect of good drape and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

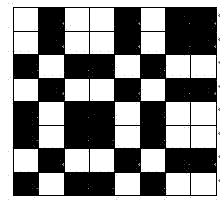

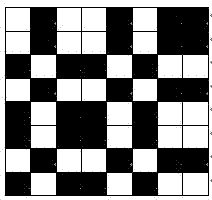

Image

Examples

Embodiment Construction

[0007] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0008] The hemp-like fabric of the present invention comprises four kinds of raw material yarns A, B, C and D. Raw yarns A and B form warp yarns, and raw yarns C and D form weft yarns. Wherein, the raw material yarn A is cupro ammonia yarn, the raw material yarn B is air variable yarn, the raw material yarn C is spandex stretched yarn, and the raw material yarn D is cationic yarn. The arrangement order of the raw yarns in the warp direction is 1A1B, and the arrangement order in the weft direction is 1C1D.

[0009] The linen fabric forms capillarity when it comes into contact with the skin, which is an extension of the skin. This natural air per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com