Method of dyeing acrylic fiber/hair/copper ammonia fiber blended knitting fabric by use of one-bath two-stage process

A technology of cupro ammonia fiber and dyeing method, applied in the direction of dyeing method, fiber type, fiber treatment, etc., can solve the problems of difficult processing technology, low dye utilization rate, poor dyeing quality, etc., and achieve improved dyeing quality and uniform coloring The effect of firming and reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

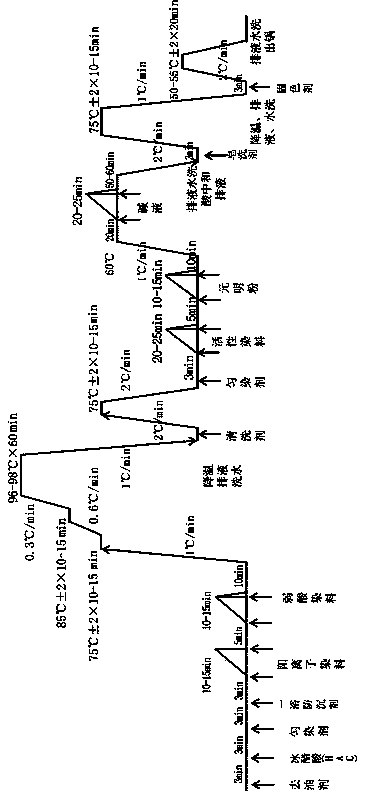

[0020] Embodiment 1: as figure 1 Shown, 40 S Acrylic / wool / cupro (70 / 10 / 20) black knitted fabric dyeing method in one bath and two stages, the steps are as follows:

[0021] (1) Pretreatment: Put the acrylic / wool / cupro fiber blended knitted fabric into the dye vat, add cold water to the dye vat and control the bath ratio to 1:4.5; add degreaser and ice to the dye vat in sequence every 3 minutes Acetic acid (HAC), leveling agent, anti-sedimentation agent for one bath; add cationic dyes into the dyeing bath evenly and slowly (10-15min), after 5 minutes, add weak acid dyes evenly and slowly (10-15min), 10 Minutes later, raise the temperature to 75°C±2 at a speed of 1°C / min and keep it for 10-15min, then raise the temperature to 85°C±2 and keep it for 10-15min, then raise the temperature to 96-98°C, keep it for 60min, and finally heat it at 1°C Cool down at a speed of 1 / min, drain and wash water to prevent oil spots;

[0022] (2) Dyeing acrylic / wool / cupro fibers: Add cleaning a...

Embodiment 2

[0027] Example 2: 60 S Acrylic / wool / cupro (35 / 30 / 35) beige knitted fabric dyeing method in one bath and two stages, the steps are as follows:

[0028](1) Pre-treatment: Put the acrylic / wool / cupro fiber blended knitted fabric into the dyeing vat, add cold water to the dyeing vat and control the bath ratio to 1:4; add degreasing agent and ice to the dyeing vat in sequence every 3 minutes Acetic acid (HAC), leveling agent, anti-sedimentation agent for one bath; add cationic dyes into the dyeing bath evenly and slowly (10-15min), after 5 minutes, add weak acid dyes evenly and slowly (10-15min), 10 Minutes later, raise the temperature to 75°C±2 at a speed of 1°C / min and keep it for 10-15min, then raise the temperature to 85°C±2 and keep it for 10-15min, then raise the temperature to 96-98°C, keep it for 60min, and finally heat it at 1°C Cool down at a speed of 1 / min, drain and wash water to prevent oil spots;

[0029] (2) Dyeing acrylic / wool / cupro fibers: Add cleaning agent, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com