Overflow dyeing method and used endless cloth

An overflow dyeing and overflow dyeing machine technology, applied in the field of textile dyeing, can solve the problems of high unit energy consumption, high unit cost, low output, etc., and achieve the effect of reducing unit energy consumption and unit cost, and increasing unit output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

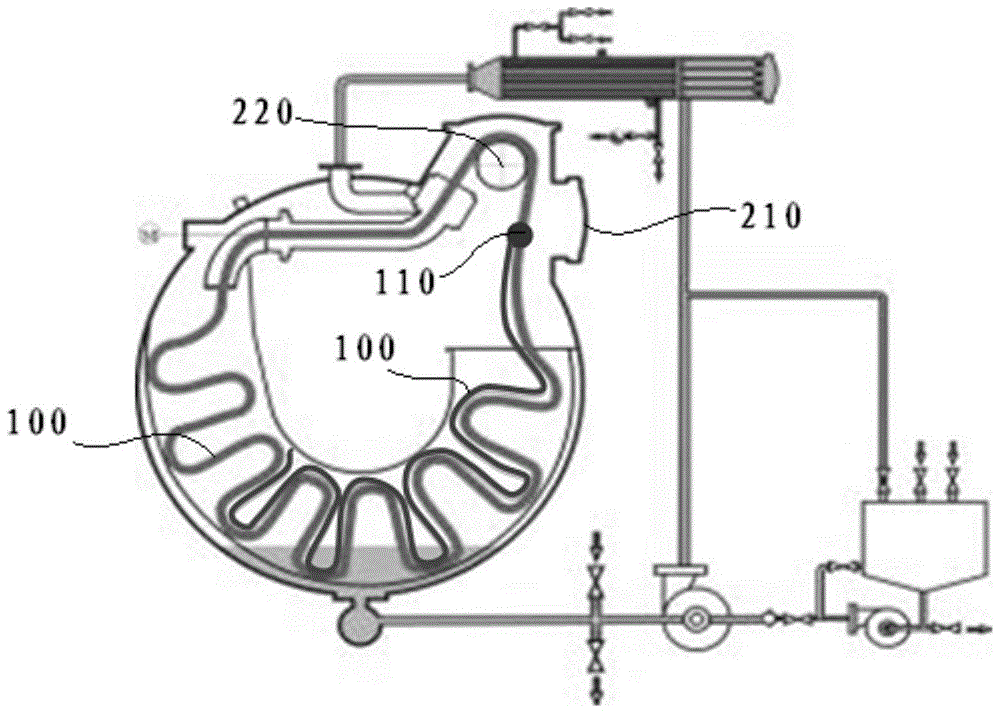

[0025] An overflow dyeing method is illustrated by taking a pipe type of inoflow type (produced by BRAZZOLI company) as an example, comprising the following steps:

[0026] 1. Prepare cloth.

[0027] The cloth heads of two pieces of cloth 100 are fixed together by sewing to form the head end 110, and the head end 110 is put into the overflow dyeing machine through the window 210 of the overflow dyeing machine, and the head end is lifted After the cloth roller 220 flows into the bottom of the overflow dyeing machine along the pipeline, the head end 110 is taken out, and the cloth tail of the longer one of the two cloths is sewn together with the head end to form a ring cloth. And the tail of the shorter of the two pieces of cloth is not fixed, such as figure 1 shown.

[0028] Second, dyeing.

[0029] Make the overflow dyeing machine run, and drive the looped piece of cloth to rotate in the overflow dyeing machine, and also drive the other piece of cloth attached to the ring ...

Embodiment 2

[0034] An overflow dyeing method is basically the same as the method in Example 1, except that the following dyeing parameters are used.

[0035] Table 2. Overflow dyeing parameters

[0036] Gram weight (grams / square meter) Pump speed(Rpm) Cloth lifting roller speed(m / min) Nozzle grade <250

experiment example

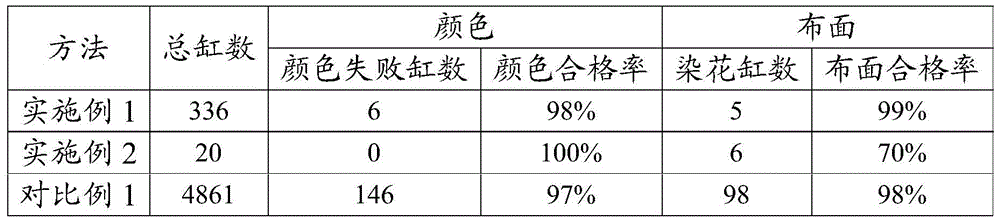

[0042] Adopt the method of above-mentioned embodiment and comparative example, and carry out test and production with identical dyeing process condition, the dyeing situation and production efficiency of cloth fabric are evaluated, and the result is shown in the table below.

[0043] Table 4. Dyeing effect evaluation results

[0044]

[0045] Among them, color failure means that the color of the dyed cloth is unqualified, and the color pass rate is the ratio of the number of vats with qualified color to the total number of dyeing vats. Dyeing refers to the uneven dyeing of the cloth surface after dyeing. The pass rate of the cloth surface is the ratio of the number of vats that pass the inspection of the cloth surface effect to the total number of dyeing vats.

[0046] As can be seen from the table above, the overflow dyeing method of the present invention can simultaneously dye multiple strips of cloth, which not only increases the unit output, but also has a good dyeing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com