Method of synthesizing biodiesel oil using fixed bed gaseous phase esterification reaction

A technology for esterification reaction and biosynthesis, which is applied in the field of biodiesel production, can solve the problems of troublesome separation of solid catalysts, increased production cost of energy, increased equipment investment, etc., so as to shorten the production process, improve the effective utilization rate, and save equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

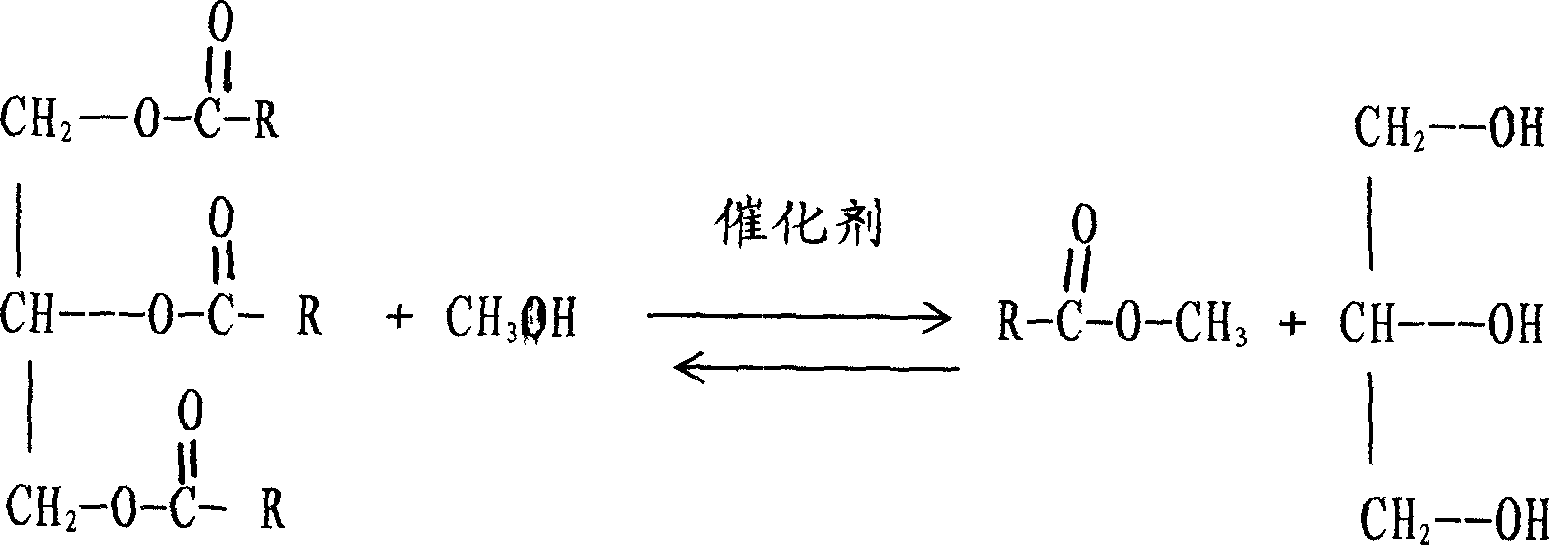

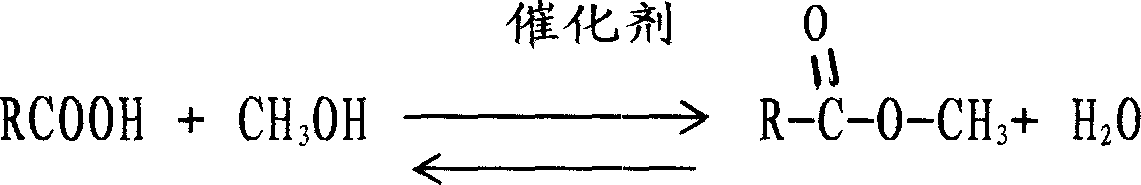

Method used

Image

Examples

Embodiment 1

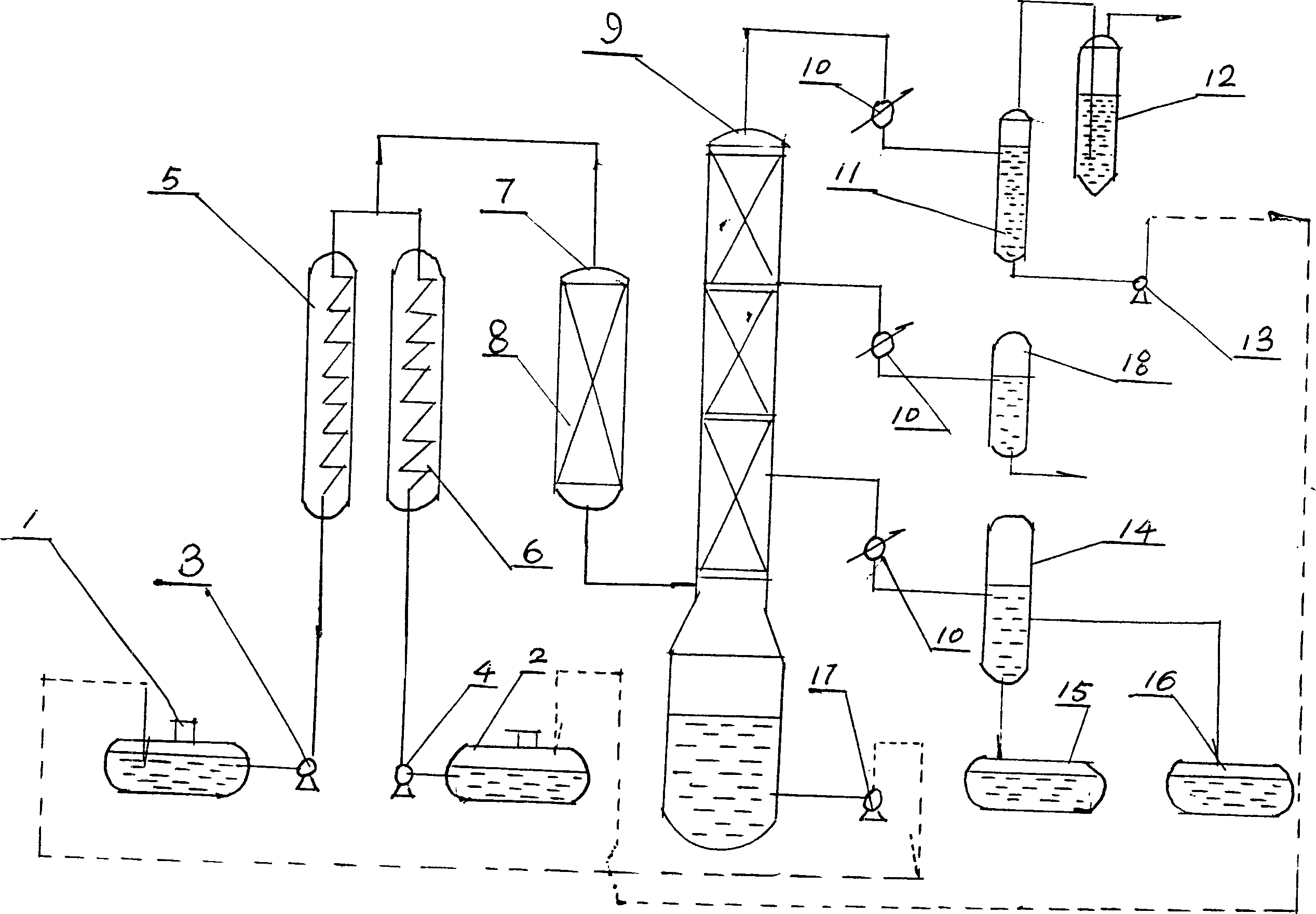

[0044] 1. 1000Kg of vegetable soybean oil after dehydration and impurity removal is passed through ¢32×4 (or 4mm wall thickness) seamless steel pipe (1Cr18Ni9Ti) from the oil raw material tank (1) with a high-pressure pump (3), and continuously input by the seamless Steel pipe (¢32×4, 1Cr18Ni9Ti) is assembled into a heat exchanger for heating and vaporization to become oil gas phase, the pressure of oil gas phase is controlled at 0.1-1.0MPa, and the hotbed is controlled at 380-400°C; at the same time, With 150Kg methyl alcohol (99% purity) according to grease: alcohol is the batching ratio of 1: 1.5 molar number, through ¢32 * 4 (or 4mm wall thickness) seamless steel pipe (1Cr18Ni9Ti) with high-pressure pump (4), input continuously by Heat and vaporize in the heat exchanger (5) assembled with seamless steel pipe (¢32×4, 1Cr18Ni9Ti) to become methanol gas phase; the gas phase temperature of methanol is controlled at 70-100°C, and the pressure is controlled at 0.1-1.0MPa, ;

[...

Embodiment 2

[0081] 1. Put the dehydrated and removed solid swill oil (acid value: 151mg KOH / g) at --- 3 ℃ into the oil raw material tank (1), and use the heat conduction oil in the tank (1) to heat the coil indirect Heat the swill oil to make it liquid; use a high-pressure pump (3) to pass through ¢32×4 (or 4mm wall thickness) seamless steel pipe (1Cr18Ni9Ti), and continuously input the seamless steel pipe (¢32×4, 1Cr18Ni9Ti) And in the heat exchanger (5) that assembles, carry out heating vaporization and become gaseous phase material, the temperature control of the gaseous phase material discharged from heat exchanger is at 385-410 ℃, and outlet pressure is 0.1-1.0MPa; Meanwhile, 150Kg Methanol (99% purity) is according to swill oil: alcohol is the batching ratio of 1: 1.5 moles, passes through ¢32 * 4 (or 4mm wall thickness) seamless steel pipe (1Cr18Ni9Ti) with high-pressure pump (4), input continuously by Seam steel pipe (¢32×4, 1Cr18Ni9Ti) is assembled into a heat exchanger for heati...

Embodiment 3

[0115] Press the processing method of embodiment 2, take the solid state animal lard when -1 ℃ as raw material production biodiesel and obtain following result:

[0116] A, Reactants:

[0117] (1) lard:

[0118] Weight: 1000Kg; unsaponifiable matter is 1.3% (Wt%),

[0119] Acid value: 1.6(mg KOH / g);

[0120] Saponification value: 194 (mg KOH / g);

[0121] Density: 0.934 (15°C);

[0122] Iodine value: 65;

[0123] Melting point: 31°C;

[0124] (2) Methanol:

[0125] Weight: 150Kg; Purity: more than 99.5%, national standard industrial first-class commodity;

[0126] (3) ZQ type catalyst:

[0127] The fixed bed is loaded with 300Kg of catalyst at one time, which can be continuously recycled, and can convert 60000Kg-100000Kg of the above-mentioned lard into biodiesel through catalytic esterification reaction;

[0128] B, the product or residue after the esterification reaction:

[0129] (1) residual methanol: 49g, purity: 99%;

[0130] (2) Glycerin:

[0131] Weight: 97K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com