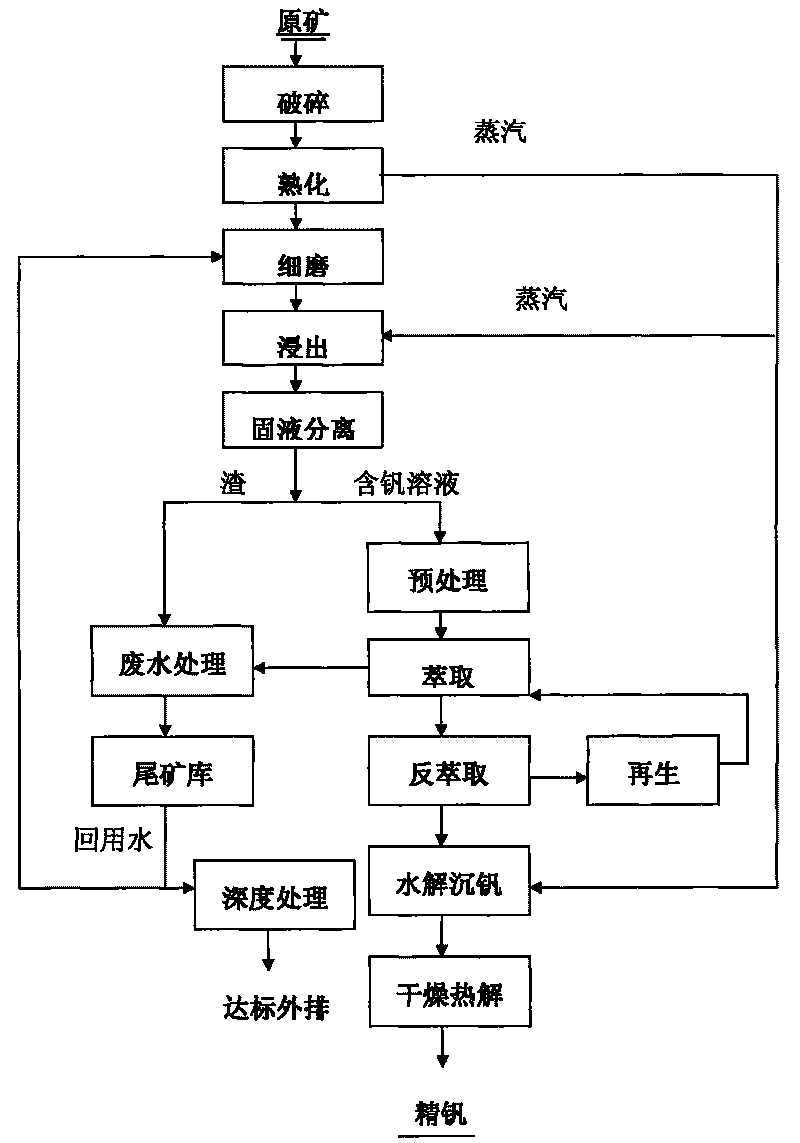

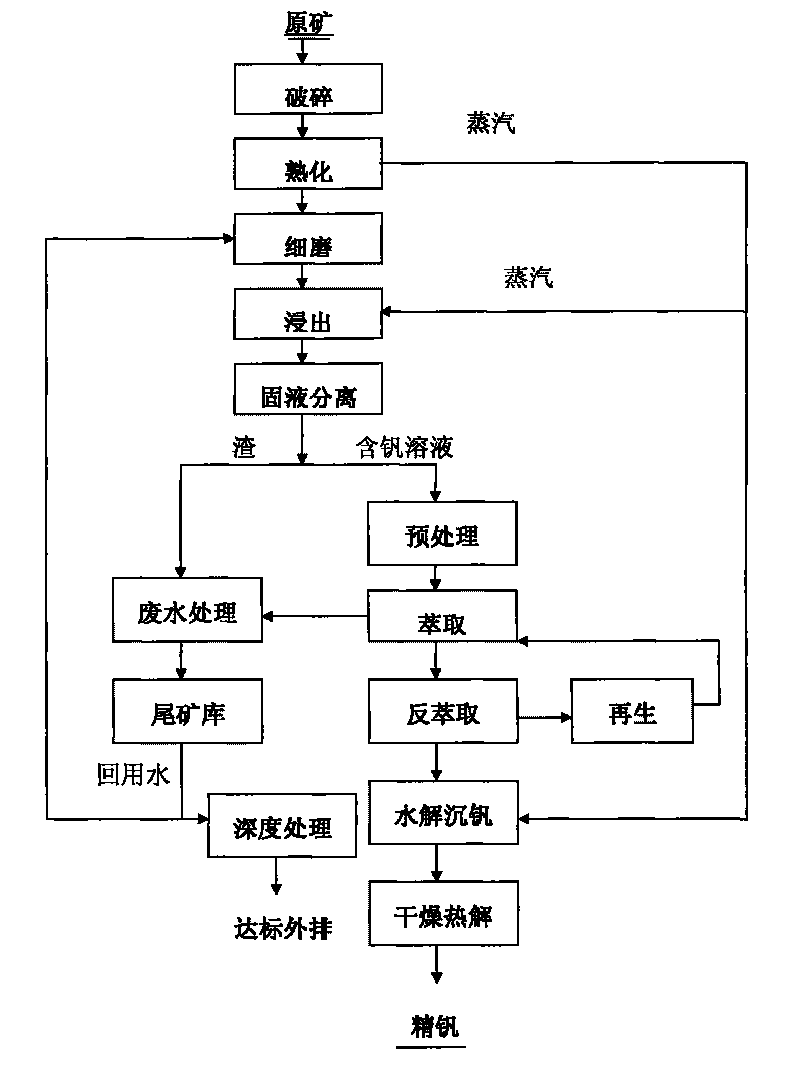

Process for extracting vanadium from stone coal by acid method for performing curing pretreatment on raw ore

A technology for pretreatment and stone coal acid, applied in the field of vanadium extraction by stone coal acid method, can solve the problems of wasting vanadium-containing resources, low sedimentation performance leaching rate, etc., and achieves improved leaching rate, filtration and sedimentation performance, iron content reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Put the raw ore crushed to 1 mm into the aging furnace; heat the aging furnace, the temperature of the aging heating is controlled at 600°C, and the aging time is 2 hours; stop heating, take the matured clinker out of the aging furnace, and let it stand to cool down to Appropriate temperature for wet grinding; then wet grind the matured clinker to the particle size required by the acid leaching process; then carry out the rest of the procedures, V 2 o 5 The leaching rate was 65%.

Embodiment 2

[0038] Put the raw ore broken to 4mm into the slaking furnace; heat the slaking furnace, the temperature of the slaking heating is controlled at 900°C, and the slaking time is 4 hours; stop heating, take out the matured clinker from the slaking furnace, and let it stand to cool down to Appropriate temperature for wet grinding; then wet grind the matured clinker to the particle size required by the acid leaching process; then carry out the rest of the procedures, V 2 o 5 The leaching rate was 66%.

Embodiment 3

[0040] Put the raw ore broken to 2mm into the slaking furnace; heat the slaking furnace, the temperature of the slaking heating is controlled at 650°C, and the slaking time is 2.5 hours; stop heating, take the matured clinker out of the slaking furnace, let it stand and cool down to Appropriate temperature for wet grinding; then wet grind the matured clinker to the particle size required by the acid leaching process; then carry out the rest of the procedures, V 2 o 5 The leaching rate was 68%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com