Patents

Literature

58results about How to "Do not change color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

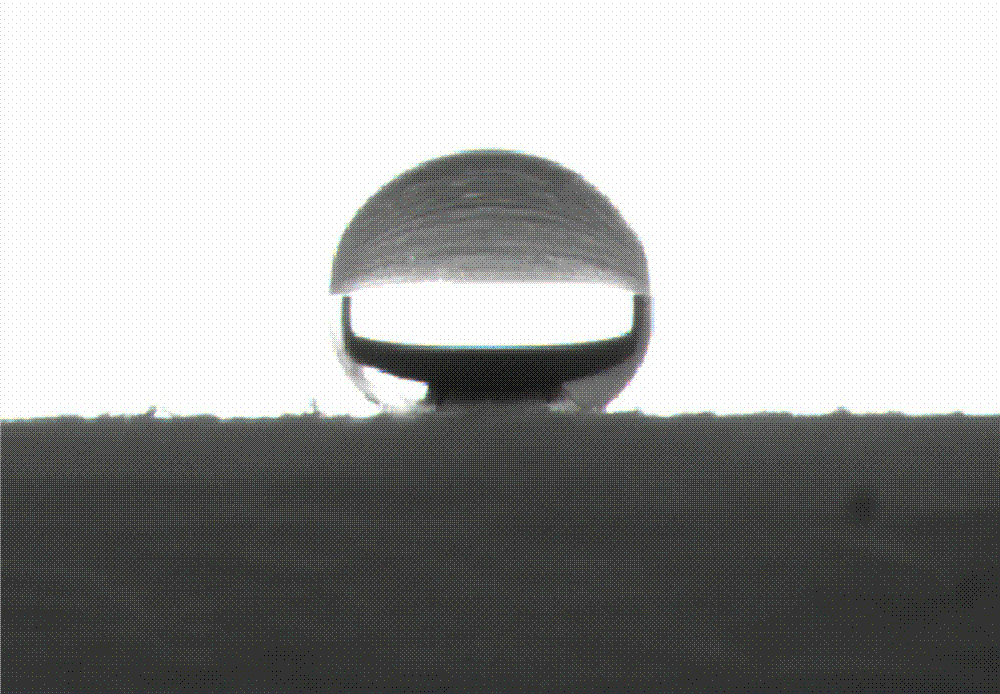

Organic silicon waterproof agent with respiratory function and preparation method thereof

The invention relates to an organic silicon waterproof agent with a respiratory function, which contains an active ingredient, a solvent and a catalyst, and is characterized in that the active ingredient is obtained in a way that alkyl siloxane coupling agent and / or fluoro alkyl siloxane coupling agent are / is mixed with a solvent, and then are / is subjected to hydrolysis reaction under the action of acid or alkali; and the structural formula of the siloxane coupling agent is Rn-Si(OR')4-n, wherein R is a saturated long-chain alkyl with the carbon atom number of 3-12 or a full-fluoro or partial-fluoro saturated long-chain alkyl with the carbon atom number of 3-12, R' is methyl or ethyl, and n is 1 or 2. By introducing fluoro alkyl siloxane, the waterproof agent not only has excellent waterproof performance and respiratory function, but also has the advantages of being good in adhesive force, solvent -resistant, acidproof and alkaliproof, aging- resistant, dirt-resistant and the like, and is especially applicable to water prevention of the surfaces of concrete and other porous members, particularly the surfaces of buildings, highways, bridges, guardrails and the like.

Owner:HENAN PROVINCIAL TRANSPORTATION RES INST

Slub dyeing technique for bamboo charcoal modified polyester fibre

InactiveCN101041936ADo not change colorGuaranteed fastnessDyeing processMonocomponent polyesters artificial filamentPolyesterAcetic acid

The invention relates to a dye method of bamboo charcoal modified polyester fiber, which uses Ascracen disperse cation dye produced by German Desda Fabric Dye Company. And the method comprises that coming bamboo charcoal modified polyester fiber to be arranged in high-temperature drying machine to operate for 3-5min at 30-40Deg. C, adding 0.3-0.5g / L glacial acetic acid and 2.5-4g / L glauber salt to operate for 5-10min, adding dye to operate for 5-10min, increasing temperature at 1-2Deg. C / min, stopping increasing temperature when the temperature is 80+-2Deg. C, and holding temperature for 10-15min, increasing temperature to 100-115Deg. C at 0.75-1Deg. C / min, to operate for 40-60min, discharging liquid and washing, then arranging the dyed bamboo charcoal modified polyester fiber into soap detergent, to process for 20-30min at 80-90Deg. C. The invention can be used dye bamboo charcoal modified polyester fiber, with better dye effect, high color stability and no hurt on copper ammonia fiber in the dye process.

Owner:HEILAN HOME

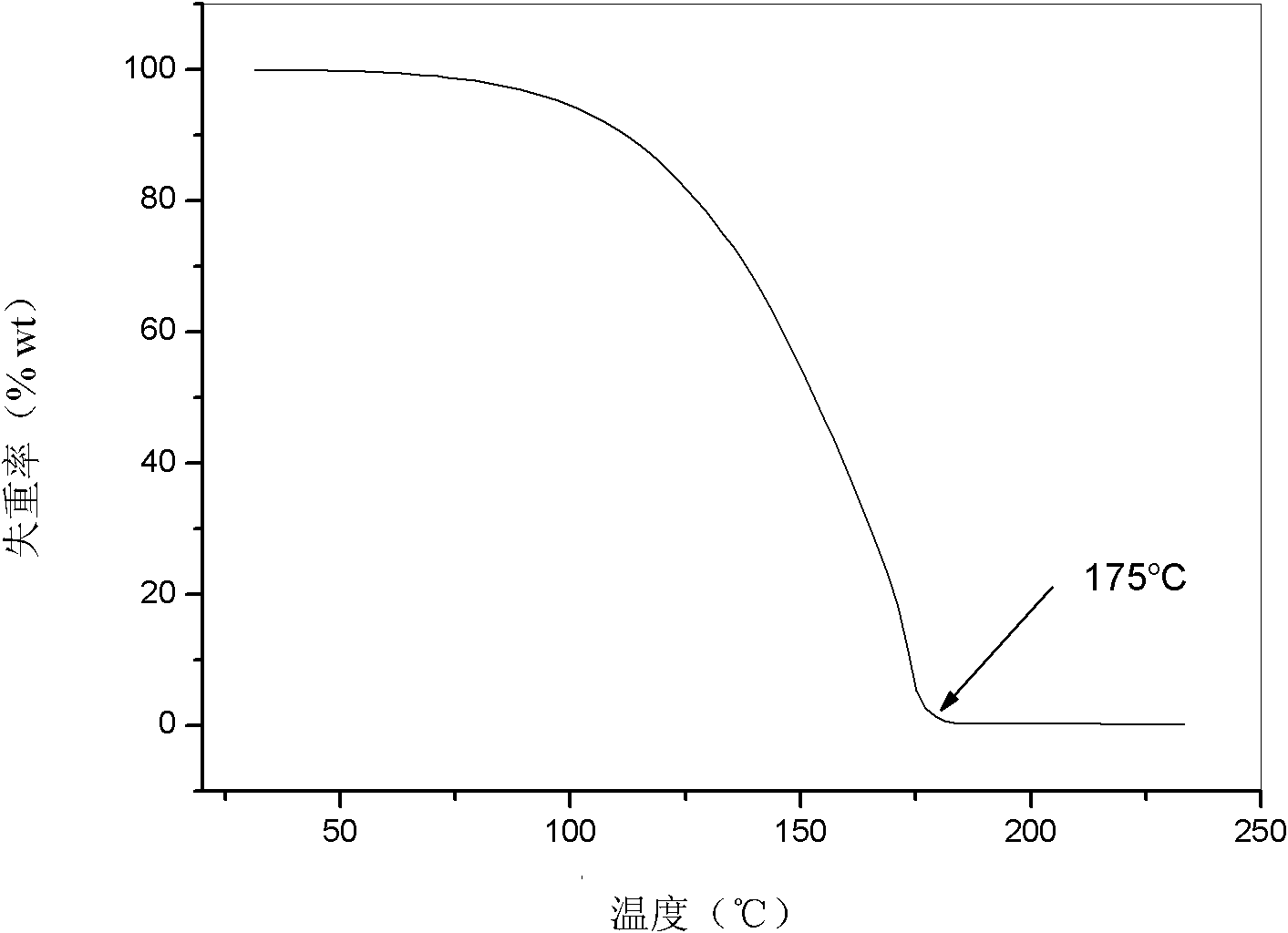

Preparation method of novel hydrophobic wood

InactiveCN103302708AGood dimensional stabilityHigh mechanical strengthWood treatment detailsPressure impregnationPolymer scienceEmulsion

The invention relates to a preparation method of a novel hydrophobic wood. The preparation method comprises the following steps of: firstly, melting alkyl ketene dimer colloidal particles at 40-60 DEG C; then adding a certain amount of cationic starch and an emulsifying agent and water; preparing an alkyl ketene dimer emulsion through treatment with a high-pressure homogenizer, and then blending the alkyl ketene dimer emulsion with a certain amount of nano cellulose gel to prepare a composite emulsion; then putting the wood and the composite emulsion into a reaction tank, vacuumizing and then injecting the emulsion for a period of time; taking the wood out, draining off the composite, and drying in a drying oven for 3-8 hours to obtain the novel hydrophobic wood. The preparation method is simple in process, causes no changes to the color of the wood and no corrosion to equipment, and is low in energy consumption, and the product does not have peculiar smells and can be widely used as indoor and outdoor furniture base materials and decorative materials.

Owner:GUANGDONG YIHUA TIMBER IND +1

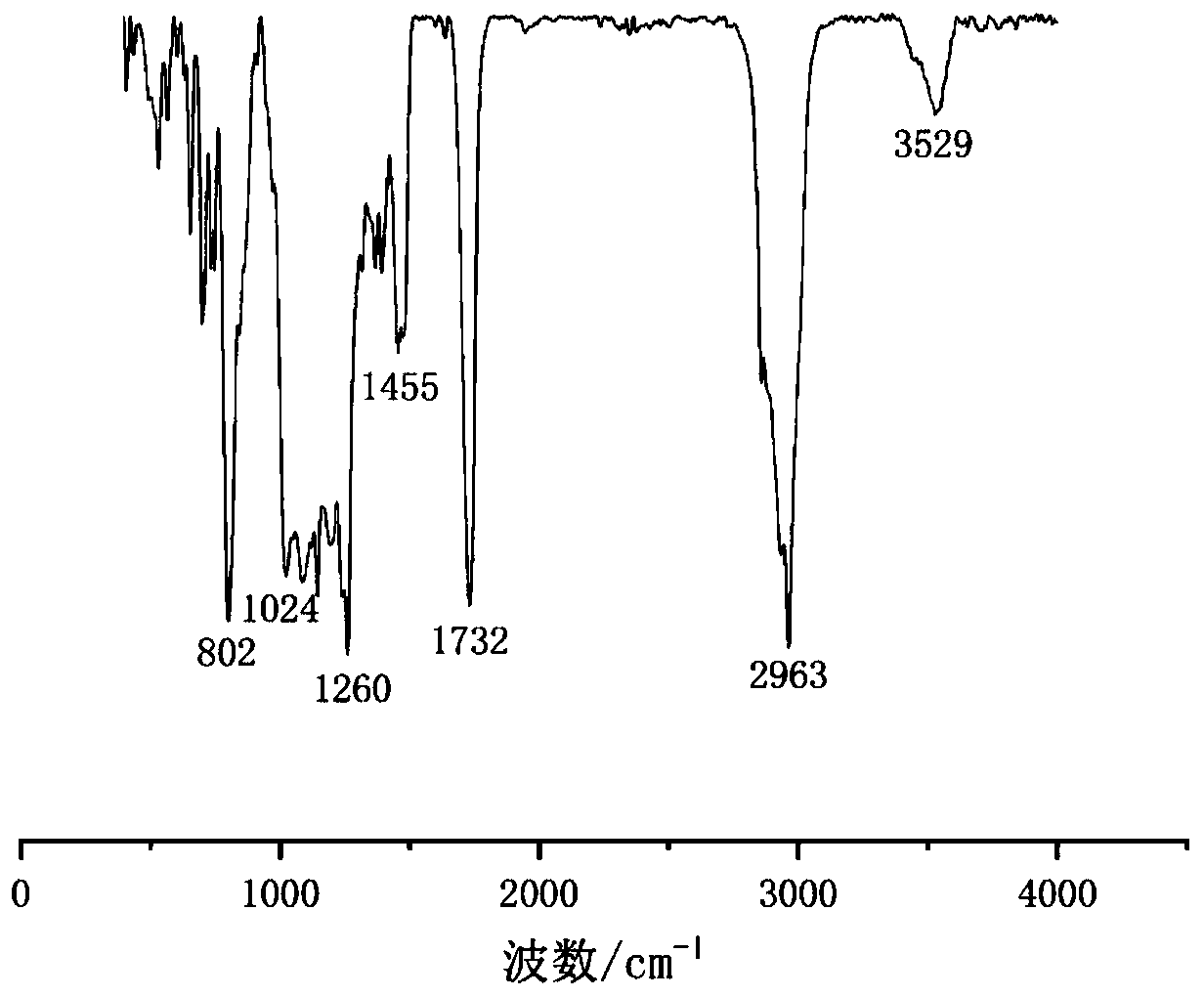

Organic silicon fluoro water proofing agent and its preparation method

ActiveCN1718665AGood solvent resistanceImprove acid resistanceOther chemical processesHigh resistanceSolvent

An organic Si-F water-proofing agent is composed of solvent and the organic Si-F resin prepolymer which is prepared from one or more alkyl siloxane coupling agents and hydroxy F-Si oil through catalytic hydrolysis reaction. Its preparing process is also disclosed. Its advantages are high water-proofing effect and high resistance to solvent, acid, alkali and ageing.

Owner:GUANGZHOU BAIYUN CHEM IND +1

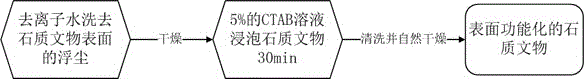

Calcium carbonate biomineralization reinforcing method for calcium carbonate type stone cultural relics

The present invention discloses a calcium carbonate biological mineralizing and strengthening method for calcium carbonate stone cultural relic. The technical process of the present invention is that: the solvent is first used for cleaning the surface of the stone cultural relic; and then the present invention uses a compound solution with biological amphipathic function as a organic molding board to pretreat the surface of the stone cultural relic and to make the surface of the stone add with a functional group unit; the supersaturation solution of calcium carbonate is used for making with infiltration treatment; under the control of the functional group unit, the calcium carbonate is inducted to grow into core directional crystal; the rocked and incompact grain can be connected so as to make the strengthened protection for the surface of the stone material. The present invention has the advantages of similar property between the protective material and the base material, much better compatibility; the present invention does not change the appearance, color and hand feeling of the protected stone cultural relic; and the compression strength, water resistance, acidity resistance and soiling resistance are improved and enhanced greatly.

Owner:ZHEJIANG UNIV

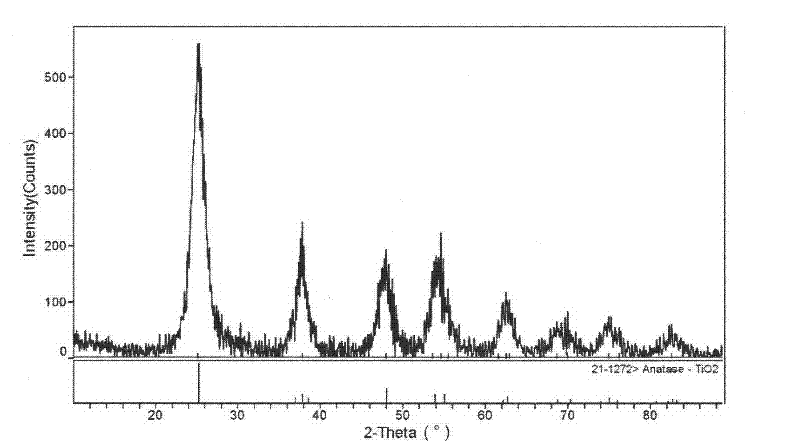

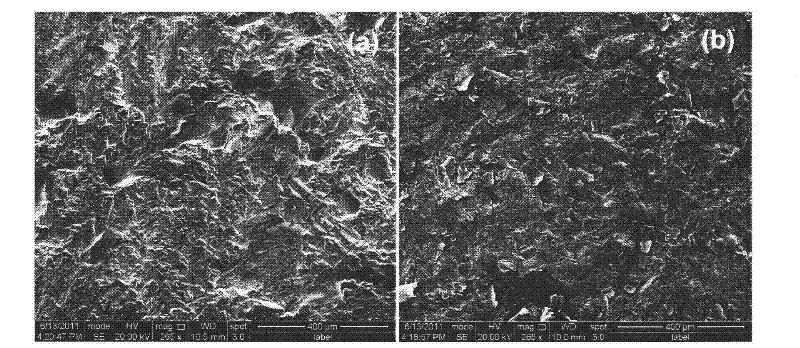

Nanometer photocatalysis surface protection material for stones and stone cultural relic and preparation method of same

InactiveCN102491781ALong-term protection engravingLong-term protective structureTitaniumSoil resistance

The invention relates to the field of protection of stones and stone cultural relic and provides a nanometer photocatalysis surface protection material for stones and stone cultural relic and a preparation method of the material. According to the invention, titanium alcoholate is taken as the main raw material; the titanium alcoholate, solvent, chelating agent, catalyst and the like are mixed, and are stirred fully under the condition of normal pressure and below the temperature of 100 DEG C to react, so as to obtain anatase titanium dioxide collosol surface protection liquid for stones and stone cultural relic; and a surface protection film made of anatase titanium dioxide photocatalysis material is formed on the surface of a stone, which is cleaned with solvent, through the method of brushing, soaking or the like. The nanometer photocatalysis surface protection material has the advantages that the reversibility is good; the compatibility with stones is good; the acid resistance is strong; the alkaline resistance is strong; the weatherability and the soil resistance are good; the self-cleaning capability is strong; the fungus resistance is good; and the appearance, the color and the hand feeling of the original stone are not affected.

Owner:YUNNAN UNIV

Ashless diesel fuel additive, and its preparing method and use method

InactiveCN1470618ALowering the freezing pointChange colorLiquid carbonaceous fuelsSorbitan monostearateAlcohol

The present invention relates to an ash-less diesel oil additive, its preparation and application method. Said additive is formed from sorbitan monostearate, alkylolpolyethenoxyether and its derivative, alkylphenolpolyethenoxyether and its derivative, alcohol diethoxyethane, water, medium carbon alcohol and solvent oil, and its preparation method includes: mixing sorbiton nanostearate, alkylolpolyethenoxyether and its derivative and alkylphenol polyethenoxyether and its derivative by using mechanical stirring device or ultrasonic stirrer, then adding other materials successively and fully stirring them to obtain the transparent solution, i.e. said invented product which can improve combustion property of diesel oil and reduce discharge of CO, NOx, HC and PM pollutants in the tail gas, andcan prevent secondary pollution.

Owner:SOUTH CHINA UNIV OF TECH

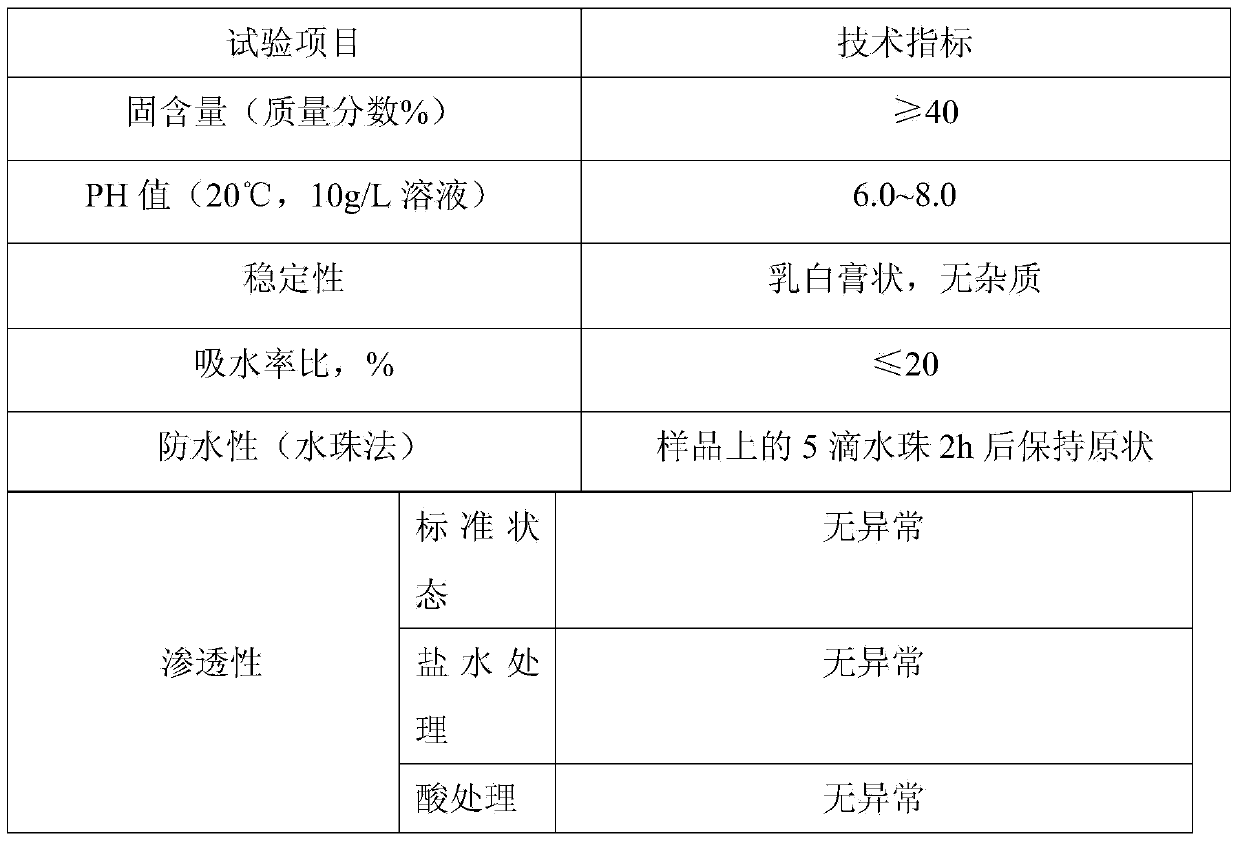

Joint mixture

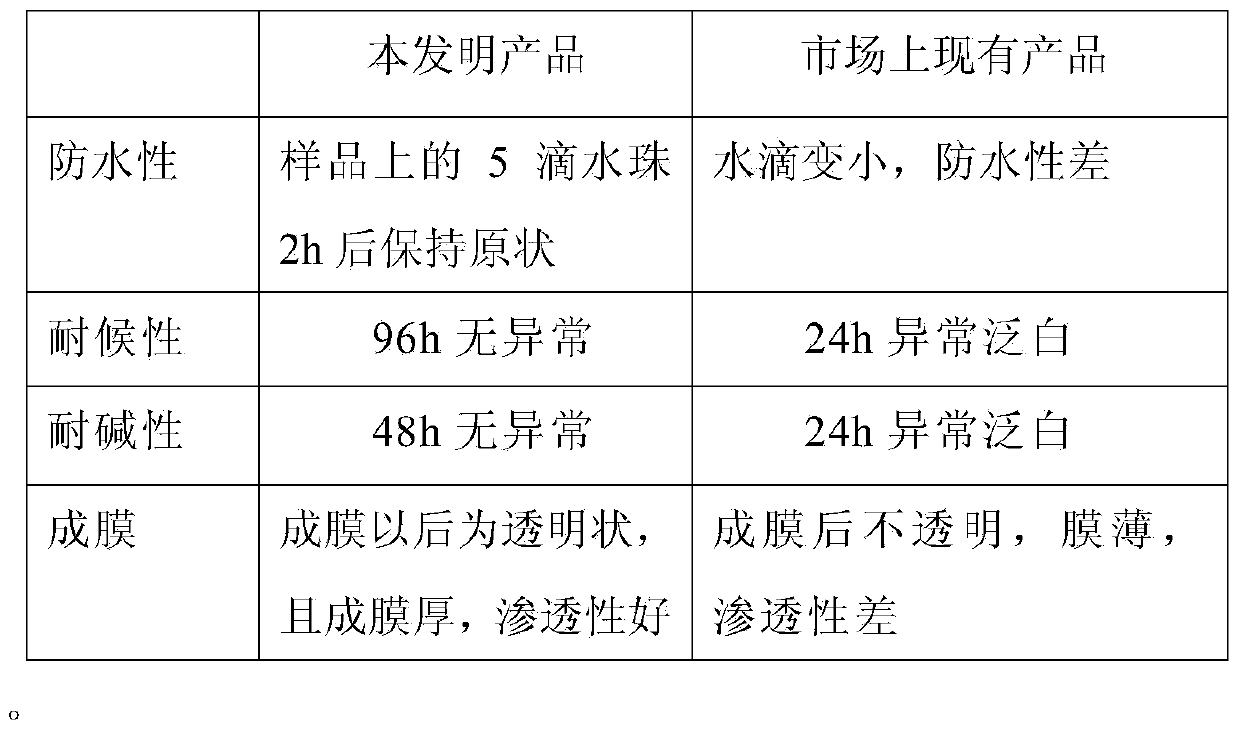

ActiveCN103421425AHigh solid contentAlkali resistance, strong weather resistanceCoatingsDefoamerEmulsion

The invention discloses a joint mixture. The joint mixture comprises the following components, by weight, 400-600 parts of organic silicon emulsion, 400-600 parts of acrylic emulsion, 1-2 parts of bactericide, 1-2 parts of defoamer and 10-20 parts of thickening agent which are mixed and stirred, wherein the solid content of the acrylic emulsion is 52-55%. The joint mixture is of a capillary crystalline type, and is of a transparent shape after coating the surface of a substrate to form a film, the color of the substrate is not changed after the film is formed, in addition, the weatherability and the stain resistance of the joint mixture are high, and the water seepage prevention performance is good.

Owner:南京博云悦邦工贸实业有限公司

A lychee and longan fresh-keeping agent with nano-chitosan as main ingredient and method for preparing same

InactiveCN1883279AReduce manufacturing costGuaranteed edible safetyFruit and vegetables preservationFlavorChemistry

The invention discloses a fresh keeping agent using nano chitosan as main material and its preparation method. Litchi, longan are easy to be dehydrated, which make it difficult for being kept fresh. In the invention chitosan is prepared in nano shape, which promote the dissemination of chitosan in water, while makes full use of its quanta effect and large surface and interfacial effect, makes its possess well film-forming property, hygroscopicity and moisture-keeping property. Applying the agent to litchi and longan, under 2-5 DEG C , the fruit can be kept fresh 40-50 days. Moisture of the fruit only reduce 4.8% afeter 40 days, while sugar increase 2%, fruit husk and pulp flavor keep invariable.

Owner:BEIHAI PINGTAI NANO MATERIAL APPL RESCO

Top dyeing and post-processing method of flame retardant polyester fiber

InactiveCN101457489ADo not change colorGuaranteed fastnessDry-cleaning apparatus for textilesDyeing processDisperse dyeAcetic acid

The invention relates to wool top dyeing of flame-retardant polyester fibers and a post-treatment method thereof. The method comprises the following steps: the flame-retardant polyester fiber wool top is placed in a wool top dyeing machine and operates for 3-5 min at the temperature of 40-50 min, glacial acetic acid is added and PH Value is adjusted to 5-6, monoammonium phosphate and Yuri Huading DIF are added for operating for 5-10min, disperse dye is added for operating for 5-10 min before the temperature rises, the temperature stops rising until 85 DEG C, then the temperature is maintained for 10-15 min, the temperature rises to 100-120 DEG C for operating for 30-60 min, liquor drainage and flushing are carried out with a bath ratio of 1:20-50; the dyed flame-retardant polyester fiber wool top is put into lotion soap with 2-5% of fiber fabric by weight, the lotion soap is processed for 20-30 min at the temperature of 80-90 DEG C, or, the dyed the flame-retardant polyester fiber wool top is first placed in bath consisting of 0.5-2g / L sodium hudroxide , 0.5-2g / L rongalite and 0.5-1g / L nonionic surface active agent for being processed for 20-30 min at the temperature of 70-80 DEG C and then placed in glacial acetic acid bath with 1-4% of fiber fabric by weight for being processed for 10-15 min at the temperature of 40-45 DEG C; the bath ratio is 1:20-1:50. The wool top dyeing of the invention features good levelling of dyeing and high color fastness of dyeing wool top.

Owner:HEILAN HOME

Preparation method of water-based organosilicone stone protecting agent

InactiveCN106833368AGuaranteed breathabilityImprove dispersion stabilityAntifouling/underwater paintsPaints with biocidesWater basedLong chain

The invention discloses a preparation method of water-based organosilicone stone protecting agent, wherein the protecting agent is prepared from, by weight, 50-75 parts of long-chain alkylsilane modified methyl silicate solution, 5-10 parts of silica sol, 5-10 parts of polyving akohol, 1-5 parts of water-based adhesive promoter. The stone protecting agent takes water as the dispersing agent, and is low in cost, safe and toxic-free; the processed stone is free from the change of appearance and color, and has good penetration performance, strong adhesive force, fast curing, and high dilution ratio; the protecting agent can form protection at the surface and the inner part of the stone, and comprehensively improve the protection performance.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

A lychee and longan fresh-keeping agent with nano-chitosan as main ingredient and method for preparing same

InactiveCN1883281ARaw materials are easy to getReduce manufacturing costFruit and vegetables preservationFlavorChitin formation

The invention disclose a fresh keeping agent using nano chitin as main material and its preparation method. Fruit husk of longan litchi has three-layer structure, which is in favor of water evaporation, result in fruit dehydration and withered, facilitate forming brown stain, in favor of invasion and propagation of pathogenic microorganism. In the invention nano chitin colloidal solution is prepared, for keeping fresh of litchi and longan under 2-5 DEG C , the fruit can be kept fresh 40-50 days, Moisture of the fruit only reduce 4.8% afeter 40 days, while sugar increase 2%, fruit husk and pulp flavor keep invariable. The material is east to get, and has low cost.

Owner:BEIHAI PINGTAI NANO MATERIAL APPL RESCO

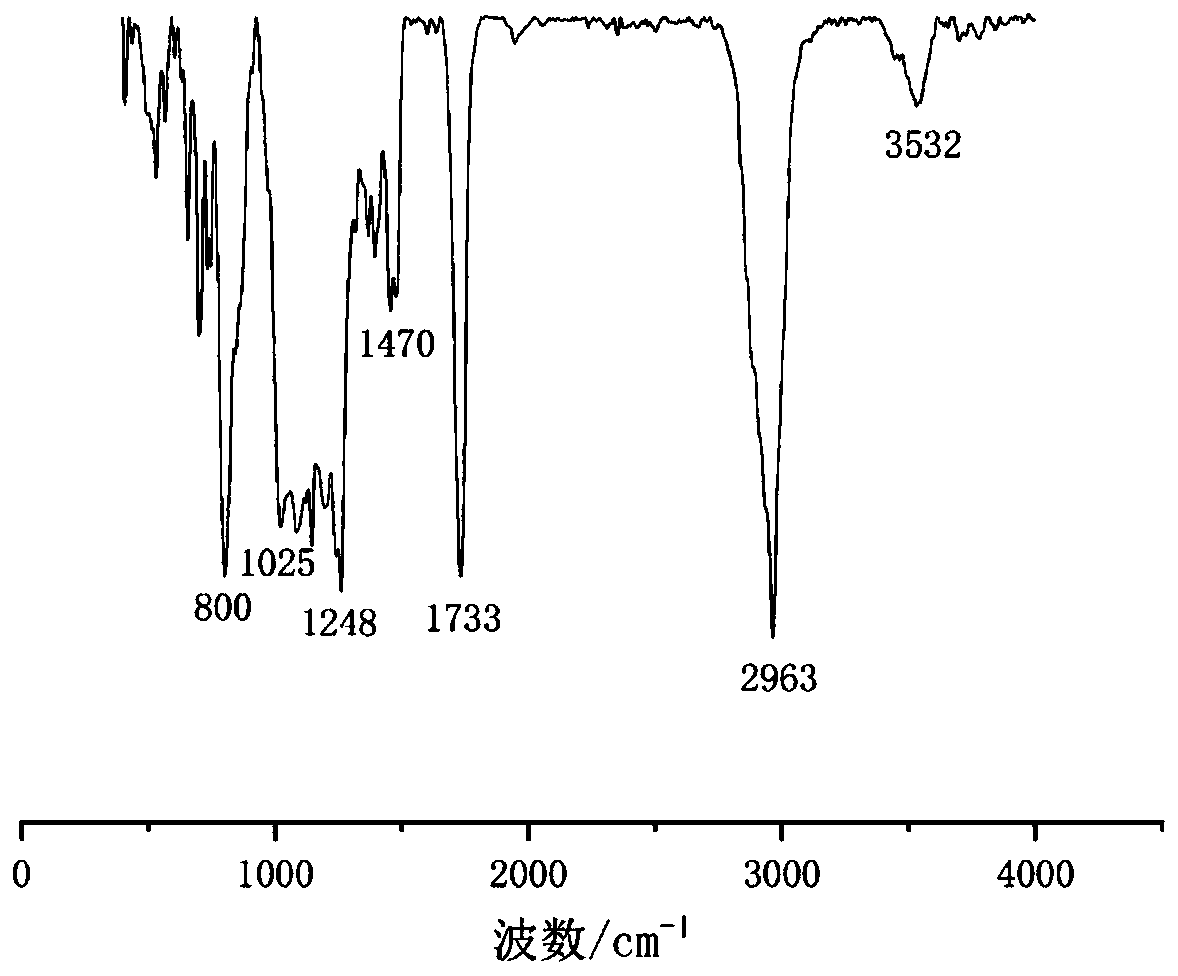

Organosilicon fluorine material for sealing and protecting irony cultural relics and method of producing the same

InactiveCN101402827ALower surface energyStrong anti-corrosion abilityAnti-corrosive paintsSilicone oilMonomer

The invention discloses an organic fluosilicic material used for sealing and protecting an iron cultural relic; the main components of the organic fluosilicic material consists of a main agent, a flatting silica and a thinner; wherein, the component of the main agent is an organic fluosilicic polymer; and the organic fluosilicic polymer is prepared by the hydrolytic polycondensation reaction of an organic silicon mixed monomer and hydroxy fluosilicic oil under the existence of an acid catalyst. The invention also discloses a preparation method of the organic fluosilicic material used for sealing and protecting the iron cultural relic. Test shows that after the organic fluosilicic material is adopted for carrying out sealing and protection on the surface of the iron cultural relic, protections of colorless, transparency, lightless and maintaining the original appearance on the iron cultural relic are realized; the corrosion resistance and the aging resistance are very good; moreover, the organic fluosilicic material has better self-cleaning performance. Not only can the problem of changing the original appearance of the cultural relic commonly existed in iron cultural relic sealing and protecting materials be solved, but also the corrosion resistance and the weatherability can be greatly improved.

Owner:广州市白云文物保护工程有限公司 +1

Polymer surface treatment method

ActiveCN107151780AImprove surface bindingImprove wear resistance and corrosion resistanceVacuum evaporation coatingSputtering coatingPolymeric surfaceWater discharge

The invention relates to a polymer surface treatment method. According to the method, an arc ion plating is adopted to enable a chromium film to be deposited on the surface of a polymer base body, the obtained chromium film has the silver appearance, and is similar to a sexavalence chromium film obtained through the electroplating process in appearance, meanwhile, in combination with the ion beam bombarding polymer surface and magneto-sputtering deposition nitride hard film technology, the film base combination force and film wear-resisting anti-corrosion performance can be greatly improved, the strong film base combination force is obtained from the polymer surface, the plating chromium imitation film which has the excellent properties of wear resistance, scratch resistance, corrosion resistance and the like can be obtained from the polymer surface, the decoration and protection function of the polymer base material can be achieved, and a full-dry type green surface treatment method without waste water discharge is obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

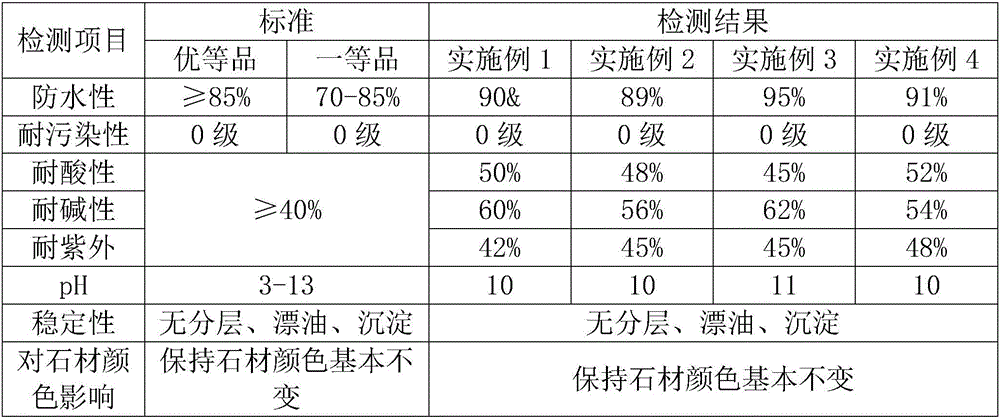

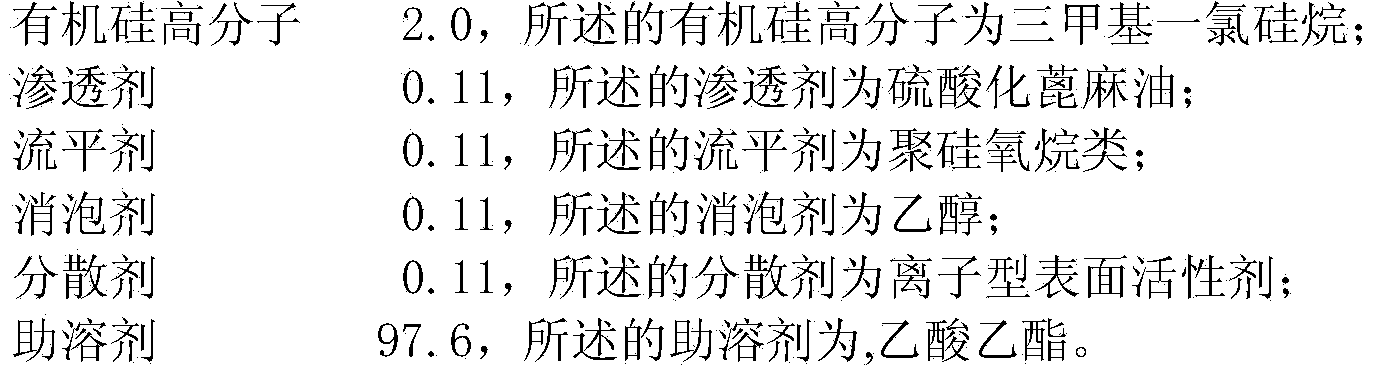

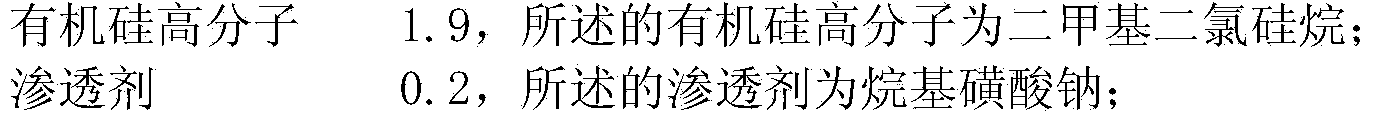

Strong permeability waterproof agent and preparation method thereof

ActiveCN104109470AAvoid the risks of HPHT synthesisSimple production methodFibre treatmentCoatingsHigh pressureMoisture

The invention discloses a strong permeability waterproof agent and a preparation method thereof. The strong permeability waterproof agent comprises the following raw materials by following mass fraction: 1.8-2.5 parts of organosilicon polymer, 0.1-0.3 parts of osmotic agent, 0.1-0.3 parts of levelling agent, 0.1-0.3 parts of antifoaming agent, 0.1-0.3 parts of dispersing agent and 96-98 parts of cosolvent. The waterproof agent is prepared by adding the ingredients in a container one by one and then stirring, controlling the temperature and filtering under normal pressure condition. The strong permeability waterproof agent has the advantages of production technology simplification, prevention of high temperature / high pressure synthesis risk, and no three wastes generation of composition; and has the beneficial effects of strong high-temperature resistance, strong permeability, fast drying and no change of color of original product. The strong permeability waterproof agent can be widely used for moisture and mildew resistant treatment before interior decoration, and used for water repellent treatment in stone industry, woodwork and textile industry, and is especially suitable for rapid construction under special environment.

Owner:WUHAN PANTHERS LEAKPROOF TECH DEV CO LTD

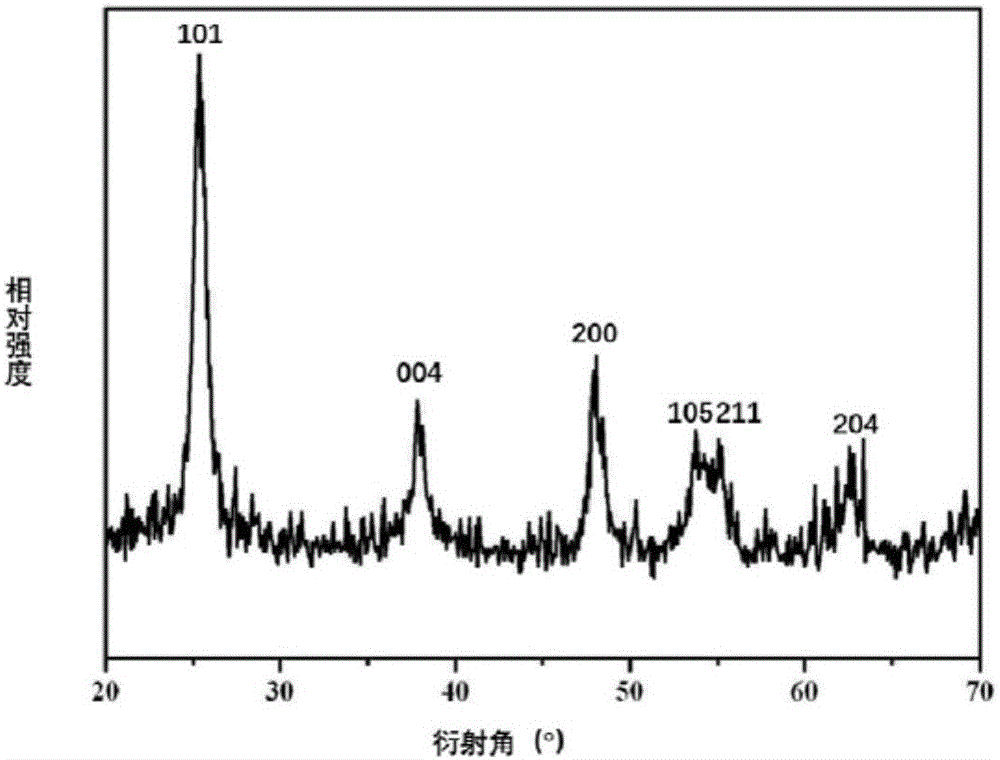

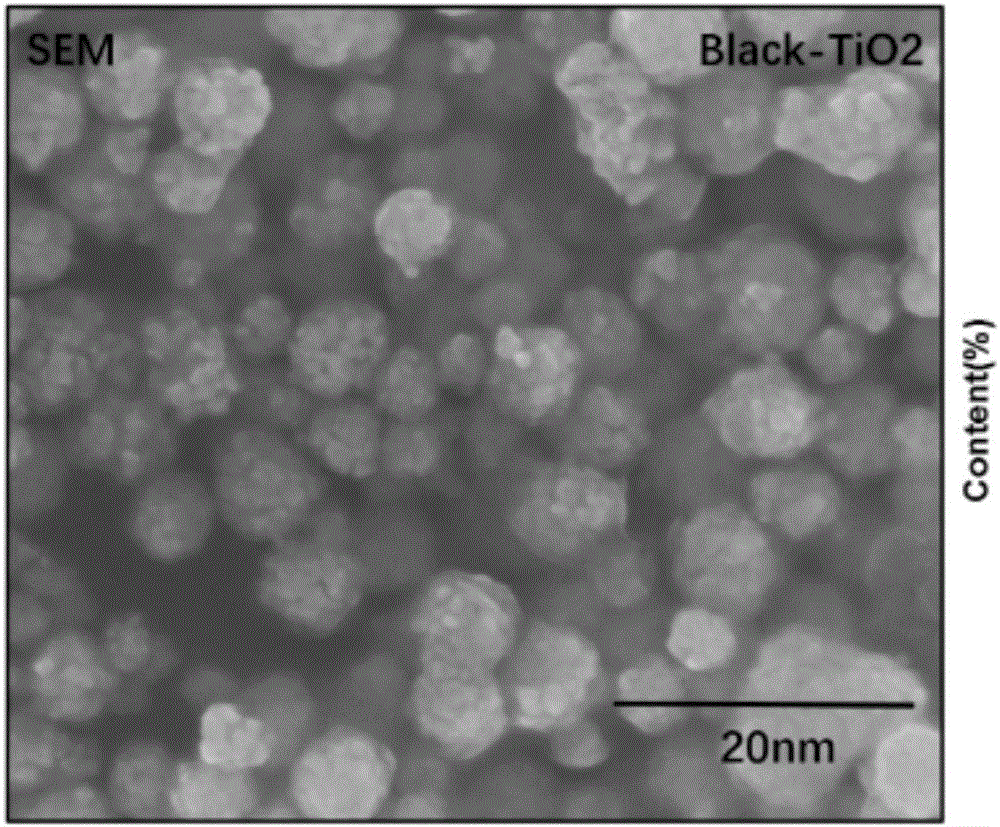

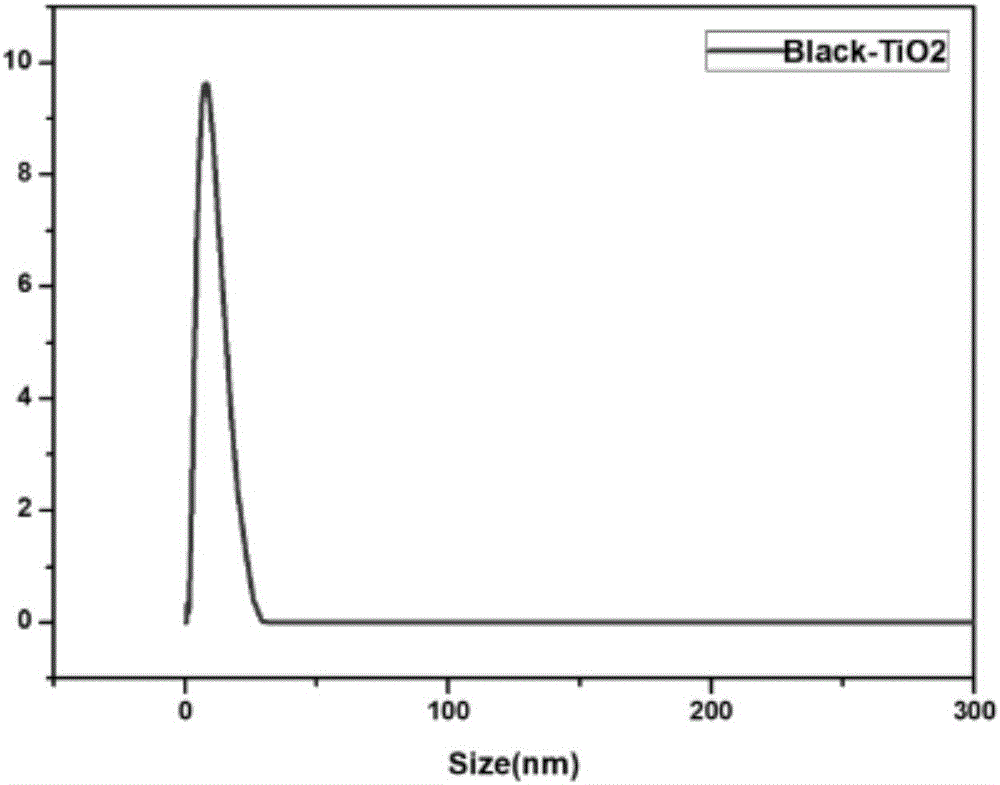

Preparation method of rare earth element co-doped nano titanium dioxide photocatalyst

ActiveCN106076307ARich sourcesReduce manufacturing costMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementEnergy storage

The invention discloses a preparation method of a rare earth element co-doped nano titanium dioxide photocatalyst. The rare earth element is embedded into self-doped titanium dioxide to obtain the rare earth element co-doped nano titanium dioxide photocatalyst with certain morphology. The preparation method is simple and low at cost, and uses the photoelectric characteristics of rare earth element to prepare the titanium dioxide rare earth element co-doped nano titanium dioxide photocatalyst, which has the advantages of controllable doping, good dispersion, efficient energy storage and high catalytic activity. The purpose of the invention is to provide a simple and low-cost preparation method, which uses self-doped black TiO2 as the base and sets the rare earth element co-doping as customized purpose; and the method can prepare the rare earth element co-doped nano titanium dioxide photocatalyst with high catalytic activity.

Owner:吕浩然

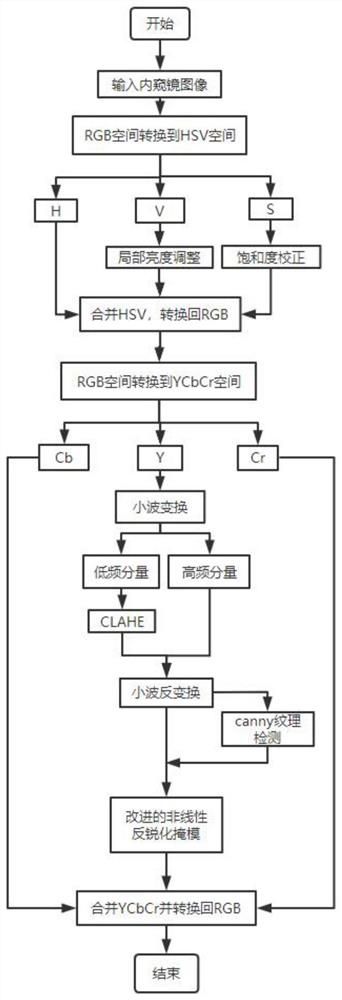

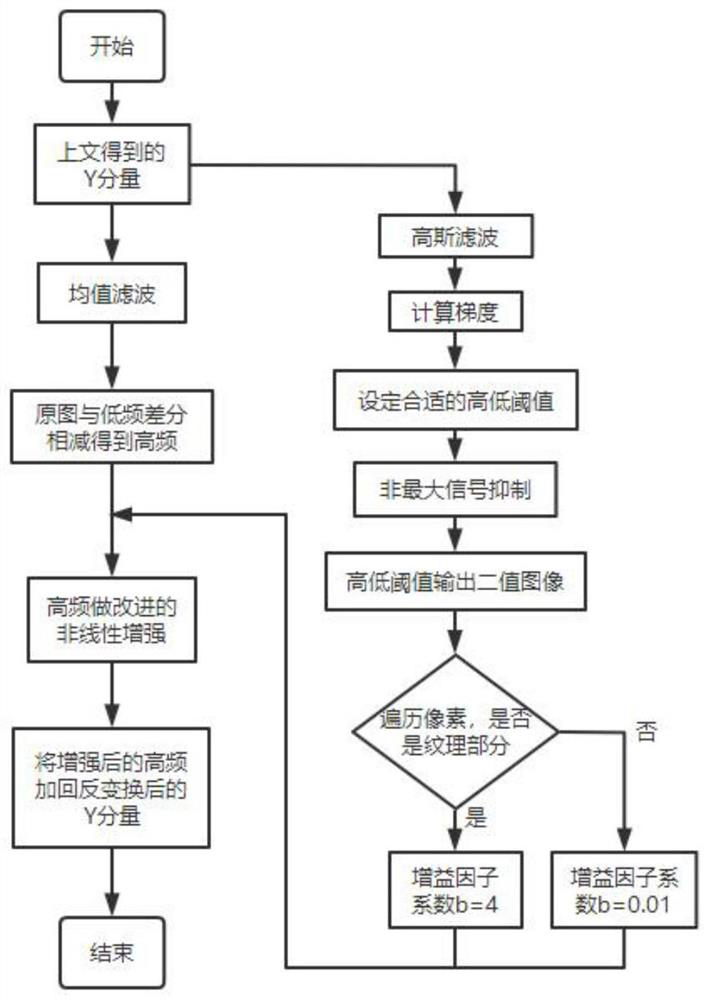

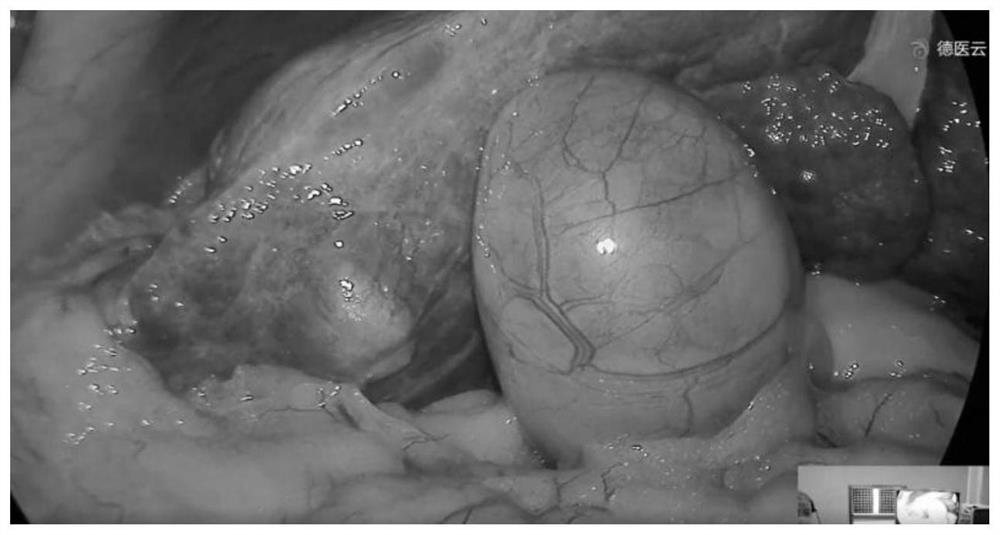

Endoscope image enhancement method based on histogram equalization and improved unsharpened mask

PendingCN113989147AIncrease contrastEnhance background detailsImage enhancementImage analysisHsv color modelImage contrast

The invention discloses an endoscope image enhancement method based on histogram equalization and improved anti-sharpening mask, which relates to the technical field of image enhancement, and comprises the following steps: acquiring an endoscope image; carrying out local brightness adjustment and saturation correction on the endoscope image by adopting an HSV color model; converting the image into a YCbCr space, and performing low-frequency background enhancement on a Y component by adopting a contrast-limited adaptive histogram equalization method; and carrying out canny texture detection, and carrying out high-frequency detail enhancement by using the improved nonlinear unsharp mask to obtain an improved endoscope enhanced image. According to the image enhancement method, a histogram equalization method, canny edge detection and an improved nonlinear anti-sharpening mask are innovatively combined, so that the low-frequency component of background intensity is effectively balanced, contour details are enhanced, the original color of the image is kept while the image contrast is naturally enhanced and detail information such as blood vessels is revealed, and the noise is reduced.

Owner:ANHUI UNIVERSITY

Polyurea waterproofing paint

ActiveCN103468110AChange colorNo solvent requiredPolyurea/polyurethane coatingsPolyether coatingsPolyesterPlasticizer

The invention discloses a polyurea waterproofing paint. The paint is prepared by mixing and stirring the following components in parts by weight: 40-60 parts of polyether, 40-60 parts of polyester, 1-2 parts of bactericide, 1-2 parts of defoaming agent, 8-10 parts of filler, 2-5 parts of plasticizer, 3-6 parts of curing agent, and 60-80 parts of water. The polyurea waterproofing paint is transparent after being coated on the surface of a base material to form a film, so that the color of the base material is not changed after the film is formed. Furthermore, the paint is solvent-free and pollution-free, is of a high reaction type, and is good in water seepage resistance.

Owner:山东正大防水材料股份有限公司

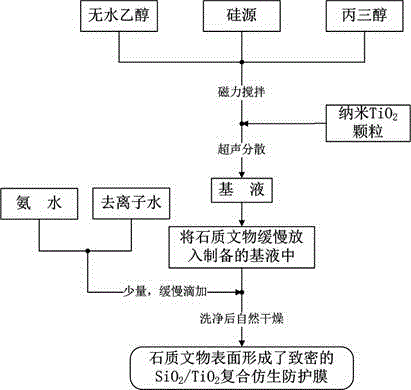

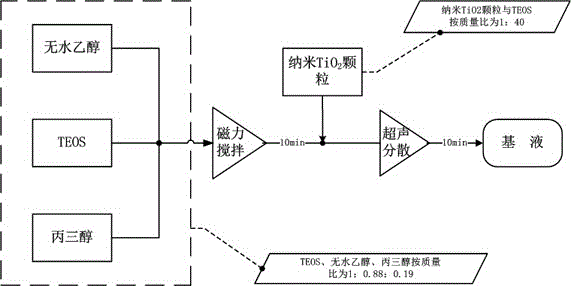

Composite bionic SiO2/TiO2 protective film and preparation method thereof on the surface of stone historical relic

The invention provides a composite bionic SiO2 / TiO2 protective film and a preparation method thereof on the surface of a stone historical relic. Ethyl orthosilicate or sodium fluosilicate is used as a silicon source, anhydrous ethanol and glycerol are added, even mixing is performed, and then nano TiO2 particles are uniformly dispersed in the solution to prepare a base solution. The stone historical relic is cleaned and is soaked and pre-treated with a cetyl trimethyl ammonium bromide solution and then is immersed into the base solution, a small amount of deionized water and ammonia water are slowly and dropwise added, and the stone historical relic is taken out, cleaned and dried naturally after sealed storage is performed at room temperature for a period of time. The composite bionic protective film containing main component SiO2 and TiO2 is formed on the surface of the stone historical relic. The composite bionic SiO2 / TiO2 protective film prepared by adopting the preparation method has good combinability with the matrix of a stone material, good acid and alkali resistance capability, hydrophily, permeability, antibacterial performance and self-cleaning performance, and the preparation method can be performed at normal temperature and pressure and is friendly and pollution-free to the environment.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

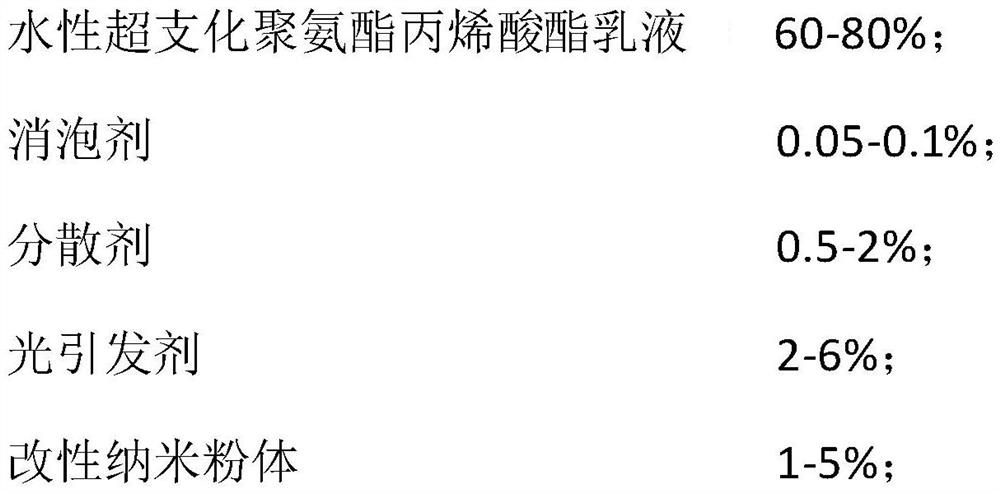

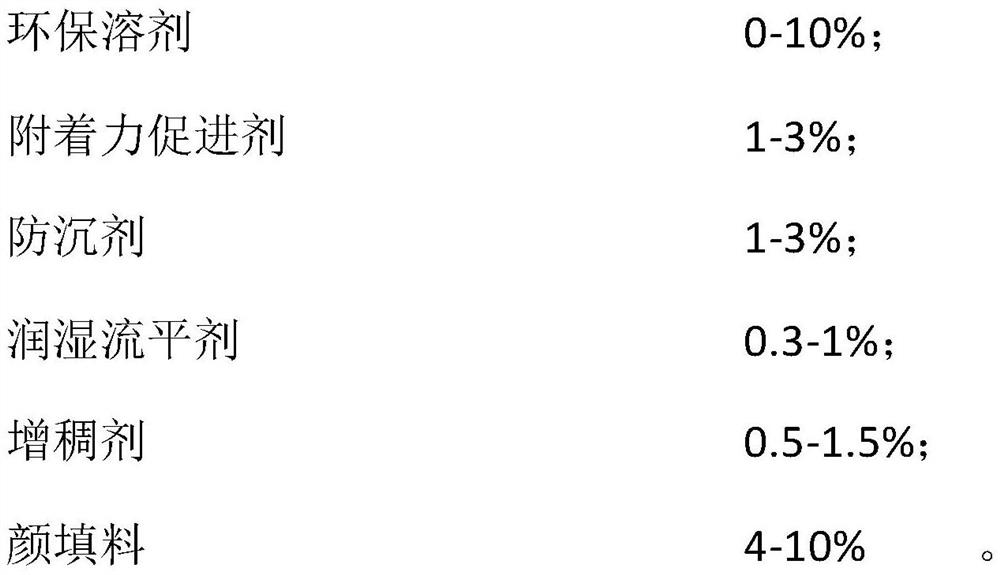

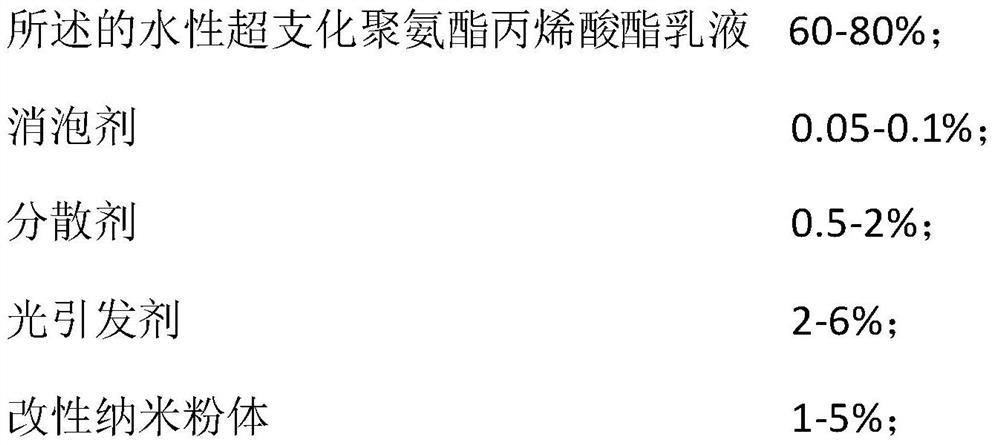

Preparation method of waterborne hyperbranched polyurethane acrylate emulsion, UV curing coating and preparation method and application of UV curing coating

ActiveCN111978506AHigh yieldHigh catalytic activityAntifouling/underwater paintsPaints with biocidesPolymer scienceUV curing

The invention belongs to the technical field of UV curing coatings, and particularly relates to a preparation method of a waterborne hyperbranched polyurethane acrylate emulsion, a UV curing coating and a preparation method and application of the UV curing coating. The UV-curable coating is prepared from the following raw materials in percentage by weight: 60 to 80 percent of waterborne hyperbranched polyurethane acrylate emulsion, 0.05 to 0.1 percent of a defoaming agent, 0.5 to 2 percent of a dispersing agent, 2 to 6 percent of a photoinitiator, 1 to 5 percent of modified nano powder, 0 to 10 percent of an environment-friendly solvent, 1 to 3 percent of an adhesion promoter, 1 to 3 percent of an anti-settling agent and 0.3 to 1 percent of a wetting leveling agent. 0.5-1.5% of a thickening agent and 4-10% of a pigment filler; the invention further provides a preparation method of the UV curing coating for a polypropylene packaging barrel. The UV curing coating for the polypropylene packaging barrel, prepared by the invention, has excellent wear resistance and relatively high adhesive force on the polypropylene packaging barrel, and has excellent weather resistance.

Owner:珠海瑞杰包装制品有限公司

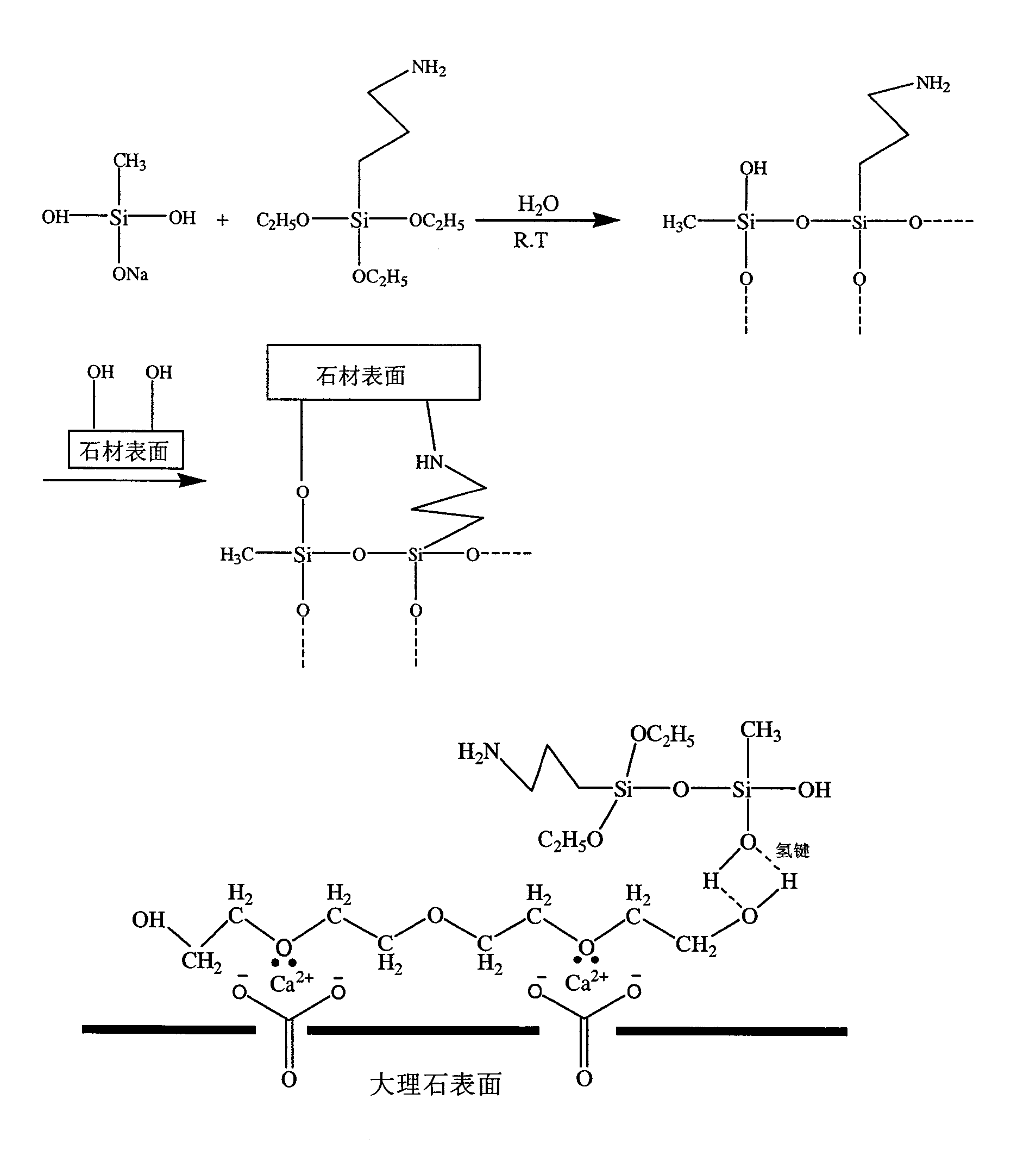

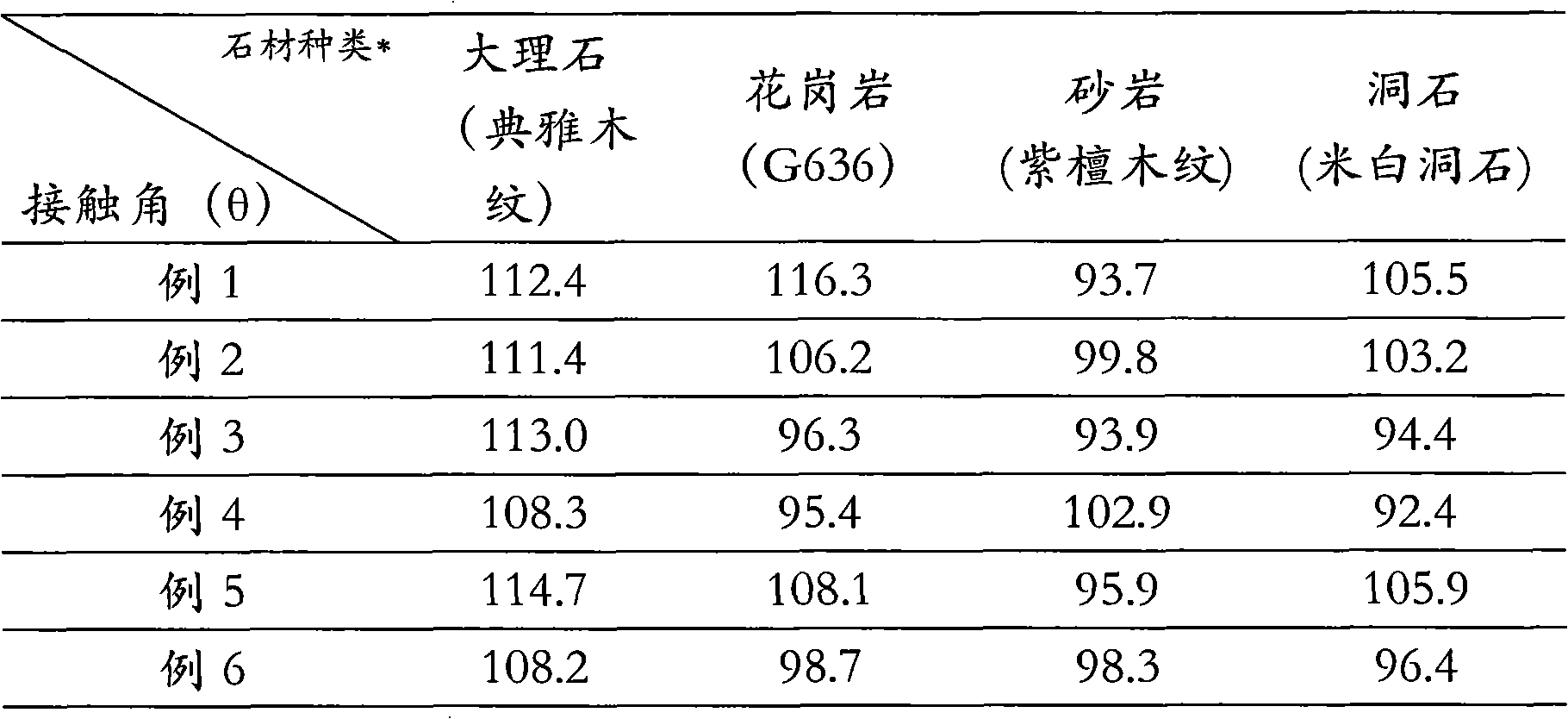

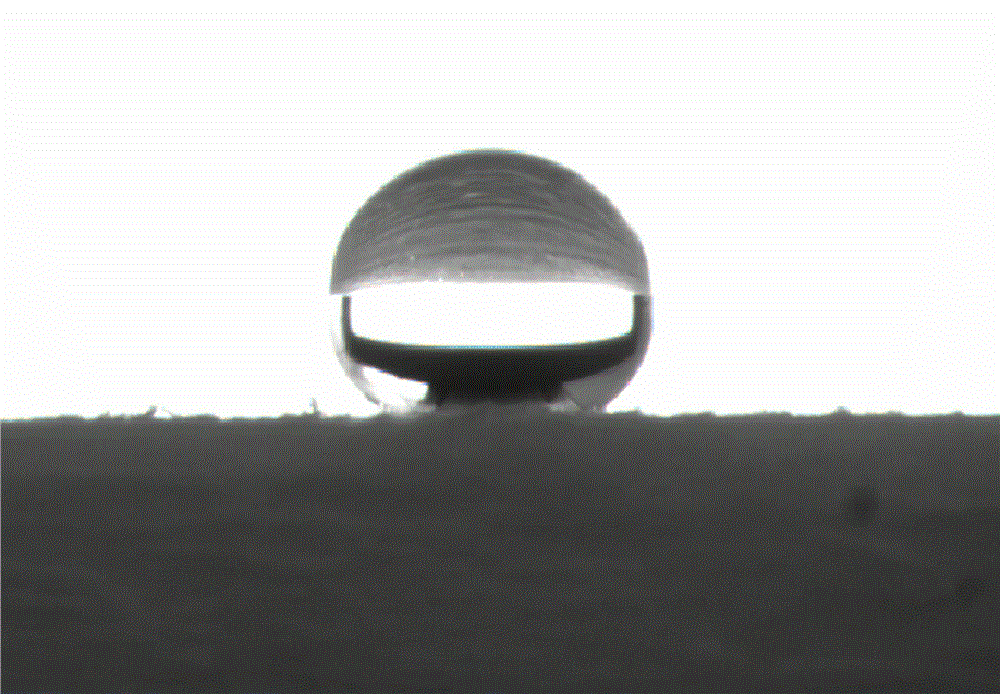

Methyl silicate stone protecting agent and manufacturing method thereof

ActiveCN103571327AKeep breath breathableIncrease contact angleCoatingsSodium silicateSilane coupling

The invention discloses a methyl silicate stone protecting agent and a manufacturing method thereof. The methyl silicate stone protecting agent comprises a methyl silicate, at least one type of silane coupling agent, at least one type of polyethylene glycol and at least one type of water, wherein the adding amount of the methyl silicate is 8-20% of the total weight of a polymer; the adding amount of the silane coupling agent is 1-5% of the total weight of the polymer; the adding amount of the polyethylene glycol is 0-5% of the total weight of the polymer; and the adding amount of the water is 70-91% of the total weight of the polymer. The manufacturing method disclosed by the invention comprises the following steps: dissolving the polyethylene glycol in a small amount of hot water according to the proportion, then sequentially adding sodium methyl silicate and the silane coupling agent in a stirring state and finally replenishing water till 100%. The methyl silicate stone protecting agent disclosed by the invention has the advantages of waterborne and environment-friendly properties, no toxicity, no volatilization, no pollution, short curing time, stable chemical performances, simplicity, convenience and flexibility in construction and operation, safety and low cost. The methyl silicate stone protecting agent is suitable for waterproofness and moisture-proofness of various natural stones, artificial stones and the like. The methyl silicate stone protecting agent particularly has an excellent waterproof effect on the stones with relatively large holes, such as sandstone, cavity stone and the like, and can simultaneously prevent affecting the air permeability of the stones.

Owner:XIAMEN NORNS TECH

Preparation method of novel hydrophobic wood

InactiveCN103302708BGood dimensional stabilityHigh mechanical strengthWood treatment detailsPressure impregnationPolymer scienceEmulsion

The invention relates to a preparation method of a novel hydrophobic wood. The preparation method comprises the following steps of: firstly, melting alkyl ketene dimer colloidal particles at 40-60 DEG C; then adding a certain amount of cationic starch and an emulsifying agent and water; preparing an alkyl ketene dimer emulsion through treatment with a high-pressure homogenizer, and then blending the alkyl ketene dimer emulsion with a certain amount of nano cellulose gel to prepare a composite emulsion; then putting the wood and the composite emulsion into a reaction tank, vacuumizing and then injecting the emulsion for a period of time; taking the wood out, draining off the composite, and drying in a drying oven for 3-8 hours to obtain the novel hydrophobic wood. The preparation method is simple in process, causes no changes to the color of the wood and no corrosion to equipment, and is low in energy consumption, and the product does not have peculiar smells and can be widely used as indoor and outdoor furniture base materials and decorative materials.

Owner:GUANGDONG YIHUA TIMBER IND +1

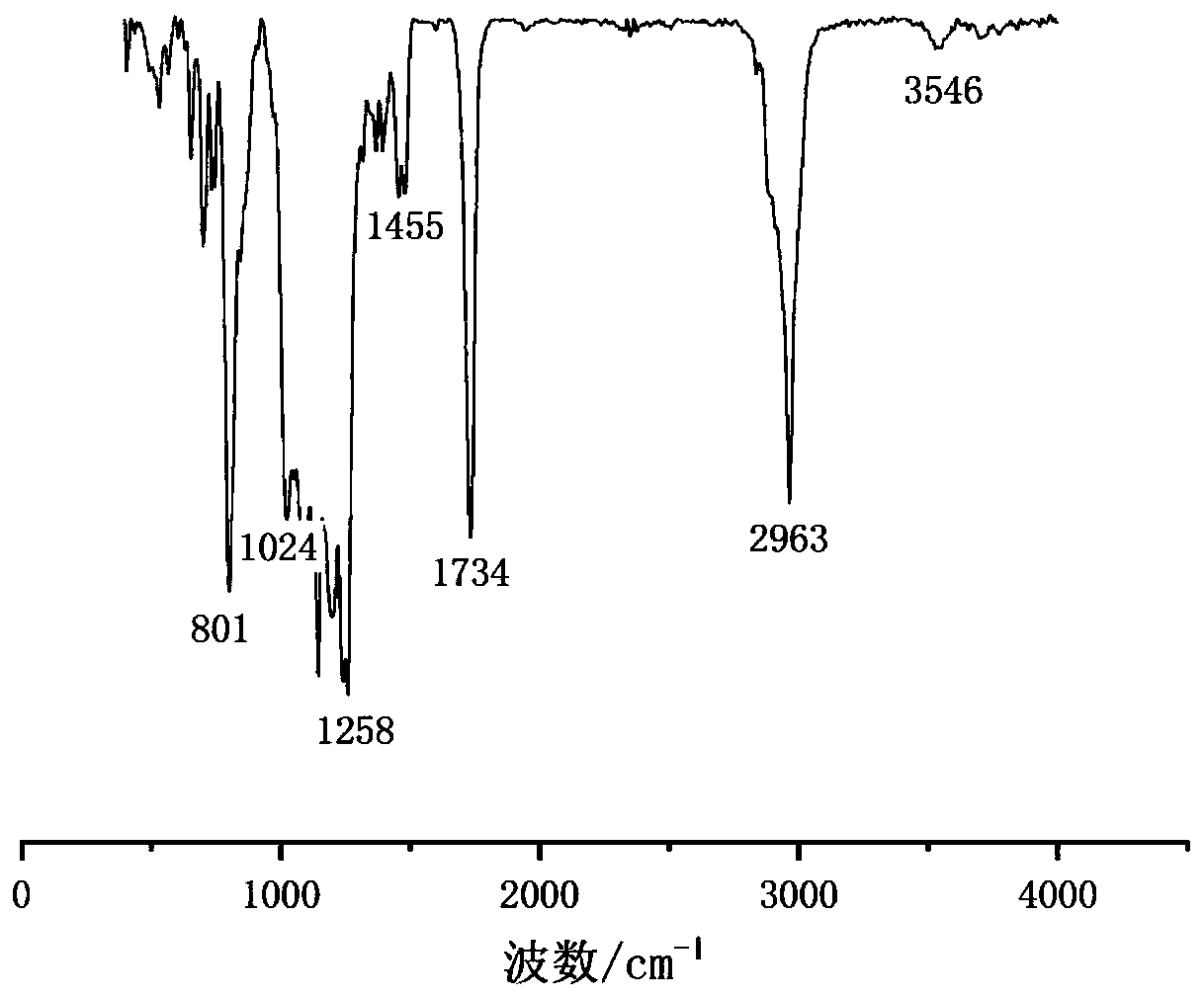

Finishing type stone protection agent based on fluorosilicone acrylic resin, and preparation method thereof

ActiveCN110643251AMeet environmental protection requirementsMeet the needs of environmental protectionAntifouling/underwater paintsPaints with biocidesMethacrylatePolymer science

The invention discloses a finishing type stone protection agent based on fluorosilicone acrylic resin, and a preparation method thereof. The finishing type stone protection agent comprises, by weight,5-20 parts of a fluorosilicone acrylic resin solution, 10-50 parts of a silane coupling agent, 1-10 parts of low molecular weight hydroxyl-terminated silicone oil, 20-85 parts of a diluent and 0.5-2parts of a catalyst. The preparation method comprises the following steps: uniformly mixing the fluorosilicone copolymer resin solution, the silane coupling agent, the hydroxyl-terminated silicone oil, the diluent and the catalyst, and spraying the obtained mixture on the surface of a stone. A perfluorohexyl side group, a long siloxane side group, methacrylate and a side group containing a crosslinkable functional group exist in the molecular structure of the fluorosilicone acrylic resin. The preparation method has the advantages of reasonable cost, simple process and facilitation of large-scale production, and the prepared stone protection agent has good waterproof and oil-repellent effects, does not change the natural appearance or the air permeability of the stone, does not contain eight or more perfluoro chain segments, and meets the environmental protection requirement.

Owner:SOUTH CHINA UNIV OF TECH

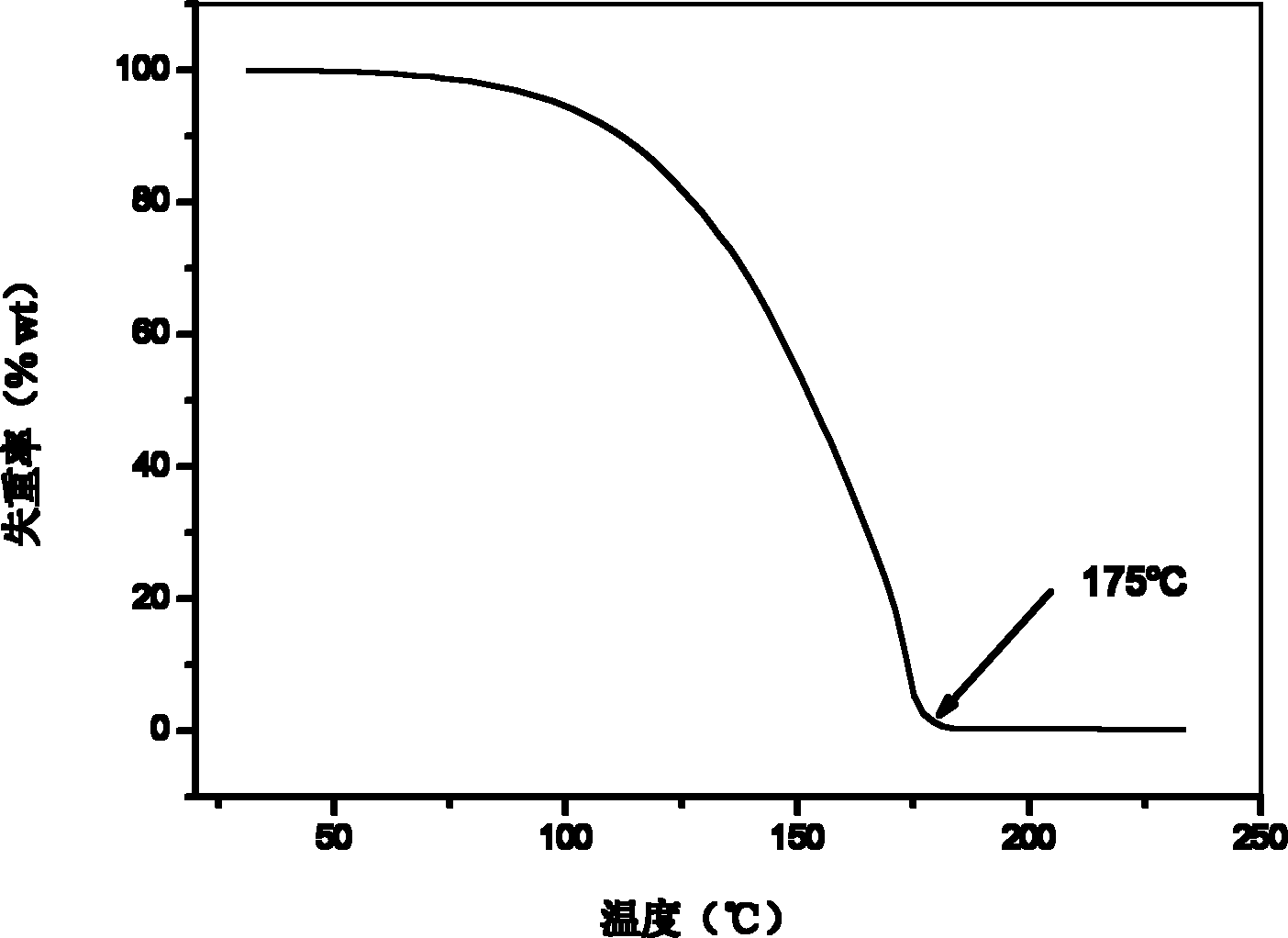

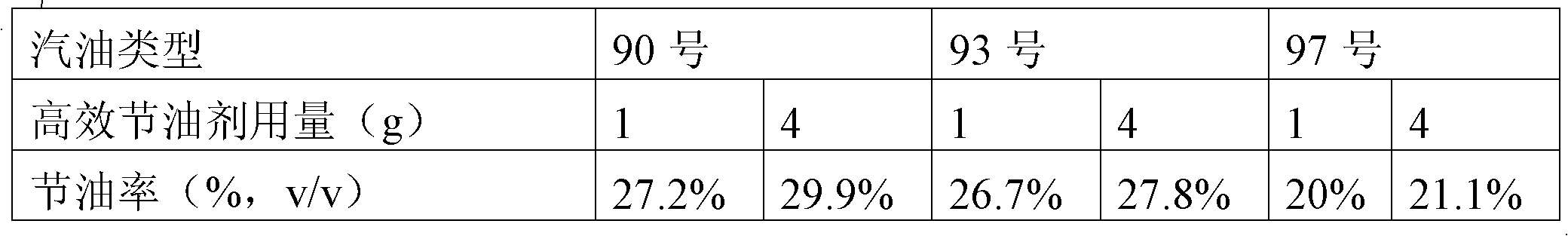

High-efficiency oil-saving agent, preparation method and application thereof

InactiveCN101845338AObvious fuel-saving effectImprove fuel efficiencyLiquid carbonaceous fuelsActive agentLower grade

The invention discloses a high-efficiency oil-saving agent, a preparation method and the application thereof. The high-efficiency oil-saving agent comprises 0.05-2.0% of fluorenone compound, 0.05-2.0% of nitrotoluene, 80-99.5% of camphor, 0.3-12% of borneol and balance low-grade fatty alcohol. The preparation method of the high-efficiency oil-saving agent comprises the steps of: completely dissolving the fluorenone compound and the nitrotoluene into the low-grade fatty alcohol, then fully mixing the camphor and the borneol, and obtaining the high-efficiency oil-saving agent. When being added into fuel oil, the high-efficiency oil-saving agent has the oil-saving rate reaching up to 30%. As metal salt is not used as an active agent in the high-efficiency oil-saving agent, residues are not left after the fuel oil is fully burnt, and the service life of an engine can be prolonged; the high-efficiency oil-saving agent is solid additive, thus being convenient for transportation and storage, easily dissolved into the fuel oil and low in adding proportion, and not changing the physical property of the fuel oil; and furthermore, the high-efficiency oil-saving agent is safe and can improve the antiknock property. The invention has simple preparation method and low cost, and is wide in application prospect.

Owner:GUANGZHOU DONGDI ENVIRONMENTAL PROTECTION TECH

Concrete curing agent

The concrete curing agent consists of 30-50 wt% concentration styrene-acrylic emulsion in 30-70 weight and 2-10 wt% concentration acrylamide in 30-70 weight, and is prepared through low speed stirring for mixing. The concrete curing agent is sprayed to the surface of concrete to form film avoiding water evaporation and ensuring the fluent hydration reaction in the curing period. The film does not alter the original color of concrete and facilitates the cleaning of concrete surface. During use, the concrete curing agent may be diluted with water.

Owner:李全堂 +1

Dirt-resistant antibacterial tile grout and preparation method thereof

InactiveCN108504283AHas antibacterial functionWith self-cleaning functionAntifouling/underwater paintsPaints with biocidesFiberCalcite

The invention discloses a dirt-resistant antibacterial tile grout. The tile grout comprises the following raw materials in parts by weight: 20-30 parts of a silicone emulsion, 15-25 parts of sepiolitepowder, 10-15 parts of modified fly ash, 7-14 parts of calcite powder, 12-18 parts of a vinyl acetate-ethylene copolymer emulsion, 3-6 parts of lignin fibers, 2-4 parts of nano titanium dioxide, 1-3parts of hydroxyethyl cellulose, 2-3 parts of a bactericide, 1-3 parts of an antifoaming agent, 4-9 parts of a thickening agent and a proper amount of water. The dirt-resistant antibacterial tile grout provided by the invention has antibacterial and self-cleaning functions, is resistant to dirt, and is easy to scrub, the color of a substrate is not changed after film is formed, the core is soft, and the shell is hard. In addition, the weather resistance and the alkali resistance of the tile grout are strong, and the water seepage resistance is good.

Owner:合肥语林装饰工程有限公司

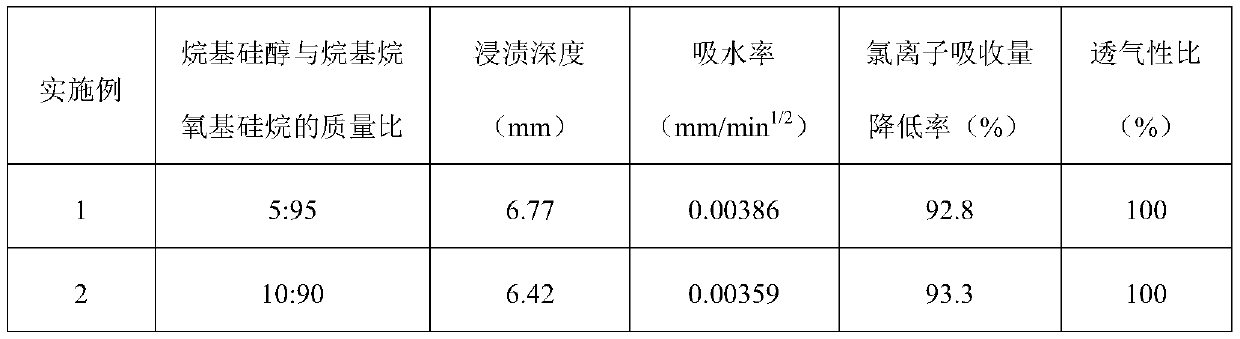

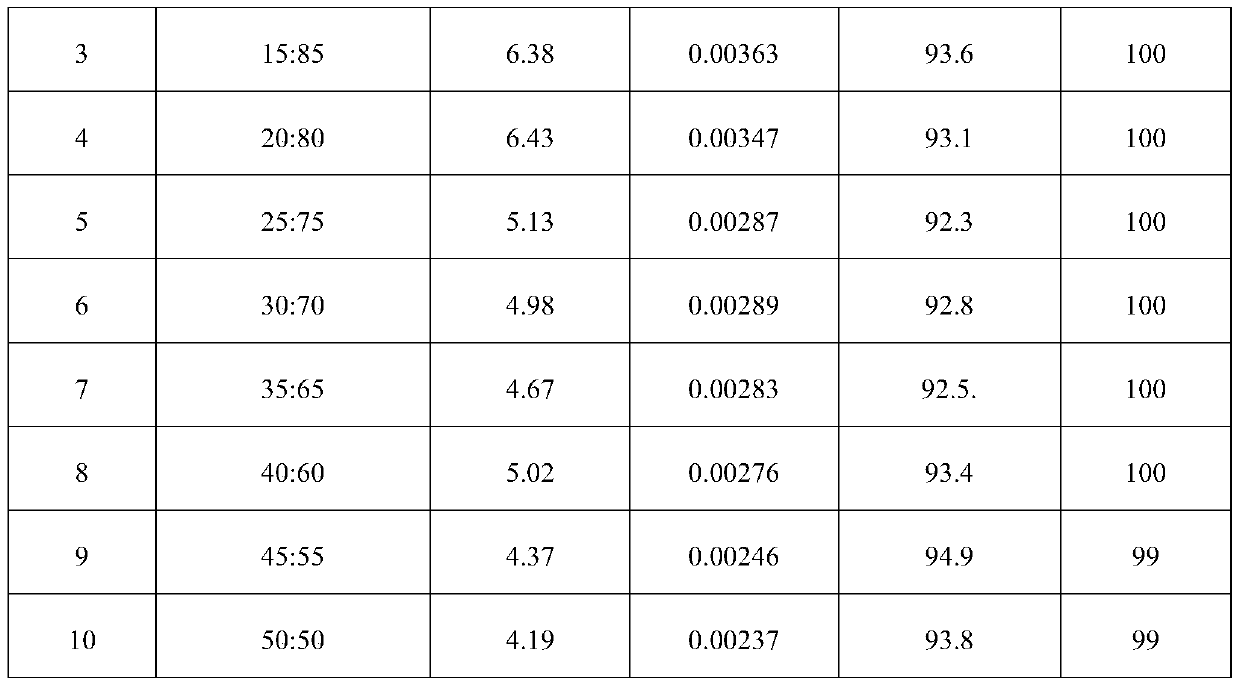

Self-crosslinked alkyl alkoxy silane impregnant

ActiveCN110183246ALow water absorptionImprove water resistanceSilicon organic compoundsSilanesChloride

The invention relates to the field of waterproofness and corrosion prevention of a porous base material and particularly discloses a self-crosslinked alkyl alkoxy silane impregnant. The silane impregnant is prepared from alkyl alkoxy silane and alkylsilanol, and a mass ratio of alkylsilanol to alkyl alkoxy silane is (5-50):(50-95). According to the silane impregnant, alkylsilanol is prepared fromalkyl alkoxy silane by hydrolysis. The silane impregnant has excellent waterproof performance, the crosslinking reaction of the silane impregnant is independent of external moisture, meanwhile, the silane impregnant has excellent permeability, breathing function, chloride ion erosion resistance and antifouling function, and besides, the silane impregnant is a colorless transparent liquid, so thatthe color of the surface of a concrete material is not changed after application of the silane impregnant.

Owner:河南聚研材料科技有限公司

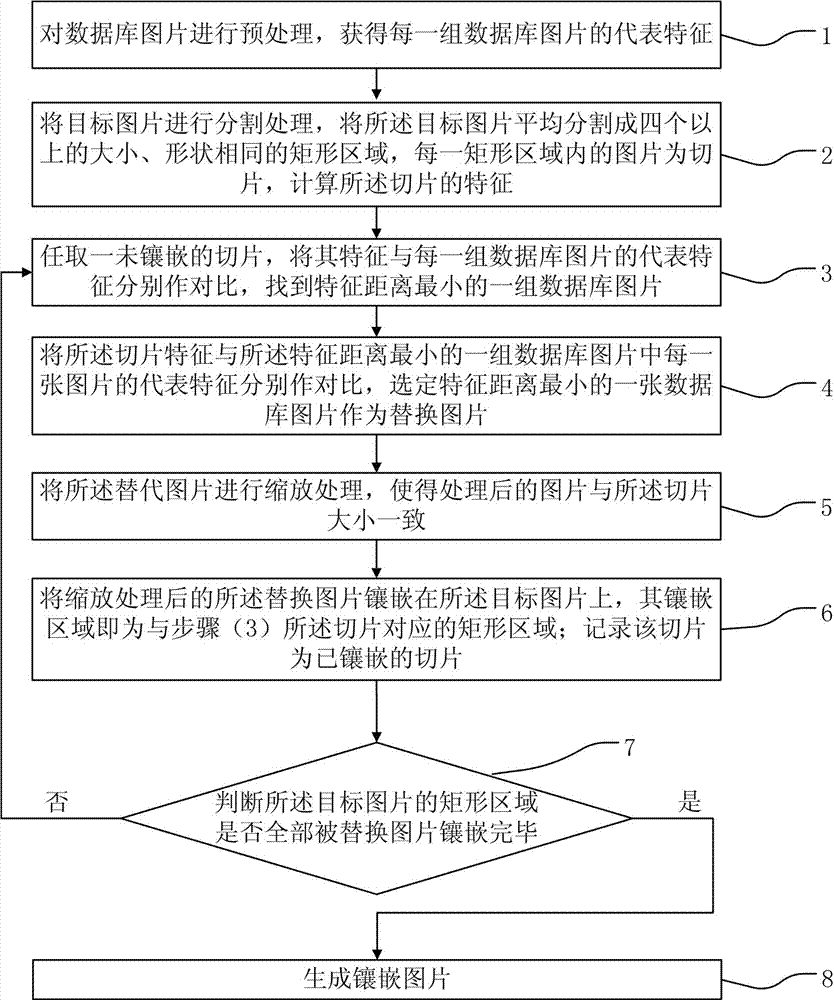

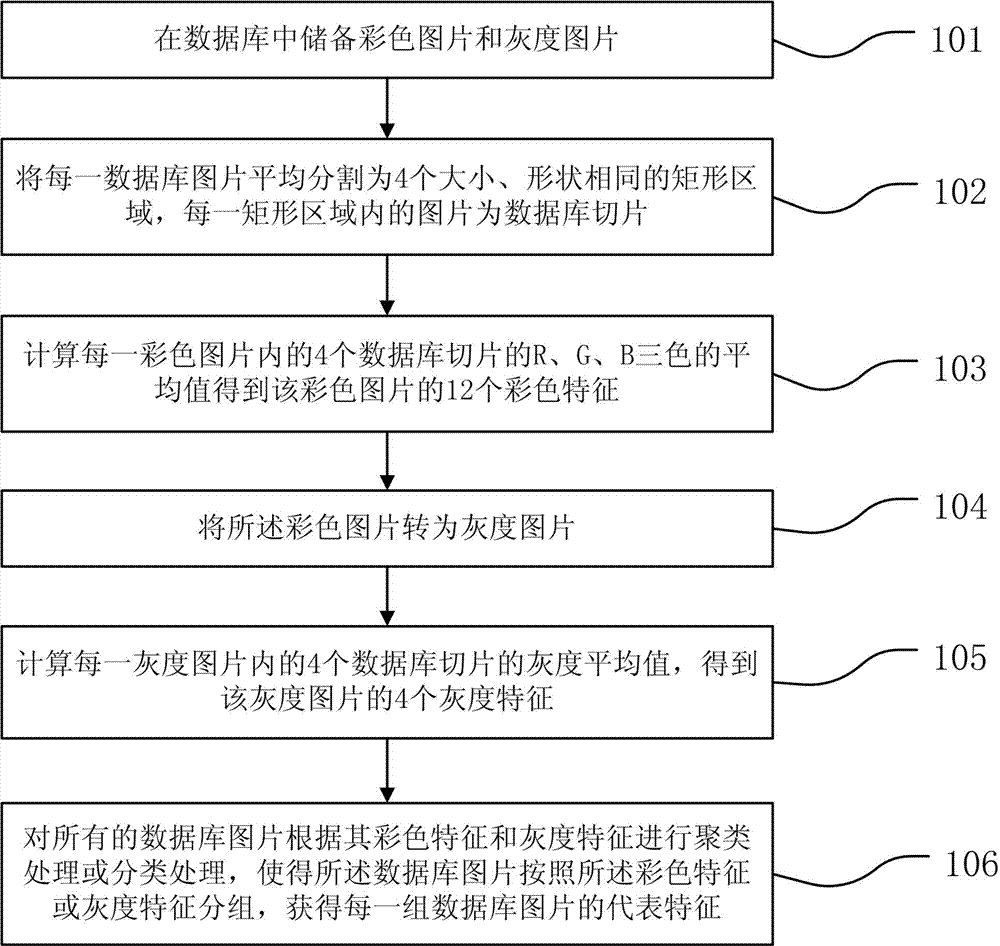

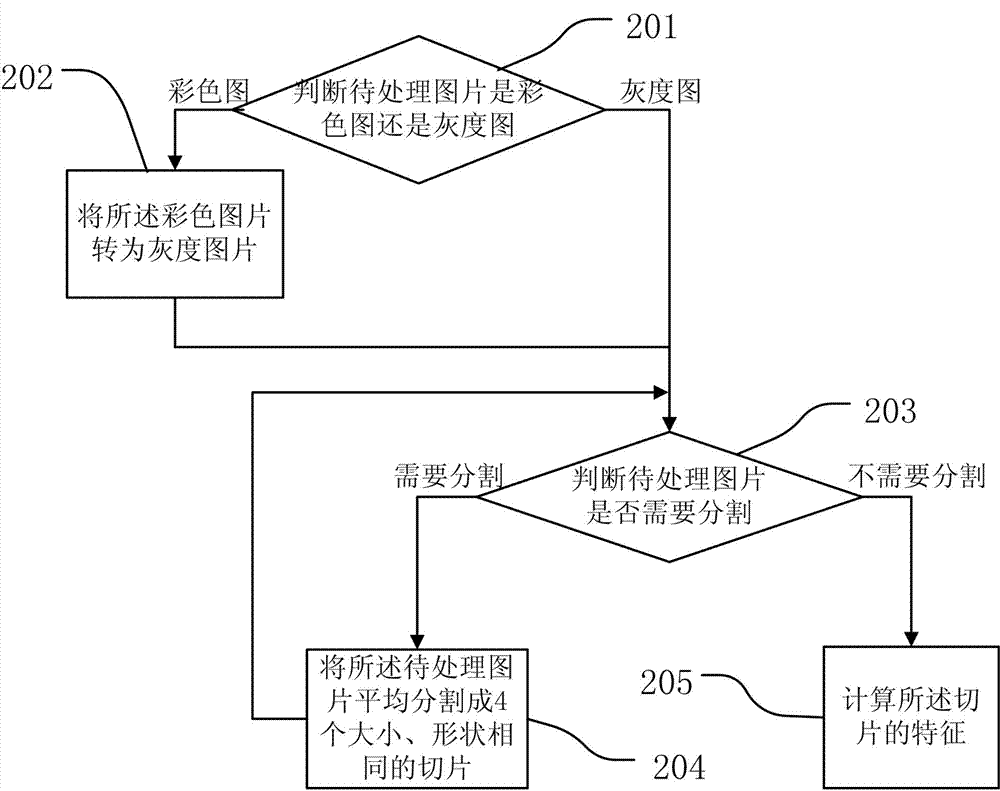

Mosaic image generation method

InactiveCN102930521ADo not change colorAutomatic generationImage enhancementImage analysisChange colorImage segmentation

The invention provides a mosaic image generation method. The mosaic image generation method comprises the following steps of: database image preprocessing, target image segmentation processing, taking any one of slices, selecting an image to be inlaid from database images, scaling processing of the image to be inlaid, inlaying processing, completing the mosaic image, and the like. The mosaic image generation method effectively solves the technical problems of oversized image database, poor visual effect after the target image is inlaid, easiness in distortion of details of the mosaic image, and the like in the prior art. The mosaic image generation method can be used for automatically and quickly generating the mosaic image corresponding to the target image based on different database images by taking a computer as a tool. The mosaic image generation method does not change colors of the database images without distortion or strict requirements for the database size, and can complete the mosaic image by using a smaller image database.

Owner:SHANGHAI DIANJI UNIV

Methyl silicate stone protective agent and manufacturing method

ActiveCN103571327BNon-toxic and non-volatileNo pollution in the processCoatingsPolyethylene glycolMethyl group

The invention discloses a methyl silicate stone protecting agent and a manufacturing method thereof. The methyl silicate stone protecting agent comprises a methyl silicate, at least one type of silane coupling agent, at least one type of polyethylene glycol and at least one type of water, wherein the adding amount of the methyl silicate is 8-20% of the total weight of a polymer; the adding amount of the silane coupling agent is 1-5% of the total weight of the polymer; the adding amount of the polyethylene glycol is 0-5% of the total weight of the polymer; and the adding amount of the water is 70-91% of the total weight of the polymer. The manufacturing method disclosed by the invention comprises the following steps: dissolving the polyethylene glycol in a small amount of hot water according to the proportion, then sequentially adding sodium methyl silicate and the silane coupling agent in a stirring state and finally replenishing water till 100%. The methyl silicate stone protecting agent disclosed by the invention has the advantages of waterborne and environment-friendly properties, no toxicity, no volatilization, no pollution, short curing time, stable chemical performances, simplicity, convenience and flexibility in construction and operation, safety and low cost. The methyl silicate stone protecting agent is suitable for waterproofness and moisture-proofness of various natural stones, artificial stones and the like. The methyl silicate stone protecting agent particularly has an excellent waterproof effect on the stones with relatively large holes, such as sandstone, cavity stone and the like, and can simultaneously prevent affecting the air permeability of the stones.

Owner:XIAMEN NORNS TECH

Preparing method of long-acting natural stone protective agent

The invention discloses a preparing method of a long-acting natural stone protective agent, and relates to the technical field of stone protection. The preparing method comprises the steps of at first using lichen as a raw material, using methyl alcohol to extract the lichen, conducting concentration on filter liquor to obtain extractive pasty body, then using ethyl orthosilicate as a silicon resource to prepare and obtain a monodispersing silica solution; mixing the silica solution with deionized water, afterwards using oxalic acid to adjust ph, then adding absolute ethyl alcohol into the mixture to be subjected to still standing and aging, conducting surface finish by adding trimethylchlorosilane so as to endow the silica solution with hydrophobicity, finally mixing filter residues after being filtered with standby extractive pasty body and the like in proportion, and obtaining the long-acting natural stone protective agent. According to the preparing method of the long-acting natural stone protective agent, the effective components in the long-acting natural stone protective agent infiltrates inside a stone along with a solvent, and after the solvent volatilizes naturally, the effective components then combine with crystals and form a three-dimensional net-shape dewatering protective film on the surface of and inside the stone, thus foreign polluant is prevented from permeating in, pollutant inside and at the bottom of the stone is prevented from permeating out; meanwhile, the disadvantages that traditional wax type protective agent can only form films on the surface of the stone and thus block holes of the stone are solved.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com