Self-crosslinked alkyl alkoxy silane impregnant

A technology of alkylalkoxysilane and impregnating agent, which is applied in the field of waterproof and anticorrosion of porous substrates. It can solve the problems of the reaction crosslinking process relying on external moisture, the pollution of initiators and terminators, and the decrease in effective utilization rate, etc., to achieve good Effect of waterproof effect, excellent waterproof performance, good permeability and breathing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A self-crosslinking alkyl alkoxysilane impregnating agent, its preparation steps are as follows:

[0029] (1) Add methyltriethoxysilane, deionized water and ethanol into the reaction kettle according to the molar ratio of 1:3:1, stir at room temperature for 5min, add 0.01mol / L HCl solution to adjust the pH value of the system When the temperature is about 4, raise the temperature to 40°C and continue to stir to hydrolyze methyltriethoxysilane for 5 hours. After the reaction is completed, add 0.01mol / L NaOH solution to adjust the pH value of the system to 6-8. Stir under reduced pressure for 120 min at °C to remove ethanol to obtain methylsilanol.

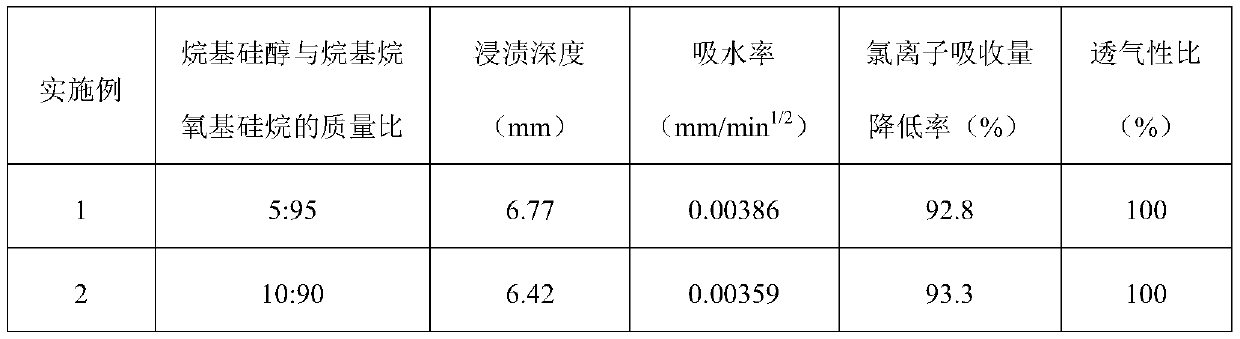

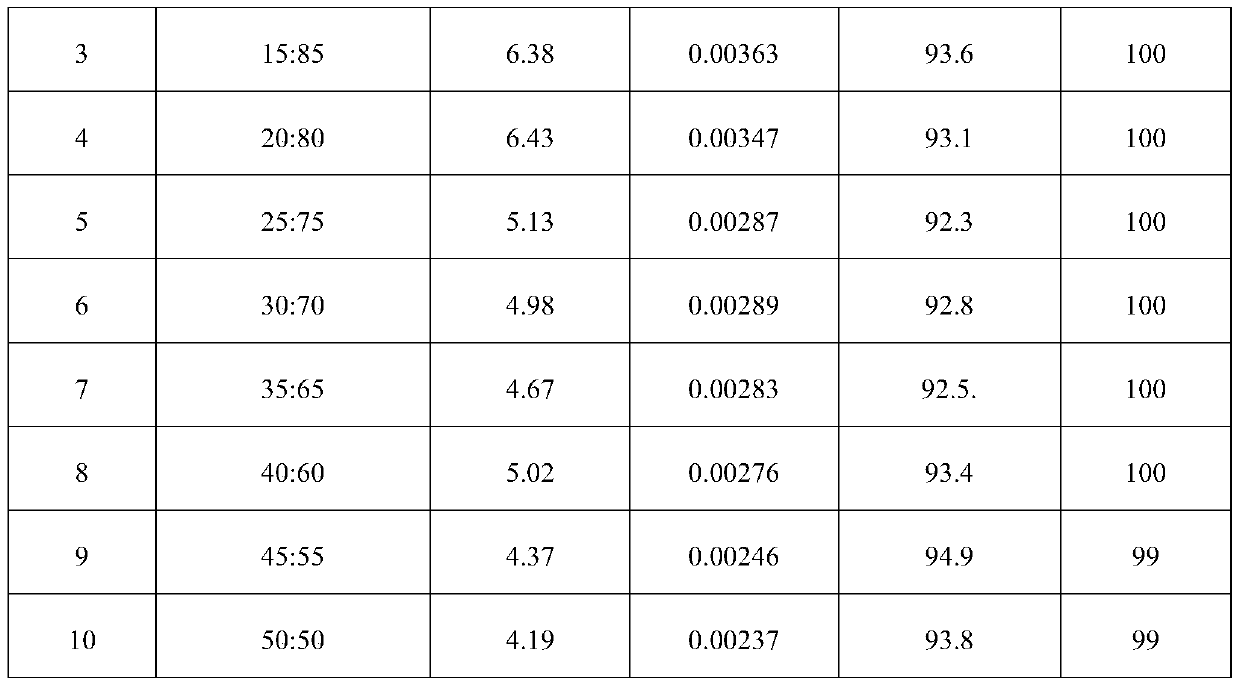

[0030] (2) Mix the above-prepared methylsilanol and methyltriethoxysilane uniformly at a mass ratio of 5:95 to obtain a silane impregnating agent containing 5% methylsilanol.

Embodiment 2

[0032] A self-crosslinking alkyl alkoxysilane impregnating agent, its preparation steps are as follows:

[0033] Add propyltriethoxysilane, deionized water and ethanol into the reaction kettle at a molar ratio of 1:3:2, stir at room temperature for 10 minutes, add 0.01mol / L HCl solution to adjust the pH of the system to about 5 , raise the temperature to 45°C and continue stirring to hydrolyze propyltriethoxysilane for 4.5h. After the reaction, add 0.01mol / L NaOH solution to adjust the pH value of the system to 6-8. Stir under reduced pressure for 100 min to remove ethanol to obtain propylsilanol.

[0034] The above-prepared propylsilanol and methyltriethoxysilane were uniformly mixed according to a mass ratio of 10:90 to obtain a silane impregnating agent containing 10% propylsilanol.

Embodiment 3

[0036]A self-crosslinking alkyl alkoxysilane impregnating agent, its preparation steps are as follows:

[0037] Add octyltriethoxysilane, deionized water and ethanol into the reaction kettle at a molar ratio of 1:3:3, stir at room temperature for 5 minutes, add 0.01mol / L NaOH solution to adjust the pH of the system to about 9 , raise the temperature to 50°C and continue stirring to hydrolyze octyltriethoxysilane for 4 hours. After the reaction, add 0.01mol / L HCl solution to adjust the pH value of the system to 6-8. Under the conditions of pressure 0.005MPa and temperature 50°C Stir under reduced pressure for 90 minutes to remove ethanol to obtain octylsilanol.

[0038] The above-prepared octylsilanol and propyltriethoxysilane were uniformly mixed according to a mass ratio of 15:85 to obtain a silane impregnating agent containing 15% octylsilanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com