Preparation method of water-based organosilicone stone protecting agent

A technology of protective agent and organic silicon, which is applied in the field of water-based organic silicon stone protective agent and its preparation, can solve the problems of affecting the efficiency and appearance of coating, high production cost, and long curing time, so as to achieve favorable production efficiency, low cost, The effect of fast curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

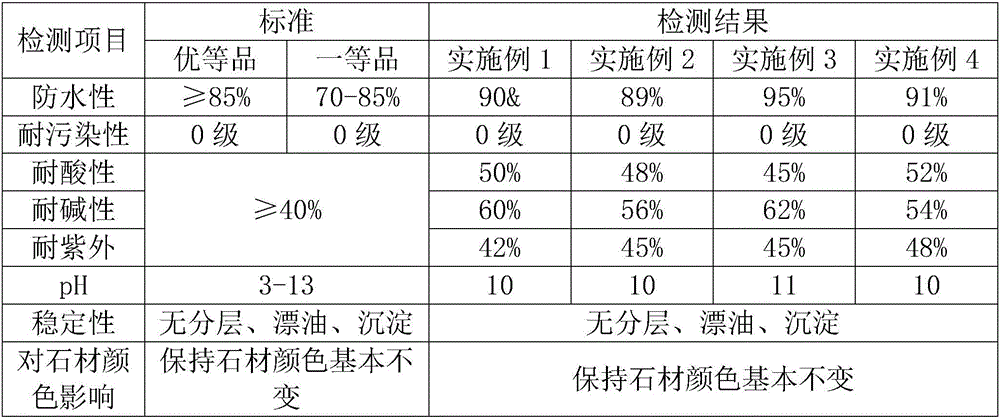

Examples

Embodiment 1

[0020] A water-based organosilicon stone protective agent, comprising the following components in parts by weight: 75 parts of long-chain alkylsilane-modified methyl silicate sodium salt solution with a solid content of 20 wt%, 5 parts of silica sol, polyethylene 5 parts of alcohol, 5 parts of water-based adhesion promoter.

[0021] The preparation method of water-based organosilicon stone protection agent described in the present embodiment may further comprise the steps:

[0022] 1) Dissolve 10g of n-butyltriethoxysilane and 50g of sodium methyl silicate in 240g of water, stir and dissolve evenly, heat up to 60°C, and react for 2 hours to obtain 20wt% long-chain alkylsilane modified Sodium methyl silicate solution.

[0023] 2) Weigh 75 parts of the long-chain alkylsilane-modified methyl silicate sodium salt solution prepared in step 1) and 5 parts of polyvinyl alcohol, mix and heat to 60°C, after the solution is transparent, keep the temperature for 30 minutes, and then dro...

Embodiment 2

[0025] A water-based organosilicon stone protective agent, which comprises the following components in parts by weight: 50 parts of long-chain alkylsilane-modified potassium methyl silicate solution with a solid content of 40 wt%, 10 parts of silica sol, poly 10 parts of vinyl alcohol, 1 part of water-based adhesion promoter.

[0026] The preparation method of water-based organosilicon stone protection agent described in the present embodiment may further comprise the steps:

[0027] 1) Dissolve 10g of n-octyltrimethoxysilane and 150g of potassium methyl silicate in 240g of water, stir and dissolve evenly, heat up to 90°C, and react for 4 hours to obtain 40wt% long-chain alkylsilane modified Potassium methyl silicate solution.

[0028] 2) Weigh 50 parts of the 40 wt% long-chain alkylsilane-modified potassium methyl silicate solution prepared in step 1) and 10 parts of polyvinyl alcohol, mix and heat to 40°C, after the solution is transparent, keep the temperature for 60 minut...

Embodiment 3

[0030] A water-based organosilicon stone protective agent, which comprises the following components in parts by weight: 60 parts of long-chain alkylsilane-modified methyl silicate sodium salt solution with a solid content of 30 wt%, 8 parts of silica sol, poly Vinyl alcohol 6 parts, water-based adhesion promoter 2 parts.

[0031] The preparation method of water-based organosilicon stone protection agent described in the present embodiment may further comprise the steps:

[0032] 1) Dissolve 10 n-tridecyltrimethoxysilane and 100 g sodium methyl silicate in 256 g water, stir and dissolve evenly, heat up to 80°C, and react for 3 hours to obtain 30 wt% long-chain alkyl silane modified Sodium methyl silicate solution.

[0033] 2) Weigh 60 parts of long-chain alkylsilane-modified methyl silicate sodium salt solution prepared in step 1) and 6 parts of polyvinyl alcohol, mix and heat to 50°C, after the solution is transparent, keep the temperature for 45 minutes, Cool down to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com