Finishing type stone protection agent based on fluorosilicone acrylic resin, and preparation method thereof

A technology of fluorosilicone acrylic acid and acrylic resin, which is applied in the field of protective agents, can solve the problems of poor oil pollution protection ability, and achieve the effects of avoiding biological hazards, good water resistance, and shortening the curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

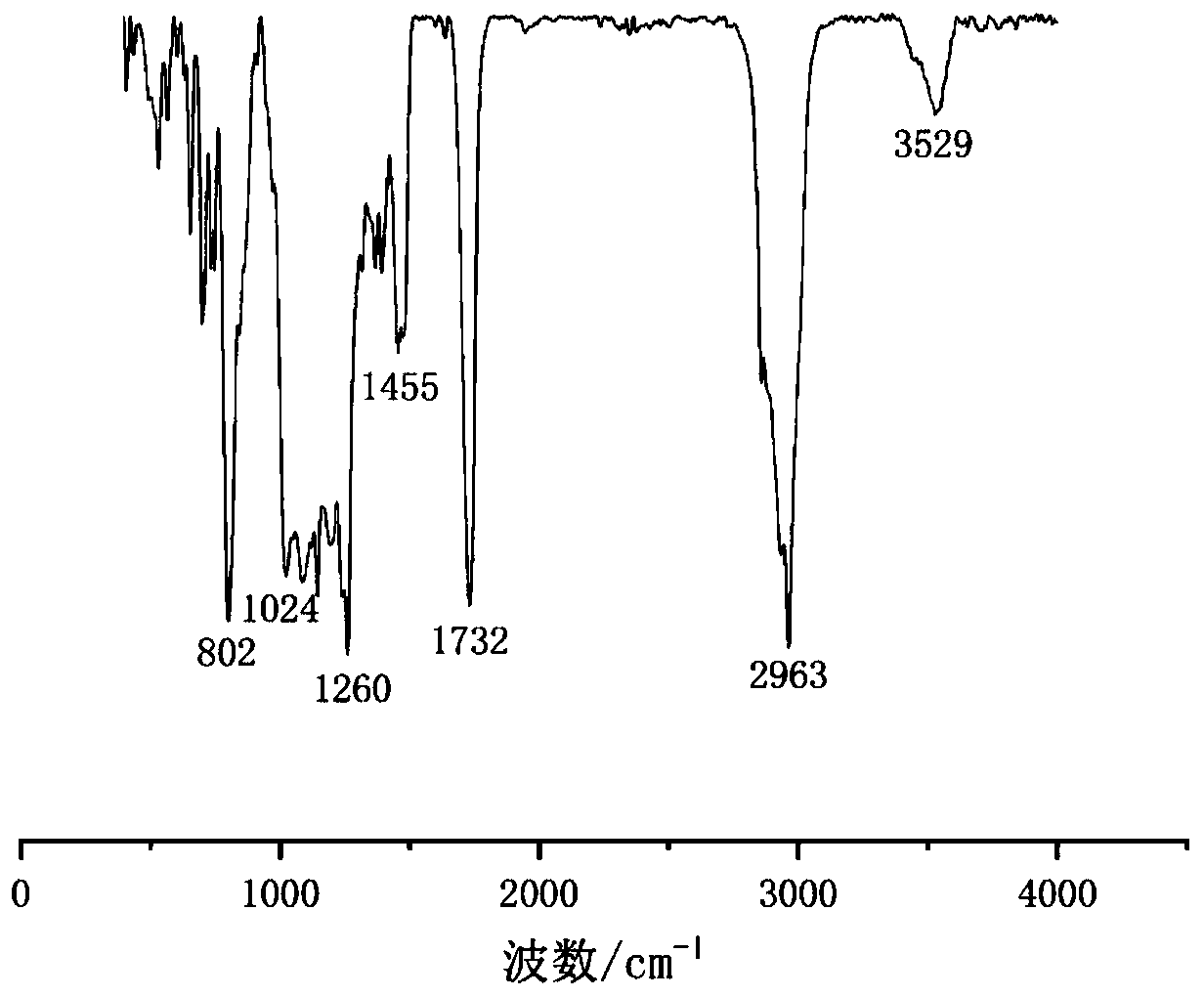

[0046] Preparation of fluorosilicone acrylic resin solution: add 44.7g of butyl acetate into the reaction kettle and heat to 75°C, then add 0.2g of azobisisobutyronitrile once. Then 14.5g perfluorohexyl ethyl acrylate, 5.5g DCA-2208 (Guangzhou Ruiju Chemical Co., Ltd., molecular weight ≈ 1900) silicone monomer, 1.0g lauryl methacrylate, 1.0g cyclohexyl methacrylate , 2.5g of methyl methacrylate, 0.5g of hydroxypropyl methacrylate and 15.0g of butyl acetate were uniformly mixed to obtain a mixture, and the mixture was added dropwise to the reactor. After 2.5 hours of dripping, keep warm for 0.5 hours. Subsequently, 0.1 g of azobisisobutyronitrile dissolved in 10.0 g of butyl acetate was added dropwise to the reaction kettle, and the drop was completed in 0.5 hours. Finally, the temperature was raised to 95° C., kept at a constant temperature for 1.5 hours, and cooled to room temperature to obtain a fluorosilicone acrylic resin solution.

[0047] The structural formula of DCA-...

Embodiment 2

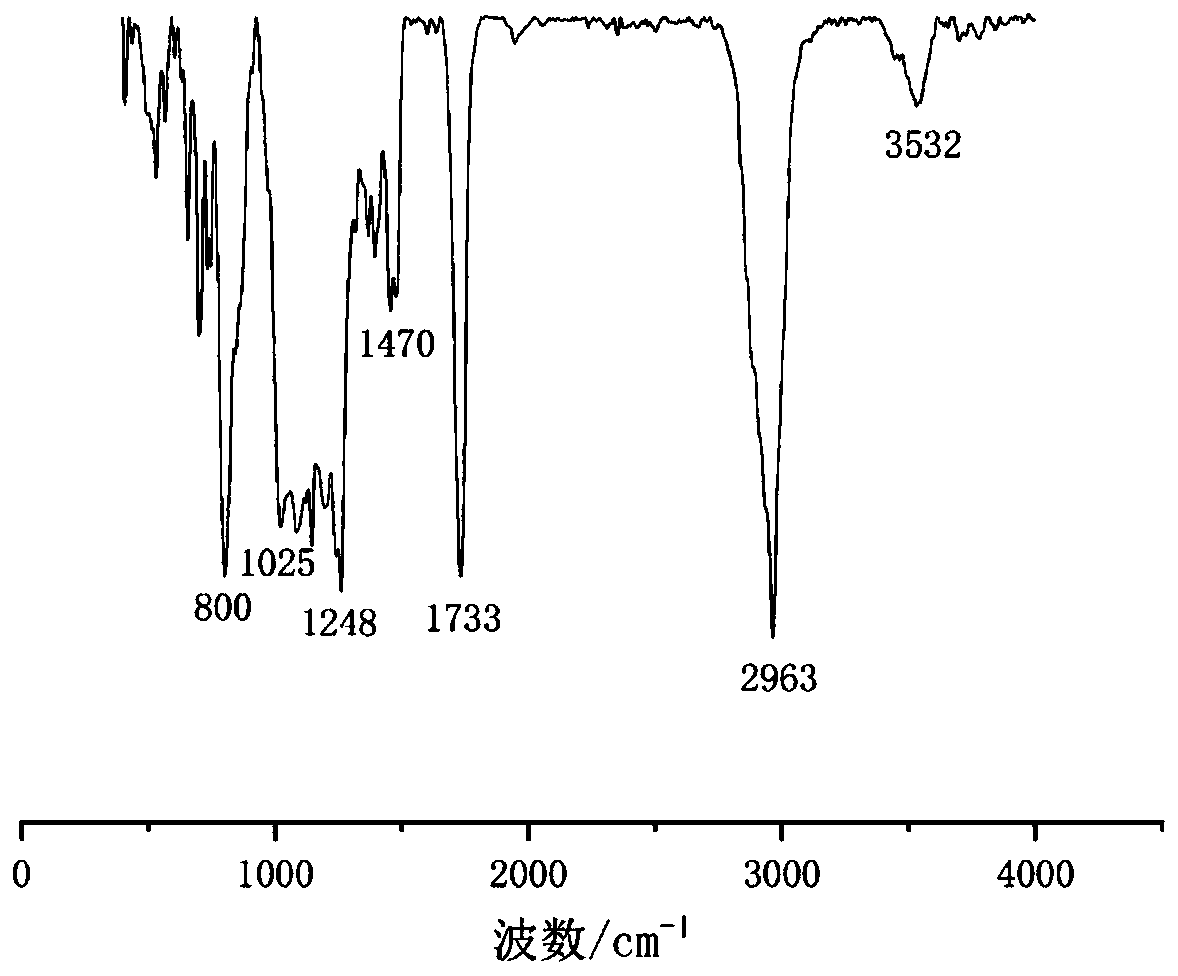

[0050] Preparation of resin solution: After heating 42g of methyl isobutyl ketone to 75°C, add 0.24g of azobisisobutyronitrile at one time, then add 17.3g of perfluorohexylethyl methacrylate, 6.6g of silane-modified ethylene Base monomer SMV (Guangzhou Double Bond Trading Co., Ltd., molecular weight ≈1500), 1.2g lauryl methacrylate, 4.2g methyl methacrylate, 0.6g hydroxyethyl methacrylate and 14g methyl isobutyl ketone After mixing, add the above-mentioned mixed solution dropwise to the methyl isobutyl ketone containing azobisisobutyronitrile, drop it in 2.5 hours, keep warm for 0.5 hour after the dropwise addition is completed, then dissolve 0.06g of azobisisobutyronitrile in 14g of formaldehyde In methyl isobutyl ketone, add above-mentioned methyl isobutyl ketone containing initiator dropwise in the solution that insulation finishes, 0.5 hour drops. Finally, the temperature was raised to 95° C., kept at a constant temperature for 1.5 hours, and cooled to room temperature to ...

Embodiment 3

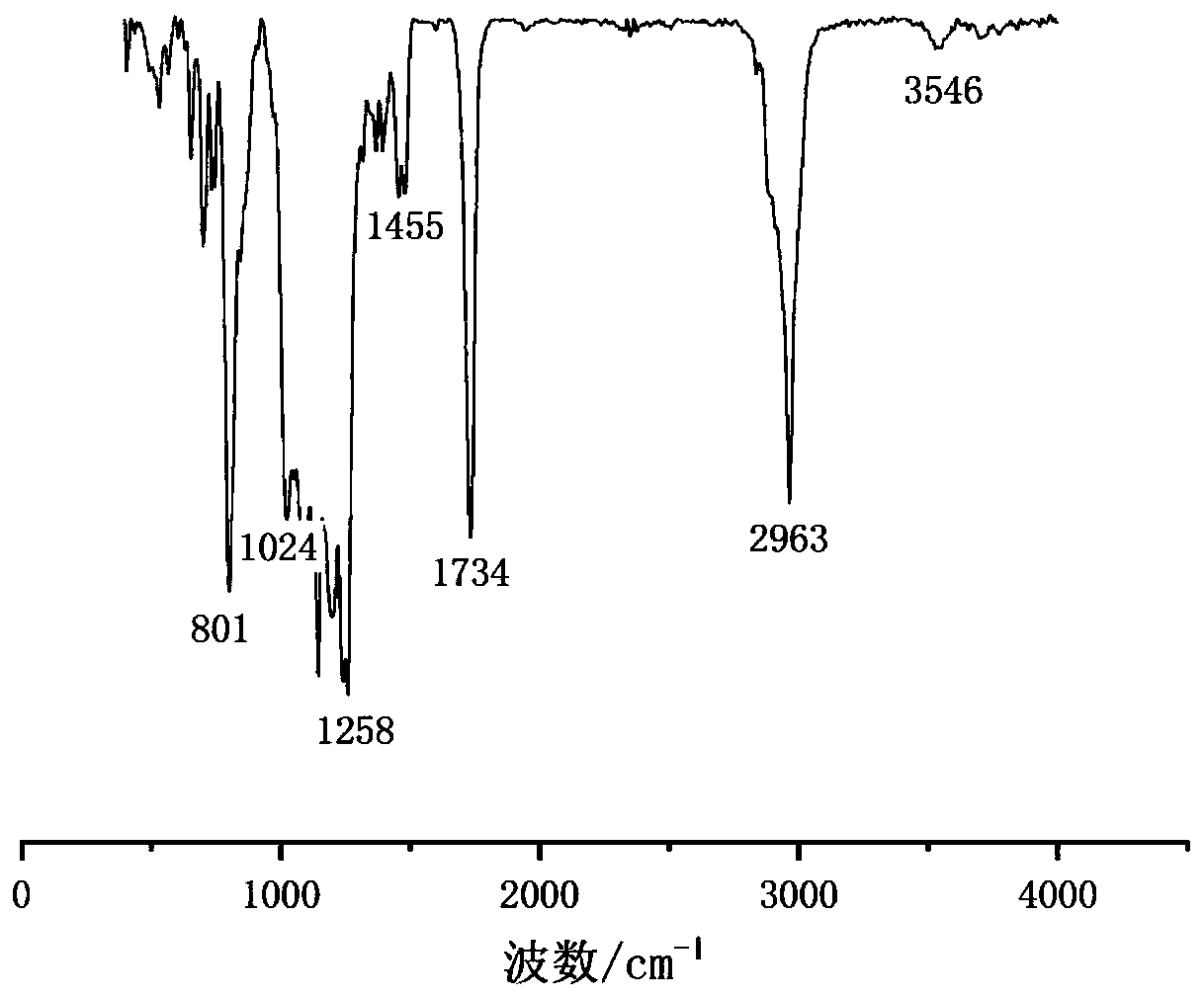

[0055] Preparation of resin solution: Mix 24.5g butyl acetate and 24.5g methyl isobutyl ketone evenly, heat to 85°C, add 0.28g dibenzoyl peroxide at one time, then add 21.6g perfluorohexyl ethyl acrylate , 7.5g DCA-2206 (Guangzhou Ruiju Chemical Co., Ltd., molecular weight ≈ 1200), 4.9g isobornyl methacrylate, 1.0g hydroxyethyl methacrylate and 16.3g methyl isobutyl ketone are evenly mixed, and the Add the above mixed solution dropwise to the butyl acetate containing dibenzoyl peroxide, drop it in 3.5 hours, keep it warm for 1.5 hours after the addition is completed, then dissolve 0.07g of dibenzoyl peroxide in 16.3g of butyl acetate , Add dropwise the above-mentioned butyl acetate containing initiator in the solution that the insulation finishes, and finish dropping in 0.5 hour. Finally, the temperature was raised to 99° C., kept at a constant temperature for 2 hours, and the reaction was completed after cooling to room temperature to obtain the target polymer solution.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com