Preparation method of novel hydrophobic wood

A hydrophobic, wood-based technology that is used in wood treatment, wood impregnation, wood impregnation, etc. to achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

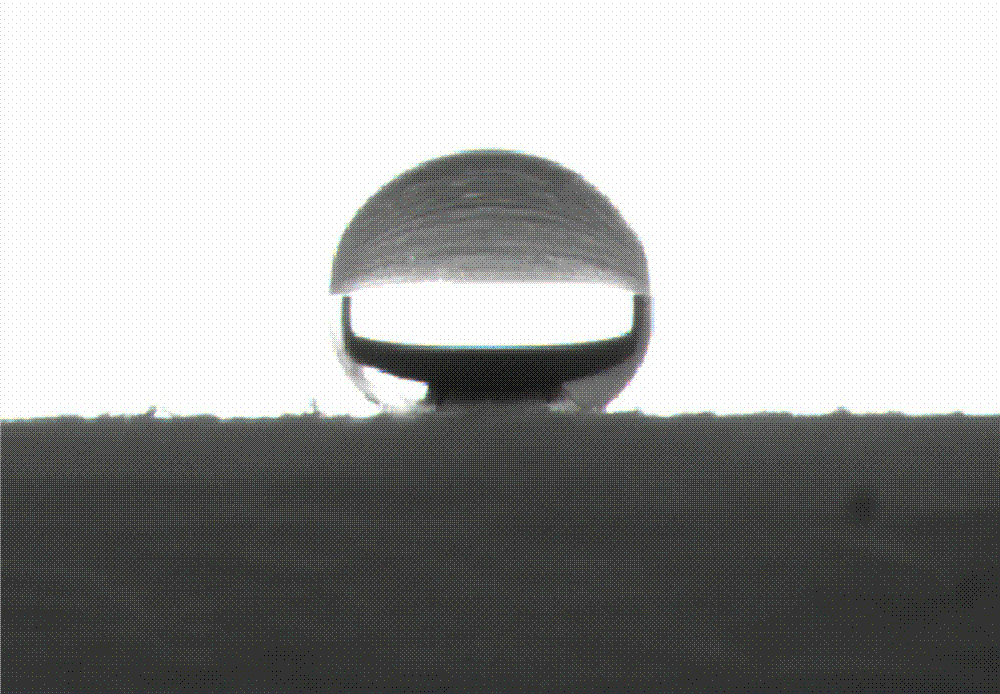

Image

Examples

preparation example Construction

[0018] The preparation method of novel hydrophobic wood of the present invention comprises the following steps:

[0019] (1) The alkyl ketene dimer colloids are melted at 40°C-60°C, then a certain amount of cationic starch, emulsifier, and water are added, and the mass concentration is 0.01%-10% after being processed by a high-pressure homogenizer The alkyl ketene dimer emulsion, standby;

[0020] (2) Mix the alkyl ketene dimer emulsion with a mass concentration of 0.01%-10% and the nanocellulose gel with a mass concentration of 0.5%-20% in a weight ratio of (1-5):1 , and high-speed stirring to prepare a composite emulsion, set aside.

[0021] (3) Put the wood into the reaction tank, seal the reaction tank and evacuate to -0.13Mpa~-0.09MPa, and keep the negative pressure for 15min-60min.

[0022] (4) Inject the composite emulsion obtained in step (2) into the reaction tank in a vacuum state, and immerse the wood in the composite emulsion, keep the vacuum state for 15min-60mi...

Embodiment 2

[0037] Embodiment two: The preparation method of the new superhydrophobic wood described in this embodiment is carried out according to the following steps: 1. According to the melting of the alkyl ketene dimer (AKD) colloidal particles at 50°C, a certain amount of sodium dodecylsulfonate is added and quaternary aluminum salt cationic starch and water, wherein the weight ratio is cationic starch: emulsifier: AKD colloid: water=4.9:0.1:8:87, and the emulsion is obtained through high-pressure homogenizer treatment; 2. According to the alkyl The mass concentration of ketene dimer (AKD) is 0.2%, and the mass concentration of nanocellulose gel is 1%. High-speed stirring and blending are used to configure the composite emulsion; 3. Inject the composite emulsion obtained in step 2 under vacuum, and make Immerse the wood in the composite emulsion, remove the vacuum and return to normal pressure for 60 minutes; 4. Take out the wood, drain the composite emulsion, and dry it in an oven ...

Embodiment 3

[0040] Embodiment three: The preparation method of novel superhydrophobic wood described in the present embodiment is carried out in the following steps:

[0041] 1. According to the melting of alkyl ketene dimer (AKD) colloidal particles at 60°C, a certain amount of sodium dodecylsulfonate, quaternary aluminum salt cationic starch and water are added, and the weight ratio is cationic starch: Emulsifier: AKD Colloidal Particles: Water = 3:2:6:89, processed by a high-pressure homogenizer to obtain an emulsion. 2. The mass concentration of alkyl ketene dimer (AKD) is 0.4%, and the mass concentration of nanocellulose gel is 5%. High-speed stirring and blending are used to configure the composite emulsion. 3. Put the wood in the reaction tank, seal the reaction tank and evacuate to -0.09MPa, and keep it for 30 minutes; 4. Inject the composite emulsion obtained in step 2 under vacuum, and immerse the wood in the composite emulsion to release Vacuum return to normal pressure and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com