Preparation method of rare earth element co-doped nano titanium dioxide photocatalyst

A nano-titanium dioxide and rare earth element technology, applied in the field of photocatalyst, can solve problems such as affecting the photocatalytic efficiency, and achieve the effects of suppressing electron-hole pair recombination, abundant raw material sources, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of rare earth element co-doped nano-titanium dioxide photocatalyst, which comprises the following steps:

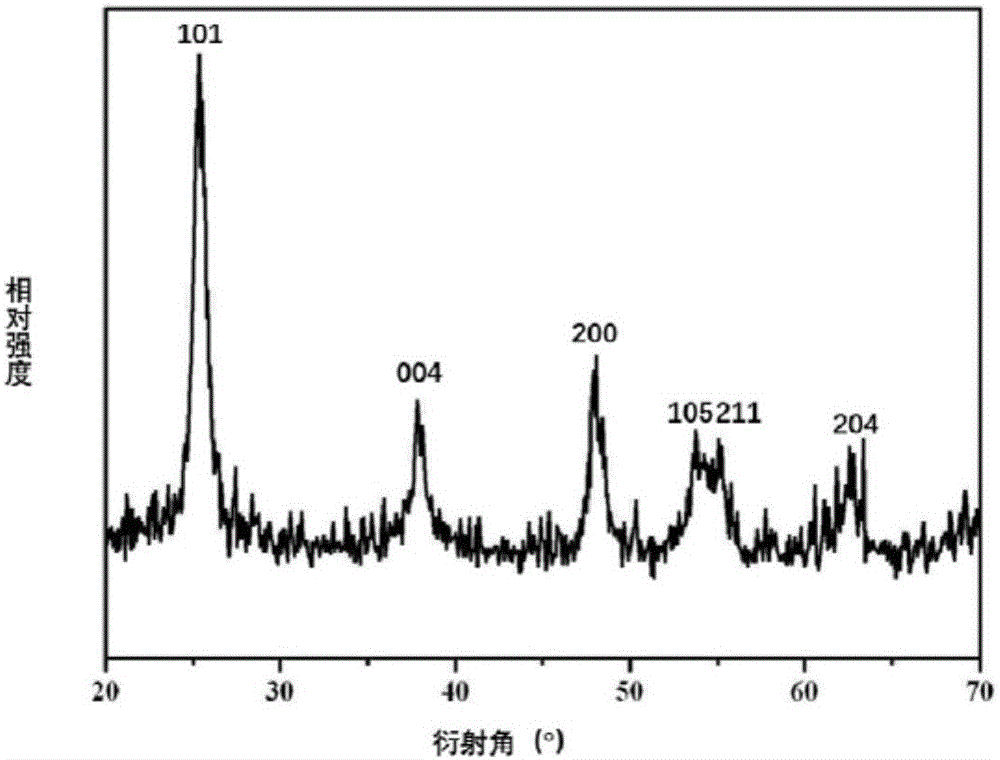

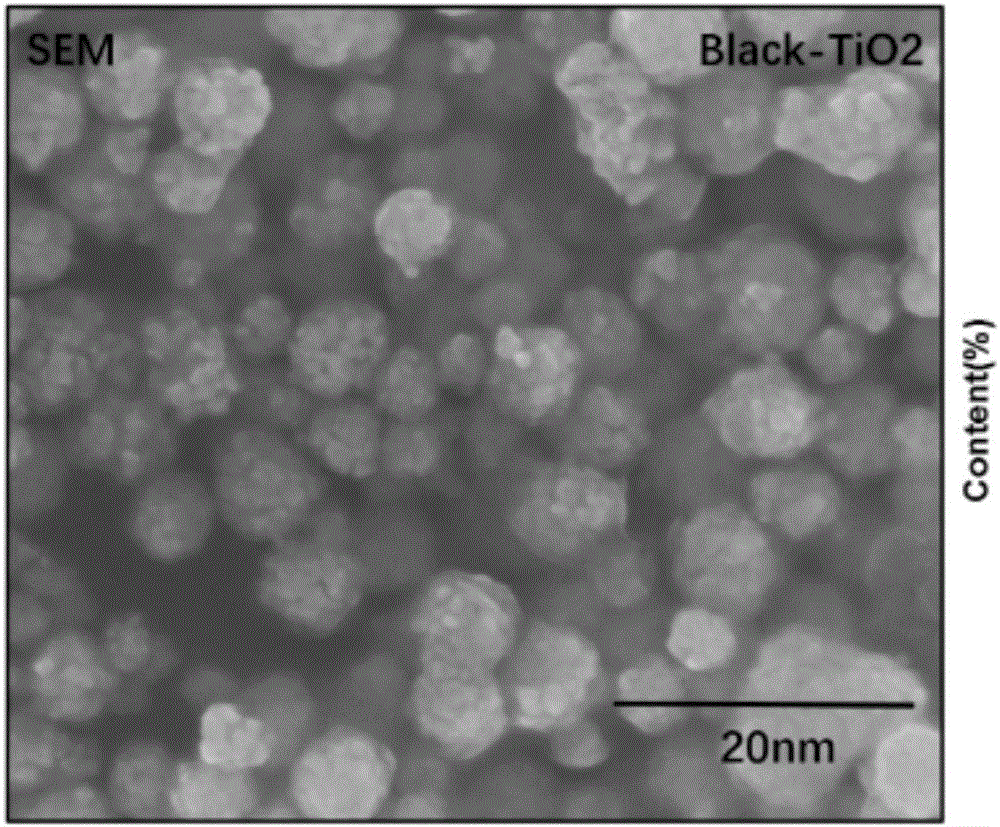

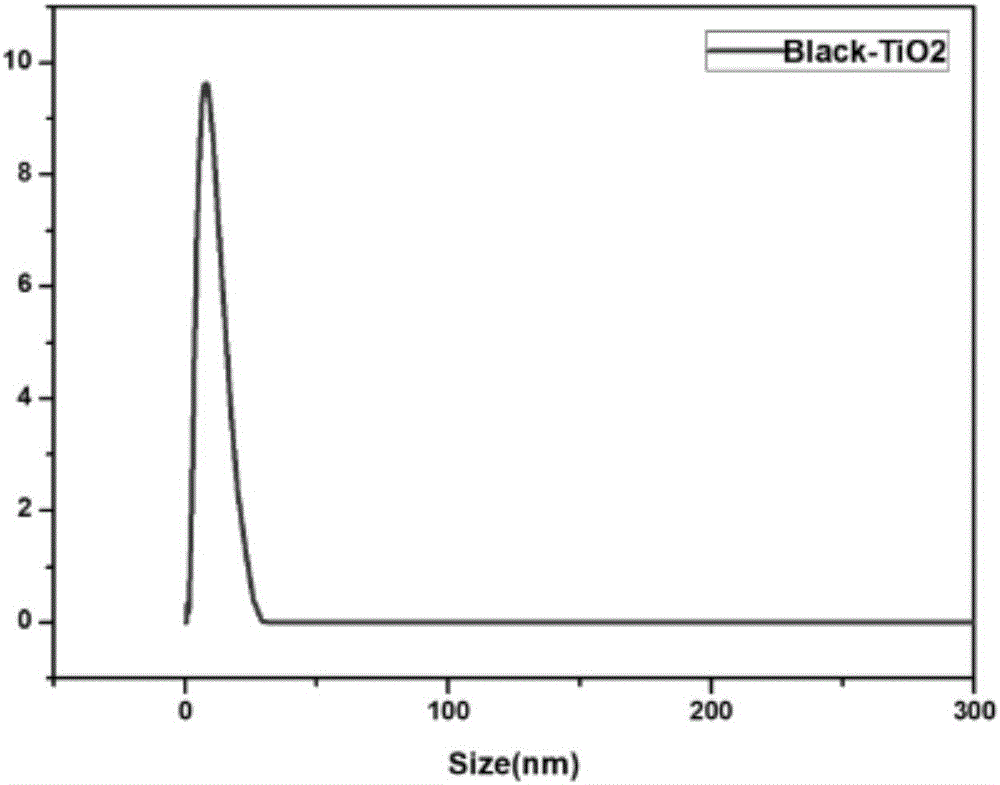

[0028] (1), the titanium nitride powder of 80 weight parts is mixed with the sodium peroxide of 80 weight parts, the titanium nitride powder after mixing and peroxide mixture are added in the reactor that contains 100 weight parts water, the mixture is in Stir and mix evenly in the reaction kettle, and react in the reaction kettle at a constant temperature and equal volume for 6 hours at 200°C. After the reaction, the product in the reaction kettle is centrifuged, and the obtained precipitate is centrifugally washed, and the washed precipitate is dried. After drying, black nano titanium dioxide powder is obtained;

[0029] (2), adding 10 parts by weight of rare earth oxides into the cerium hydrochloric acid solution, stirring at a constant speed in a stirring device, to obtain a rare earth hydrochloric acid solution with a concentration of 0.1%...

Embodiment 2

[0033] A preparation method of rare earth element co-doped nano-titanium dioxide photocatalyst, which comprises the following steps:

[0034] (1), the titanium nitride powder of 50 weight parts is mixed with the sodium peroxide of 100 weight parts, the titanium nitride powder after mixing and peroxide mixture are added in the reactor that contains 150 weight parts water, the mixture is Stir and mix evenly in the reaction kettle, and react in the reaction kettle at a constant temperature and equal volume for 4 hours at 150°C. After the reaction, the product in the reaction kettle is centrifuged, and the obtained precipitate is centrifugally washed, and the washed precipitate is dried. After drying, black nano titanium dioxide powder is obtained;

[0035] (2), adding 8 parts by weight of rare earth oxides into the sulfuric acid solution of praseodymium salt and samarium salt, stirring at a constant speed in a stirring device, to obtain a rare earth hydrochloric acid solution wit...

Embodiment 3

[0039] A preparation method of rare earth element co-doped nano-titanium dioxide photocatalyst, which comprises the following steps:

[0040] (1), the titanium nitride powder of 10 weight parts is mixed with the sodium peroxide of 70 weight parts, the titanium nitride powder after mixing and peroxide mixture are added in the reactor that contains 300 weight parts water, the mixture is in Stir and mix evenly in the reaction kettle, and react in the reaction kettle at a constant temperature and equal volume for 6 hours at 220 ° C. After the reaction, the product in the reaction kettle is centrifuged, and the obtained precipitate is centrifugally washed. After drying, black nano titanium dioxide powder is obtained;

[0041] (2), 1 weight part of rare earth oxide is added in the phosphoric acid solution of neodymium salt and promethium salt, and stirred at a constant speed in a stirring device to obtain a rare earth hydrochloric acid solution with a concentration of 0.1%-0.5%;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com