Strong permeability waterproof agent and preparation method thereof

A technology of waterproofing agent and penetrating agent, which is applied in the direction of textiles and papermaking, fiber treatment, coating, etc. It can solve the problems of poor waterproofness, poor permeability, and complicated preparation methods, and achieves strong temperature resistance, simple production methods, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

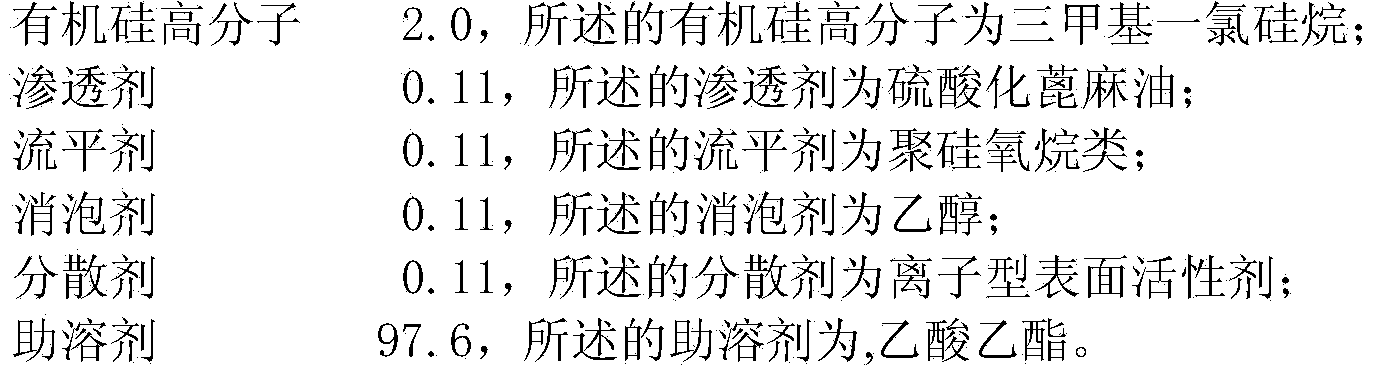

[0070] 1. Proportion (mass ratio) of strong penetrating waterproofing agent for interior and exterior walls of buildings

[0071]

[0072] 2. Preparation method

[0073] (1) Take 2.0 kg of silicone polymer, add 97.6 kg of co-solvent under stirring, and react at a temperature of 30°C for 1 hour;

[0074] (2) When the reactant is clear, add 0.11kg of penetrant under stirring, and react at a temperature of 30°C for 0.5 hours;

[0075](3) When the reactant is clear, add 0.11 kg of leveling agent under stirring, and react at a temperature of 30°C for 0.5 hours;

[0076] (4) When the reactant is clear, add 0.11kg of defoamer under stirring, and react at a temperature of 30°C for 0.5 hours;

[0077] (5) When the reactant is clear, add 0.11 kg of dispersant under stirring, and react at a temperature of 30°C for 0.5 hours;

[0078] (6) Filter through 300-mesh stainless steel mesh, pack and store.

Embodiment 2

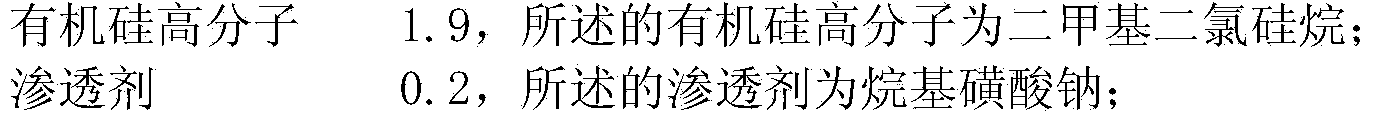

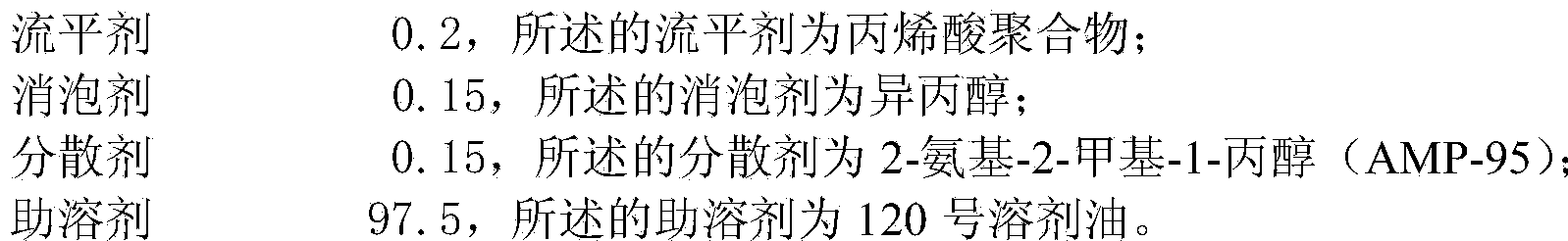

[0080] 1. Proportion of strong penetrating waterproofing agent for ancient buildings (mass ratio)

[0081]

[0082]

[0083] 2. Preparation method

[0084] (1) Take 1.9kg of silicone polymer, add 97.5kg of co-solvent under stirring, and react at 25°C for 1 hour; (2) When the reactant is clear, add 0.2kg of penetrant under stirring, and react at 25°C for 0.5 hour ;

[0085] (3) When the reactant is clear, add 0.2kg of leveling agent under stirring, and react at a temperature of 25°C for 0.5 hours;

[0086] (4) When the reactant is clear, add 0.15kg of defoamer under stirring, and react at a temperature of 25°C for 0.5 hours;

[0087] (5) When the reactant is clear, add 0.15kg of dispersant under stirring, and react at a temperature of 25°C for 0.5 hours;

[0088] (6) Filter through 300-mesh stainless steel mesh, pack and store.

[0089] The detection report (see attachment) of the strong penetrating waterproofing agent prepared according to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com