High temperature resisting epoxy resin curing agent for room temperature curing and preparation method thereof

An epoxy resin curing and room temperature curing technology, which is applied in the field of epoxy resin curing agents, can solve the problems of inability to guarantee the temperature resistance of engineering adhesives and the decrease in the strength of epoxy resin cured products, so as to avoid the risk of high temperature and high pressure synthesis, production The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

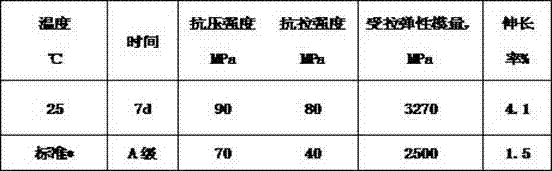

Examples

Embodiment Construction

[0047] Below in conjunction with embodiment describe in detail:

[0048] 1. Additional components

[0049] The diluent is 1 to 3 of butyl glycidyl ether, dodecyl glycidyl ether, diethylene glycol, ethylene glycol and benzyl alcohol;

[0050] The catalyst is 1 to 3 of bisphenol A, phenol, DMP-30, organic acid, cresol and polyethylene polyamine;

[0051] The diepoxy compound is 1 to 3 kinds of ethylene glycol diglycidyl ether, butanediol diglycidyl ether, diglycidyl ether, low-viscosity epoxy resin and high-viscosity epoxy resin.

[0052] According to the requirements of the bonding field, the viscosity of this curing agent can be adjusted to 300-800mPa.s (25°C).

[0053] 2. Application examples

[0054] 1. Building and bridge reinforcement adhesive ratio (weight ratio)

[0055] CYD128 (bisphenol A epoxy resin) 80

[0056] F-51 (phenolic epoxy resin) 10

[0057] LS692 (reactive diluent) 10

[0058] Fumed silica (thickener) 1~3

[0059] This curing agent 35

[0060] Fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com