Efficient filter material and preparation method thereof

A high-efficiency filtration and fiber material technology, applied in filtration separation, membrane filter, separation method, etc., can solve the problems of shortened service life of filter materials, poor physical properties of filter materials, easy to reach the adsorption limit, etc., to reduce filter resistance, Good filtration efficiency and air permeability, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

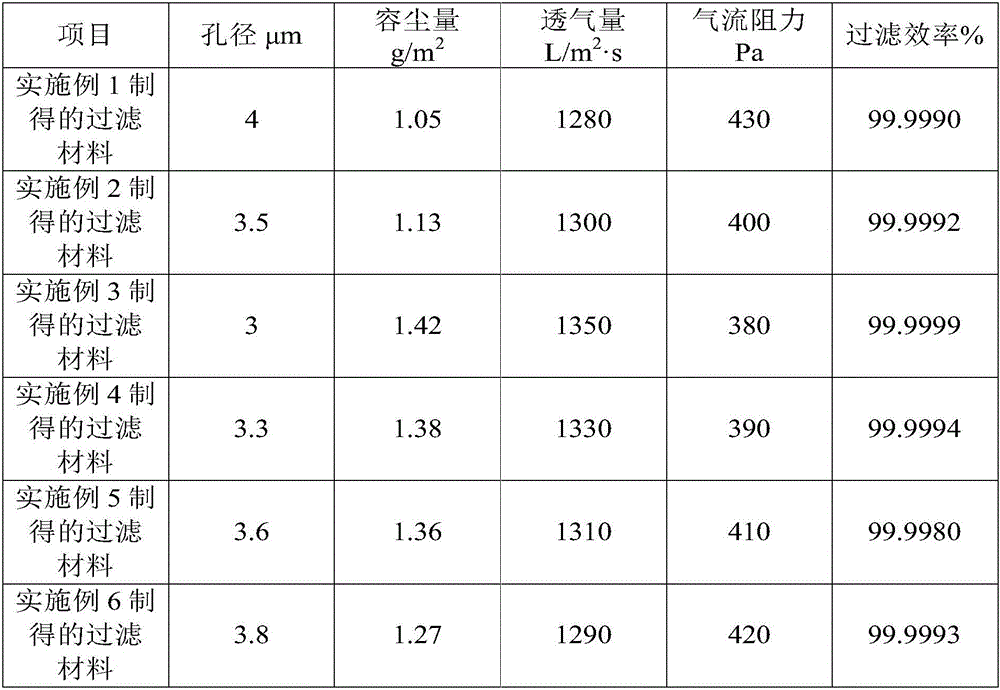

Examples

Embodiment 1

[0032] A high-efficiency filter material, the high-efficiency filter material is composed of a base cloth layer I, an electrospinning layer, a synthetic fiber layer, and a base cloth layer II;

[0033] Wherein the base fabric layer I is made of polyethylene fiber material at a temperature of 190°C at the die head, a stretching hot air temperature of 160°C, and a hot air pressure of 6MPa for extrusion and melting. Under the condition of a receiving distance of 14cm, Prepared by melt blown spinning; the grammage of the prepared base cloth layer I is 50g / m 2 , the thickness is 0.5mm, the fiber diameter is 1.0μm, and the air permeability of the material is 60μm / Pa·s;

[0034] The electrospinning layer is to add the polytetrafluoroethylene fiber material into the chloroacetic acid solution with a mass fraction of 90%, and stir it for 16h under the magnetic stirring at a speed of 400r / min to obtain an electrospinning solution with a mass fraction of 18%. Under the conditions of inj...

Embodiment 2

[0038] A high-efficiency filter material, the high-efficiency filter material is composed of a base cloth layer I, an electrospinning layer, a synthetic fiber layer, and a base cloth layer II;

[0039] Wherein the base fabric layer I is made of polypropylene fiber material at a die temperature of 220°C, a stretching hot air temperature of 185°C, and a hot air pressure of 8MPa for extrusion and melting. Under the condition of a receiving distance of 20cm, Prepared by melt blown spinning; the grammage of the prepared base cloth layer I is 70g / m 2 , the thickness is 1.0mm, the fiber diameter is 3.0μm, and the air permeability of the material is 75μm / Pa·s;

[0040] The electrospinning layer is made by adding polyacetate fiber material into the chloroacetic acid solution with a mass fraction of 100%, and stirring for 48 hours at a magnetic stirring speed of 650r / min to obtain an electrospinning solution with a mass fraction of 25%. The diameter of the injection needle is 0.2mm, th...

Embodiment 3

[0044] A high-efficiency filter material, the high-efficiency filter material is composed of a base cloth layer I, an electrospinning layer, a synthetic fiber layer, and a base cloth layer II;

[0045] Among them, the base fabric layer I is extruded and melted by polypropylene chloride fiber material at a die temperature of 205°C, a stretching hot air temperature of 172°C, and a hot air pressure of 7MPa. Under the condition of a receiving distance of 17cm , Carry out melt-blown spinning and prepare; The base cloth layer 1 gram weight that makes is 60g / m 2 , the thickness is 0.75mm, the fiber diameter is 2.0μm, and the air permeability of the material is 67μm / Pa·s;

[0046] The electrospinning layer is made of polyimide fiber material and is added to the chloroacetic acid solution with a mass fraction of 95%, under the magnetic stirring at a rotational speed of 475r / min, stirred for 32h to obtain an electrospinning solution with a mass fraction of 22%, Under the conditions of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com